Patents

Literature

52 results about "Compact tension specimen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

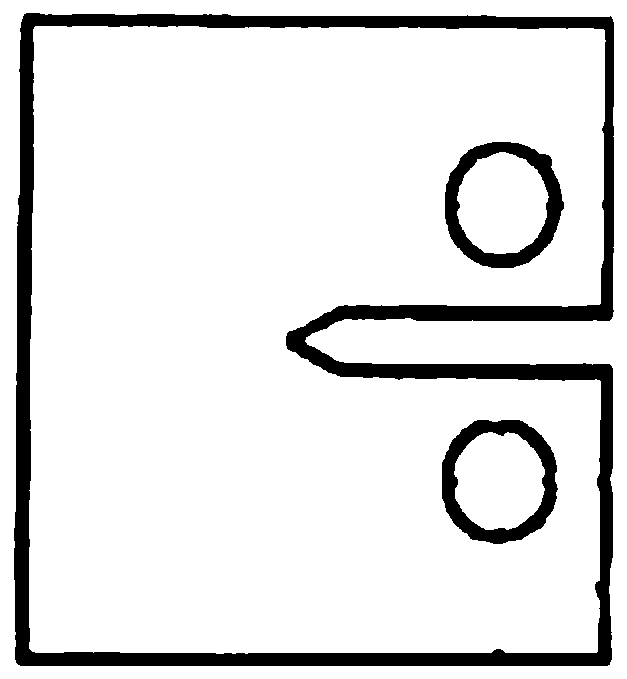

A compact tension specimen is a notched sample and is a standard specimen in accordance with ASTM and ISO standards. The purpose of using a notched sample is to create a fatigue crack by cycling the sample to maximum and minimum loads. The fatigue crack will begin on the point of the notch and extend through the sample, the fatigue crack is a good representation of 'real life' inconsistencies which are introduced to a material due to processing techniques or welding. CT specimens are used extensively in the area of fracture mechanics and corrosion testing, in order to establish fracture toughness and fatigue crack growth data for a material.

Method for measuring high-temperature creep crack growth threshold value of material

ActiveCN103217346AImprove scalabilityIncrease costInvestigating material ductilityStress intensity factorTest requirements

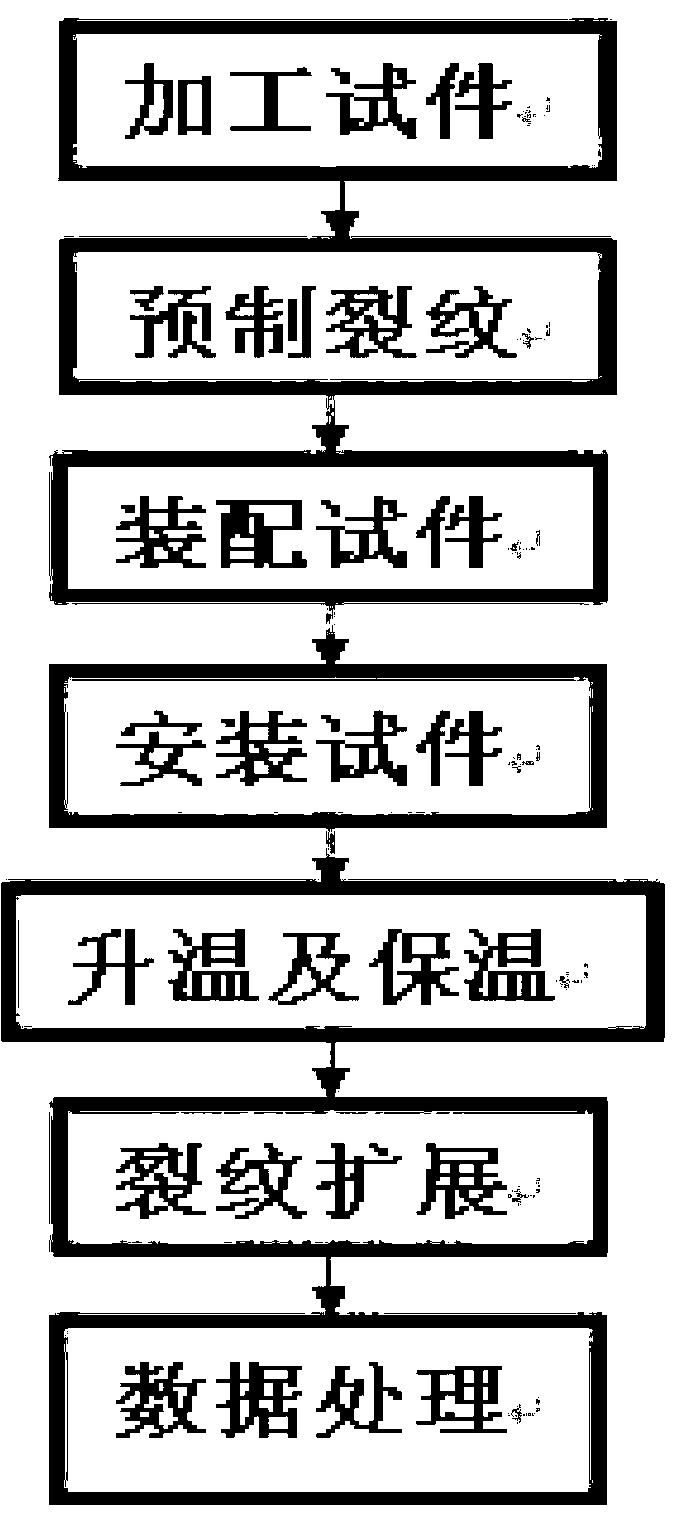

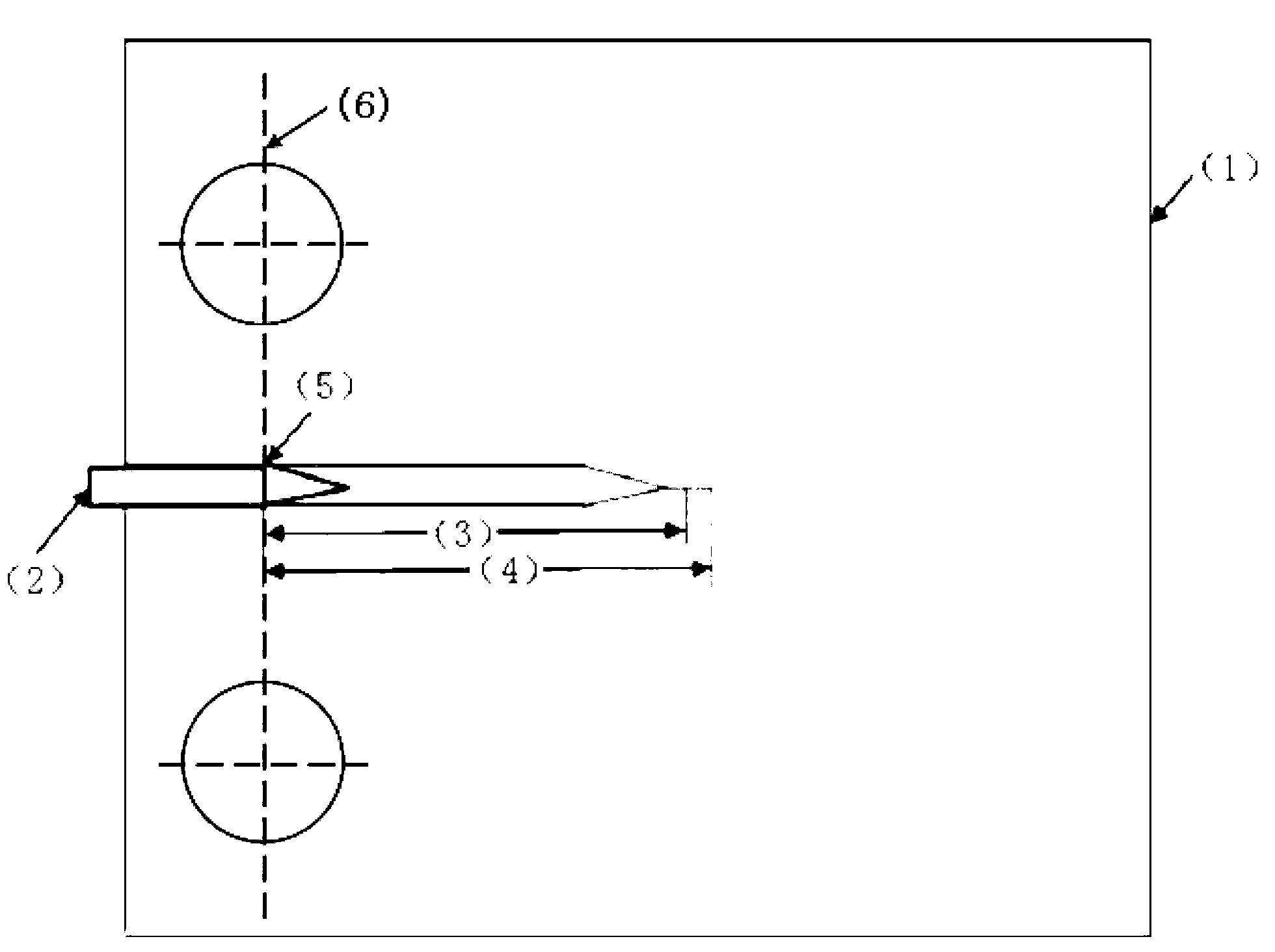

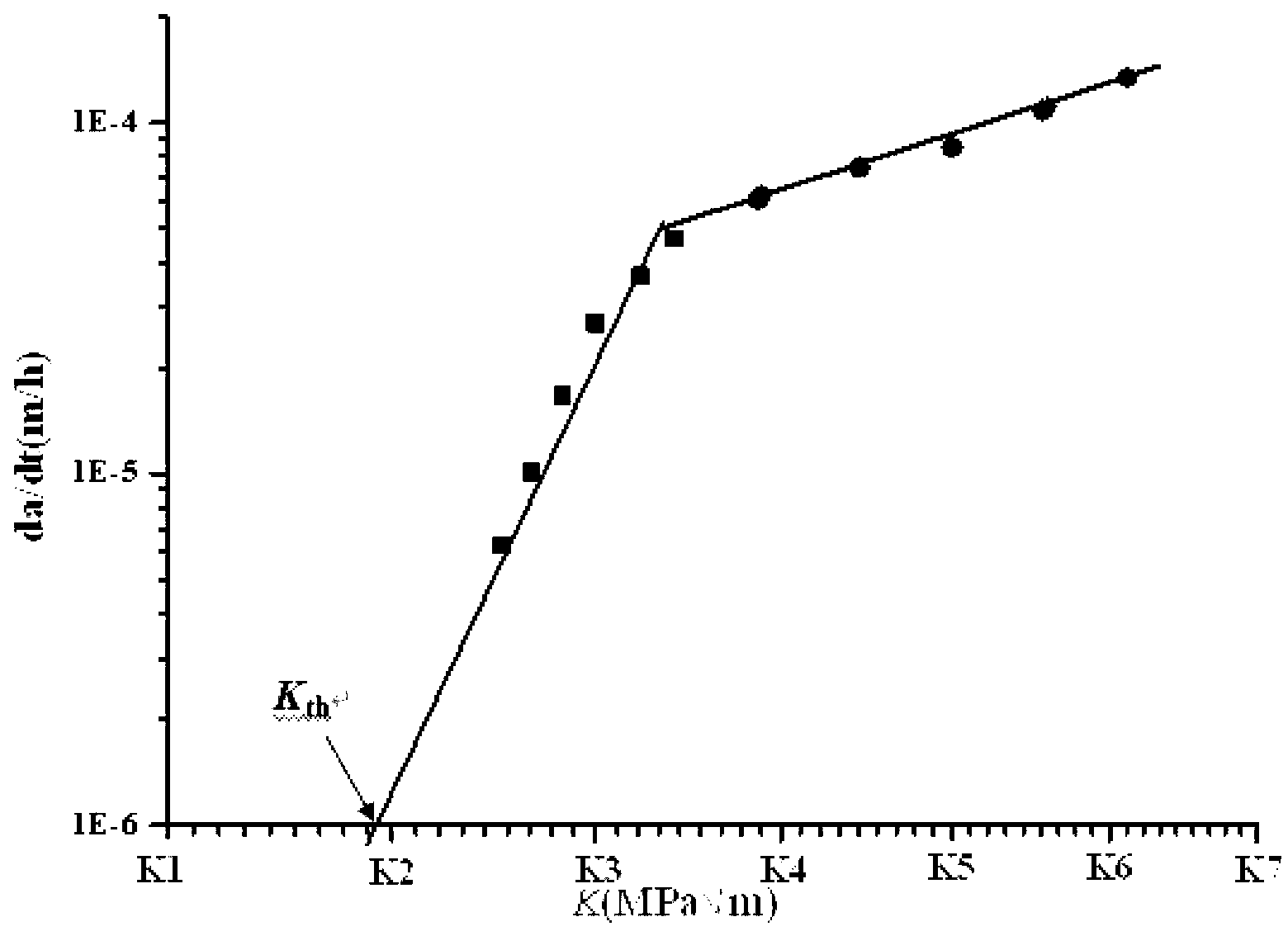

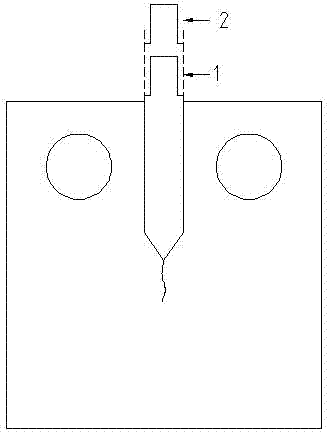

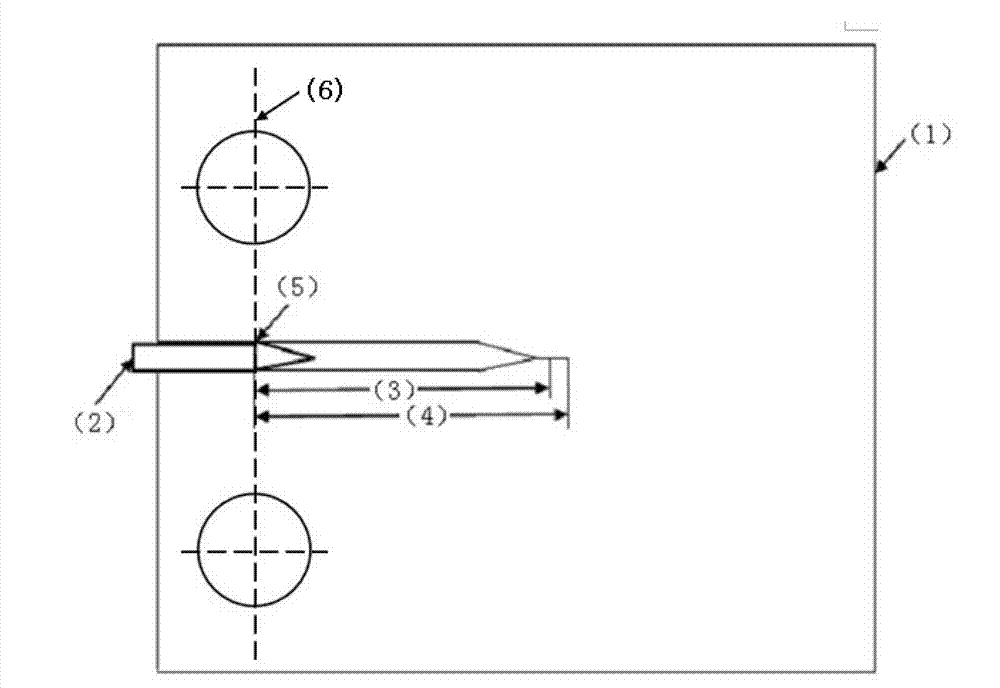

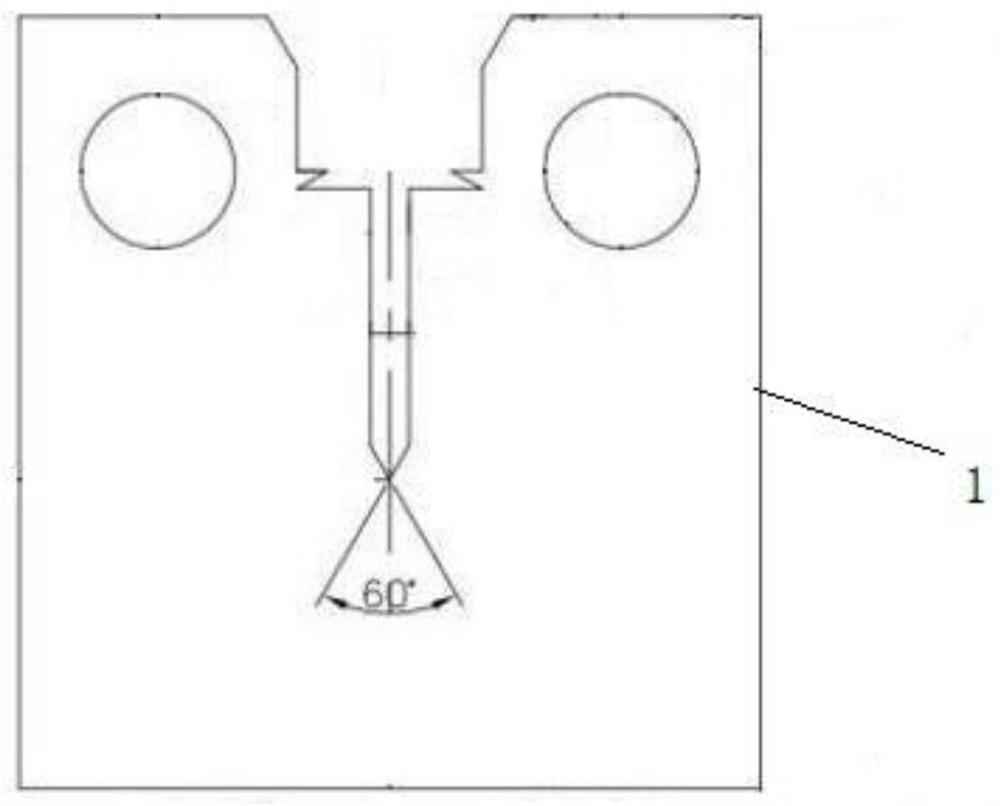

The invention discloses a method for measuring high-temperature creep crack growth threshold value of material. The method comprises the following steps of: for a specific material, according to the creep crack growth test requirement, processing at least 6 standard compact tension specimens, performing crack prefabrication for the well processed at least 6 specimens on a fatigue performance tester, wherein the prefabricated crack length is 0.5 times of the width of each specimen; wedging a wedge-shaped block into an initial notch of each specimen, placing the headmost end of the straight part of the wedge-shaped block at the position of a loading line, providing displacement for the loading line, forming a stress-strain field characterized by a stress strength factor at the tip of the specimen crack, and providing a driving force for the creep crack growth, wherein the specimens with different initial stress strength factors grow after certain time under creep effect in high-temperature environment, and in the same time interval, the crack growth lengths are different; drawing for the different stress strength factors and the corresponding crack growth rates, and solving the creep crack growth threshold value of the material through an extrapolation method. According to the method provided by the invention, multiple specimens can be tested for one time, and thus, the test cost is greatly reduced and the test time is greatly shortened.

Owner:BEIHANG UNIV

Method for detecting influence of different parameters on material fatigue crack expansion performance

InactiveCN102645385ATest accurateLow costPreparing sample for investigationMaterial strength using repeated/pulsating forcesMicrocomputerReliability engineering

The invention relates to a method for detecting the influence of different parameters on material fatigue crack expansion performance, which comprises the following steps of: firstly, processing a sample according to the standard and adopting a compact tensile sample; secondly, clamping the sample on a fatigue tester according to a standard test method, monitoring the crack length by using a microcomputer-aided potential method, and calculating and giving electric potential functions by using a boundary element method; thirdly, applying different test parameters according to different detection samples; and fourthly, treating the test data and comparing the test results. The method has the characteristics of high detection efficiency, low cost and accurate detection.

Owner:XI'AN PETROLEUM UNIVERSITY

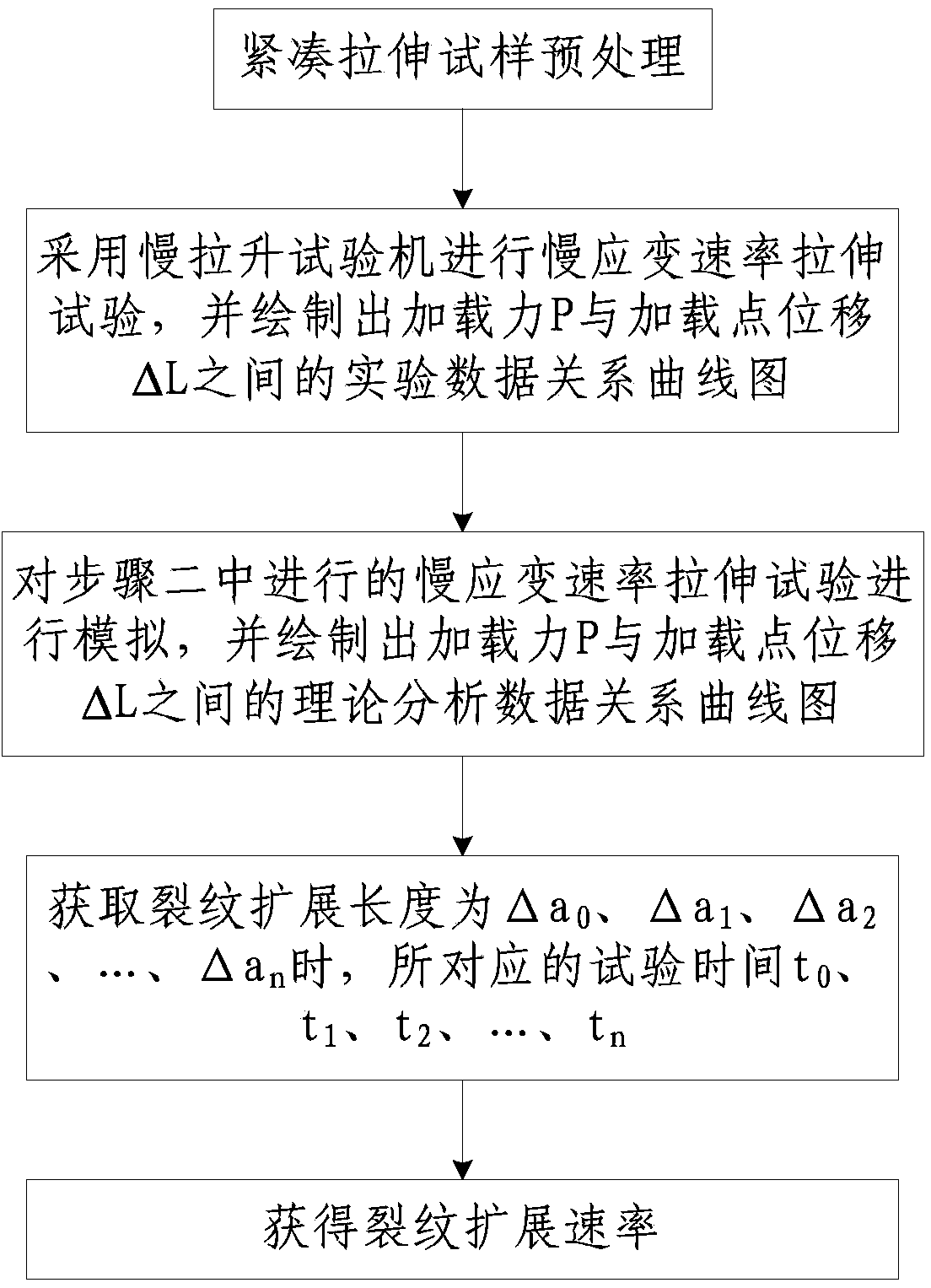

Method for measuring stress corrosion crack propagation rate by employing slow strain rate tensile

InactiveCN103698188ASimple methodEasy to implementPreparing sample for investigationMaterial strength using tensile/compressive forcesAnalysis dataTested time

