Device and method for testing breaking tenacity of compact tension specimen in low-temperature environment

A technology for compact tensile specimens and fracture toughness, applied in the direction of testing the ductility of materials, etc., can solve the problems of difficult measurement and easy damage of the extensometer, and achieve the effect of simple and reliable structure, convenient installation and operation, and avoid easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

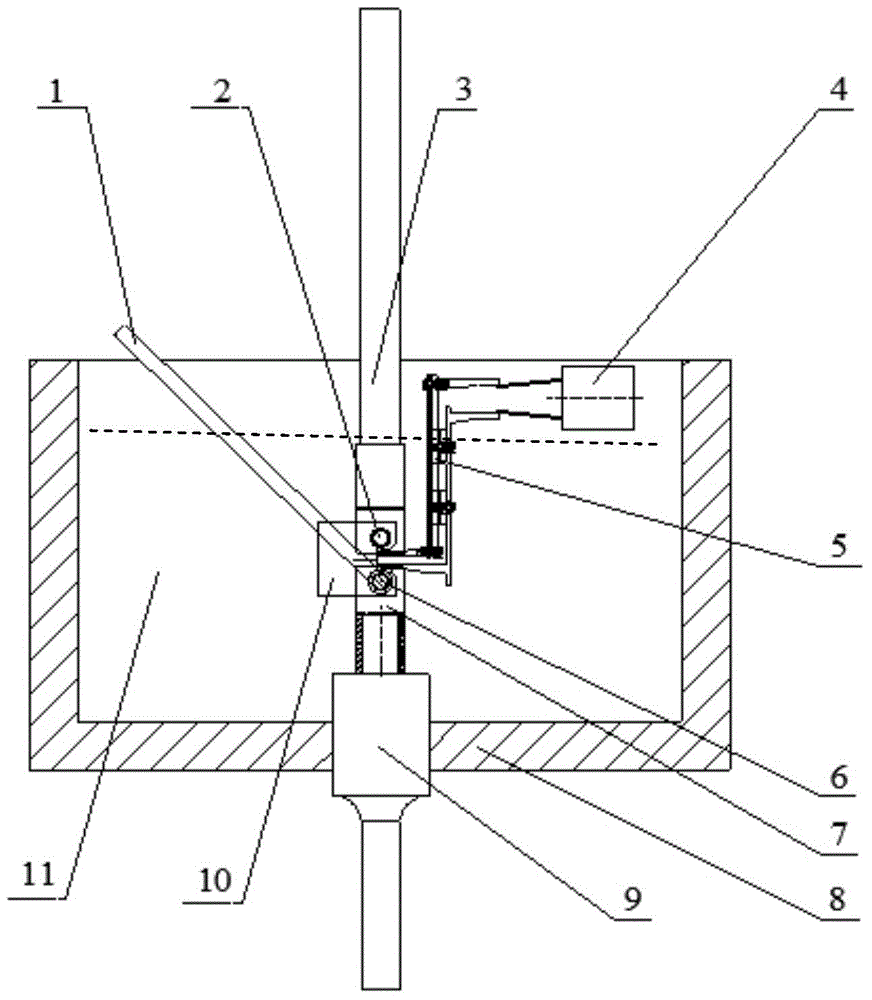

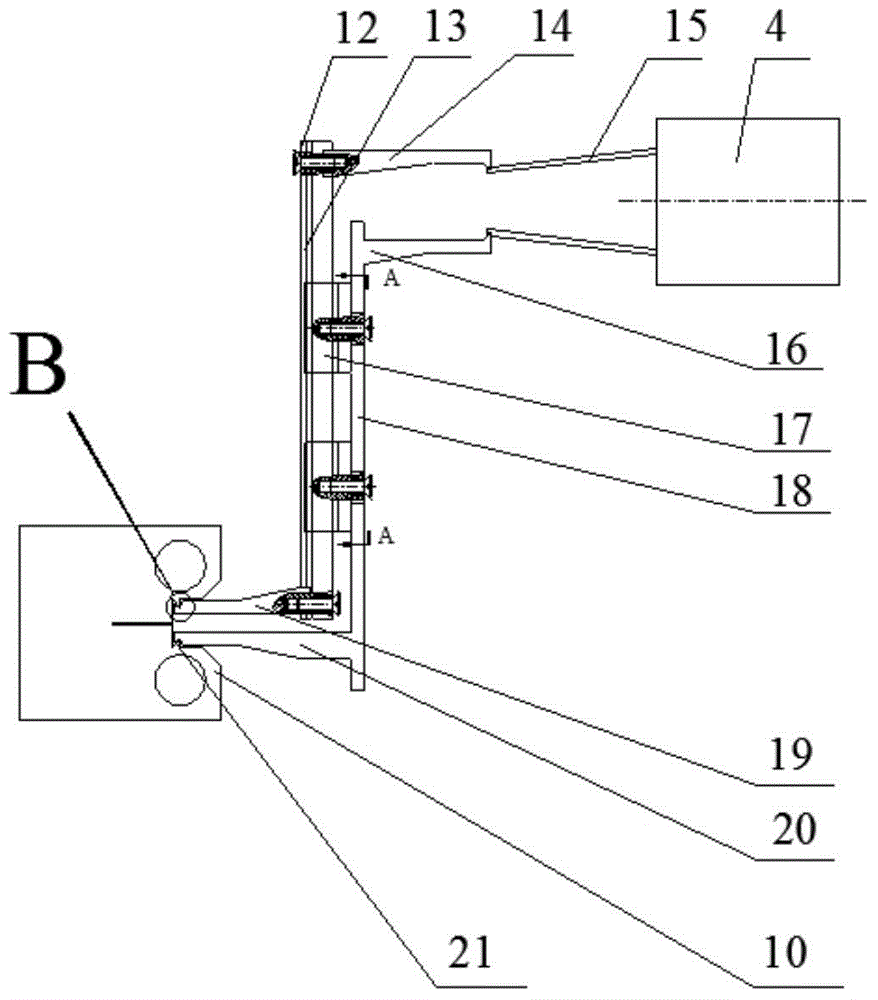

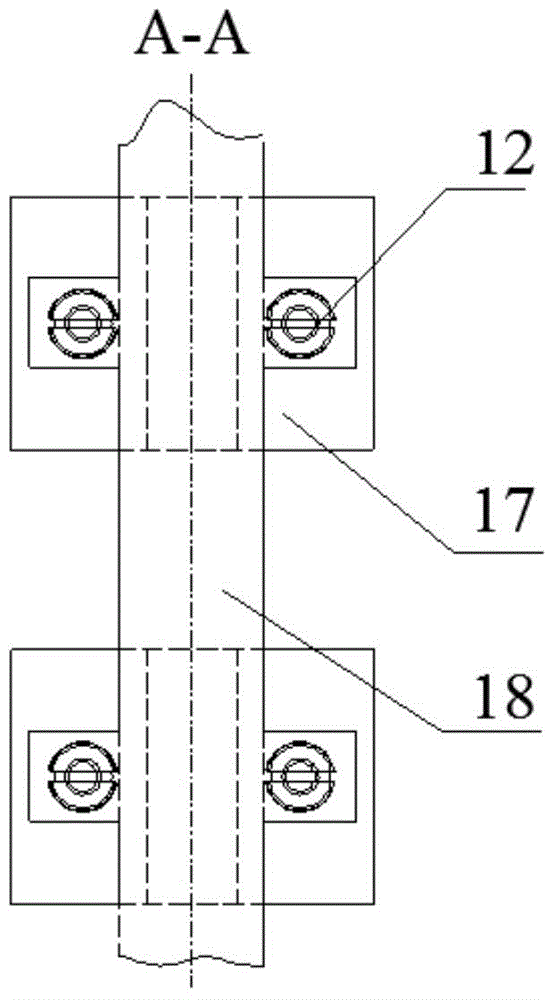

[0026] Such as figure 1 , figure 2 As shown, similar to the prior art, the fracture toughness testing device of the C(T) sample under the low temperature environment of the present invention comprises a thermal insulation container 8 containing a low temperature liquid medium 11, and the C(T) sample 10 is soaked in the low temperature liquid medium 11 and has a horizontally oriented crack mouth 21. The upper clamp 3 and the lower clamp 7 are respectively connected to the C(T) sample 10 through the upper pin 2 and the lower pin 6 and are respectively located on both sides of the crack mouth 21 . Preferably, the lower pin 6 is connected to the handle 1, so that the C(T) sample 10 can be disassembled without touching the low-temperature liquid medium 11 by hand during the test. In addition, the upper clamp 3, the lower clamp 7, the upper pin 2 and the lower pin 6 are all made of nickel-based alloys to ensure sufficient strength and high toughness to prevent brittle failure und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com