Method for measuring expansion rate of intrinsic fatigue crack of welded plate vertical to weld direction

A fatigue crack propagation, plate technology, used in measuring devices, using stable tension/pressure testing materials strength, instruments, etc., can solve the problem of the accuracy of the method needs to be studied, the structure cannot be completely released, the method is complicated, etc. Simple implementation, simple measurement process, and high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

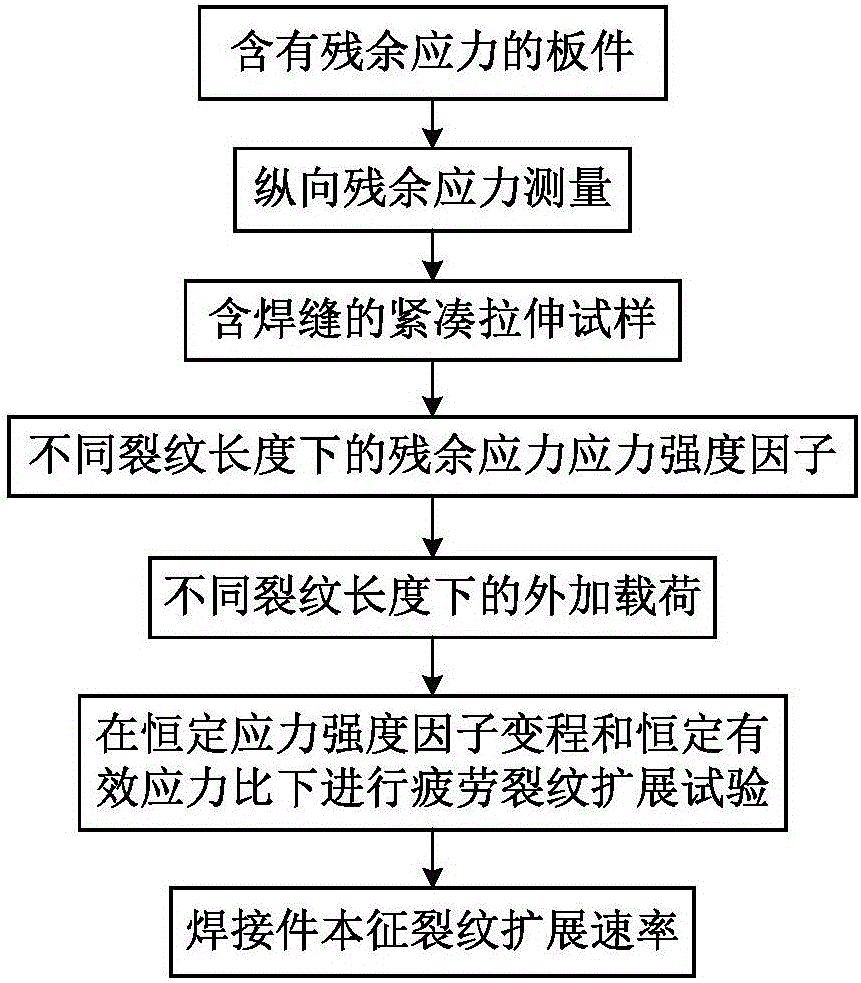

[0021] The invention provides a method for measuring the intrinsic fatigue crack growth rate of a welded plate perpendicular to the direction of the weld. The test equipment required by the test method includes an X-ray stress tester, a hydraulic servo fatigue testing machine, crack observation and length measurement Apparatus, test piece, method step process such as figure 1 As shown, the details are as follows:

[0022] The first step, residual stress measurement;

[0023] Use an X-ray stress tester to measure the residual stress distribution in the longitudinal direction (parallel to the weld direction) of the welded plate;

[0024] The second step is to process the test piece;

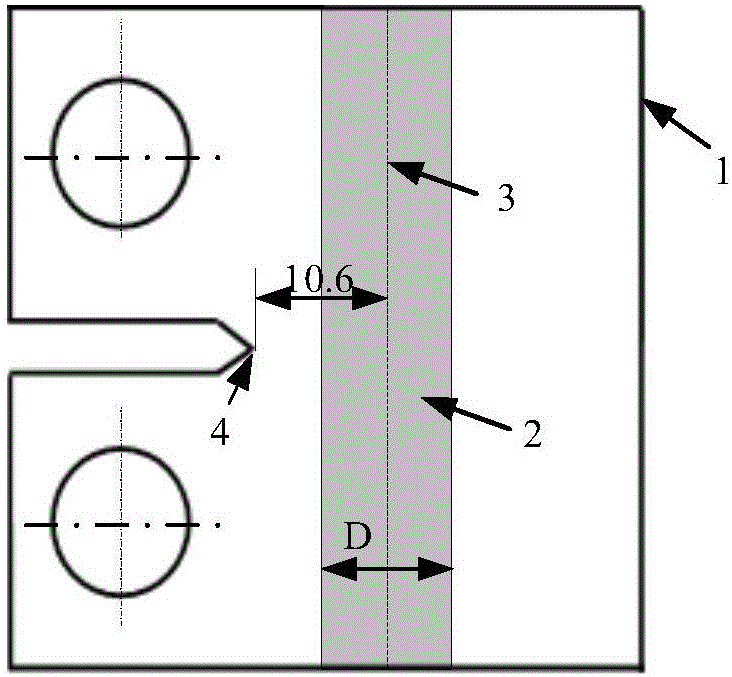

[0025] According to the requirements of the crack growth test, the welded plate is processed as figure 2 A compact tensile test piece 1 containing a weld 2, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com