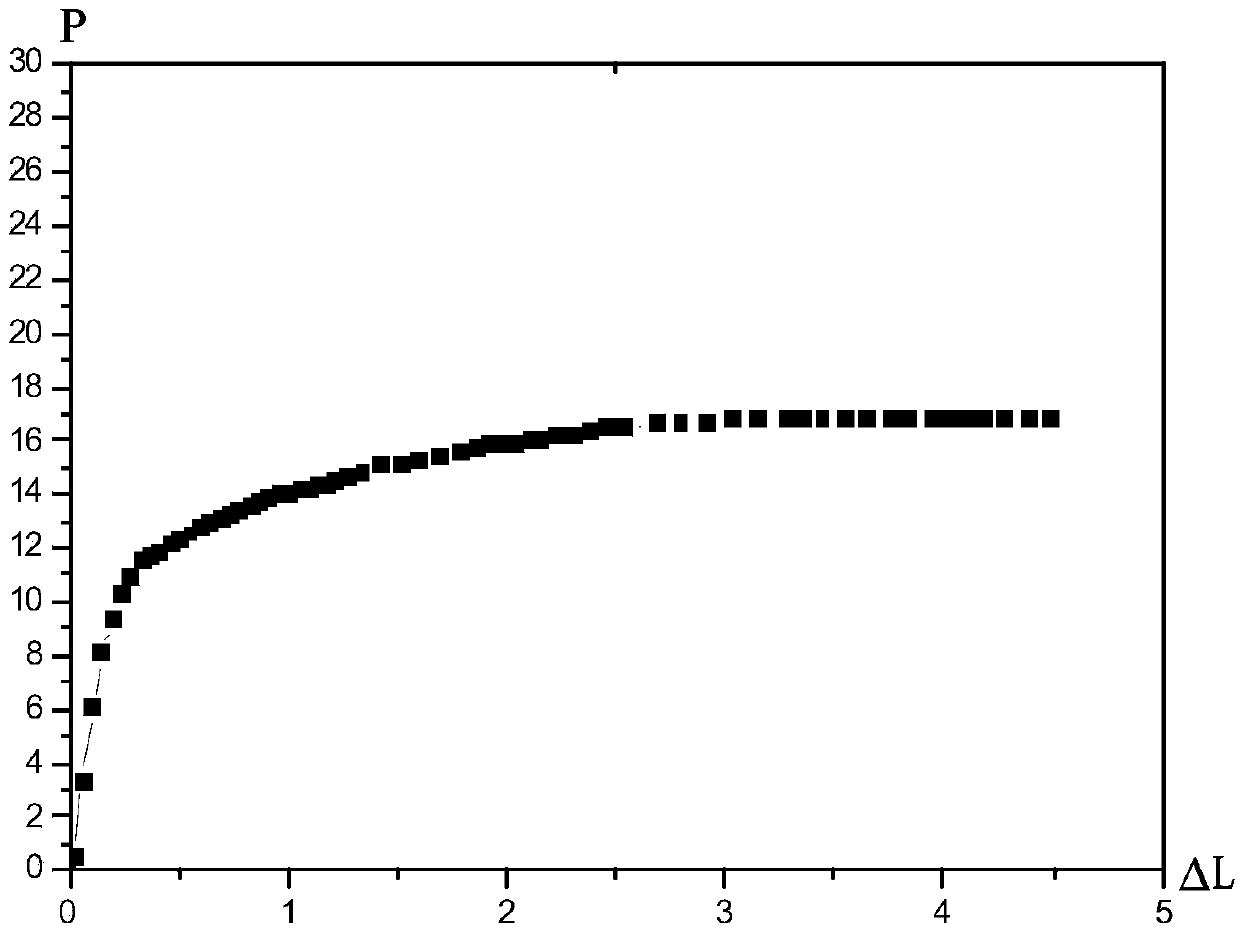

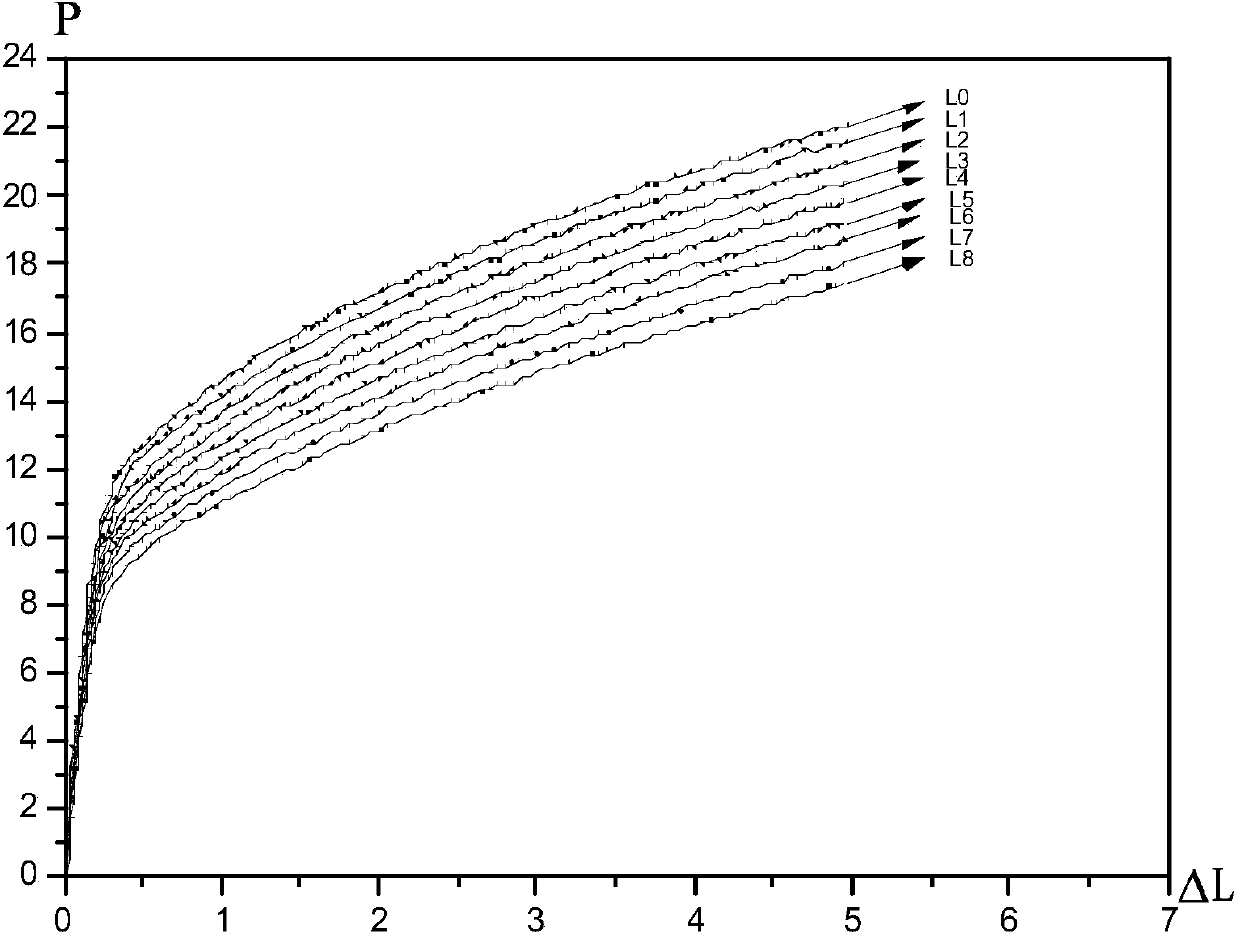

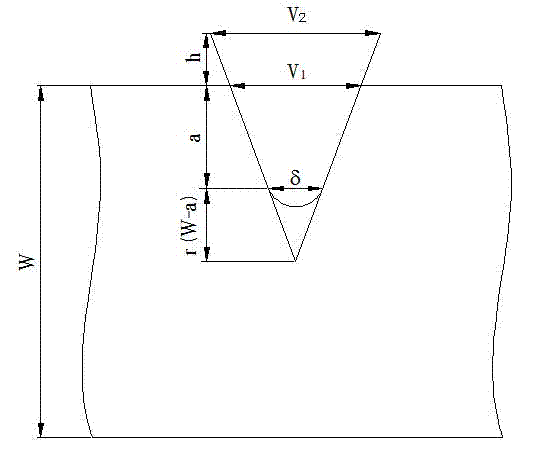

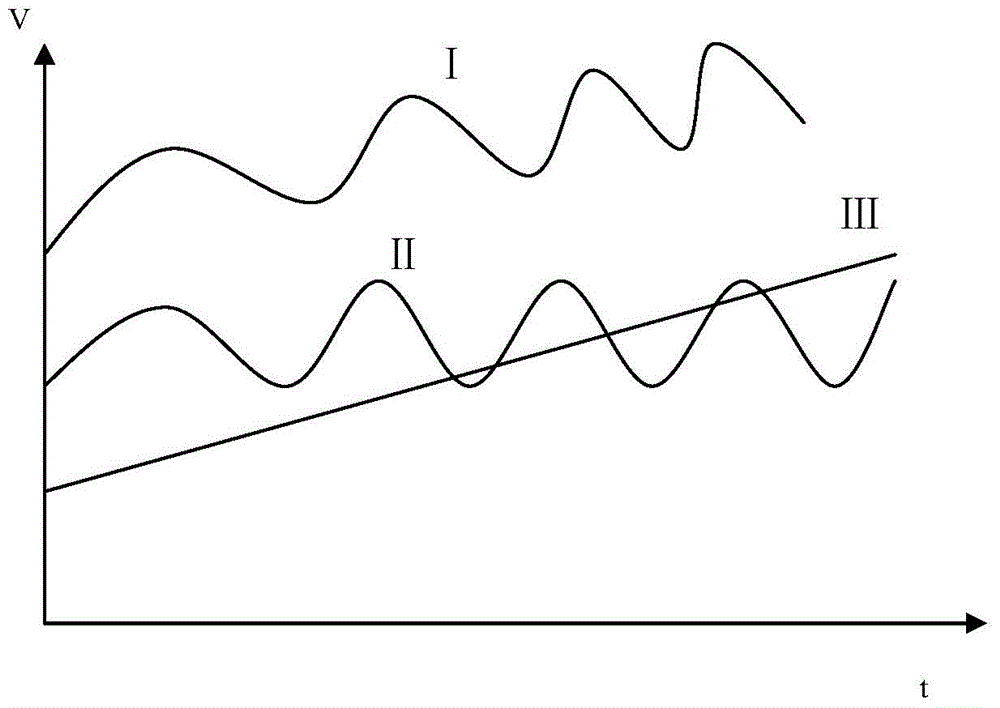

The invention discloses a method for measuring stress corrosion crack propagation rate by employing slow strain rate tensile. The method comprises the following steps: 1. preprocessing a compact tension specimen; 2. carrying out a slow strain rate tensile test by adopting a slow lifting testing machine, and drawing an experimental data relationship graph between loading force P and loading point displacement deltaL; 3. simulating the slow strain rate tensile test carried out in the step 2, and drawing a theoretical analysis data relation graph between the loading force P and the loading point displacement deltaL; 4. obtaining corresponding test time t0, t1, t2,..., tn when the crack propagation lengths are deltaa0, deltaa1, deltaa2,..., deltaan; 5. obtaining the crack propagation rate. By adopting the method, the change of the loading force P and loading point displacement deltaL caused by crack propagation can be separated out, and the change of the deltaai can be predicted in real time, so that the crack propagation rate is obtained. Thus, test data distortion caused by environmental influence can be effectively alleviated, and the data accuracy is improved.

Owner:XIAN UNIV OF SCI & TECH

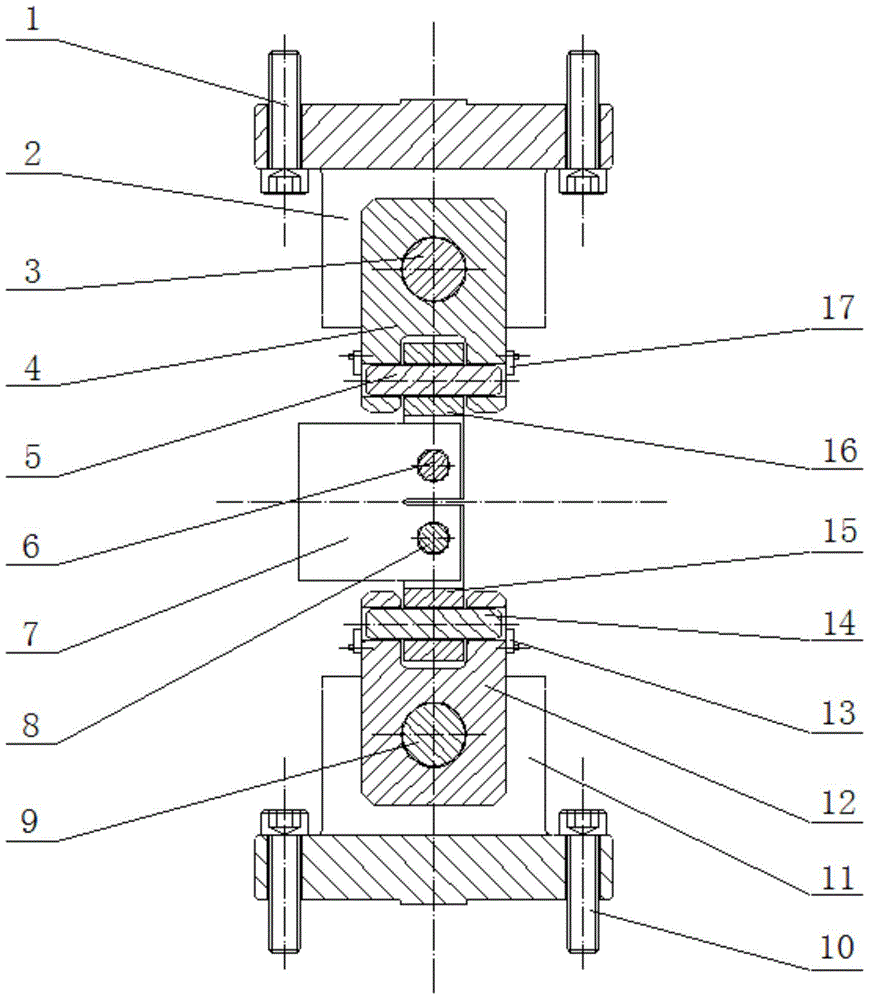

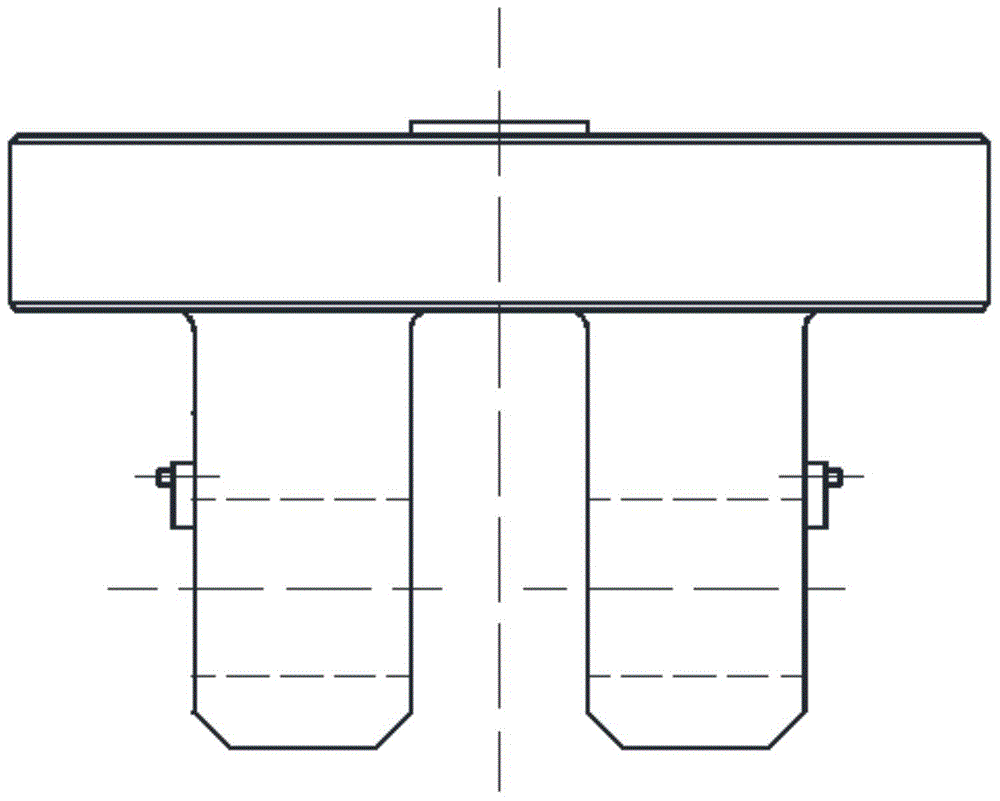

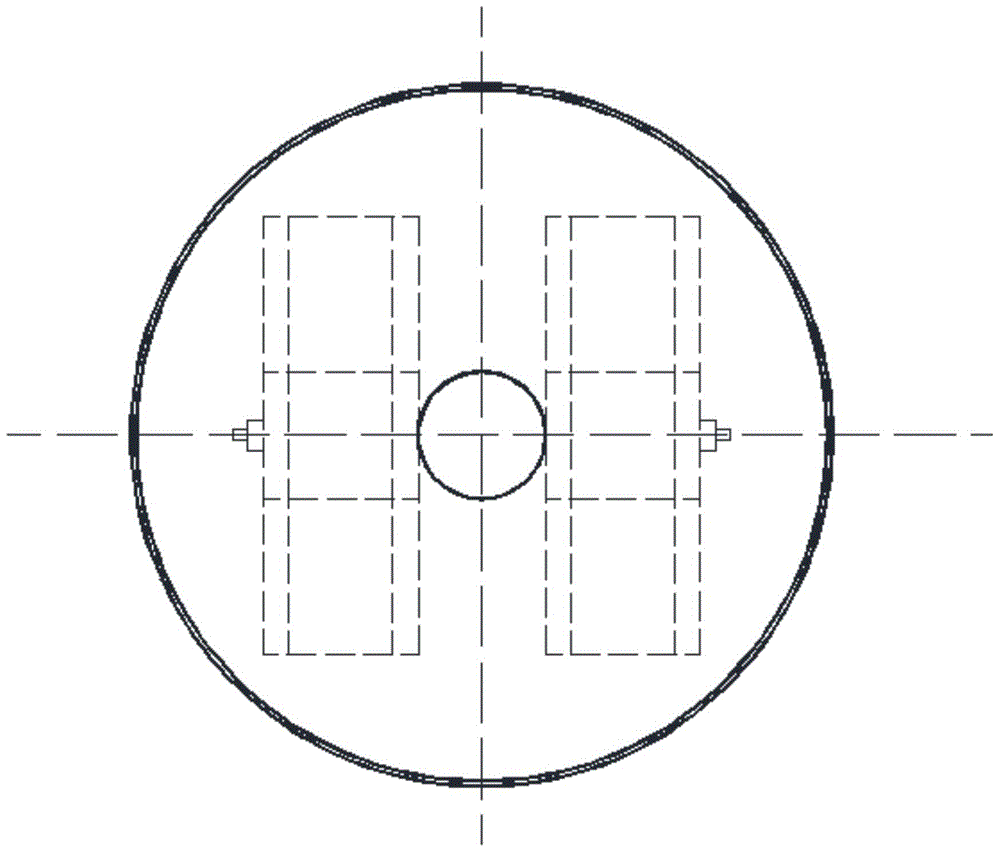

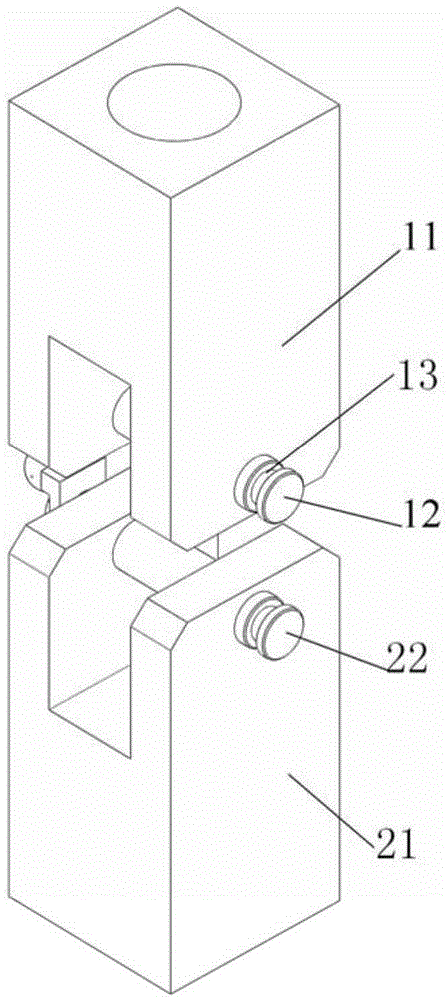

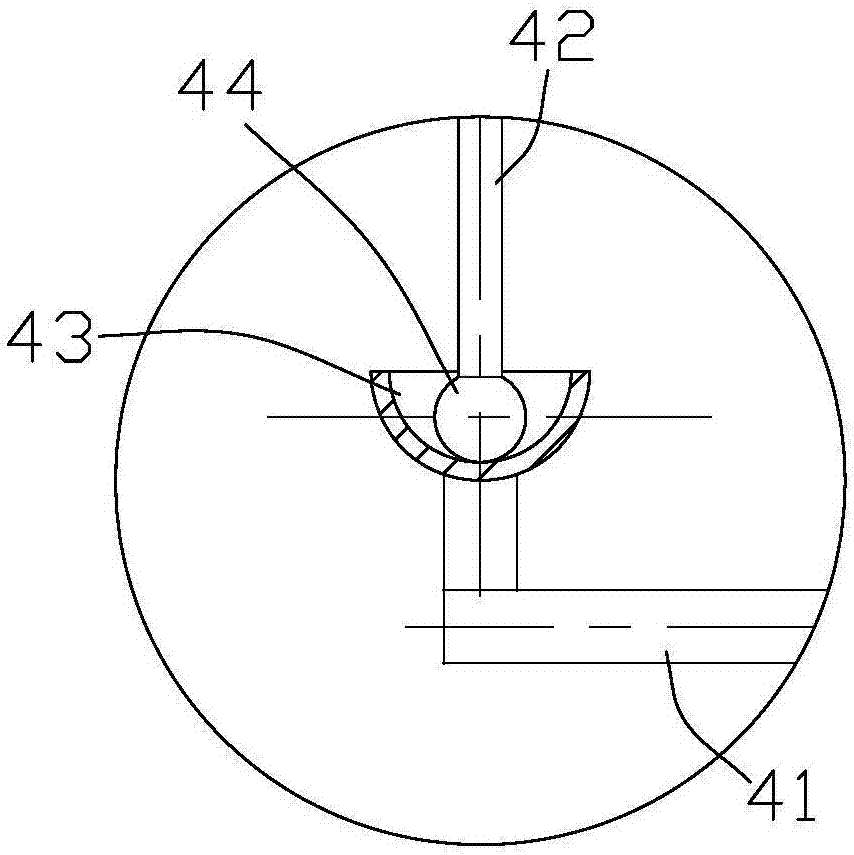

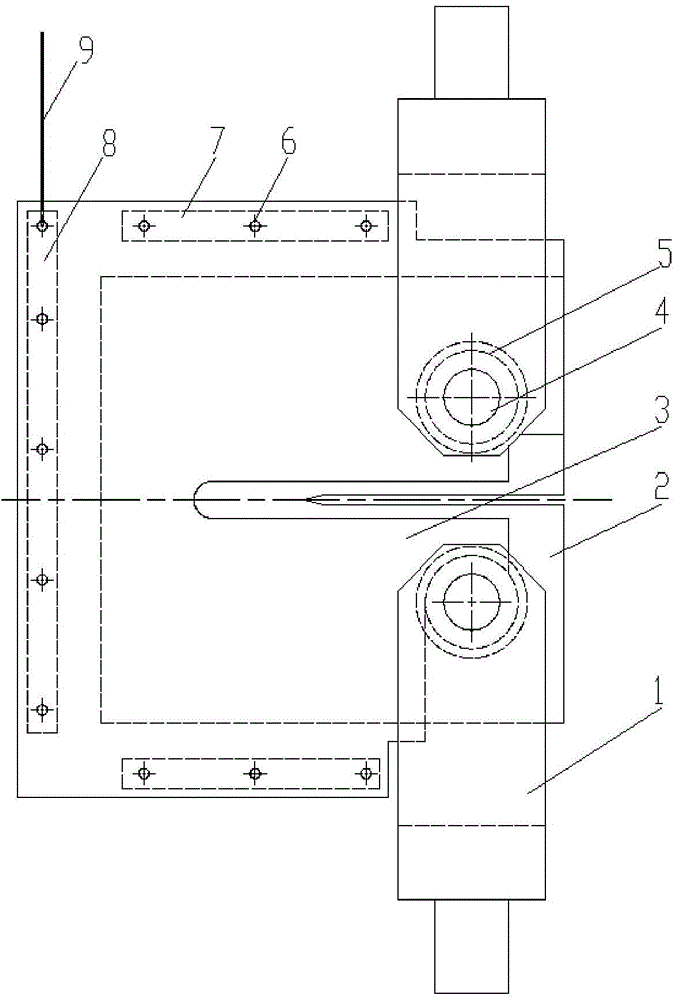

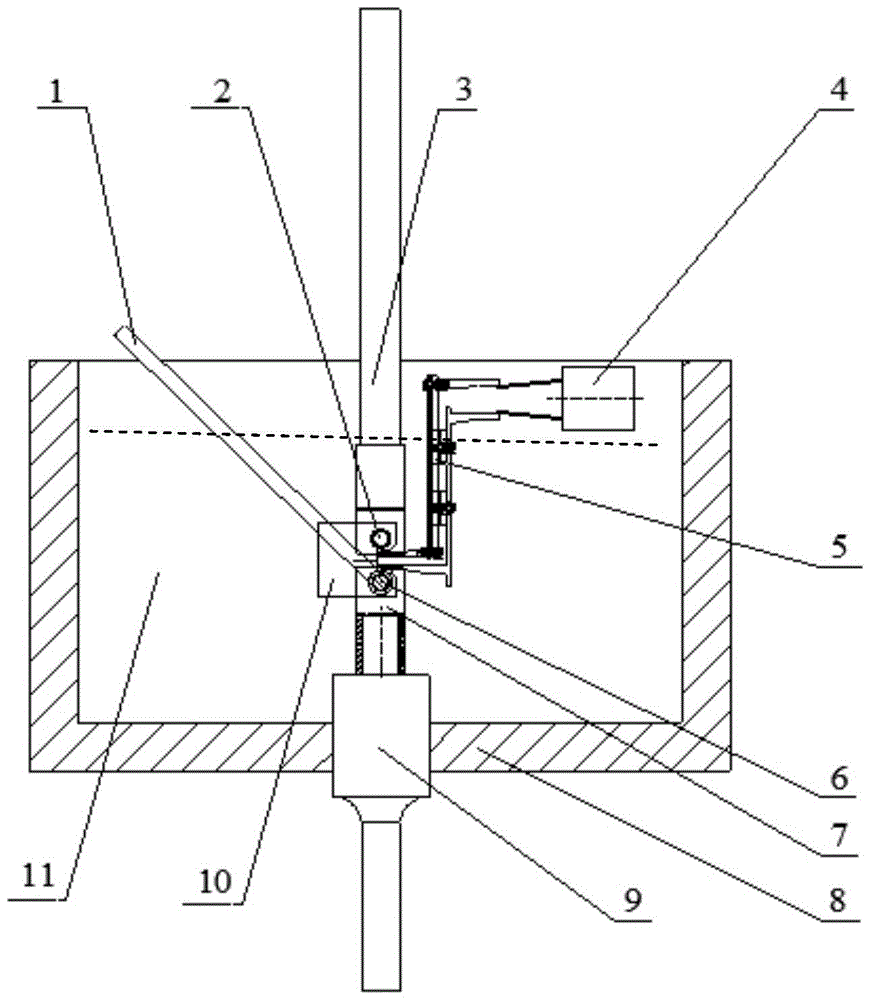

Clamp for compact tension specimen of material testing machine under high pressure hydrogen environment

ActiveCN104142266AAvoid bending momentImprove accuracyStrength propertiesHigh pressure hydrogenMaterials testing

The invention belongs to material mechanics property testing equipment, and provides a clamp for a compact tension specimen of a material testing machine under a high pressure hydrogen environment. The clamp comprises an upper clamp and a lower clamp, the upper clamp comprises an upper support, an upper primary U-shaped clamp, an upper secondary U-shaped clamp and dowels. The two ends of the upper support (the periphery of a cylindrical part) are respectively provided with a screw hole and are connected with the upper end of the testing machine through screws, two opposite rectangular blocks in the middle part of the upper support constitute a clamping interval, the two rectangular blocks and the cylindrical part of the upper support are machined to be of an integrated structure, and all the above components belong to the support part. The clamp for the compact tension specimen of the material testing machine under the high pressure hydrogen environment has the advantages that the misalignment influence can be eliminated automatically in the testing process of the compact tension specimen, it is guaranteed that the compact tension specimen is only subjected to the one-way loading action, the additional bending moment can be avoided, hence, the accuracy of test data is improved, using is simple and convenient, and the clamp is particularly suitable for material compact tension tests under the high pressure hydrogen environment.

