Patents

Literature

94 results about "Fracture Toughness Testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fracture toughness testing methods. Fracture toughness is a critical mechanical property for engineering applications. There are several types of test used to measure fracture toughness of materials, which generally utilise a notched specimen in one of various configurations.

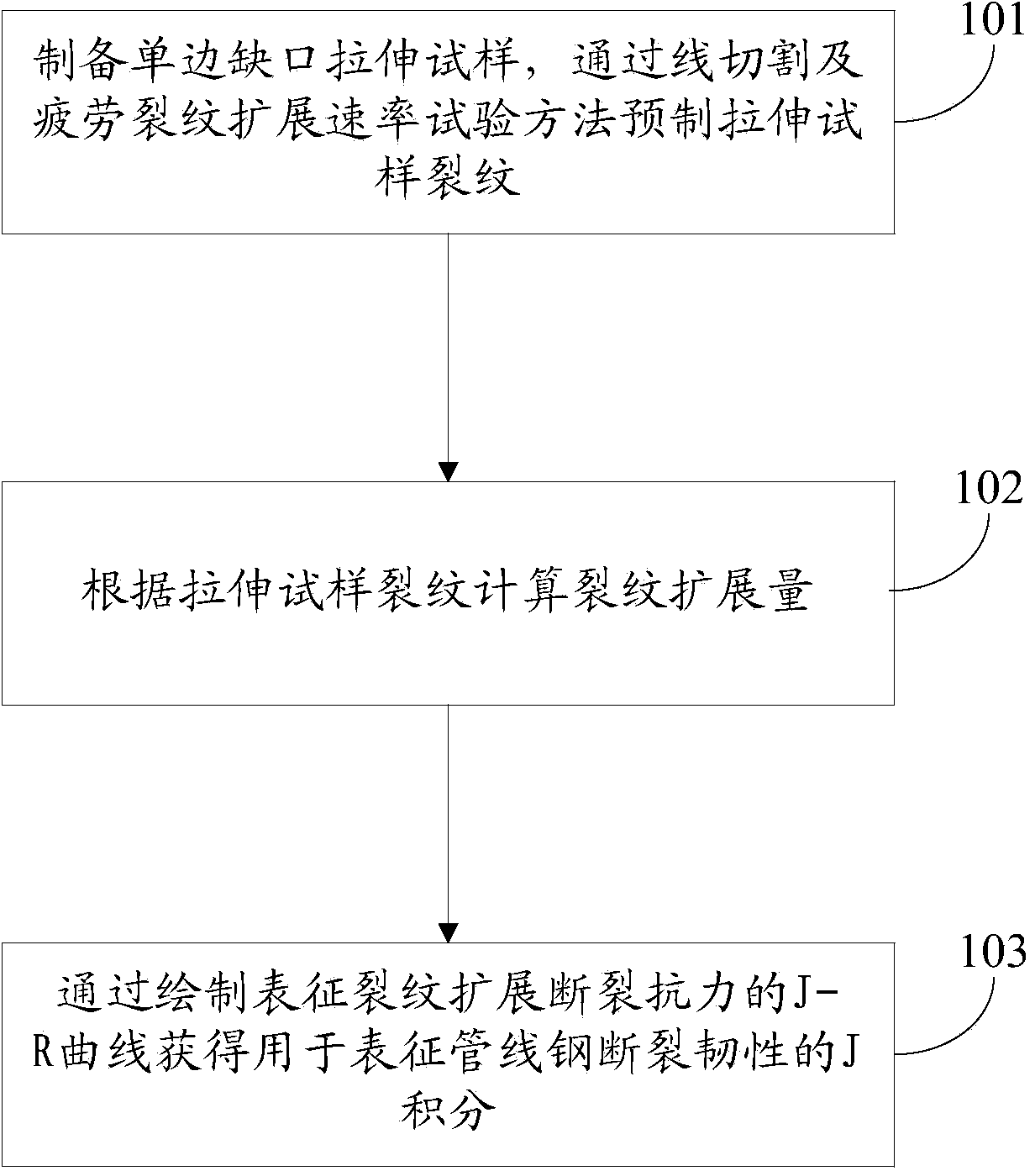

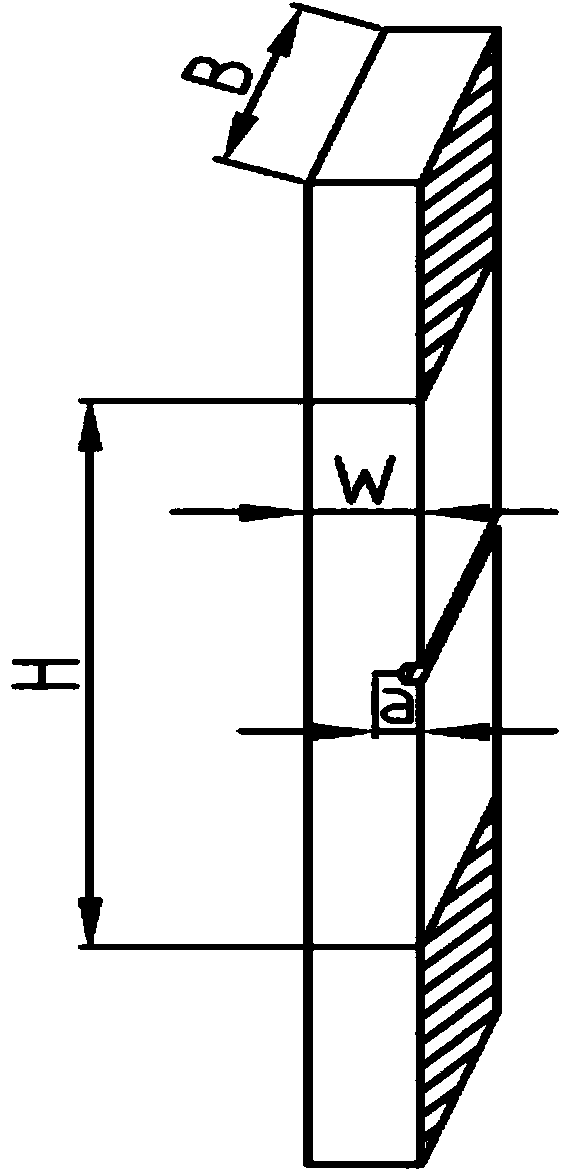

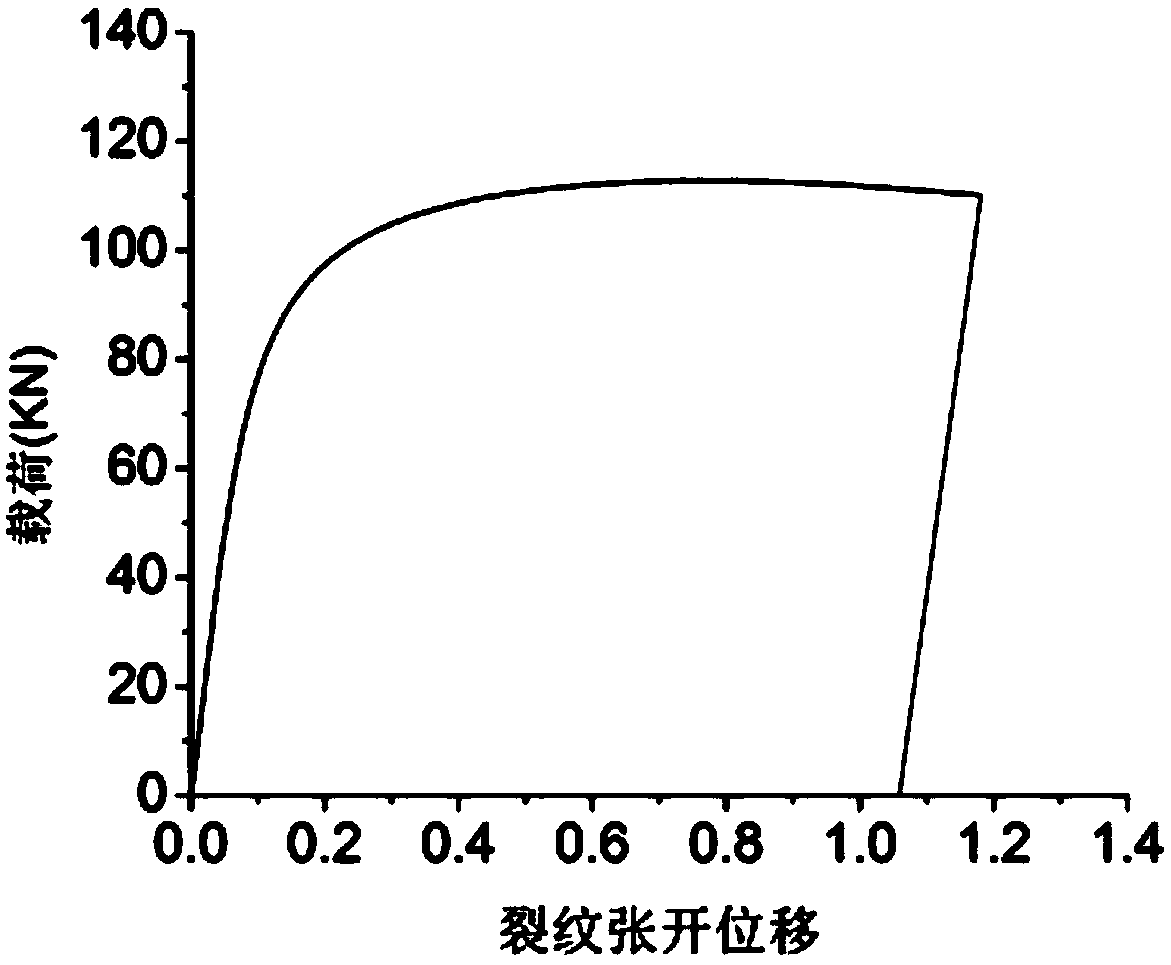

Method for measuring fracture toughness of pipeline steel by using unilateral notched tensile test

