Fatigue crack propagation simulation method for CT (Computed Tomography) sample of three-dimensional linear friction welding head

A technique for linear friction welding and fatigue crack propagation, used in geometric CAD, instrumentation, design optimization/simulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

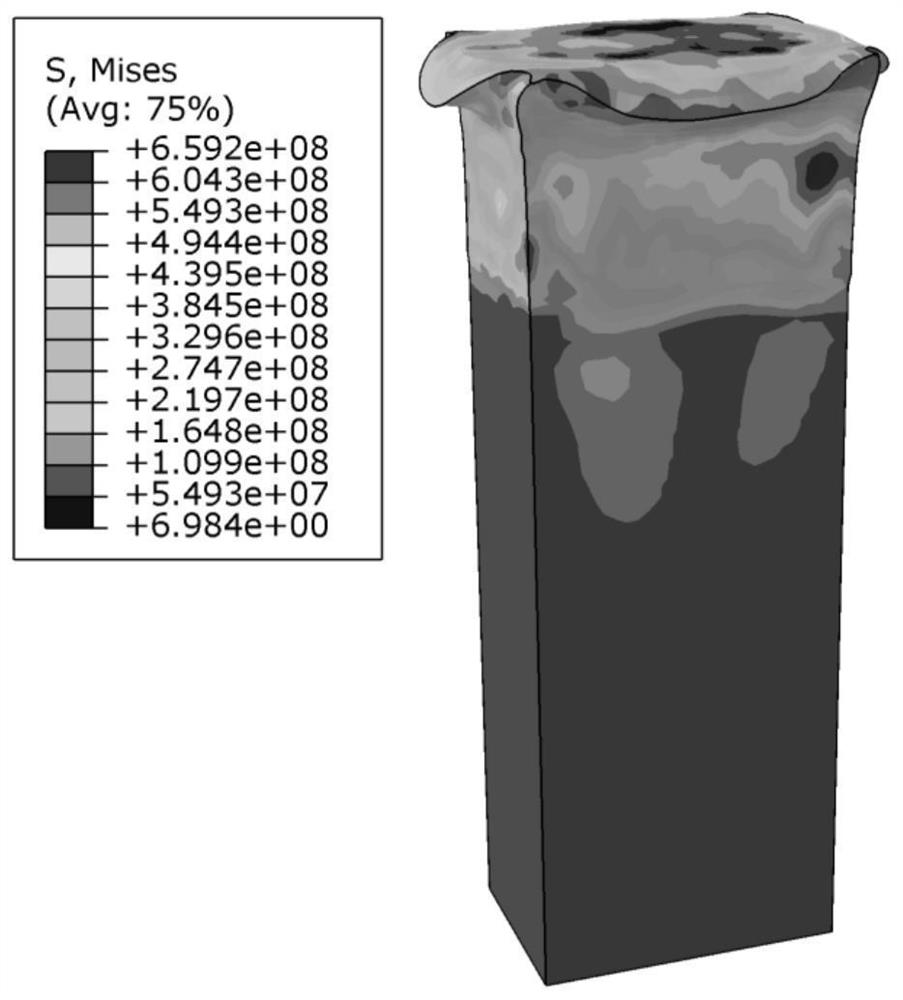

[0046] Analysis of crack fatigue growth of linear friction welded joints, the specific method of this implementation example includes the following steps:

[0047] (1) Carry out the simulation of linear friction welding of superalloy, specifically:

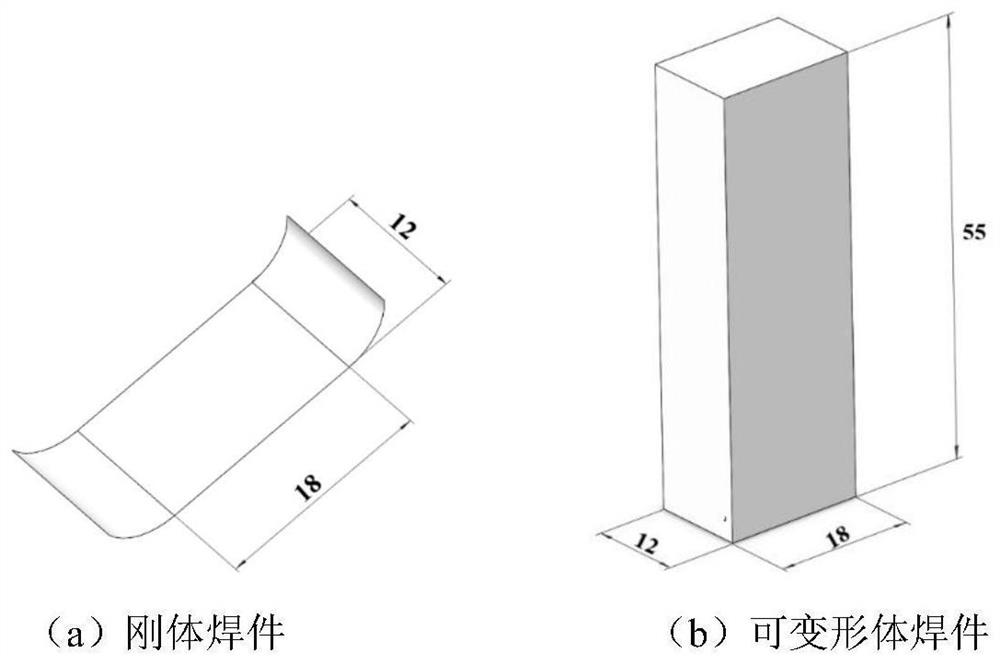

[0048] Create two models in the part module, one is a three-dimensional deformable body weldment with a size of 12mm×18mm×55mm; the other is a rigid body plane weldment with an effective size of 12mm×18mm (contact surface size), and the size is as attached figure 1 shown;

[0049] Set material property in property module: set the elastic property of material, thermal conductivity and specific heat parameter, set the constitutive model of material, the present invention selects Johnson-Cook constitutive model for use, wherein the static yield stress A=963MPa of material, material parameter B, n, m are respectively B=937MPa, n=0.33, m=1.3, material melting point T m =1260°C, room temperature T r = 20°C;

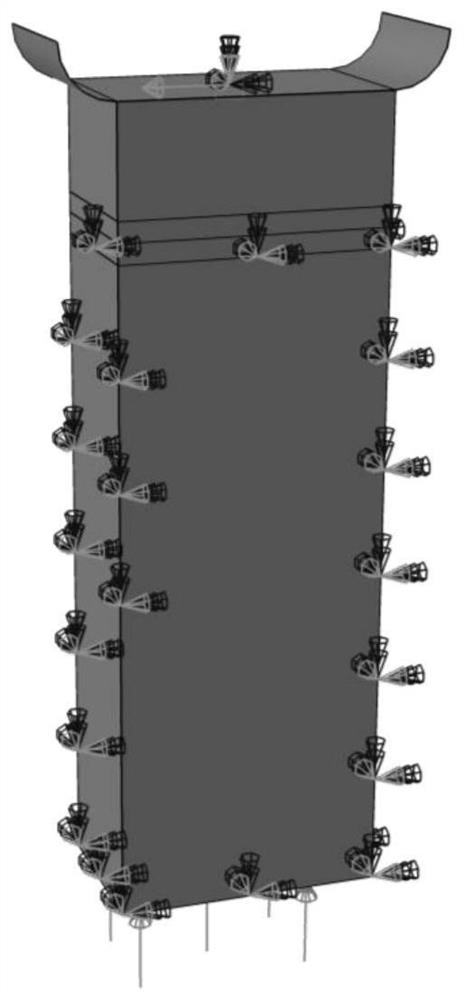

[0050] Assemble the def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com