Owner:ZHEJIANG UNIV

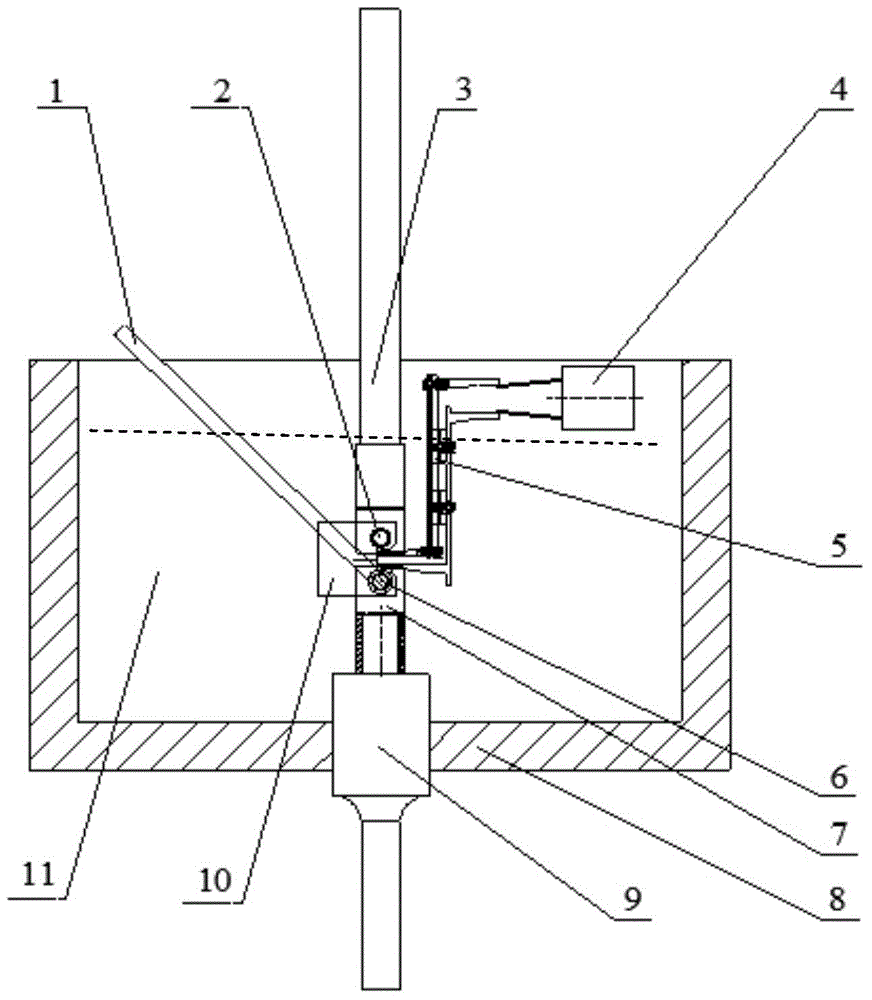

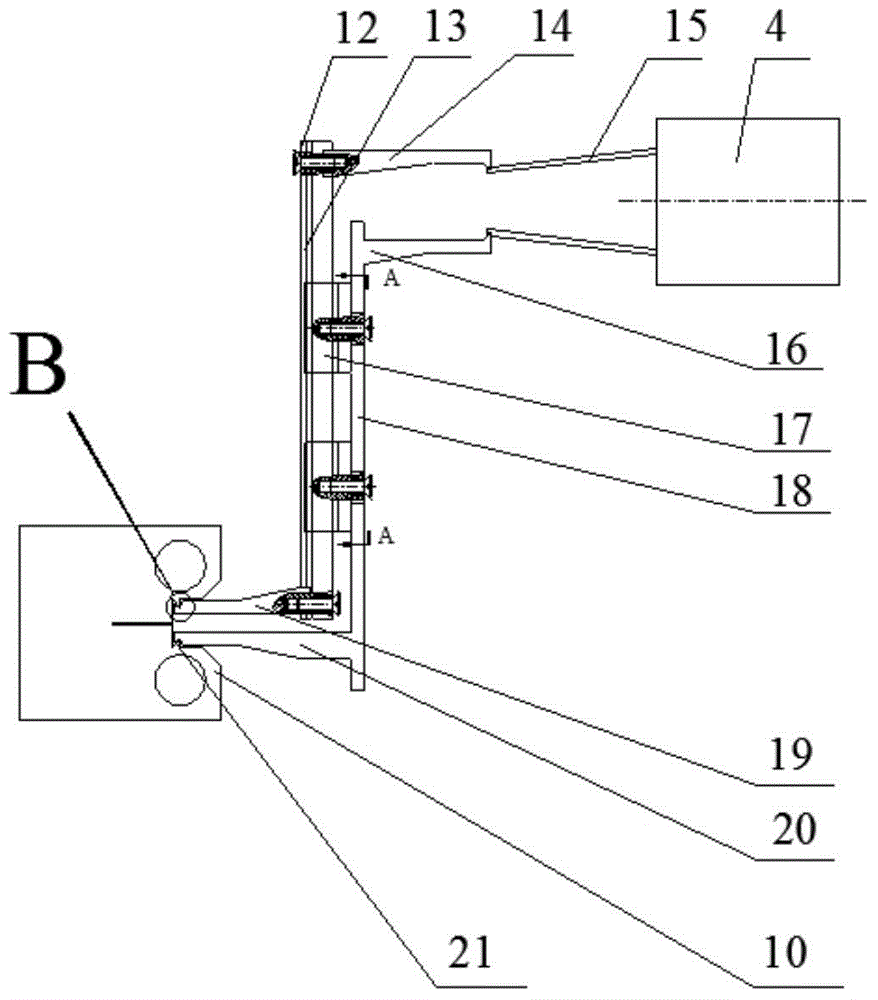

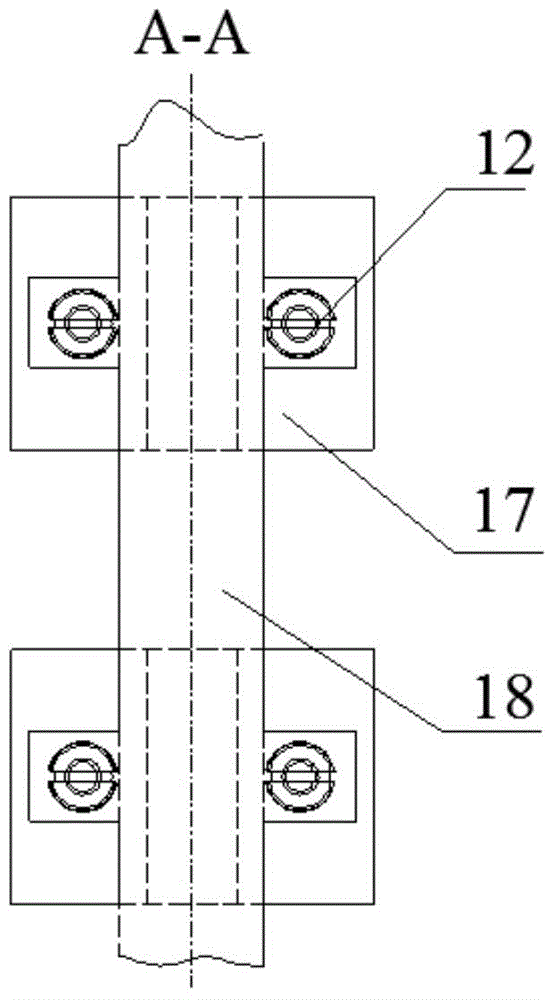

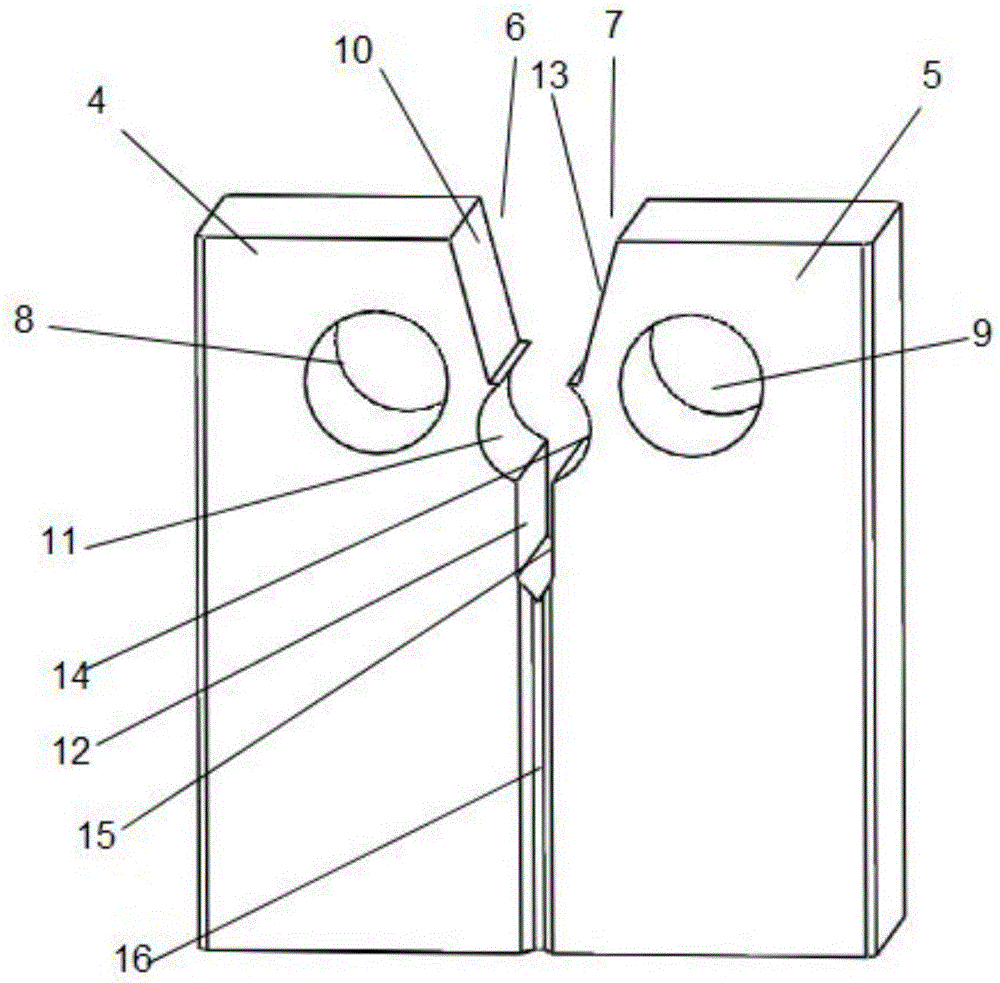

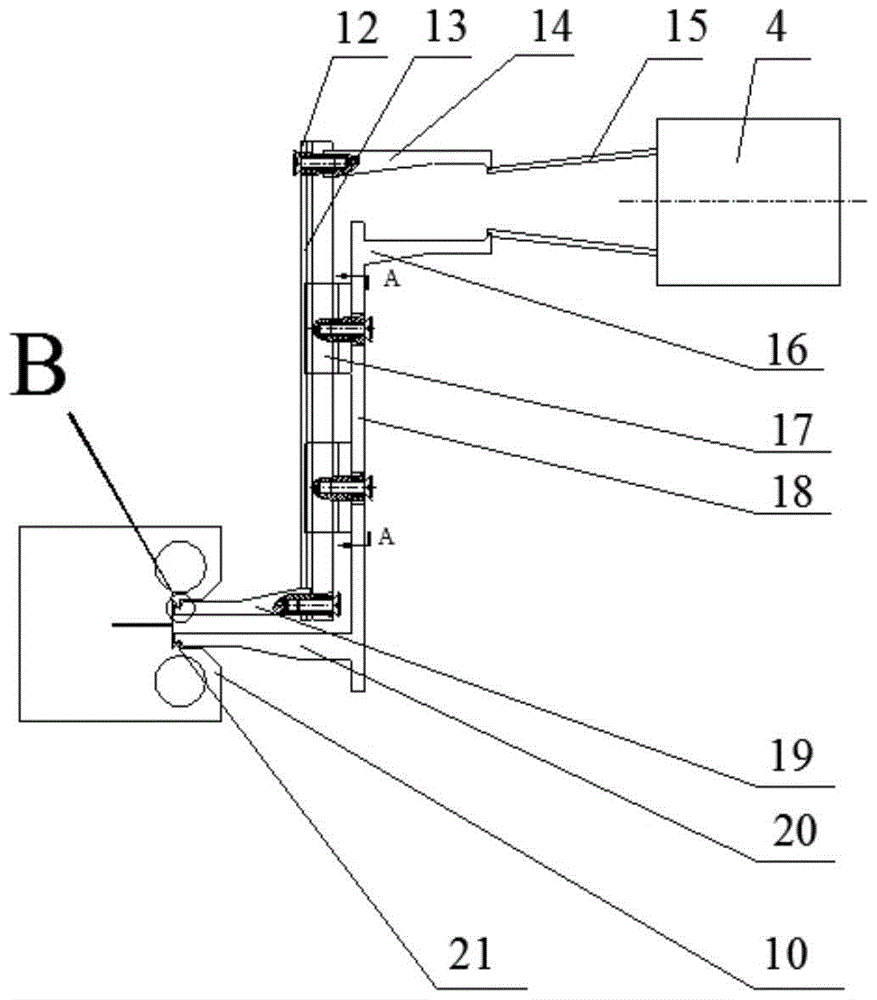

Device and method for testing breaking tenacity of compact tension specimen in low-temperature environment

ActiveCN103954512AAccurate measurementAvoid damageInvestigating material ductilityLiquid mediumEngineering

The invention provides a device and a method for testing breaking tenacity of a compact tension specimen in a low-temperature environment. The device comprises an insulated container for containing low-temperature liquid medium, upper and lower clamps and a displacement transmitting mechanism, wherein a specimen is soaked in low-temperature liquid medium and comprises a crack mouth in a horizontal orientation; the upper and lower clamps are connected with the specimen, respectively arranged at two sides of the crack mouth, and respectively connected with upper and lower pistons of a tensile testing machine; the displacement transmitting mechanism comprises two vertical guide rails which are parallel and slide oppositely; upper and lower blades are respectively arranged at two ends of the each vertical lead rail; the upper blades of the two vertical guide rails are oppositely arranged to form an upper tool edge connected with an extensometer; the lower blades of the two vertical guide rails are arranged oppositely to form a lower tool edge connected with the crack mouth, so that a loaded line displacement of the specimen is transferred to the extensometer above the liquid level of the low-temperature liquid medium, so as to accurately measure the loaded line displacement. Meanwhile, the extensometer is prevented from directly contacting the low-temperature liquid medium to be easily damaged, and the device and the method are simple and reliable in structure, and convenient to install and operate.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

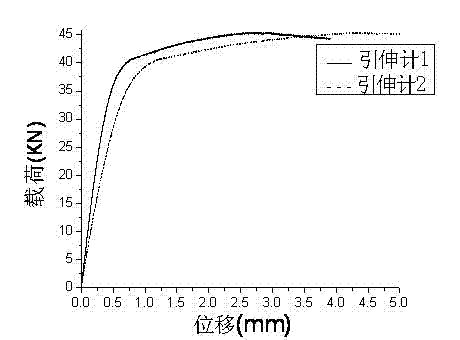

Method for measuring compact tension specimen fracture parameters by using double extensometers

ActiveCN102564844ASimple test methodData processing is simpleStrength propertiesCrack tip opening displacementInformation quantity

The invention discloses a novel method for measuring compact tension specimen fracture parameters by using double extensometers. The novel method comprises the following steps of: measuring two opening displacements by using the double extensometers; obtaining a crack tip opening displacement (CTOD) of a compact tension test through calculation by using a triangular relation; and calculating a CTOD value under each load and a nominal stress corresponding to the CTOD value, and obtaining a relation between the nominal stress and the CTOD, thereby obtaining a CTOD design curve of the compact tension test. The fracture parameter test method disclosed by the invention has the characteristics of simpleness, easy operation, simpleness for processing data, high precision of a critical CTOD value, comprehensive data, large information quantity, freeness from test precision influences of other parameters, such as strength, Young modulus, rotary factor and load, capabilities of obtaining the CTOD data of the whole test loading process and obtaining the CTOD design curve of the compact tension test under an actual board thickness condition.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

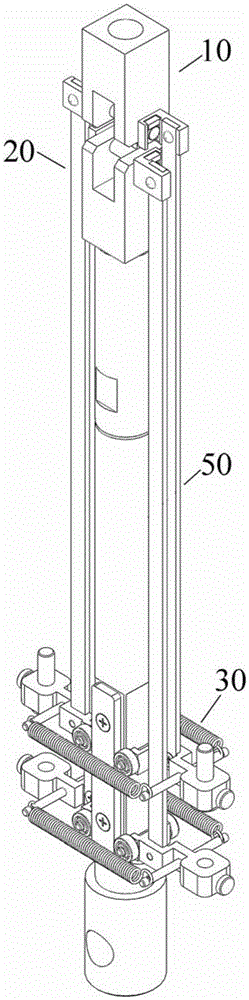

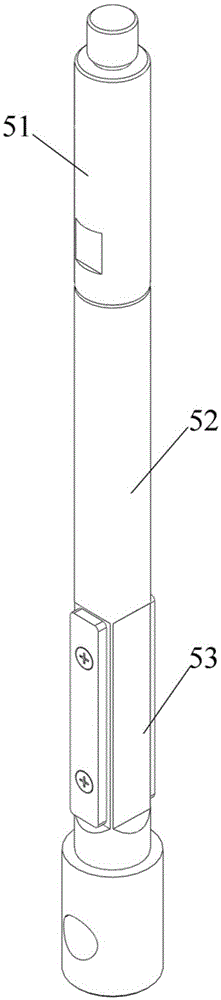

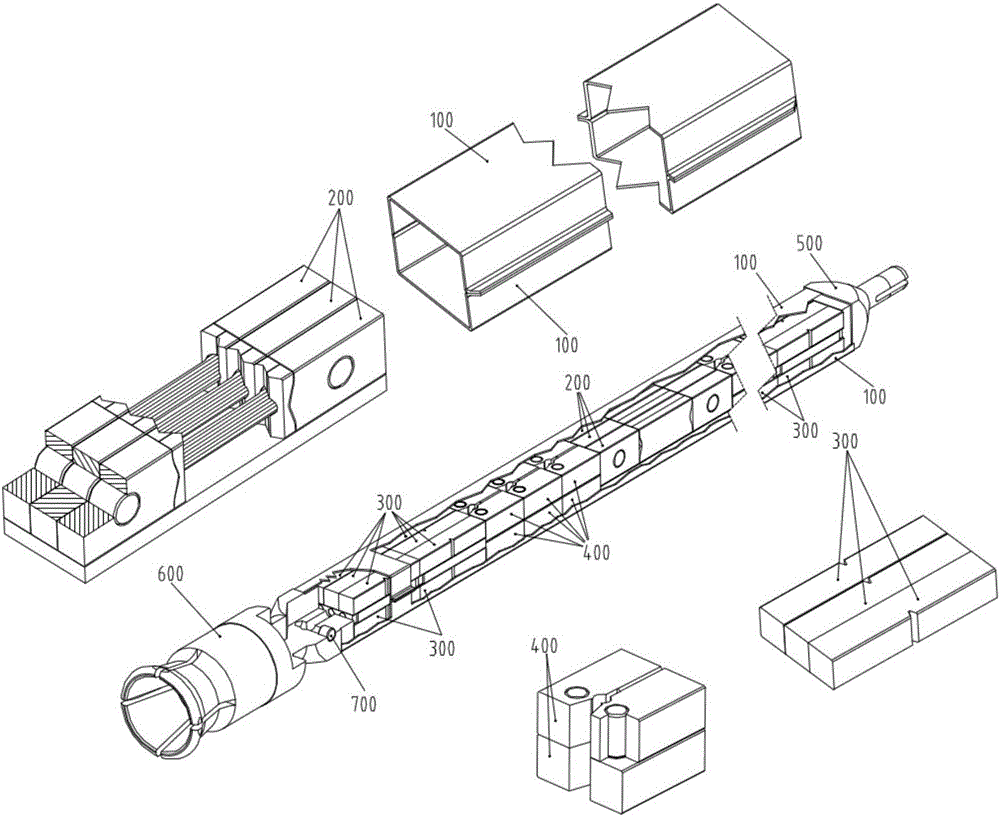

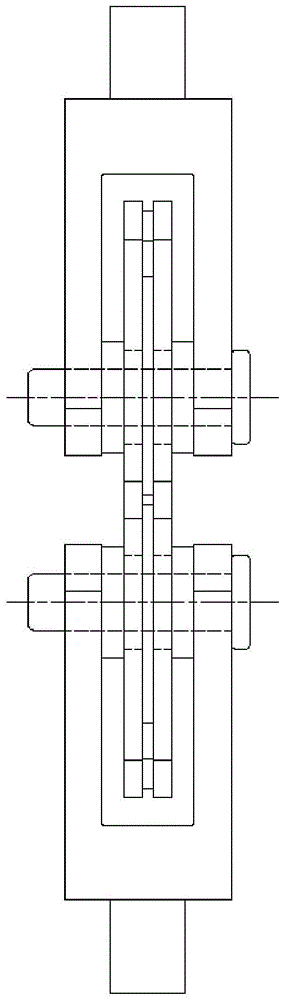

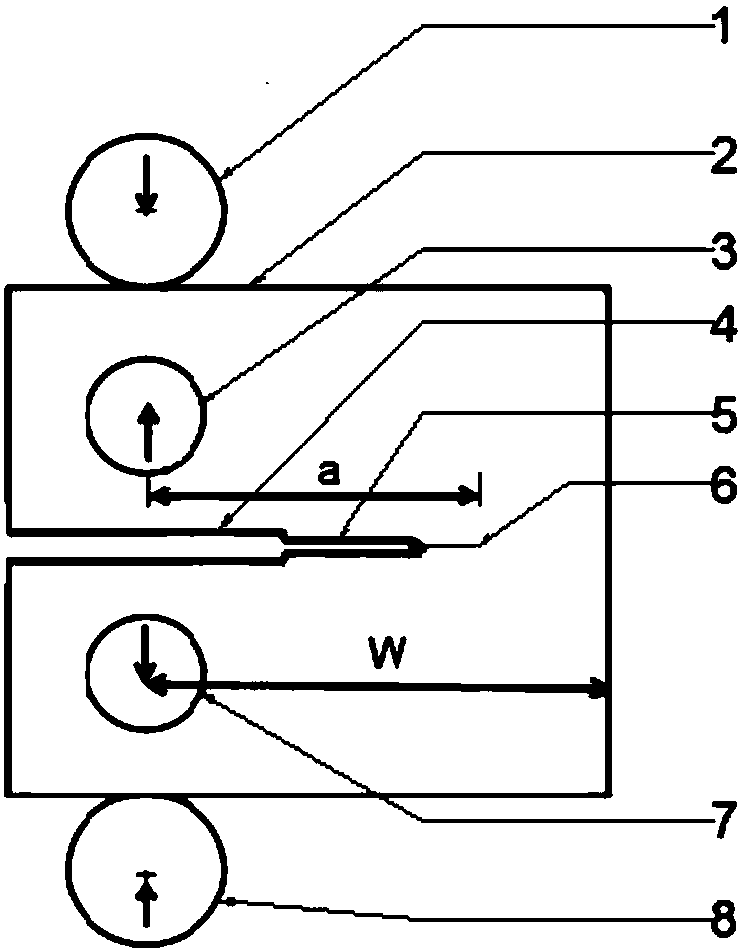

Compact tensile sample creep-fatigue crack propagation testing device

InactiveCN105277445AMaterial strength using tensile/compressive forcesEngineeringLinear displacement

The invention discloses a compact tensile sample creep-fatigue crack propagation testing device. The compact tensile sample creep-fatigue crack propagation testing device comprises a main shaft assembly, an upper chuck assembly and a lower chuck assembly are arranged at one end of the main shaft assembly, and a load linear displacement measurement assembly is arranged at the other end of the main shaft assembly. The upper chuck assembly is in threaded connection with a high-temperature pull rod of a fatigue-creep tester, the main shaft assembly comprises an upper connecting rod and a lower connecting rod, and the upper connecting rod and the lower connecting rod are coaxial. An axial guide rail is arranged at the lower end of the lower pull rod, and the lower chuck assembly is in threaded connection with the upper connecting rod. The load linear displacement measurement assembly comprises two fixing assemblies of the same structure and two measurement assemblies of the same structure, wherein the two fixing assemblies of the same structure and the two measurement assemblies of the same structure are symmetrically arranged on the two sides of the main shaft assembly respectively. Through the device, a compact tensile sample can be fixed, load linear displacement data in creep-fatigue crack propagation can be measured, and the clamp is compact and simple in structure and convenient and flexible to use and is matched with an existing tester well.

Owner:TIANJIN UNIV

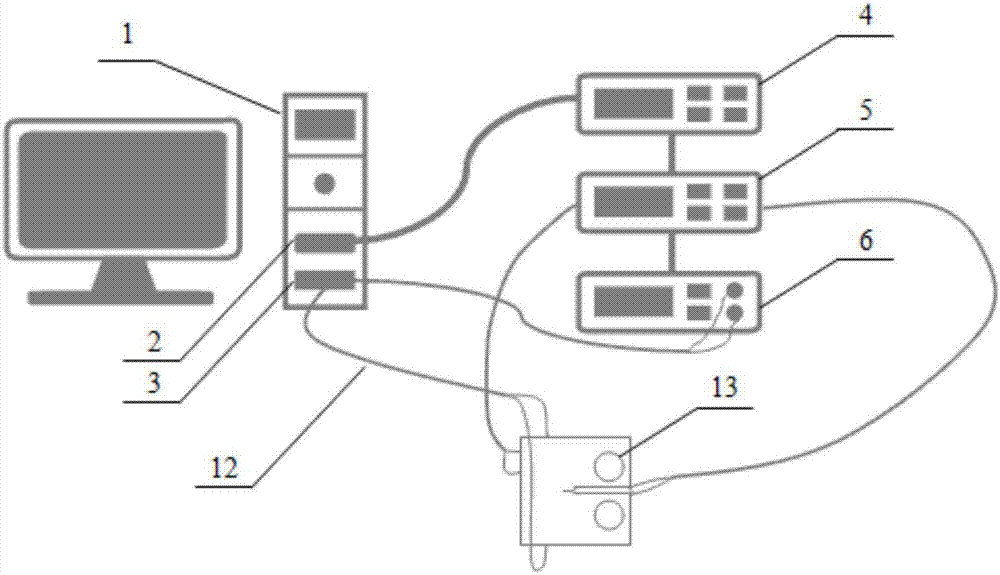

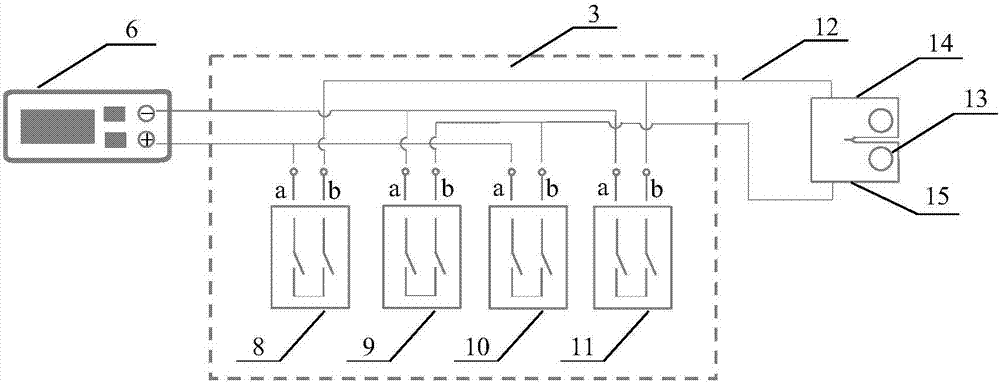

Device and method for measuring crack expanding rate of compact tension specimen

PendingCN107238531AReduce distractionsAchieve continuous high-precision measurementStrength propertiesStress corrosion crackingMeasurement precision

The invention relates to a device and a method for measuring crack expanding rate of a compact tension specimen, which are applied to continuous high-accuracy measuring of fatigue crack expanding, stress corrosion cracking, corrosion fatigue and other experiments of the compact tension specimen. The device comprises the following hardware of a computer, a GPIB (general purpose interface bus ) card, a multi-channel high-power relay card, a high-accuracy nanovolt micro-ohmmeter, a data switching unit, a high-stability direct current power supply, a shielding conducting wire or a double-strand insulation platinum wire. The device comprises the following software of direct current potential drop crack expanding rate measuring software and a user interface thereof. The device has the advantage that the relay switch is controlled by the direct current potential drop crack expanding rate measuring software to reversely change the direction of the direct current, so as to solve the problem of interference to the measuring accuracy and stability by the contact resistances of lead wire and specimen and electric potential produced by the temperature difference at both ends of the lead wire.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

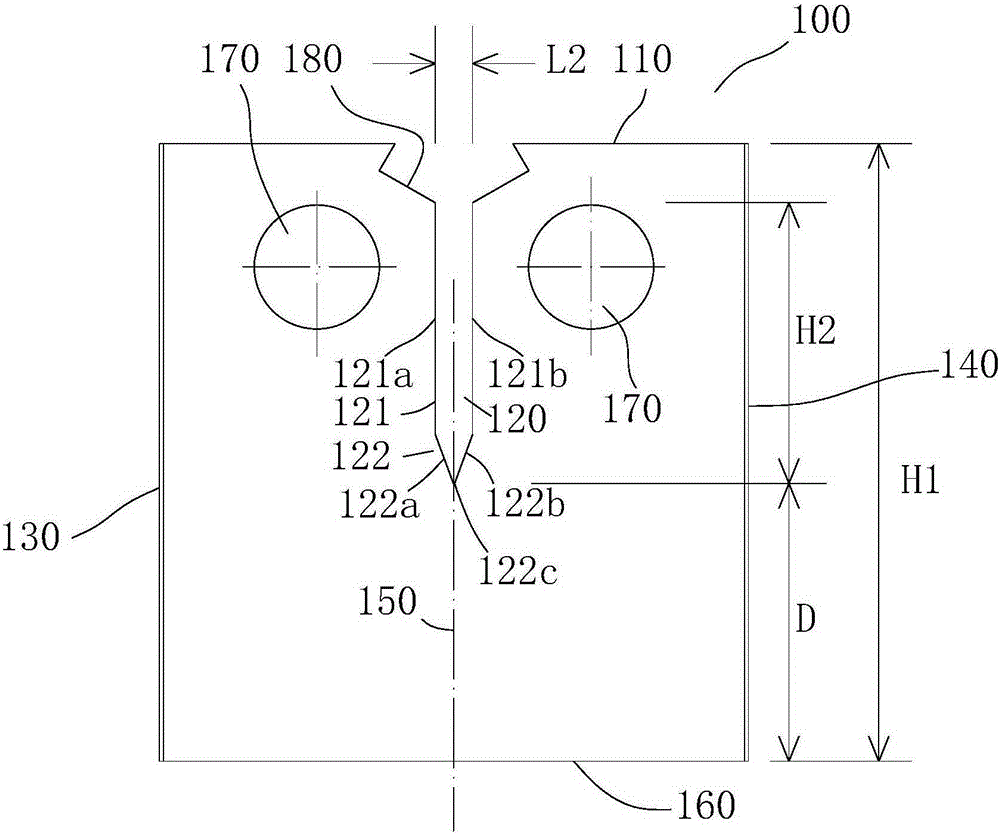

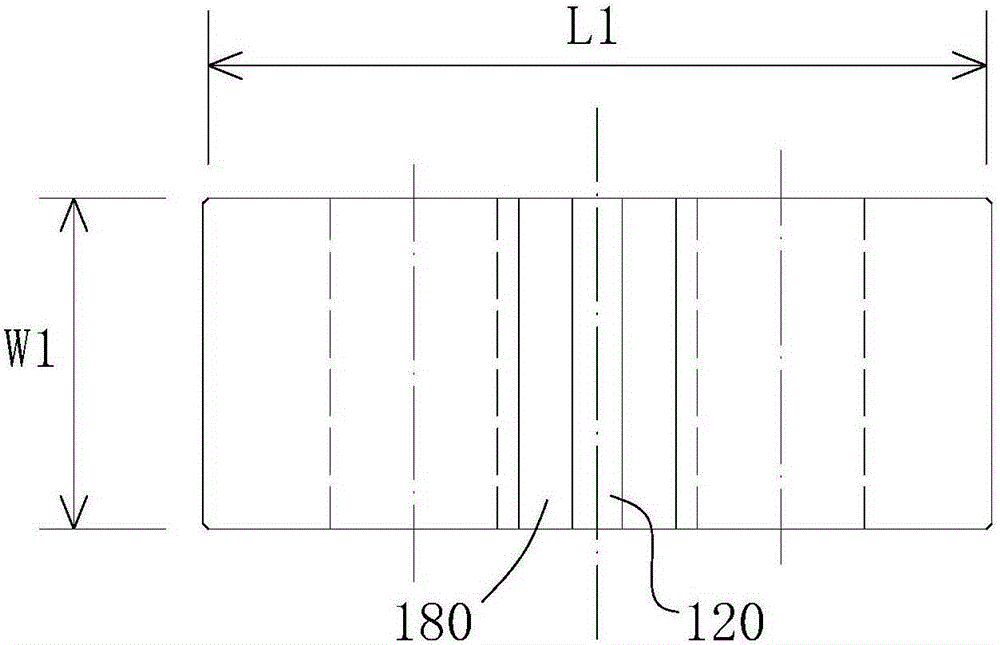

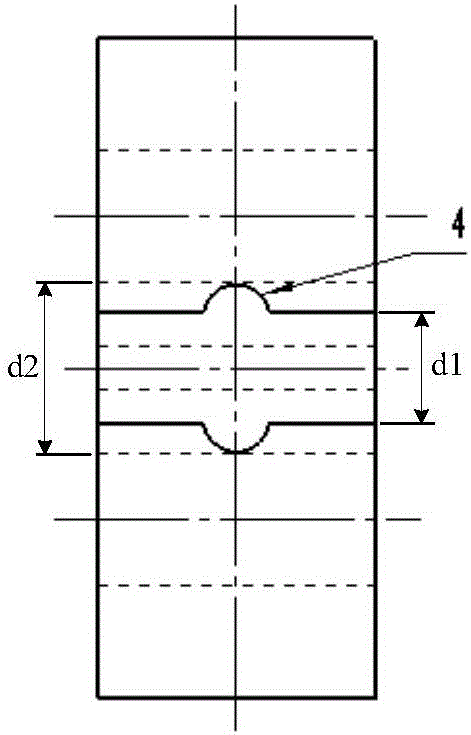

Sample component and method for nuclear power plant reactor pressure container irradiation inspection test

ActiveCN106644681AOptimal adjustment of loading quantityConsiderable loading spacePreparing sample for investigationMaterial strength using tensile/compressive forcesReduction ratioIrradiated materials

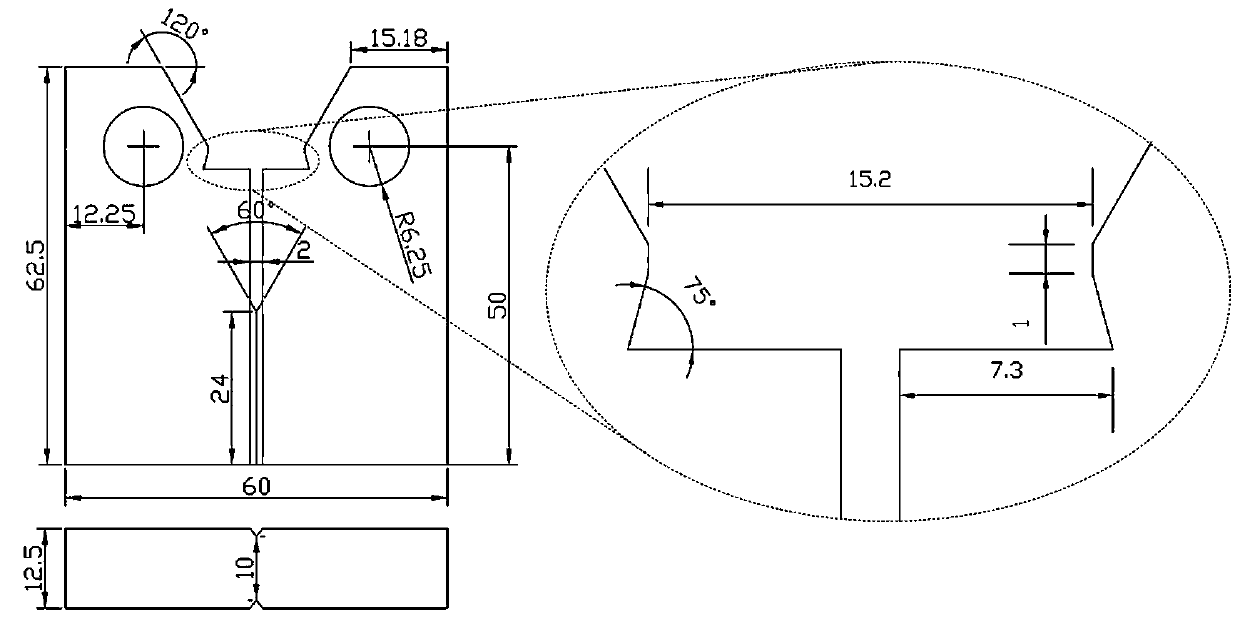

The invention discloses a sample component and method for a nuclear power plant reactor pressure container irradiation inspection test. The component comprises a tensile sample, an impact sample and a compact tensile sample, wherein the tensile sample is used for acquiring the tensile strength, the yield strength, the elongation and the cross section reduction ratio of irradiated materials, the impact sample is used for acquiring impact toughness of the irradiated materials, the compact tensile sample is used for acquiring fracture toughness of the irradiated materials and provided with notches, circular portions and side grooves which are sequentially formed in a first side face and a second side face from top to bottom, and the notch with an isosceles trapezoidal section, the circular portions and the notch with a V-shaped bottom jointly form an extensometer placement space. The method includes the steps of sample preparation, sample loading, sample testing and result evaluation. Arrangement of a bent sample is canceled, the quantity proportion of the other samples is optimized, the shape of the compact tensile sample is optimally improved, and test failure risks in fracture toughness testing are decreased.

Owner:中广核工程有限公司 +1

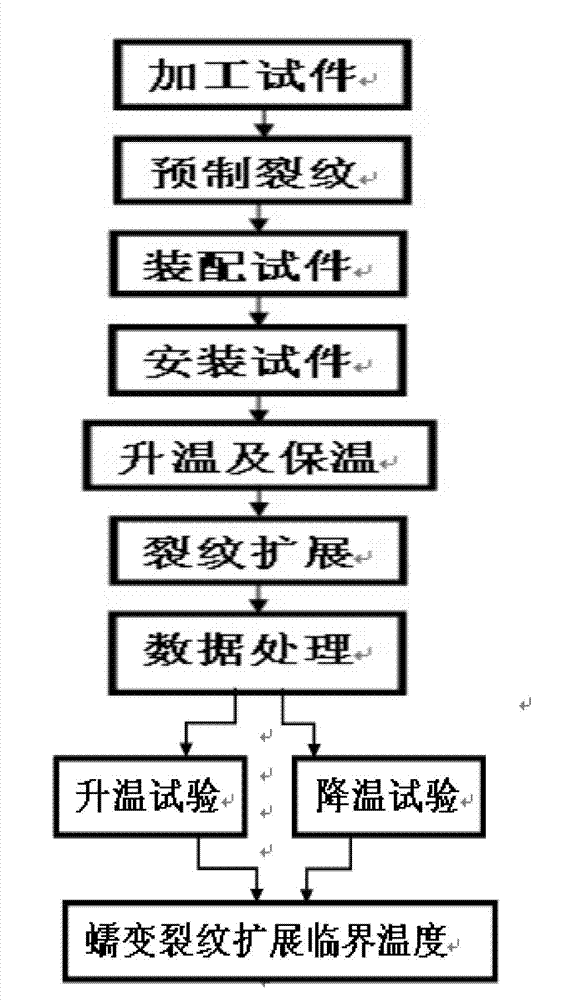

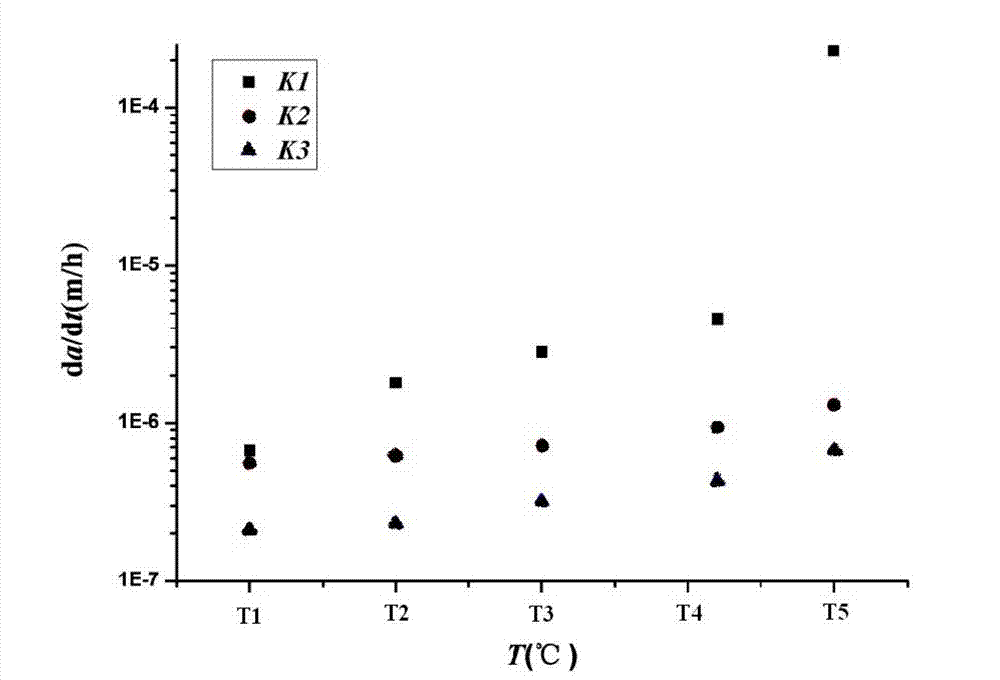

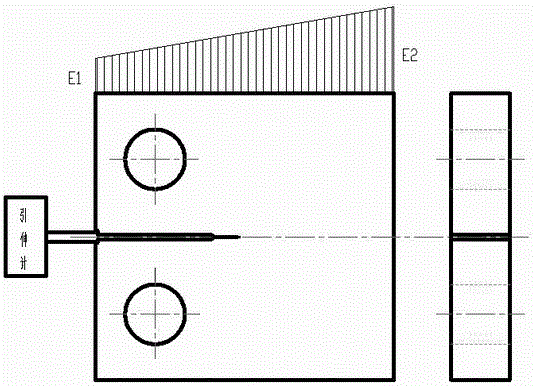

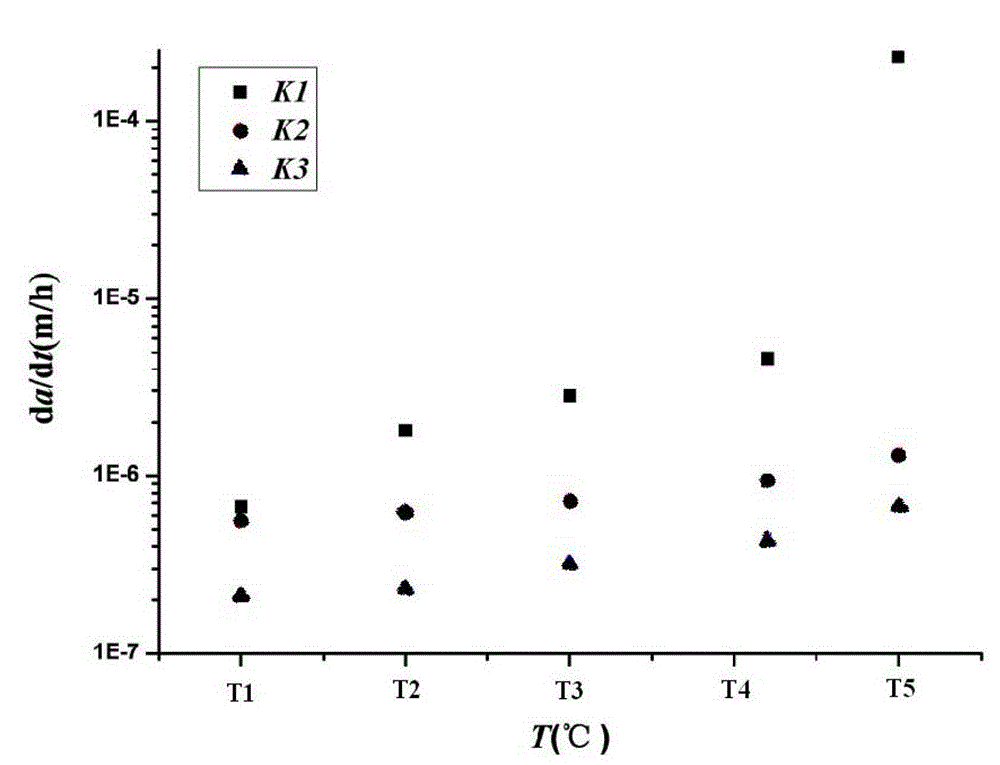

Method for measuring critical temperature of high temperature creep crack growth of material

ActiveCN103196939AIncrease costShorten test timeMaterial thermal analysisElectrical resistance and conductanceStress intensity factor

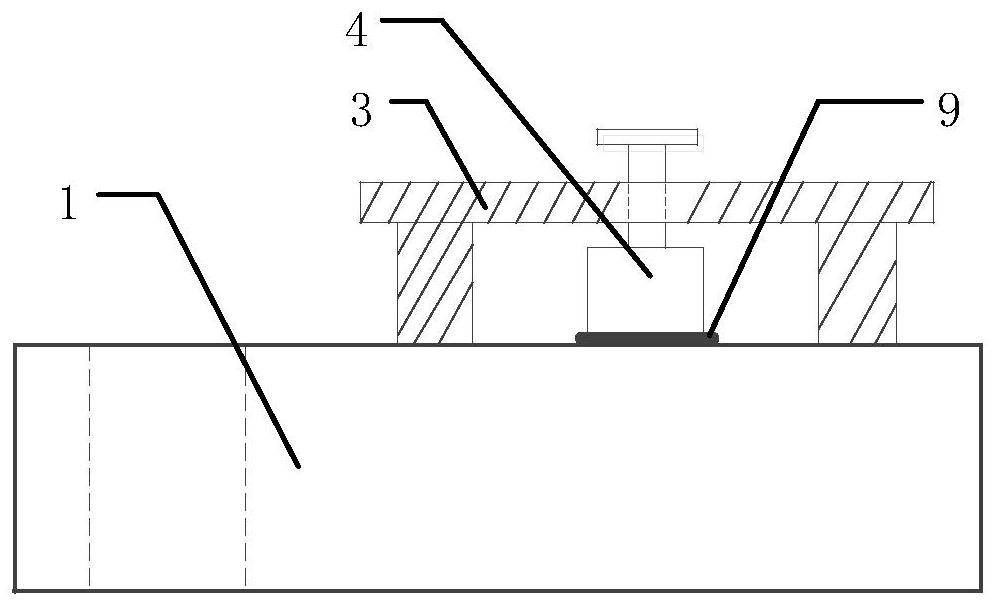

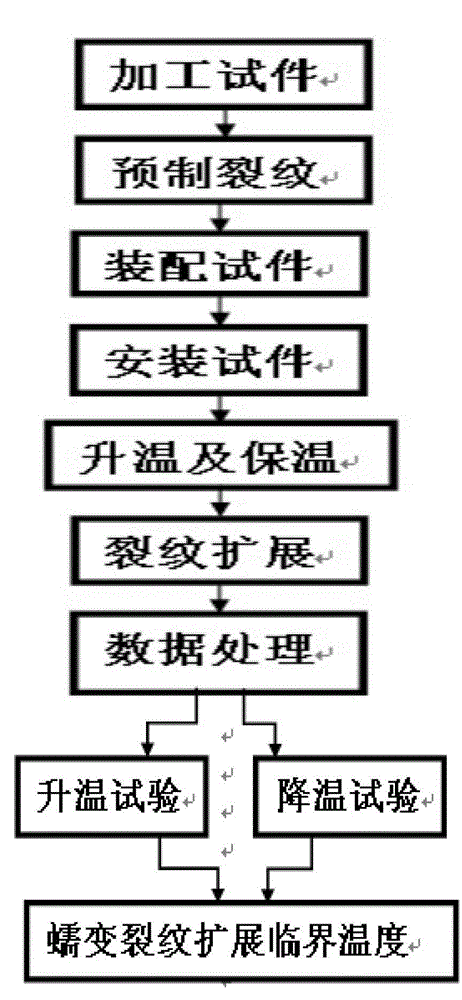

The invention discloses a method for measuring critical temperature of high temperature creep crack growth of a material. The method comprises the following steps of: processing not less than 6 standard compact tension specimens through a specific material according to creep crack growth test requirements, performing crack prefabrication on the processed not less than 6 test specimens on a fatigue performance tester, wherein the prefabricated crack length is 0.5 times as large as the width of the test specimen; wedging a wedge-shaped block in an initial slot of the test specimen, locating the most front end of the flat part of the wedge-shaped block at a loading line to provide displacement to the loading line, and forming a stress strain field characterized by stress strength factors at the crack tip of the test specimen to provide a driving force for creep crack growth; and putting the assembled test specimen in a resistance wire heating type high temperature furnace to perform heating test or cooling test until the crack growth speeds of all test specimens at a temperature are not larger than 1*10<-6>m / h, and the temperature is the critical temperature of high temperature creep crack growth of the material. The method disclosed by the invention can be used for testing a plurality of test specimens at one time, so that the test cost is greatly lowered.

Owner:BEIHANG UNIV

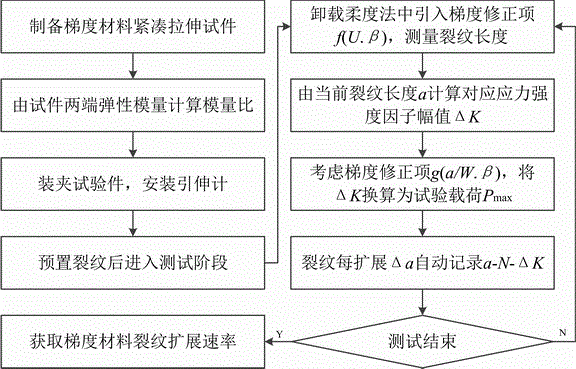

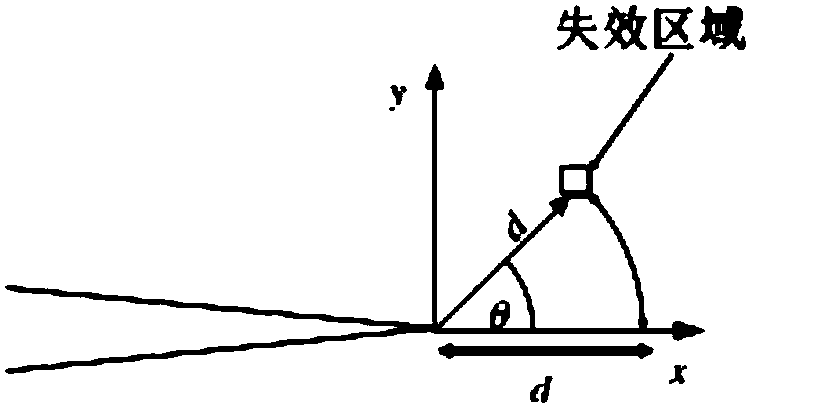

Test method for crack growth rate of linear gradient material

InactiveCN105758723ARealize full automationSimplifying the job of measuring fatigue growth ratesMaterial strength using tensile/compressive forcesGradient materialComputer science

The invention discloses a test method for a crack growth rate of a linear gradient material. The test method comprises the following steps: applying alternating load to a compact tension specimen through a fatigue test machine; rewriting a function relationship of parameters at a test control end; introducing a gradient correcting item for measuring crack length and a gradient correcting item for calculating load; and accurately controlling a test progress and automatically correcting, thereby acquiring test data and acquiring the crack growth rate of the gradient material. The test method provided by the invention has the advantages that the test method is fit for testing the crack growth rate of the linear gradient material, no human intervention is required in the testing period, the test is automatically performed and the precision is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

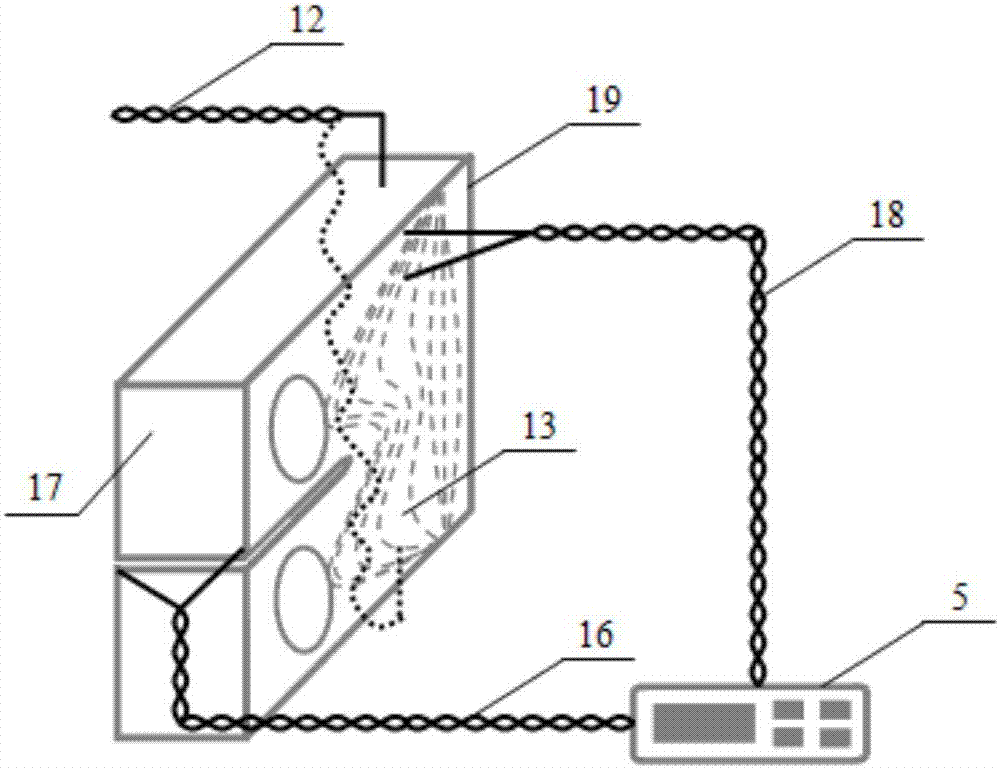

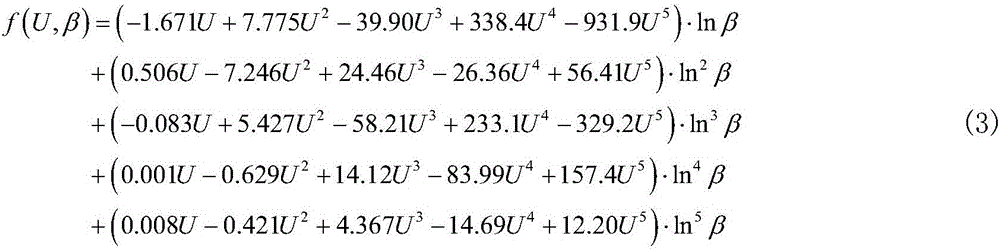

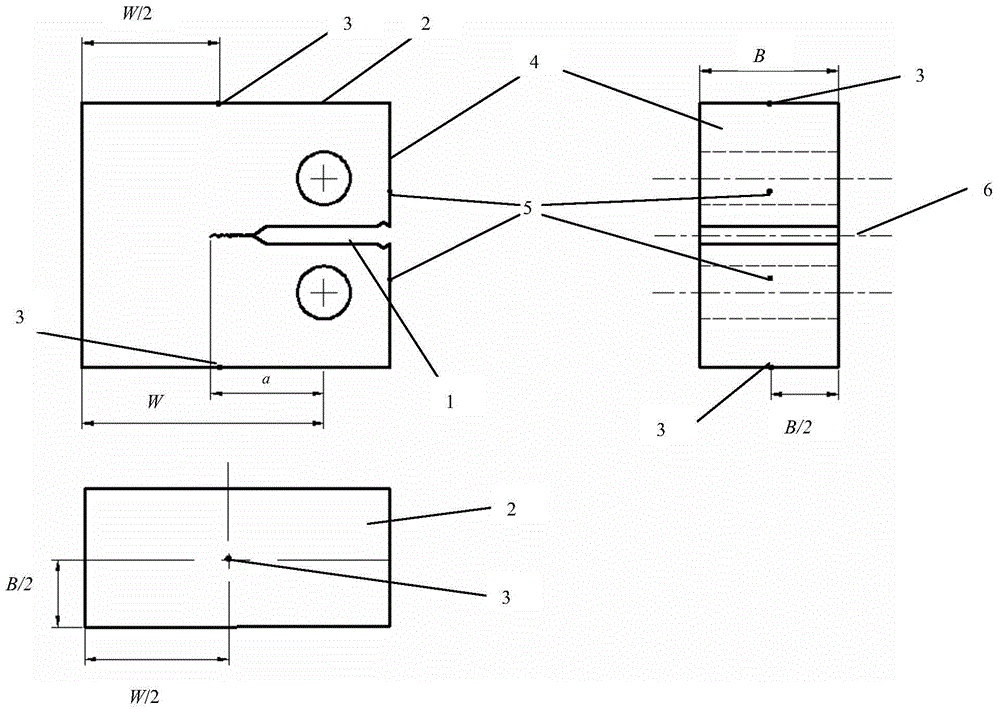

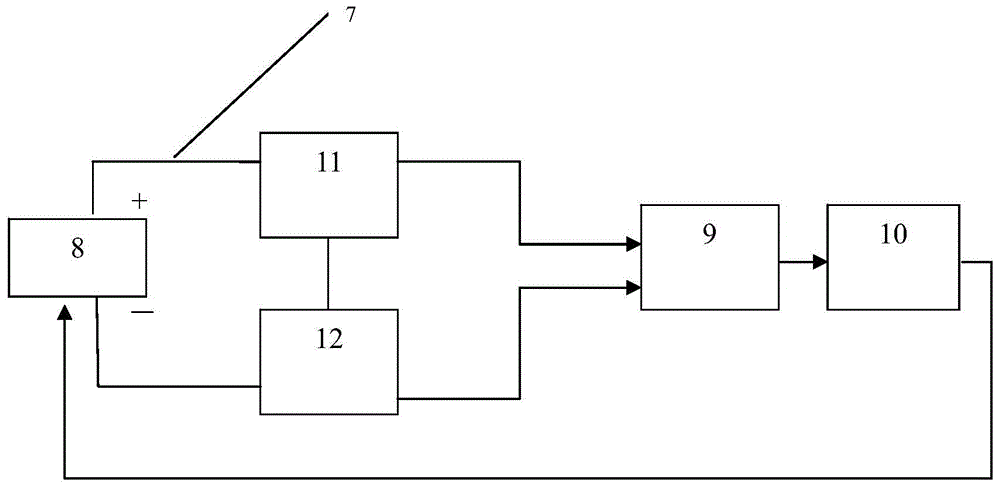

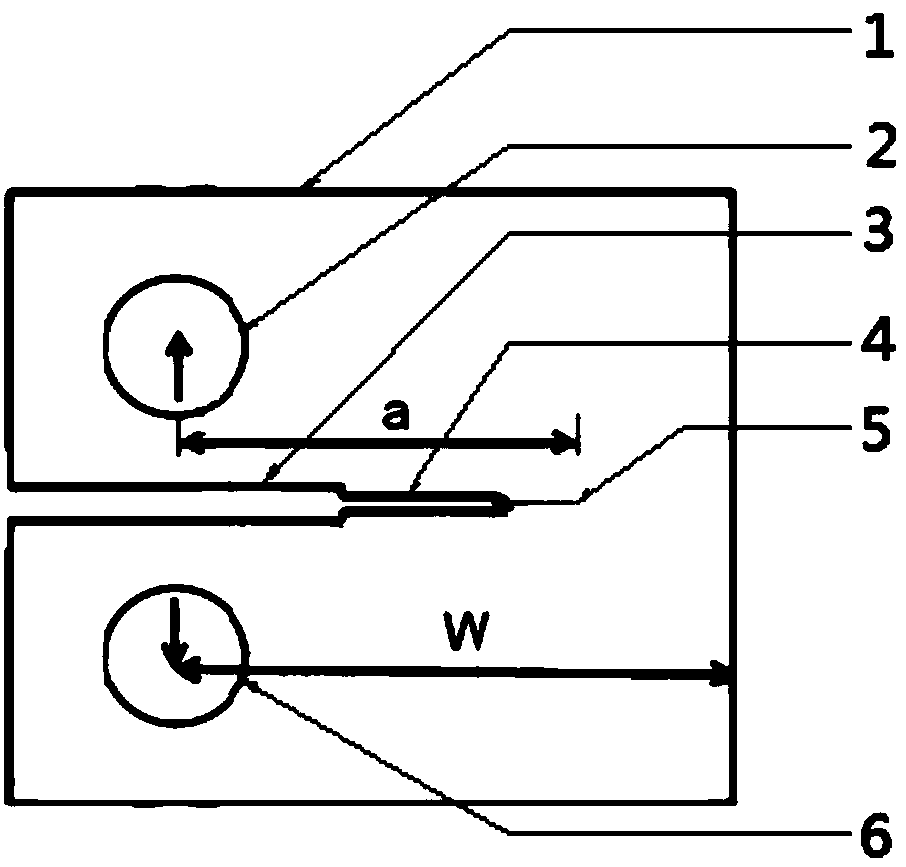

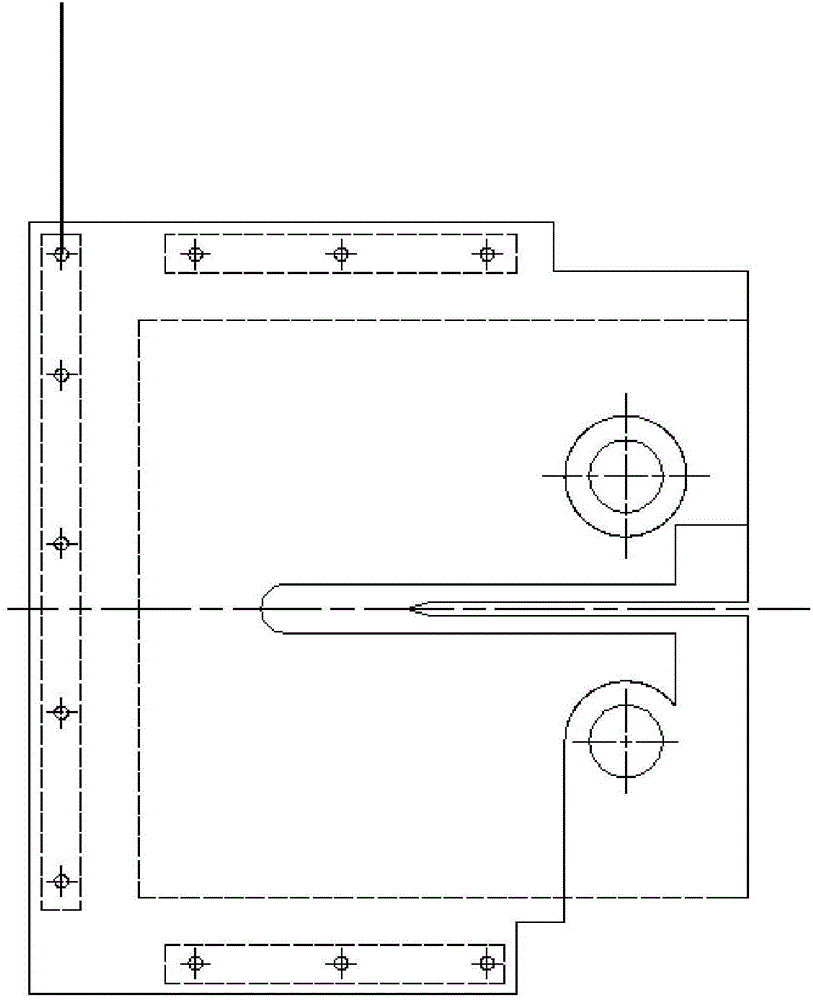

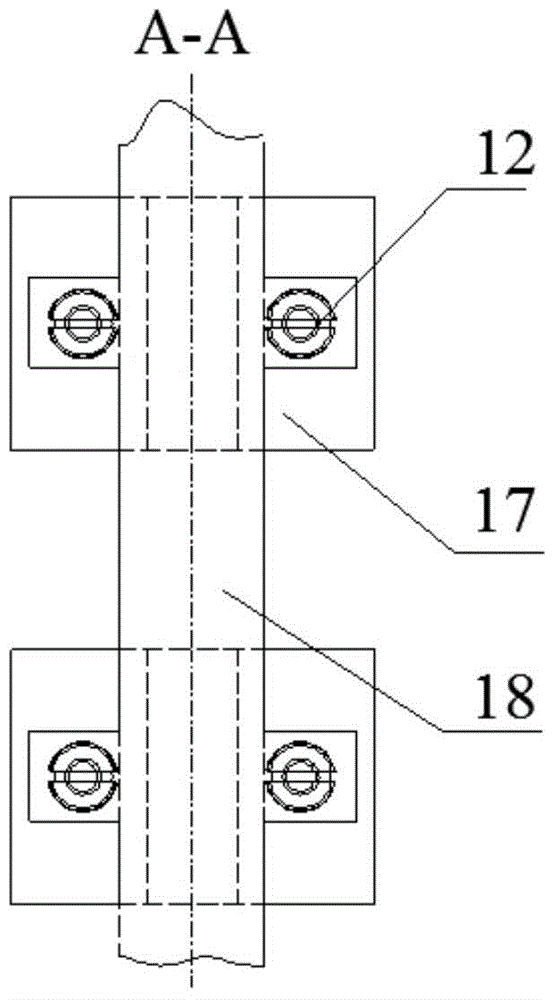

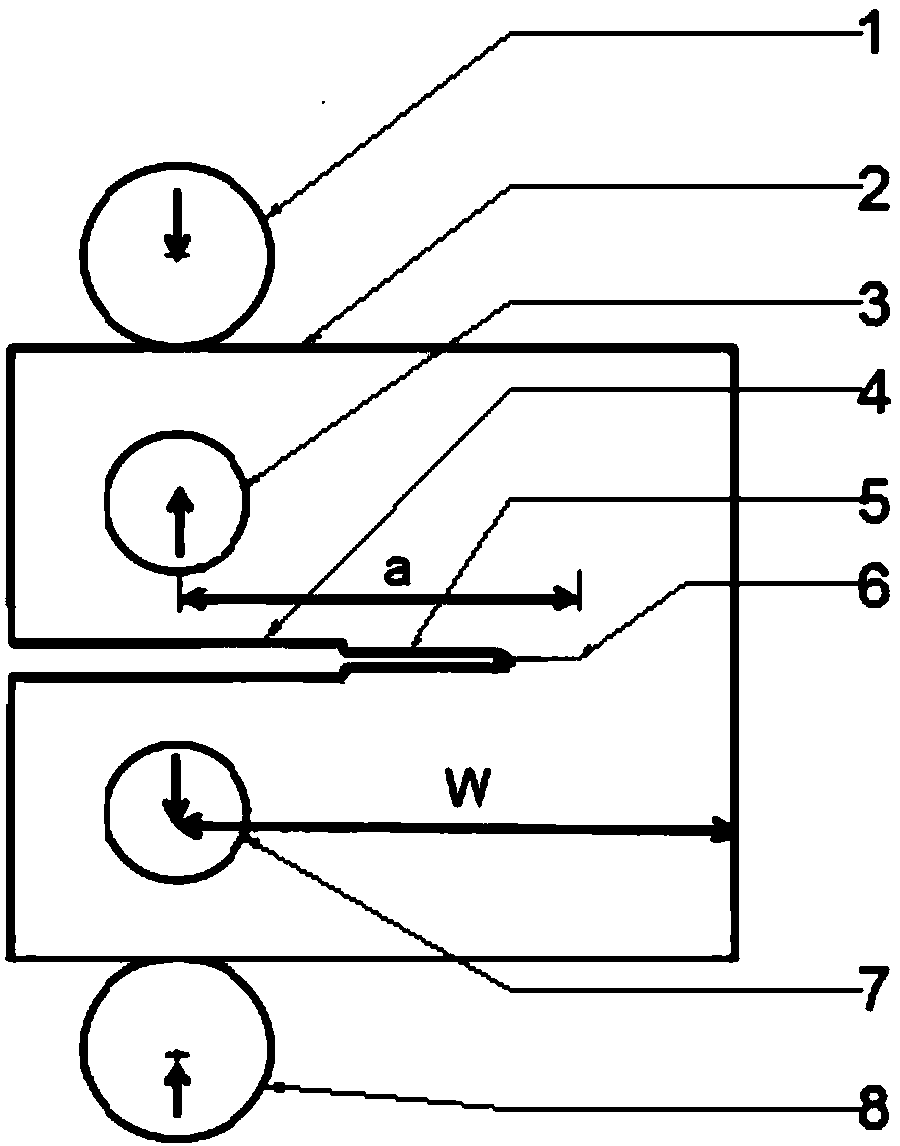

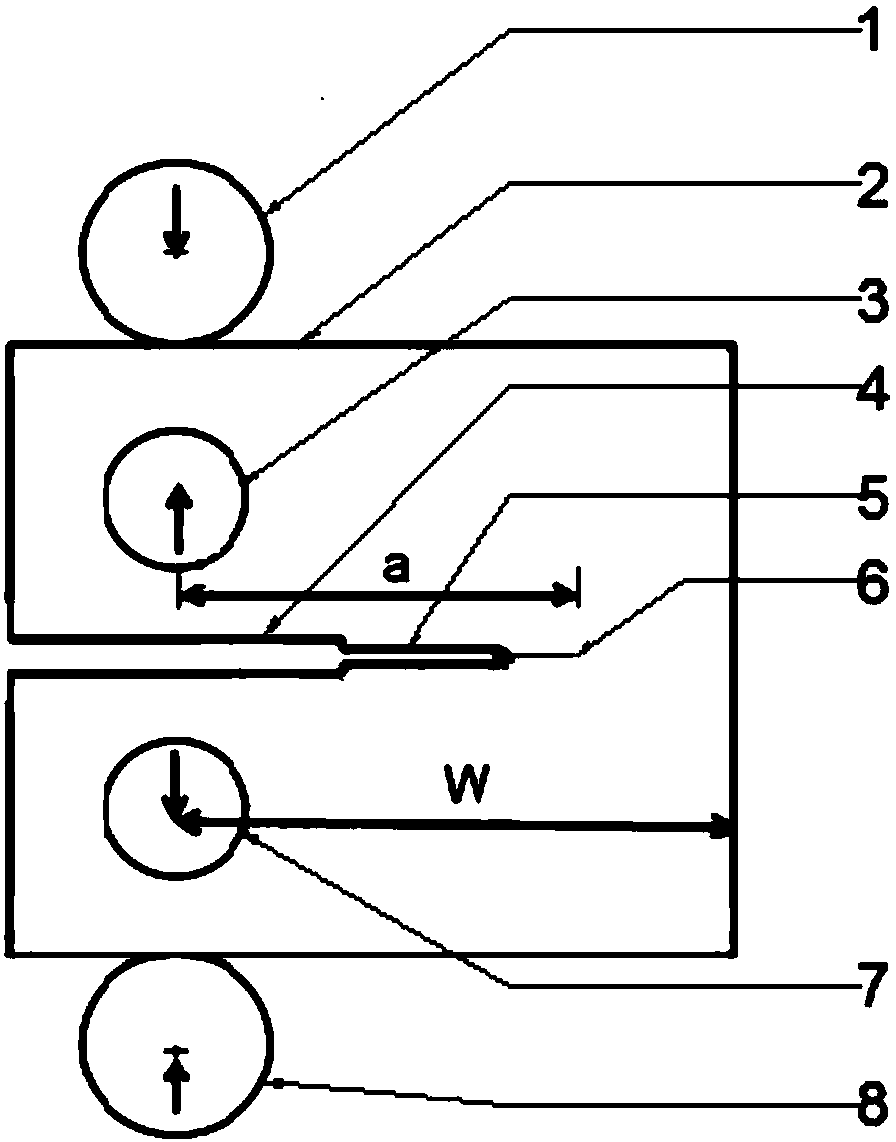

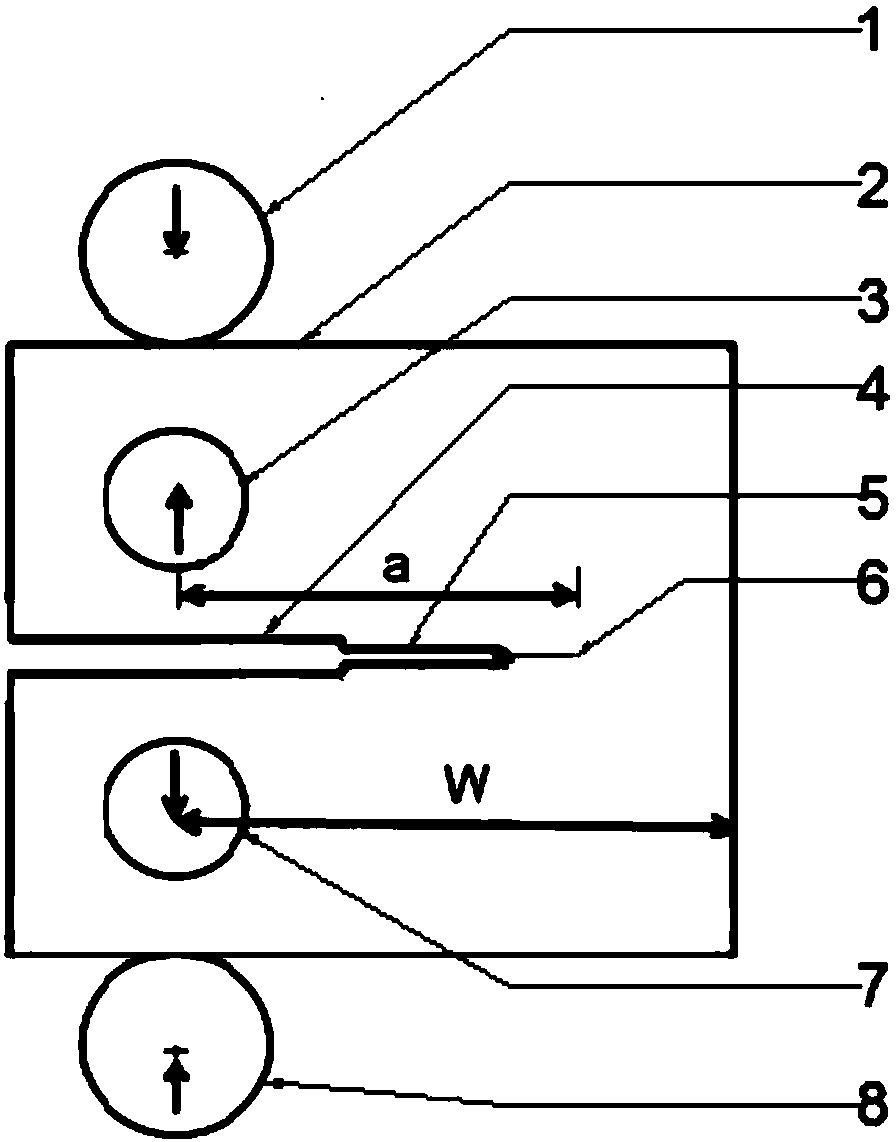

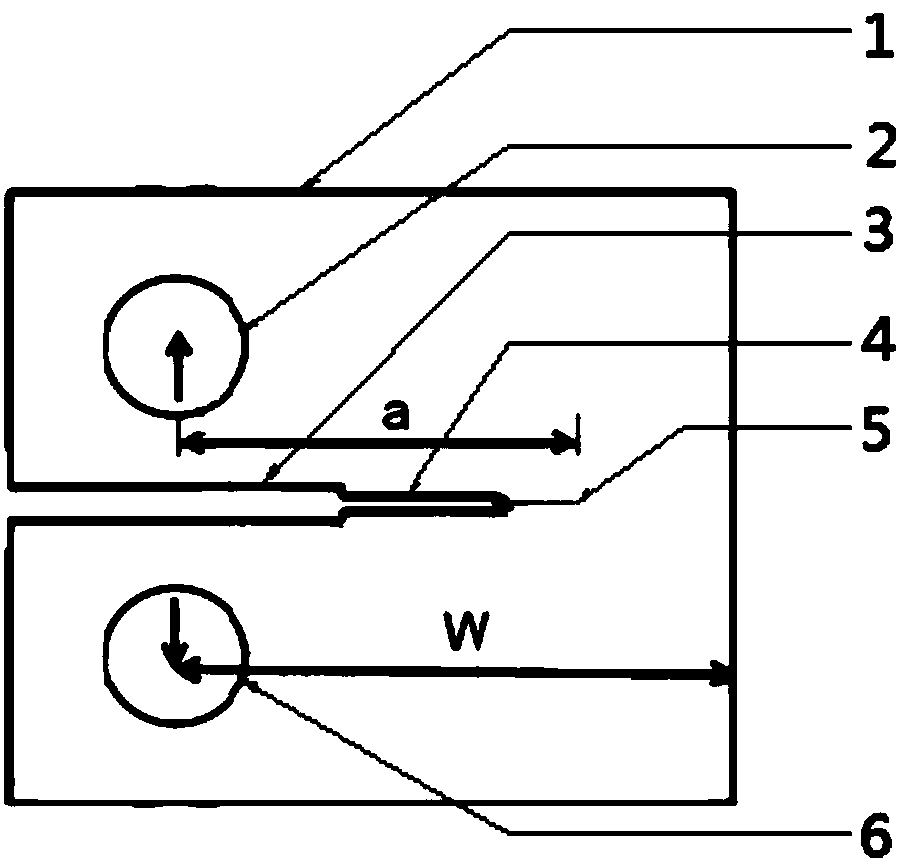

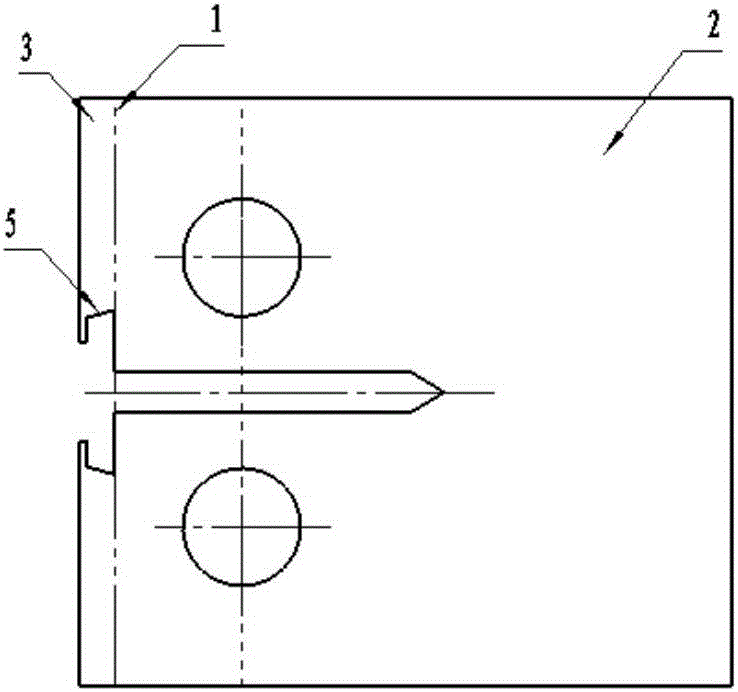

Temperature compensation method used for compact tension sample high temperature crack expansion test

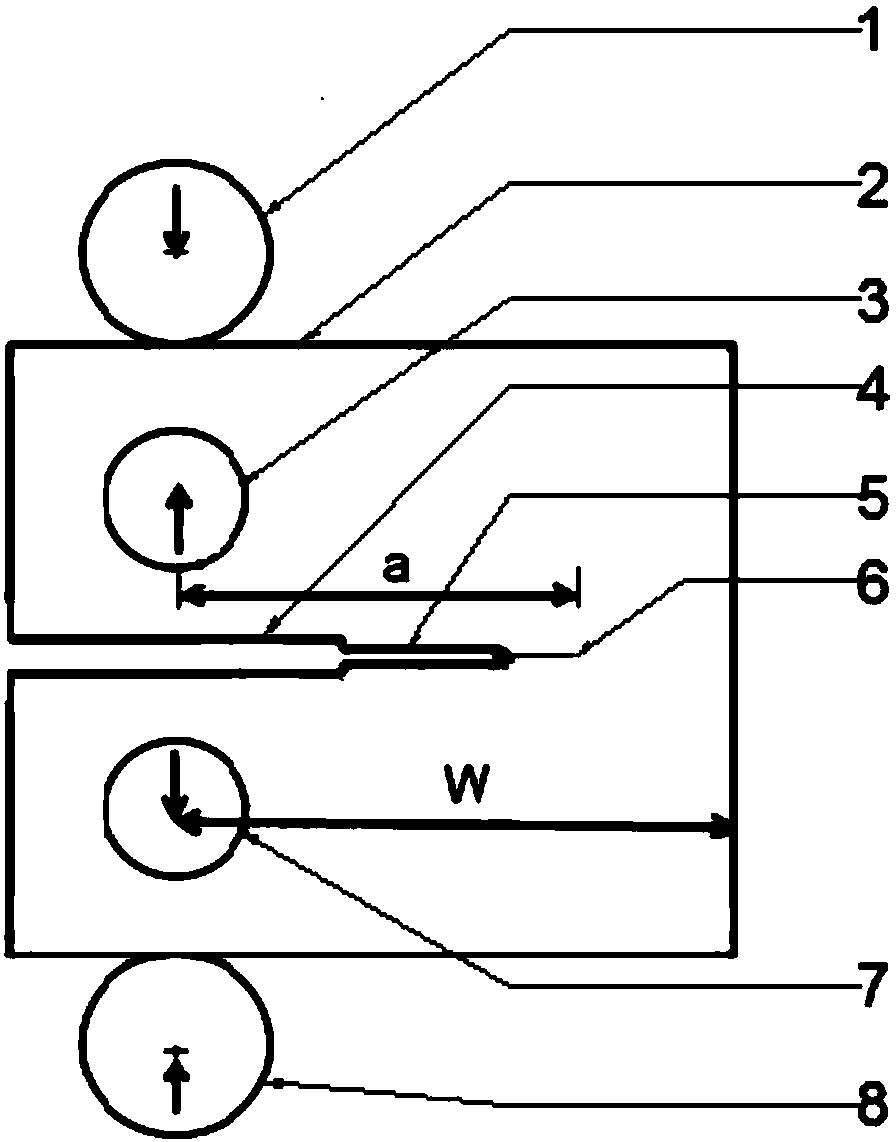

InactiveCN104535410ACrack measurement length is accurateUsing electrical meansStrength propertiesReference sampleAudio power amplifier

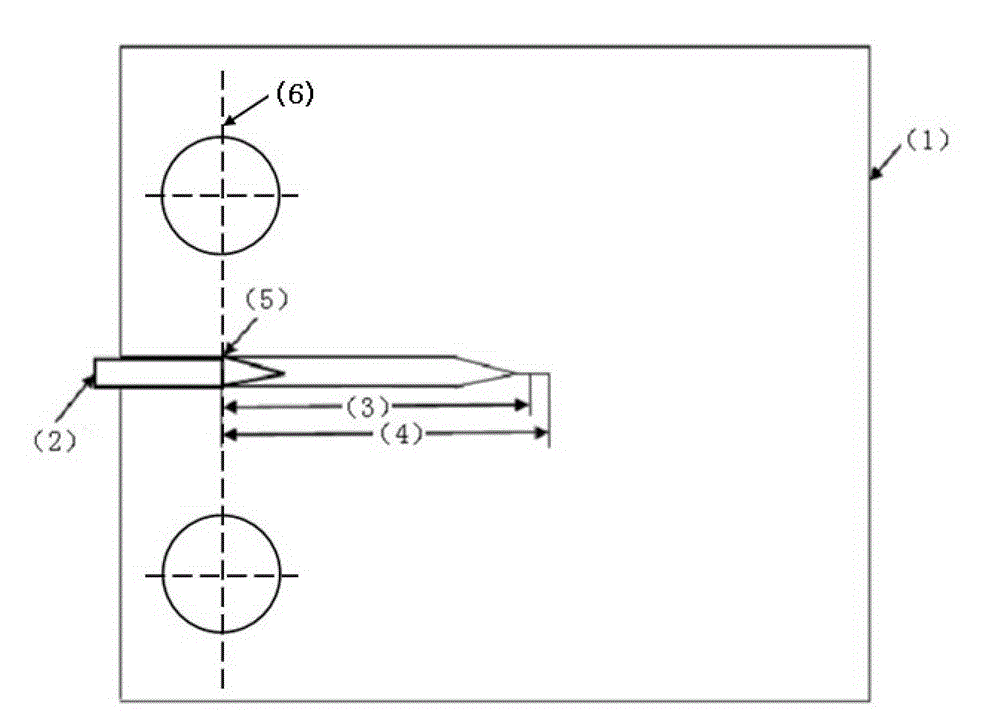

The present invention relates to a temperature compensation method used for compact tension sample high temperature crack expansion tests, sample width surfaces (2) on both sides of notches (1) of a test sample (12) and a reference sample (11) are respectively marked with current input solder joint positions (3), sample thickness surfaces (4) on both sides of opening ends of the notches (1) of the test sample (12) and the reference sample (11) are respectively marked with voltage output solder joint positions (5), four connection wires (7) at the current input solder joint positions (3) of the test sample (12) and the reference sample (11) are connected in series and connected with a DC power supply (8), every two wires (7) at the voltage output solder joint positions (5) of the test sample (12) and the reference sample (11) are connected with a signal amplifier (9), the signal amplifier (9) is connected with a computer (10), the test sample (12) and the reference sample (11) are put into a furnace and heated to test temperature, voltage time-varying curve are respectively drawn by use of voltage values during the test process of the test sample (12) and the reference sample (11), and finally a corresponding crack length a can be calculated by a voltage value.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for measuring high-temperature fracture toughness JIC of high-toughness alloys

InactiveCN110333144AThe test process is shortImprove test efficiencyMaterial strength using tensile/compressive forcesTip positionAlloy

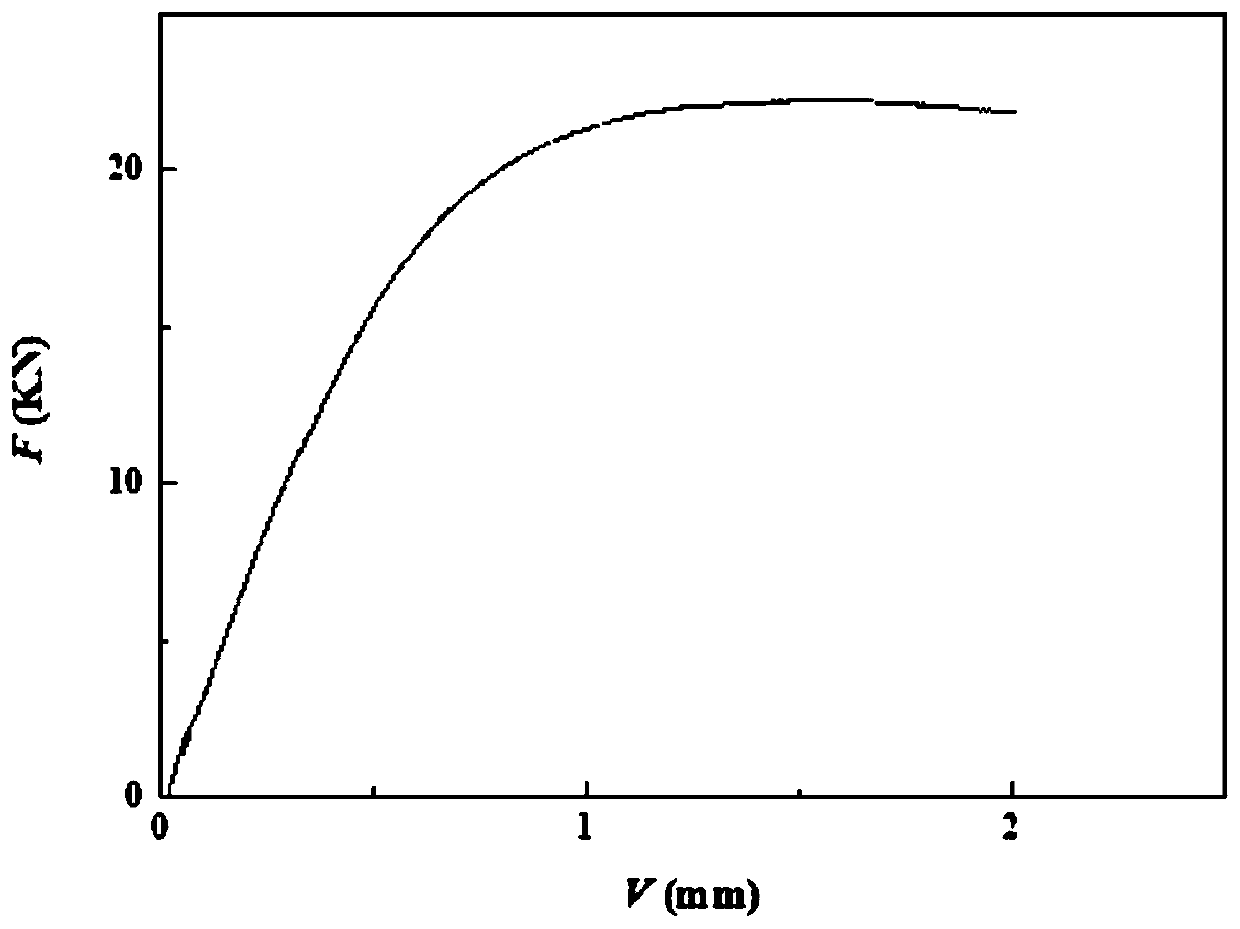

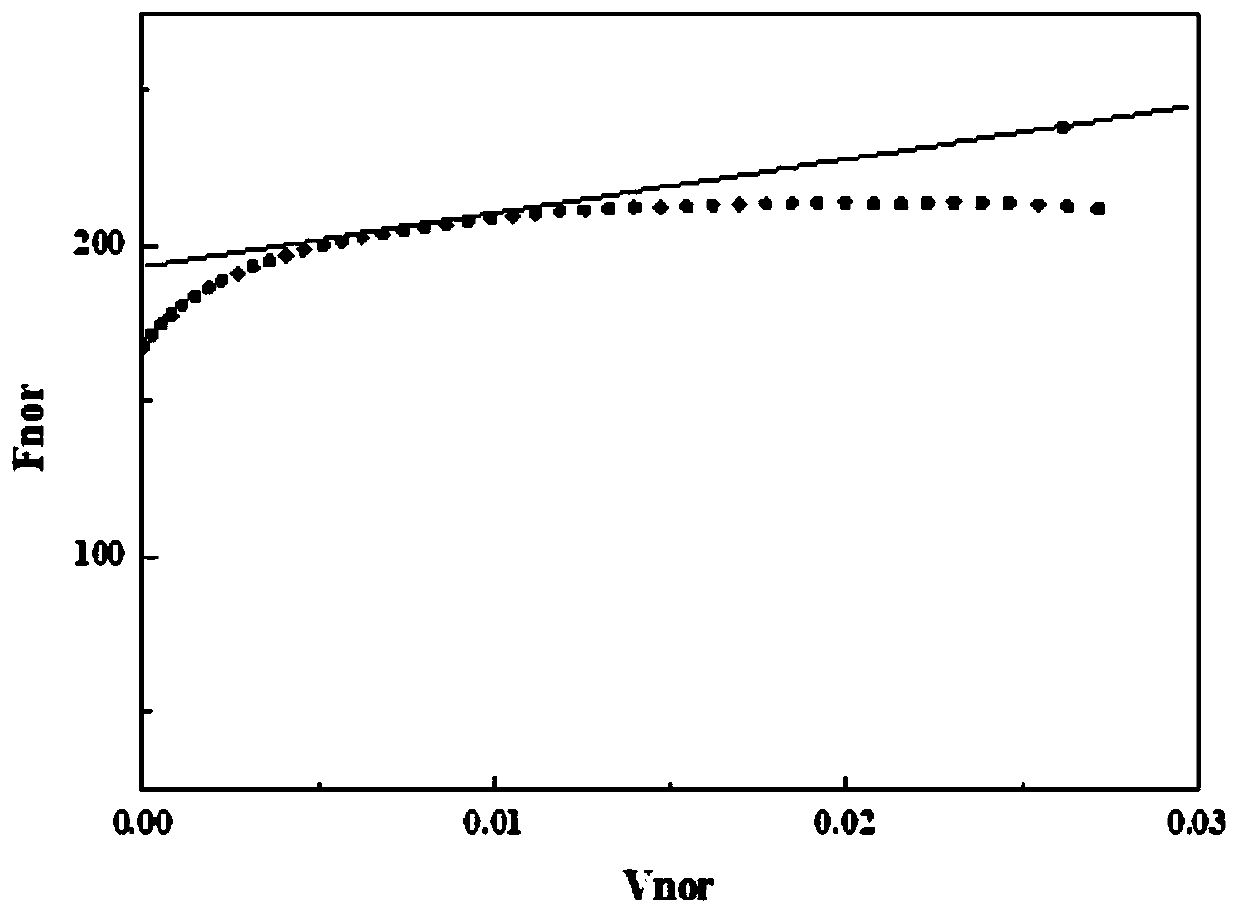

The invention discloses a method for measuring high-temperature fracture toughness JIC of high-toughness alloys, and relates to the technical field of fracture mechanics. The method comprises the steps of processing a compact tension specimen and forming a V-shaped slot in the tip position of a gap in the side surface of the specimen; carrying out fatigue crack prefabrication on the specimen; carrying out a tension test after heating and heat preservation so as to obtain a load displacement curve, snapping the specimen after cooling, and measuring the lengths of quasi-static cracks; regularizing the load displacement curve and carrying out parameter fitting to obtain a load displacement fitting curve; and iteratively calculating the lengths of the cracks, fitting the test data to obtain aresistance curve, and solving a JIC value. The method for measuring the high-temperature fracture toughness is disclosed on the basis of a load separation method, the high-temperature load displacement curve of the compact tension specimen is processed through a regularization method, and the length of the quasi-static crack corresponding to each point on the curve is iteratively calculated, so that a J integral value is effectively measured and then the high-temperature fracture toughness is calculated.

Owner:SHANGHAI JIAO TONG UNIV +1

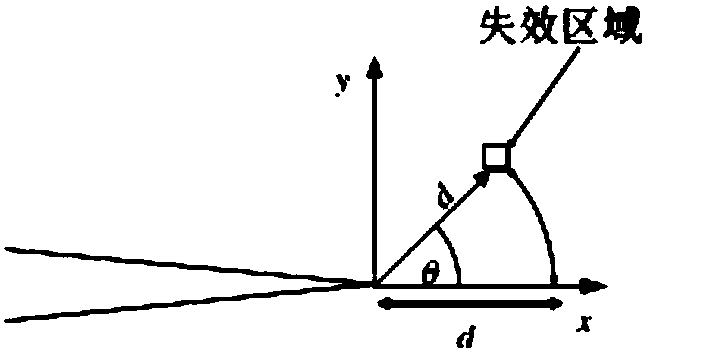

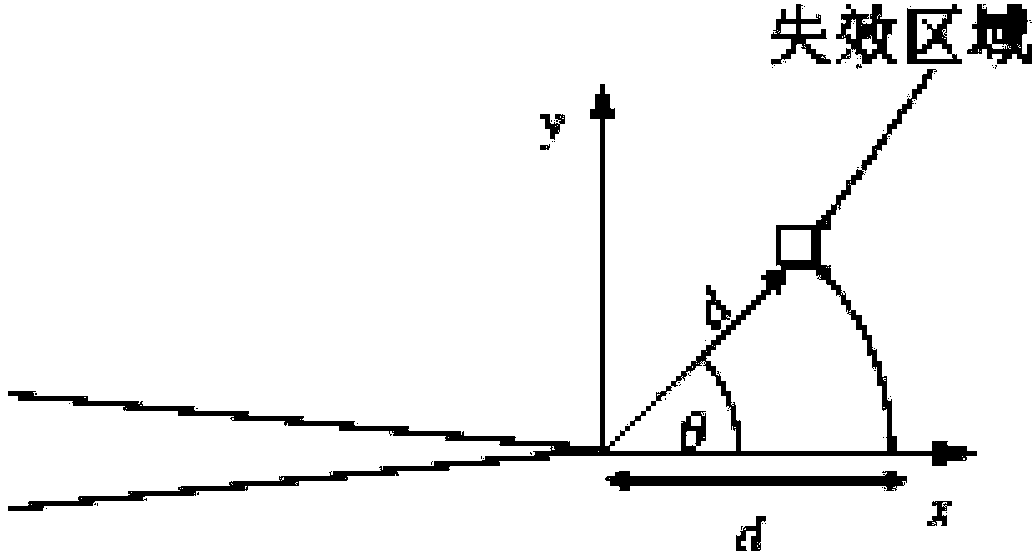

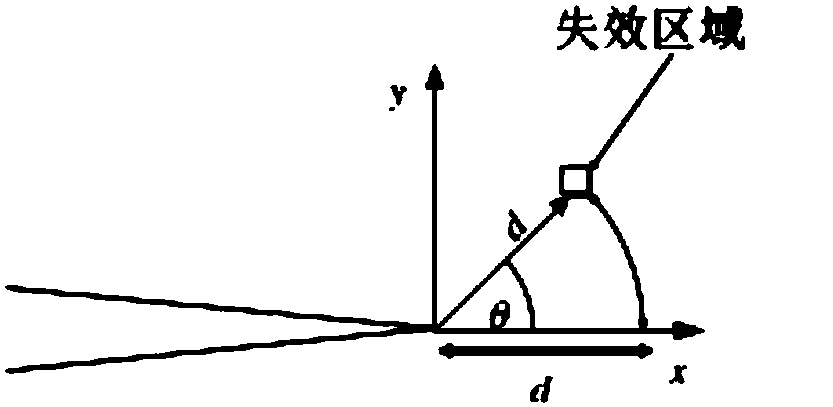

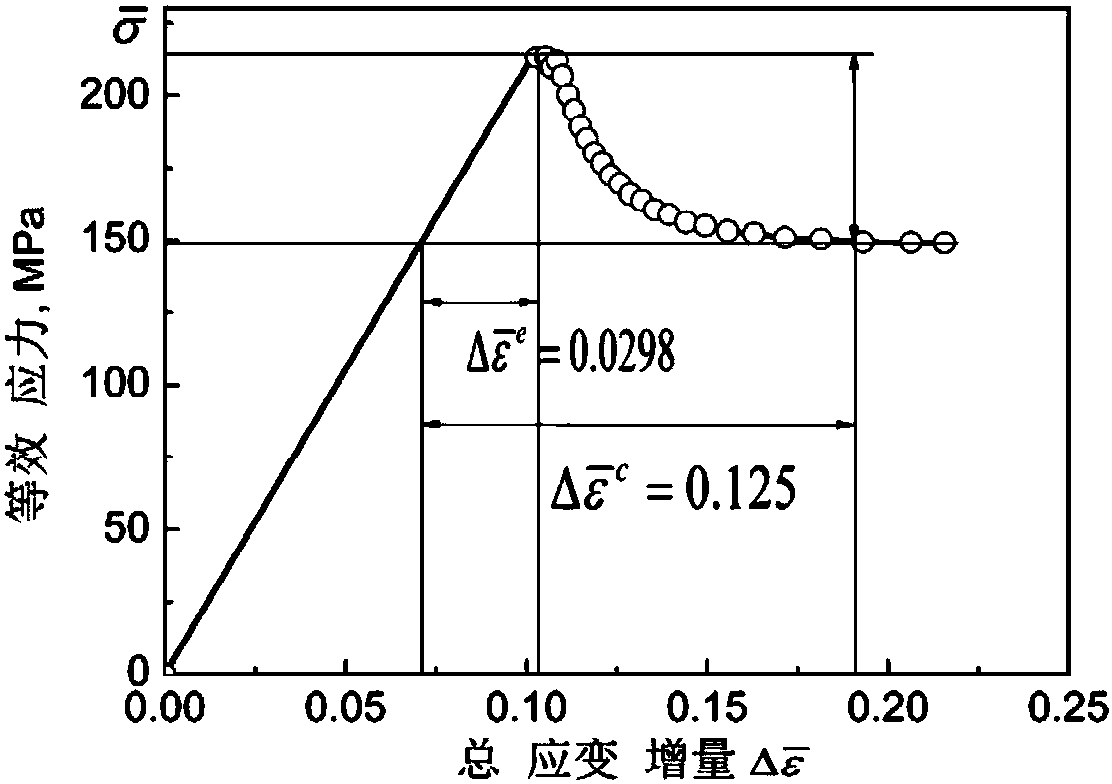

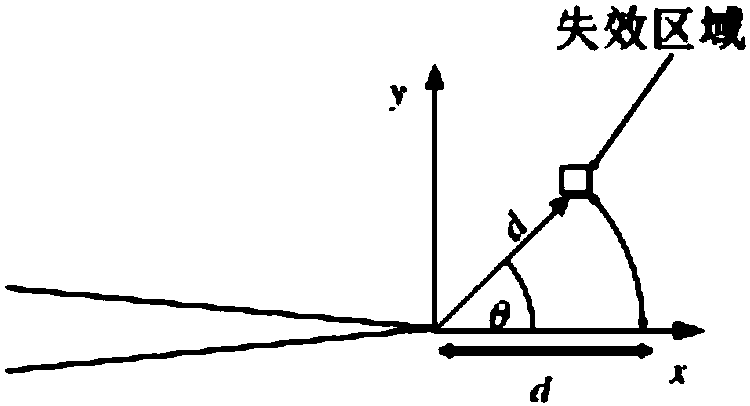

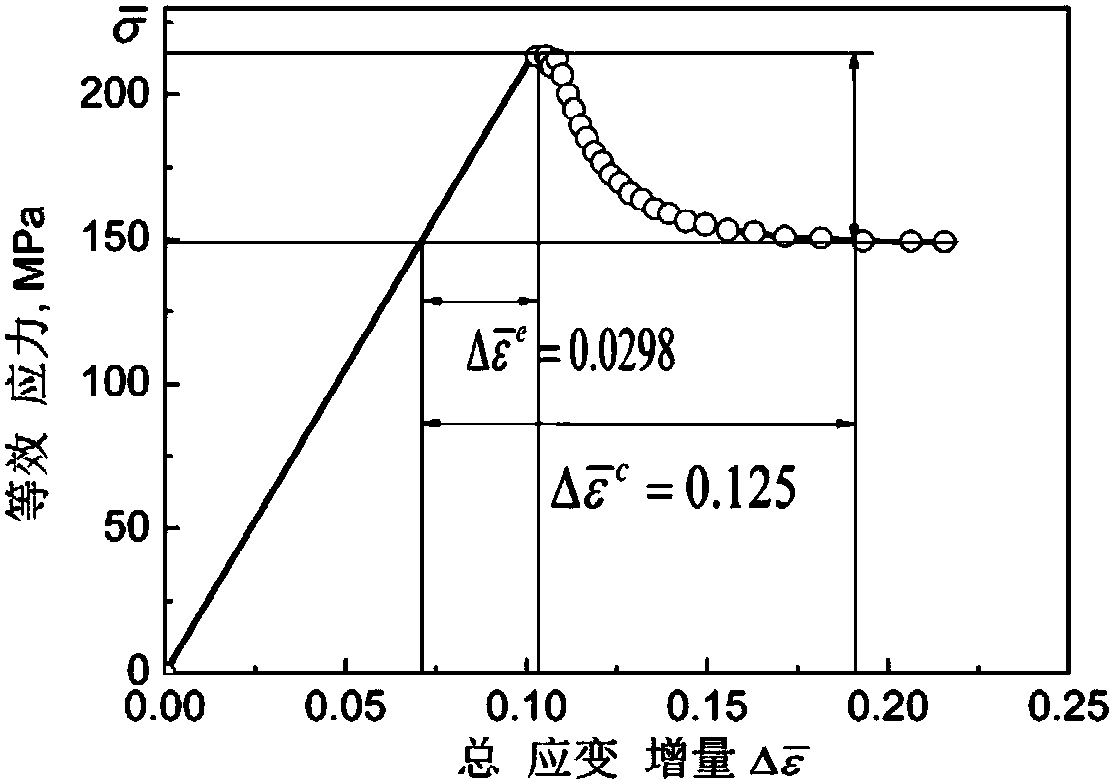

Prediction method for creep incubation period taking constraint effect into consideration under plasticity transient creep condition

ActiveCN108733860APrediction is concise and effectivePrediction of creep incubation period is concise and effectiveDesign optimisation/simulationInvestigating material ductilityPredictive methodsComputer science

The invention discloses a prediction method for a creep incubation period taking constraint effect into consideration under a plasticity transient creep condition. On the basis of Davies work, a prediction model for the creep incubation period taking the constraint effect into consideration under the plasticity transient creep condition is provided. Through unitization of a toughness dissipation damage model, a constraint parameter Q is imported for calculation of the creep incubation period taking the constraint effect into consideration. Main load is applied through utilization of a compacttension specimen (CT), thereby carrying out a creep simulation experiment. The method has the beneficial effects that the corrected prediction model for the creep incubation period under the plasticity transient creep condition is provided, so the simplified prediction method for the creep incubation period under the plasticity transient creep condition is provided, and the creep incubation period can be concisely and effectively predicted under the plasticity condition in a structure.

Owner:TIANJIN UNIV

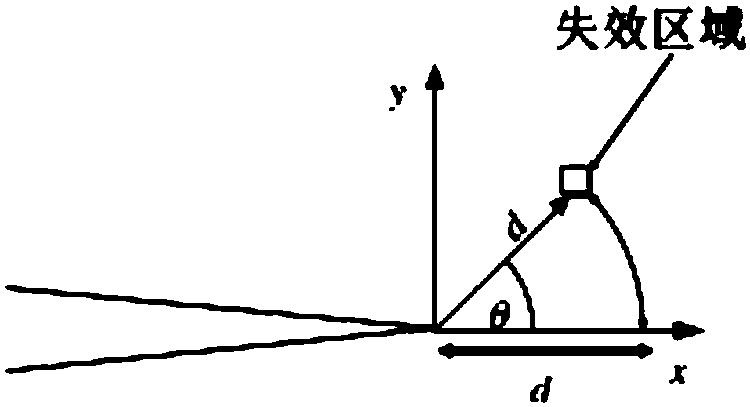

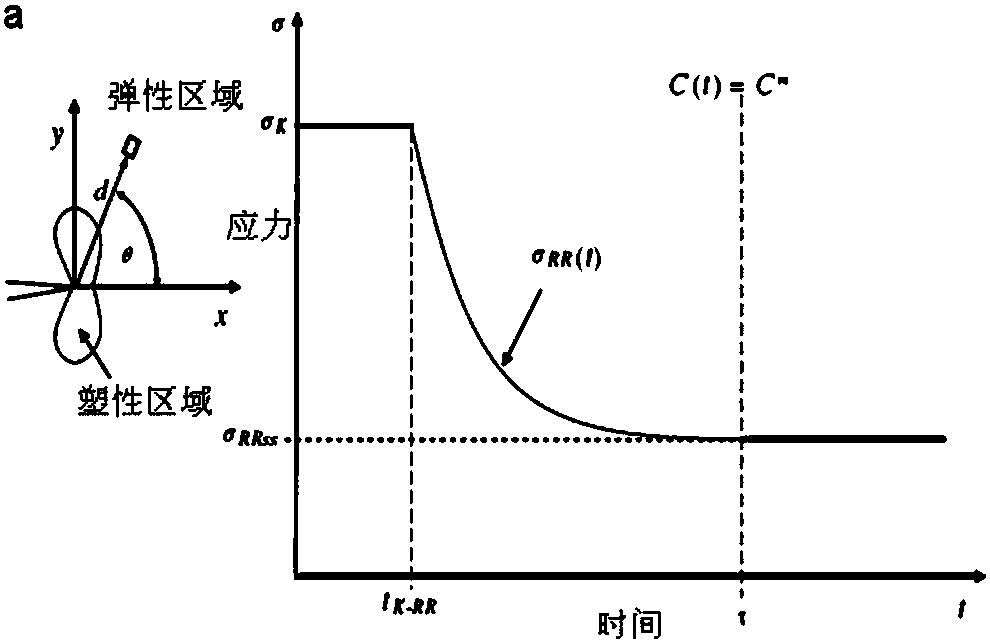

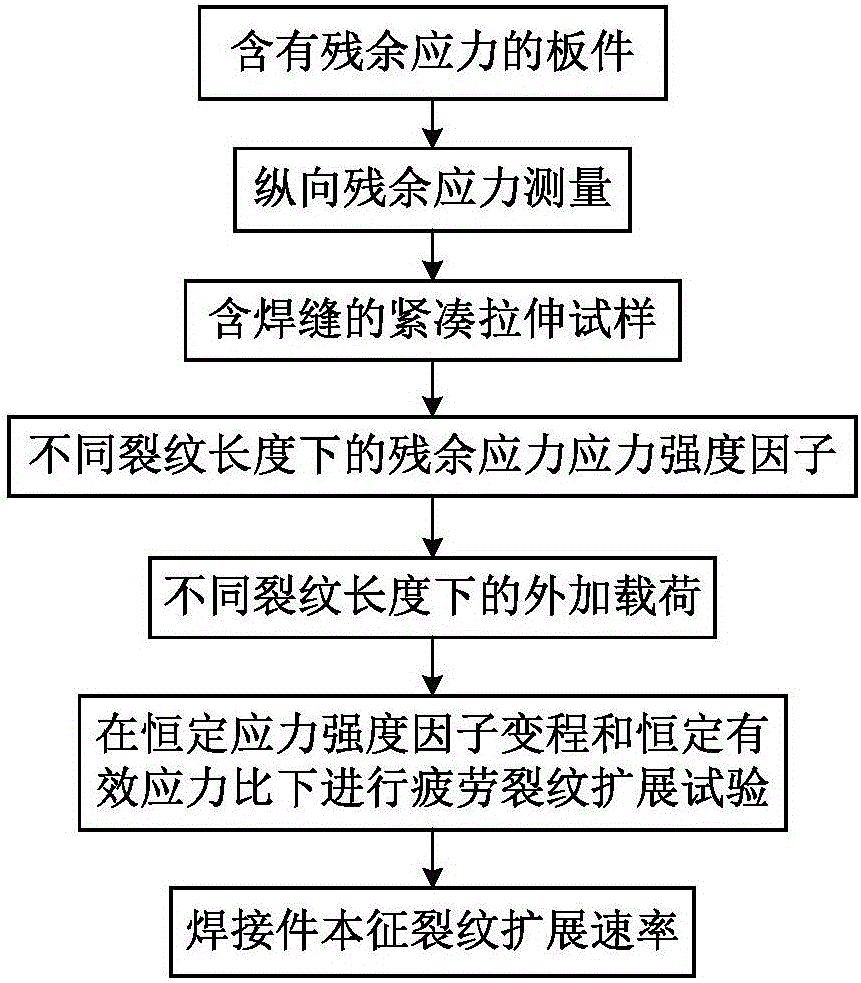

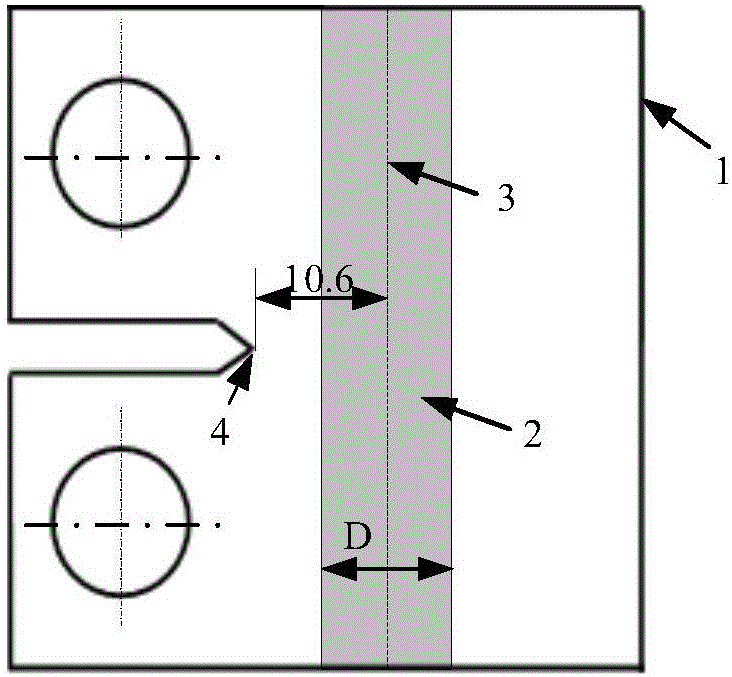

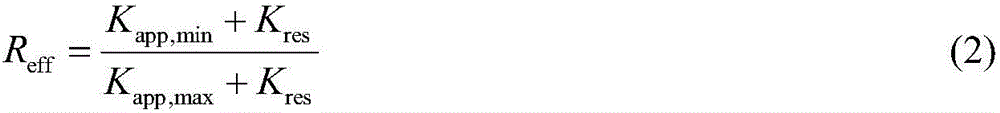

Method for measuring expansion rate of intrinsic fatigue crack of welded plate vertical to weld direction

InactiveCN106596261AImprove accuracyEliminate the effect of scaling rateMaterial strength using tensile/compressive forcesCrazingStress strength

The invention discloses a method for measuring the expansion rate of an intrinsic fatigue crack of a welded plate vertical to the weld direction, and belongs to the technical field of solid mechanics. The method comprises the following steps: at first, measuring residual stress horizontal to the weld direction; making a welded plate into a weld containing compact stretch sample, wherein the crack expansion direction is vertical to the weld direction; calculating the stress strength factor of residual stress corresponding to different crack lengths; through a residual stress superposition model, by combining a given constant stress factor range and a constant effective stress ratio, calculating the applied external loads under different crack lengths; carrying out fatigue crack expansion experiments under the calculated external loads, and determining the expansion rate of an intrinsic fatigue crack in a welded member under a given constant stress factor range and constant effective stress ratio. The provided method can directly obtain the expansion rate of an intrinsic fatigue crack in a welded member under a given stress state through fatigue experiments, is simple, and has a high accuracy.

Owner:BEIHANG UNIV

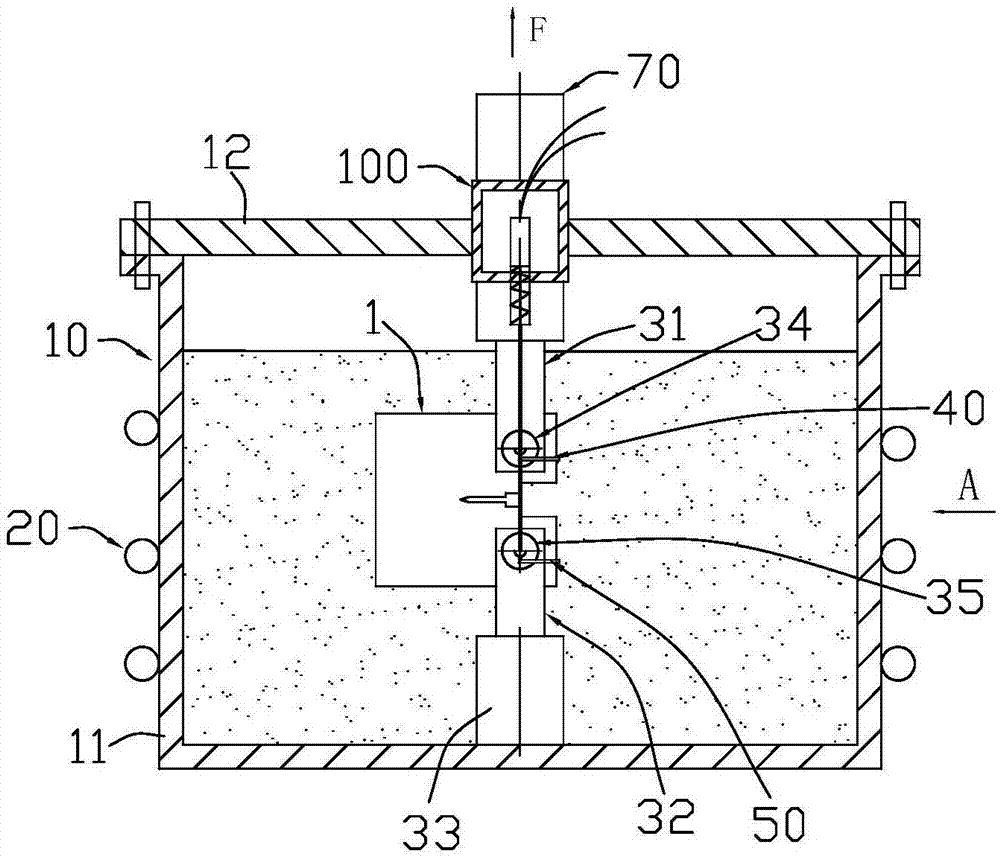

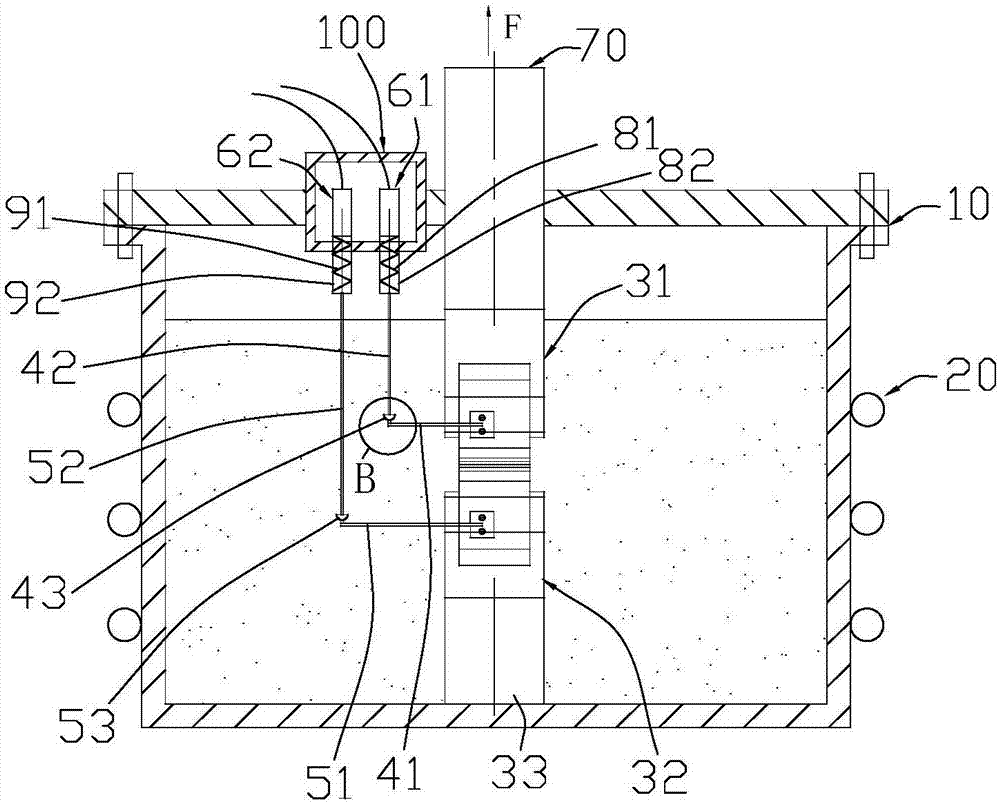

Crack opening displacement measuring device

PendingCN107449676AAvoid normal workAccurate measurementMaterial strength using tensile/compressive forcesNuclear energy generationLiquid mediumCrazing

The invention discloses a crack opening displacement measuring device which comprises a sealed container, a heating unit, a first fixing part, a second fixing part, a first connecting rod component, a second connecting rod component, a first displacement sensor and a second displacement sensor, wherein the sealed container is used for containing a high-temperature corrosion conductive medium; the first fixing part and the second fixing part are used for fixing test samples; the first fixing part and the second fixing part are oppositely arranged inside the sealed container; the first displacement sensor and the second displacement sensor are arranged on the sealed container; the first connecting rod component and the second connecting rod component are respectively connected between a test sample and the first displacement sensor and between the test sample and the second displacement sensor on a thickness cross section of the test sample. By adopting the crack opening displacement measuring device disclosed by the invention, precise measurement measures for testing elastic-plastic cracking toughness and fatigue crack spreading rates of a high-temperature corrosion conductive liquid medium cooling reactor material in complex special environments are provided.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

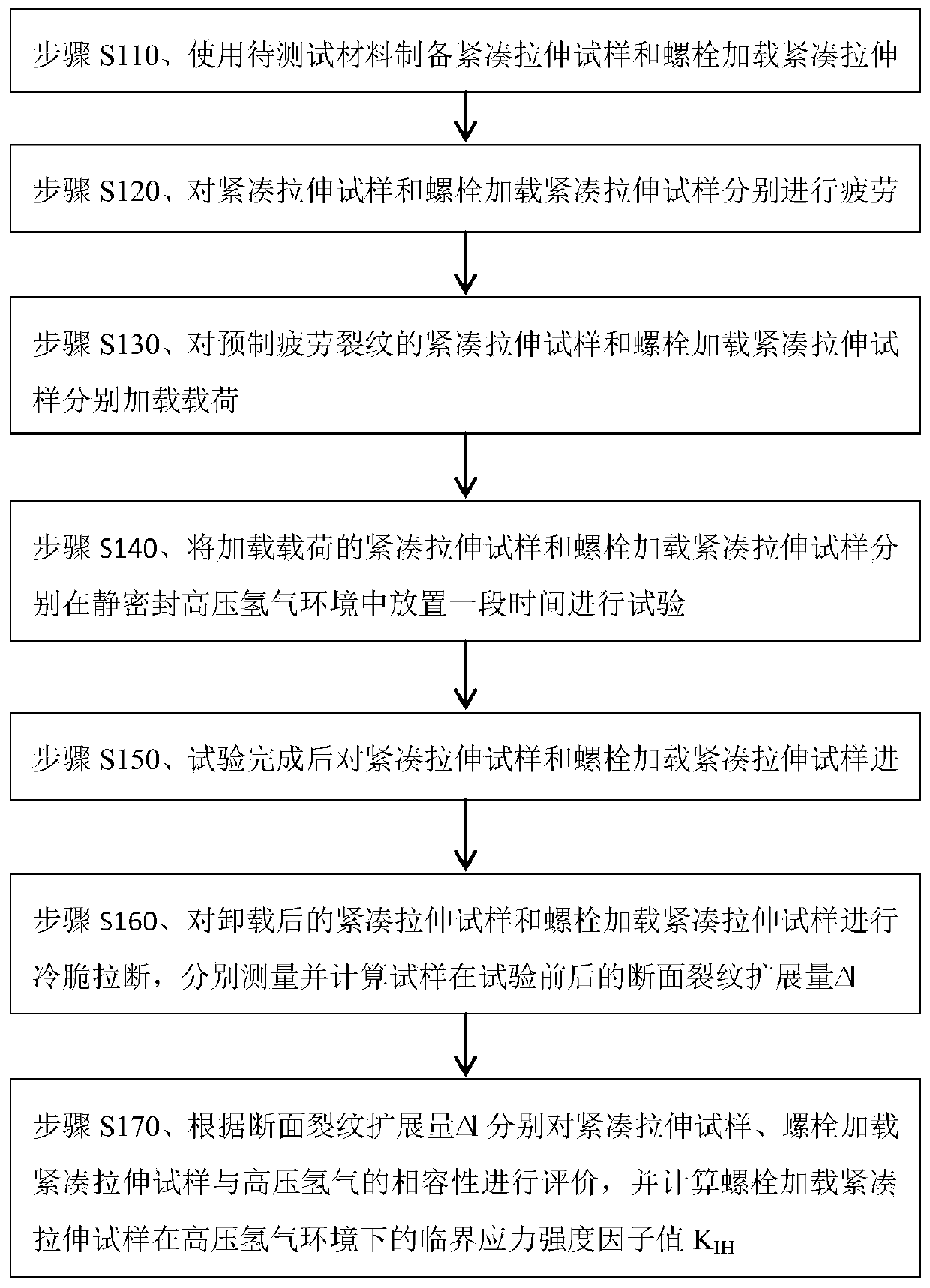

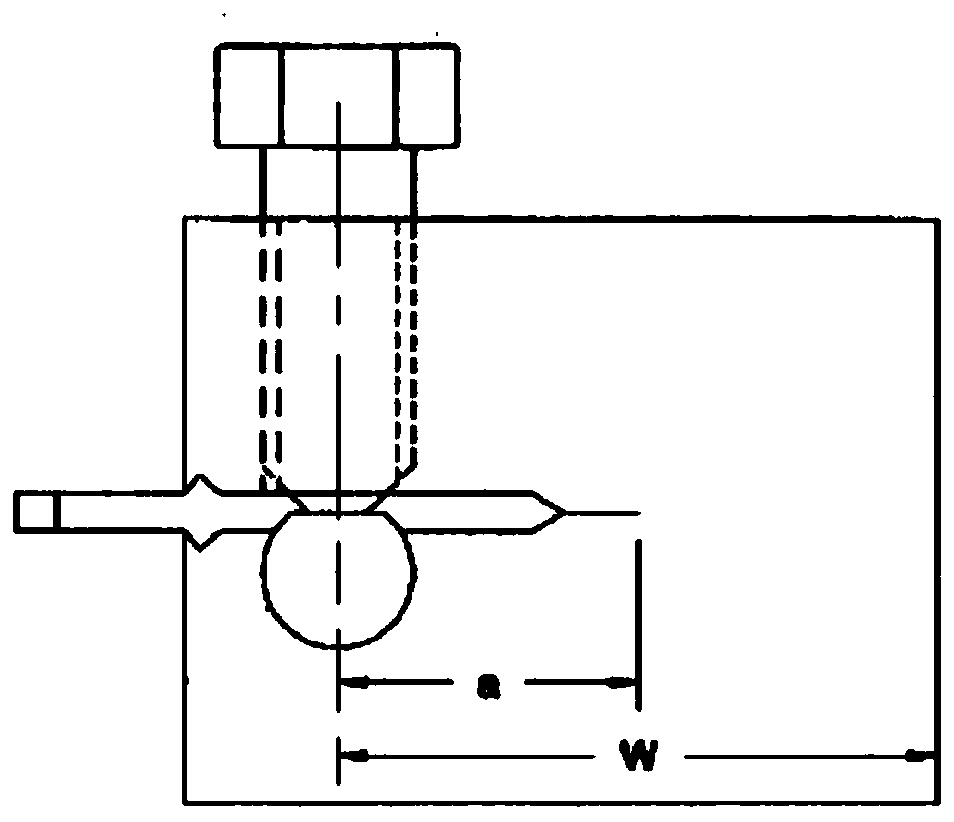

Compatibility evaluation method and system for material loaded based on constant displacement and high-pressure hydrogen

PendingCN110455627AReduce risk of leakageAvoid close contactMaterial strength using tensile/compressive forcesHigh pressure hydrogenEngineering

Embodiments of the invention disclose a compatibility evaluation method and system for a material loaded based on constant displacement and high-pressure hydrogen. Based on a fracture mechanics theory, a compatibility test method for the material in a static seal isolation environment and the high-pressure hydrogen is carried out by adopting a compact tension specimen (CT specimen) and a bolt loaded compact tension specimen (WOL specimen); through the test method, the crack hydrogen induced cracking sensitivity of the specimen material in the constant displacement loading state and a criticalstress intensity factor value KIH of the bolt loading compact tension specimen in a high-pressure hydrogen environment can be measured; material parameters obtained according to the method disclosed by the invention not only can be used for measuring the applicability of the material in the high-pressure hydrogen environment, but also can provide necessary design parameters for the design and manufacture of hydrogen environment service equipment; and a test process can be remotely monitored, so that the test personnel can be prevented from being in close contact with the hydrogen high-pressuretest device, and the test risk is reduced.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

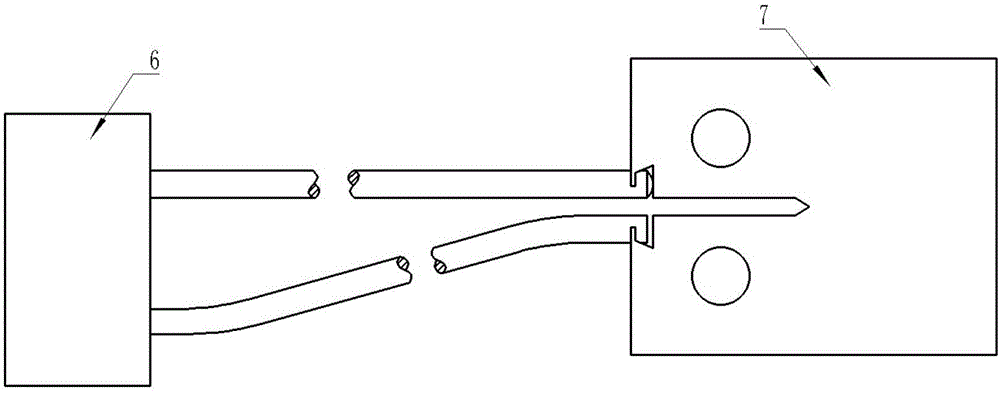

Anti-warping device

InactiveCN105651590ASimple structureEasy to installStrength propertiesStress distributionEngineering

The invention provides an anti-warping device of compact tension samples. The anti-warping device can be used for preventing warping deformation of samples in detecting of thin plate material K-R curve without changing stress distribution situations of the samples or influencing crack observation in tests. The anti-warping device comprises rectangular anti-warping plates 3, stepped gaskets 5, connecting bolts 6, horizontal backing plates 7, a vertical backing plate 8, and a device button rope 9; wherein the rectangular anti-warping plates 3 are two steel plates with identical shapes, the two horizontal backing plates 7 and the vertical backing plate 8 are steel plates with a thickness of 0.2 to 0.3mm thicker than that of the samples.

Owner:CHINA AIRPLANT STRENGTH RES INST

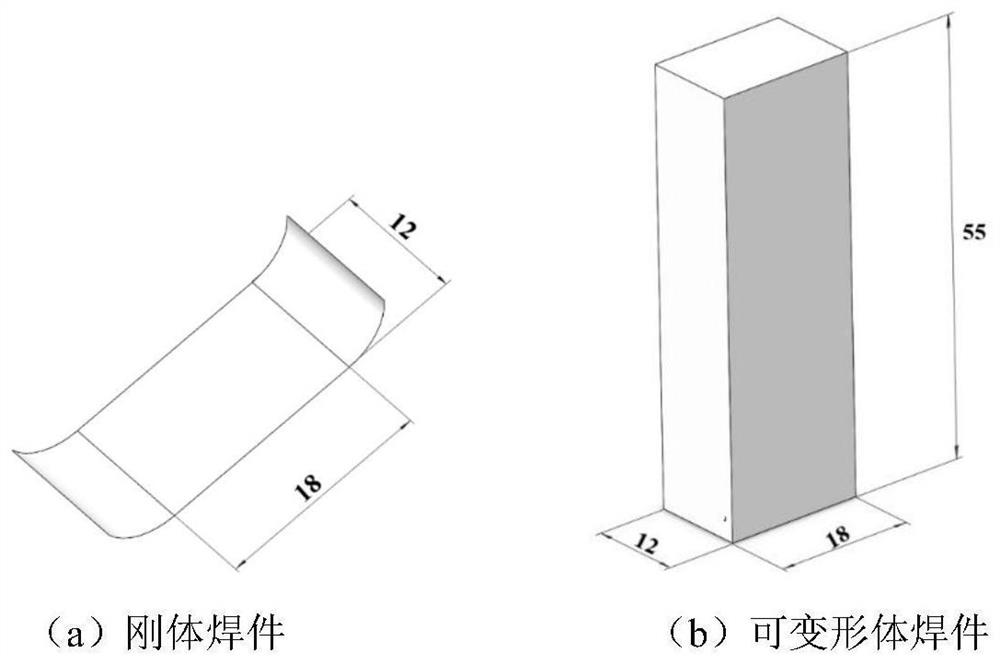

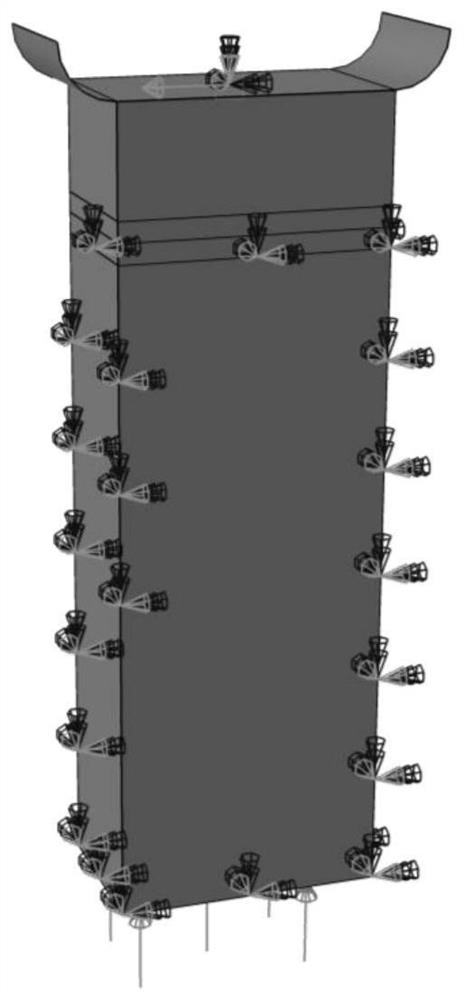

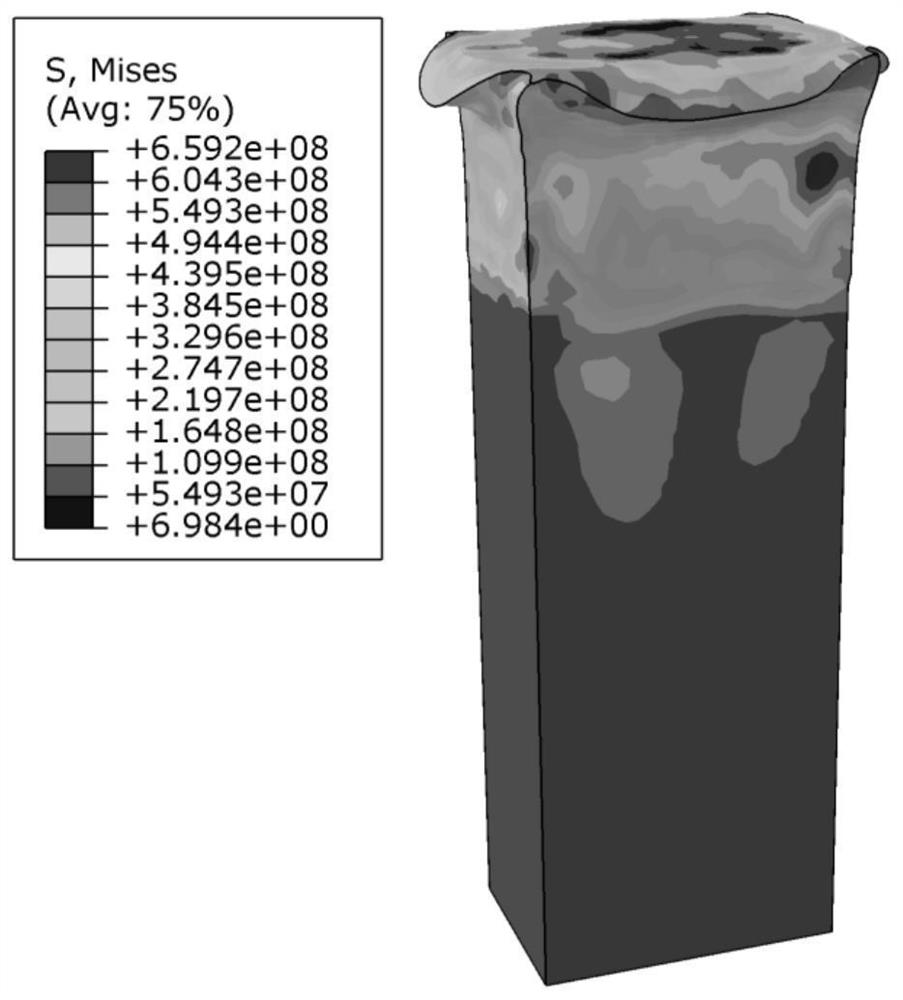

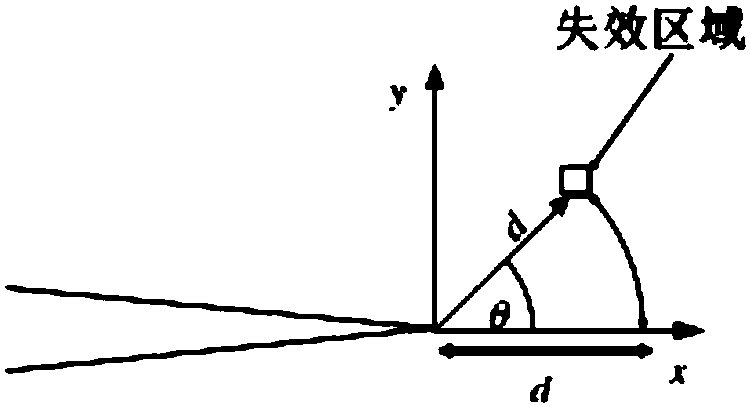

Fatigue crack propagation simulation method for CT (Computed Tomography) sample of three-dimensional linear friction welding head

ActiveCN112883507AImprove accuracyReduce preprocessing timeGeometric CADSustainable transportationFriction weldingComputed tomography

The invention discloses a fatigue crack propagation simulation method for CT (Computed Tomography) sample of a three-dimensional linear friction welding head, and belongs to the field of solid-phase welding and fracture mechanics. The method comprises the following steps of establishing a three-dimensional linear friction welding model; firstly, after a three-dimensional linear friction welding model is established in finite element simulation software ABAQUS, submitting operation simulation welding in a job module to acquire a linear friction welding head; then, selecting a micro-area compact tensile sample area, and drawing a stress nephogram sketch; finally, establishing a linear friction welding joint micro-area crack propagation compact tensile sample model, and respectively importing the iges files in the three directions obtained in the step 2 into sketch modules of the three compact tensile sample models; and acquiring crack propagation results in three directions so that the crack propagation trend of the three-dimensional linear friction welding head is estimated. According to the simulation method, a new thought is provided for research on the fracture behavior of the welded joint, and a large amount of pretreatment and calculation time can be shortened.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A method of fracture toughness testing using a fracture toughness testing device for compact tensile specimens in a low temperature environment

ActiveCN103954512BAccurate measurementAvoid damageInvestigating material ductilityLiquid mediumEngineering

The invention provides a device and a method for testing breaking tenacity of a compact tension specimen in a low-temperature environment. The device comprises an insulated container for containing low-temperature liquid medium, upper and lower clamps and a displacement transmitting mechanism, wherein a specimen is soaked in low-temperature liquid medium and comprises a crack mouth in a horizontal orientation; the upper and lower clamps are connected with the specimen, respectively arranged at two sides of the crack mouth, and respectively connected with upper and lower pistons of a tensile testing machine; the displacement transmitting mechanism comprises two vertical guide rails which are parallel and slide oppositely; upper and lower blades are respectively arranged at two ends of the each vertical lead rail; the upper blades of the two vertical guide rails are oppositely arranged to form an upper tool edge connected with an extensometer; the lower blades of the two vertical guide rails are arranged oppositely to form a lower tool edge connected with the crack mouth, so that a loaded line displacement of the specimen is transferred to the extensometer above the liquid level of the low-temperature liquid medium, so as to accurately measure the loaded line displacement. Meanwhile, the extensometer is prevented from directly contacting the low-temperature liquid medium to be easily damaged, and the device and the method are simple and reliable in structure, and convenient to install and operate.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

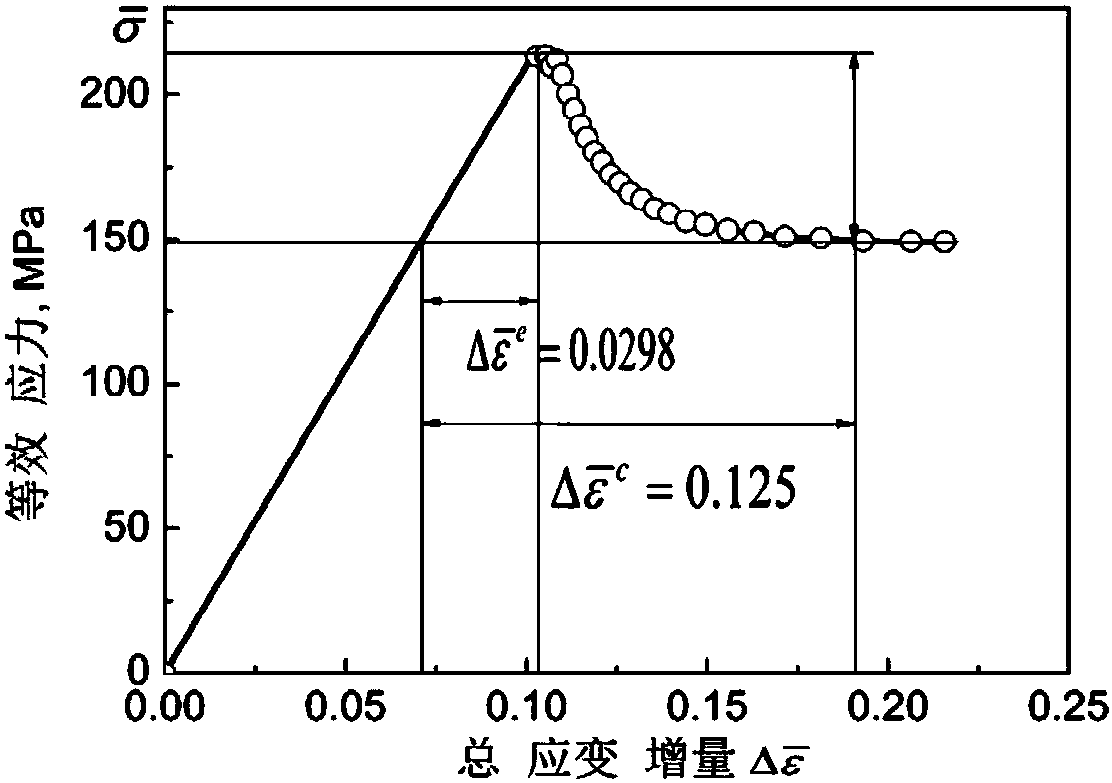

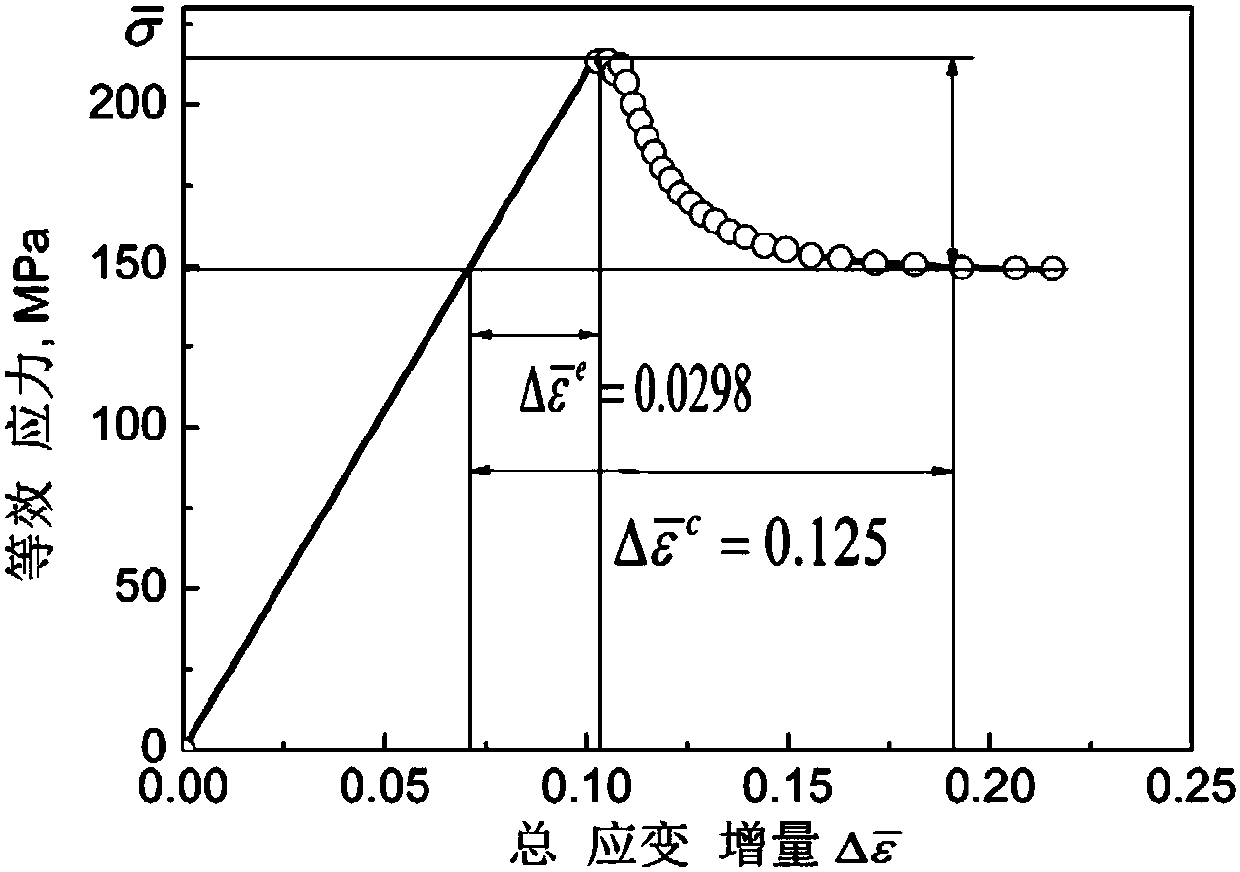

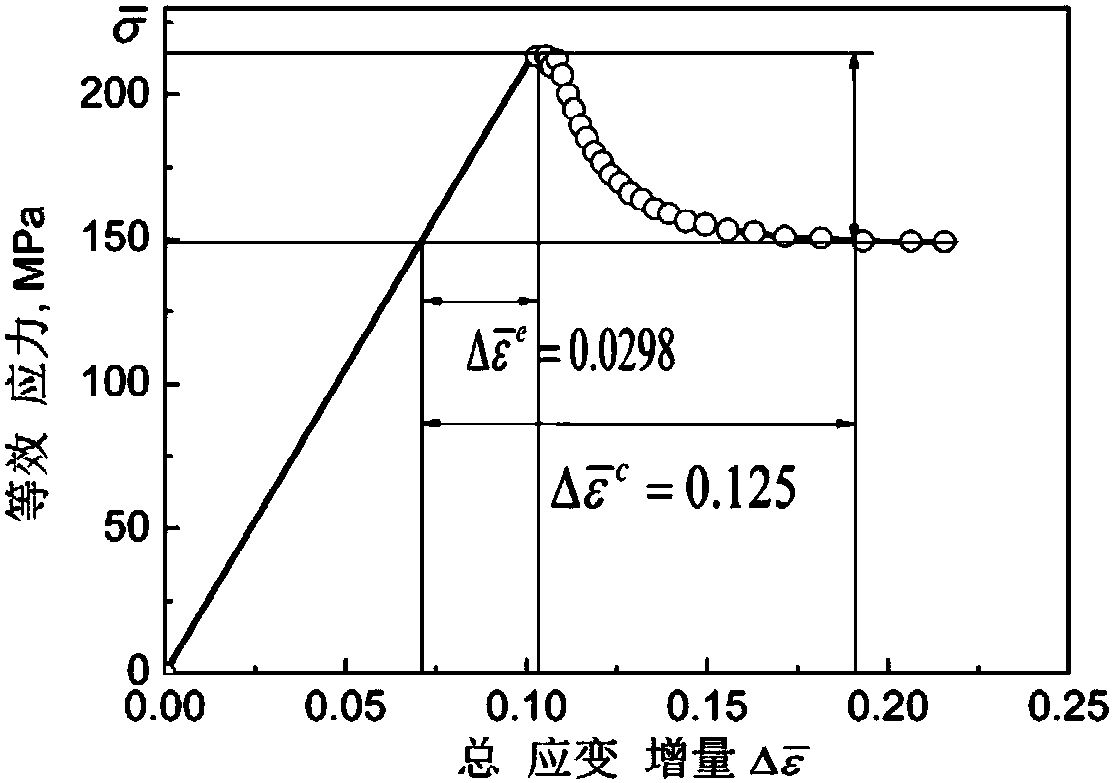

Method for predicting creeping incubation period containing residual stress under plastic transient creeping condition

ActiveCN108731989ACreep incubation period is simple and effectivePrediction of creep incubation period is concise and effectivePreparing sample for investigationMaterial strength using tensile/compressive forcesReference stress methodPredictive methods

The invention discloses a method for predicting a creeping incubation period containing residual stress under a plastic transient creeping condition. A prediction model for the creeping incubation period considering the residual stress is proposed; by utilizing a referential stress method, an elastic following factor Z is introduced so as to calculate the creeping incubation model considering theresidual stress; a compact tension specimen (CT) is pre-compressed to produce the residual stress, and main load is applied to carry out a creeping experiment. The method disclosed by the invention has the beneficial effects that a creeping incubation period prediction model under a modified elastic transient creeping condition is proposed, so that the simplified method for predicting the creepingincubation period under the transient creeping condition is provided; therefore, the creeping incubation period under the elastic transient creeping condition can be simply and effectively predictedin the structure.

Owner:TIANJIN UNIV

A creep incubation period prediction method coupling residual stress and a restraint effect under an elastic transient creep condition

ActiveCN109933816APrediction of creep incubation periodCreep incubation period is simple and effectiveSpecial data processing applicationsReference stress methodPredictive methods

The invention discloses a method for predicting a creep incubation period of a high-temperature structure by coupling residual stress and a restraint effect under an elastic transient creep condition,and provides a creep incubation period prediction model coupling the residual stress and the restraint effect on the basis of Davis work. A reference stress method is utilized, and an elastic following factor Z is introduced to calculate the creep incubation period considering the residual stress. A compact tensile specimen (CT) is used to generate residual stress through pre-compression, and a main load is applied to carry out a creep experiment. According to the method, the creep incubation period under the elastic transient creep condition can be simply and effectively predicted in the structure.

Owner:TIANJIN UNIV

Prediction method for creep inoculation period considering residual stress under plastic condition

ActiveCN108733861ACreep incubation period is simple and effectivePrediction of creep incubation period is concise and effectiveDesign optimisation/simulationInvestigating material ductilityReference stress methodPre compression

The invention discloses a prediction method for a creep inoculation period considering a residual stress under a plastic condition. On the basis of Davies work, the prediction model for the creep inoculation period considering the residual stress is provided. By means of a reference stress method, an elastic follow factor Z is introduced to calculate the creep inoculation period considering the residual stress. The residual stress is generated through pre-compression by using a compact tensile sample (CT), and a main load is applied to perform a creep test. The method has the beneficial effects that an original prediction model can be expanded into a model comprising the residual stress, and the simplified prediction method for the creep inoculation period under the plastic condition is provided, so that the creep inoculation period under the plastic condition can be concisely and effectively predicted in a structure.

Owner:TIANJIN UNIV

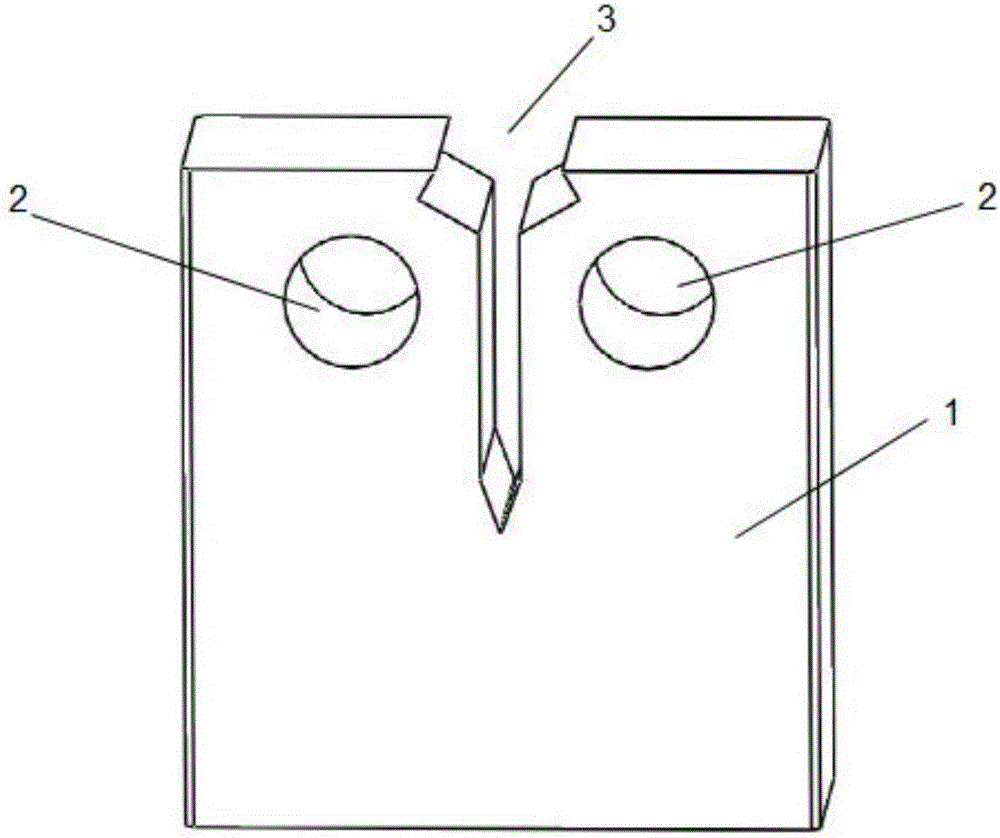

Fabrication method for compact tension specimen used for performance testing of material

InactiveCN105158033AImprove manufacturing precisionImprove surface qualityPreparing sample for investigationHardnessEngineering

The invention discloses a fabrication method for a compact tension specimen used for performance testing of a material. The method comprises the following steps: 1, coarse grinding of a deep groove: a, selecting a first grinding wheel with a hardness in a range of grade L to grade N, grinding the first grinding wheel in a left-and-right symmetrical grinding manner, wherein the actual thickness of the ground first grinding wheel is 0.02 to 0.12 mm smaller than designed width of the groove, and then coarsely grinding a straight groove part with the first grinding wheel; and b, carrying out secondary grinding on the first grinding wheel in the left-and-right symmetrical grinding manner and coarsely grinding a sharp-angled part with the first grinding wheel; and 2, fine grinding of the deep groove: c, selecting a second grinding wheel with a hardness in a range of grade L to grade N, grinding the second grinding wheel in the left-and-right symmetrical grinding manner, wherein the actual thickness of the ground second grinding wheel is 0.01 to 0.025 mm smaller than the upper limit value of the designed width of the groove, and then finely grinding the straight groove part with the second grinding wheel; and d, carrying out secondary grinding on the second grinding wheel in the symmetrical grinding manner and finely grinding the sharp-angled part with the second grinding wheel. The deep groove in the specimen fabricated by using the method has high precision and ideal surface quality.

Owner:四川航天谦源科技有限公司

Predicating method for creep incubation period containing residual stress under elastic transient creep condition

ActiveCN108732034ACreep incubation period is simple and effectivePrediction of creep incubation period is concise and effectivePreparing sample for investigationMaterial strength using tensile/compressive forcesReference stress methodIncubation period

The invention discloses a predicating method for a creep incubation period containing residual stress under an elastic transient creep condition. On the basis of Davies work, a predicating model for the creep incubation period taking residual stress into consideration is disclosed; a reference stress method is utilized, and an elastic following factor Z is introduced to calculate a creep incubation period taking residual stress into consideration. A compact tensile specimen (CT) is pre-compacted to generate residual stress, and main load is applied to perform a creep test. The predicating method for the creep incubation period has the beneficial effects that the original predicating model can be expanded into a model containing the residual stress, so that a simplified predicating method for the creep incubation period under the transient creep condition is disclosed, and the creep incubation period can be simply and effectively predicated under the elastic transient creep condition inthe structure.

Owner:TIANJIN UNIV

Prediction method for creep inoculation period considering constraint effect under steady-state creep condition

ActiveCN108733862ACreep incubation period is simple and effectivePrediction is concise and effectiveDesign optimisation/simulationSpecial data processing applicationsPredictive methodsAlgorithm

The invention discloses a prediction method for a creep inoculation period considering a constraint effect under a steady-state creep condition. A corrected prediction model for the creep inoculationperiod under the steady-state creep condition is provided; a ductility exhaustion damage model is utilized; a constraint parameter Q is introduced; and the creep inoculation period considering the constraint effect is calculated. A creep simulation experiment is carried out by applying a main load by using a compact tensile sample (CT), and the creep inoculation period under a plastic condition can be concisely and effectively predicted in a structure. The method has the beneficial effects that the simplified prediction method for the creep inoculation period under the steady-state creep condition is provided, so that the creep inoculation period under the plastic condition can be concisely and effectively predicted in the structure.

Owner:TIANJIN UNIV

Sample for measuring high temperature fracture toughness and preparation method thereof

InactiveCN106290000AEasy to install and clamp on the machineGuaranteed clamping accuracyPreparing sample for investigationMaterial strength using tensile/compressive forcesEngineeringMetal

The invention relates to a sample for measuring high temperature fracture toughness and a preparation method thereof. The sample comprises a sample body with a gap in the left end, the left end of the sample body is connected with an additional cutter point, a line cutting groove is formed in the additional cutter point, and the line cutting groove penetrates through the additional cutter point and is communicated with the gap. The upper side edge and the lower side edge of the line cutting groove are connected with locating baffles respectively, and a T-shaped structure is formed. The locating baffles are oppositely arranged, and cutter point locating grooves are formed in the middles of the locating baffles respectively. The compact tensile sample capable of being used for the metal material fracture toughness testing experiment under high-temperature conditions, the line cutting groove is formed, and therefore the sample and a high-temperature COD gauge can be clamped and matched conveniently. The cutter point locating grooves are formed, so that the situation that due to the fact that the high-temperature COD gauge slides and even slides out, the experiment is not precise or fails is avoided. Due to the fact that the additional cutter point and the sample are integrally machined, the assembly problem before the experiment is avoided, therefore, the sample can be clamped on a machine conveniently, meanwhile, the clamping precision of the sample is guaranteed, and finally the accuracy and effectiveness of the experiment of the sample are guaranteed.

Owner:AECC AVIATION POWER CO LTD

Predicating method for creep incubation period containing residual stress under elastic condition

ActiveCN108732029ACreep incubation period is simple and effectivePrediction of creep incubation period is concise and effectivePreparing sample for investigationMaterial strength using tensile/compressive forcesReference stress methodPredictive methods

The invention discloses a predicating method for a creep incubation period containing residual stress under an elastic condition. On the basis of Davies work, the predicting model for the creep incubation period taking residual stress into consideration is disclosed. A reference stress method is utilized, and an elastic following factor Z is introduced to calculate the creep incubation period taking residual stress into consideration. A compact tensile specimen (CT) is pre-compacted to generate residual stress, and main load is applied to perform a creep experiment. The predicating method forthe creep incubation period has the beneficial effects that the predicting model for the creep incubation period under the corrected elastic condition is disclosed, and compared with an existing model, the method can expand the original predicating model into the model containing residual stress.

Owner:TIANJIN UNIV

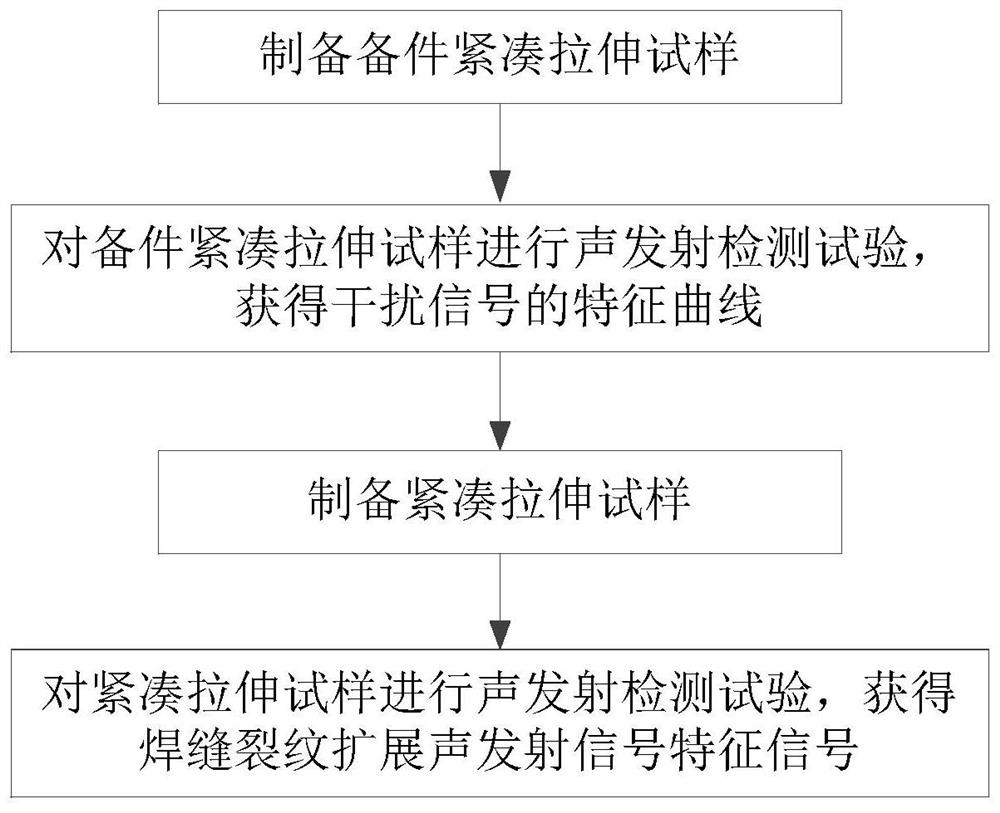

Crack propagation acoustic emission characteristic signal detection method for weld joint

PendingCN112461933AImprove Acoustic Emission Detection AccuracyMaterial analysis using wave/particle radiationMaterial analysis using acoustic emission techniquesAcoustic emissionEngineering

The invention relates to a crack propagation acoustic emission characteristic signal detection method for a weld joint. The detection method comprises the following steps of preparing a spare part compact tensile sample; carrying out a tensile experiment on the spare part compact tensile sample, and detecting vibration and friction acoustic emission characteristic signals of a tensile experiment machine in the tensile process to obtain an interference characteristic signal curve in a crack propagation acoustic emission test of the weld joint; preparing a compact tensile sample; setting a signal acquisition threshold value of acoustic emission detection software according to the interference signal characteristic curve of the spare part compact tensile sample; performing a tensile experiment on the compact tensile sample, and detecting an acoustic emission characteristic signal of precrack source expansion in the tensile process to obtain a characteristic curve of a weld crack expansionacoustic emission signal; after the tensile experiment, the compact tensile sample being subjected to fatigue breaking; and judging the fracture crack propagation characteristic morphology of the compact tensile sample. The method is advantaged in that acoustic emission detection accuracy of the pressure vessel can be improved.

Owner:国家能源集团泰州发电有限公司 +1

Method for measuring critical temperature of high temperature creep crack growth of material

ActiveCN103196939BShorten test timeReduce testing costsMaterial thermal analysisElectrical resistance and conductanceStress intensity factor

The invention discloses a method for measuring critical temperature of high temperature creep crack growth of a material. The method comprises the following steps of: processing not less than 6 standard compact tension specimens through a specific material according to creep crack growth test requirements, performing crack prefabrication on the processed not less than 6 test specimens on a fatigue performance tester, wherein the prefabricated crack length is 0.5 times as large as the width of the test specimen; wedging a wedge-shaped block in an initial slot of the test specimen, locating the most front end of the flat part of the wedge-shaped block at a loading line to provide displacement to the loading line, and forming a stress strain field characterized by stress strength factors at the crack tip of the test specimen to provide a driving force for creep crack growth; and putting the assembled test specimen in a resistance wire heating type high temperature furnace to perform heating test or cooling test until the crack growth speeds of all test specimens at a temperature are not larger than 1*10<-6>m / h, and the temperature is the critical temperature of high temperature creep crack growth of the material. The method disclosed by the invention can be used for testing a plurality of test specimens at one time, so that the test cost is greatly lowered.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com