ActiveCN103604694AAvoid wastingReasonable fracture toughness valueMaterial strength using tensile/compressive forcesCrack resistanceStress intensity factor

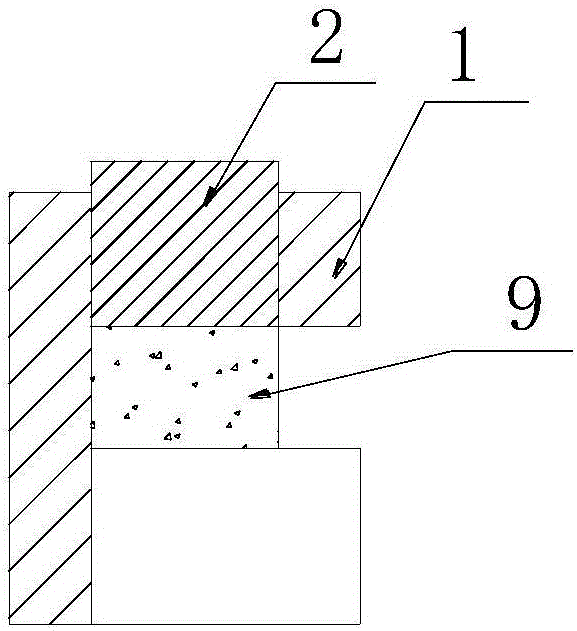

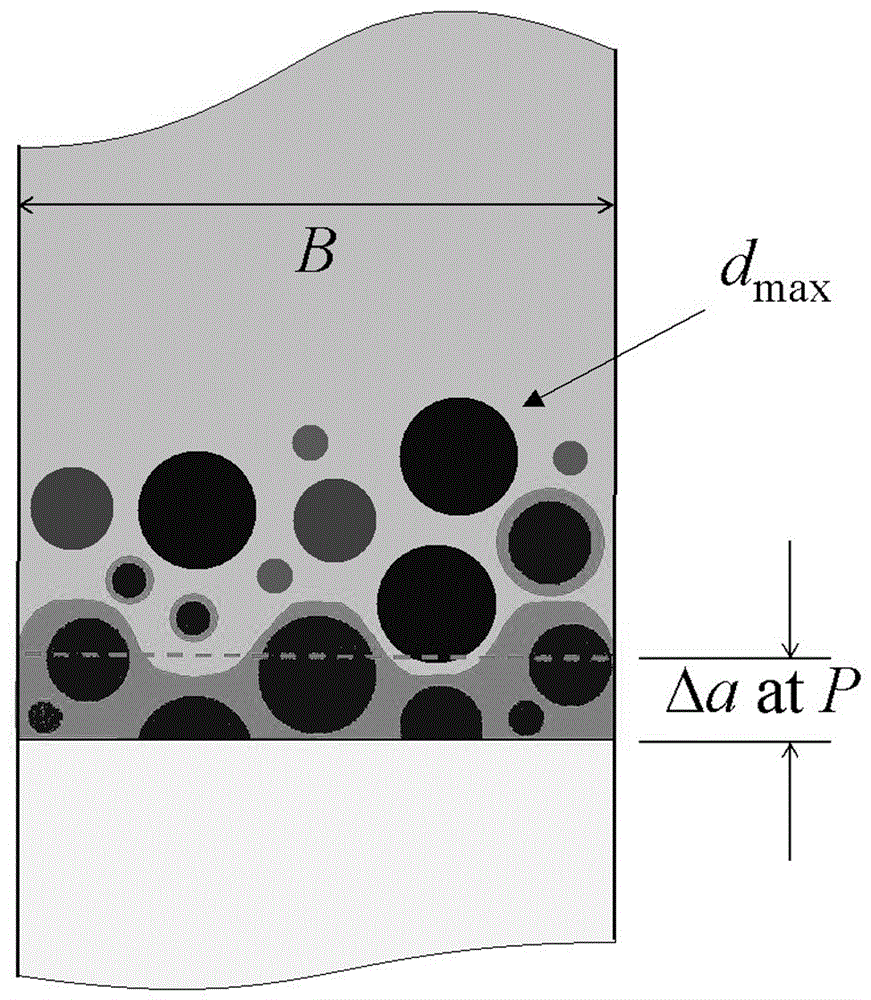

The invention discloses a method for measuring fracture toughness of pipeline steel by using a unilateral notched tensile test. The method is characterized by comprising the steps of preparing a unilateral notched tensile test sample; prefabricating a tensile sample crack by wire-electrode cutting and fatigue crack growth rate test method; calculating crack growth amount according to the tensile sample cracks; and acquiring J integration and stress intensity factor K for characterizing the fracture toughness of the pipeline steel by drawing a J-R curve for characterizing crack resistance of the crack growth. The method measures the fracture toughness of the pipeline steel by using tensile samples (SENT samples), overcomes the defects that the scope of measurement results of tensile samples (SENT samples) by a conventional technology is so small that the fracture toughness of the pipeline steel can not be evaluated; the crack toughness value of the tensile samples (SENT samples) can be more reasonable; waste of test for pipeline steel materials can be prevented; and the method has the advantages of high measurement accuracy.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

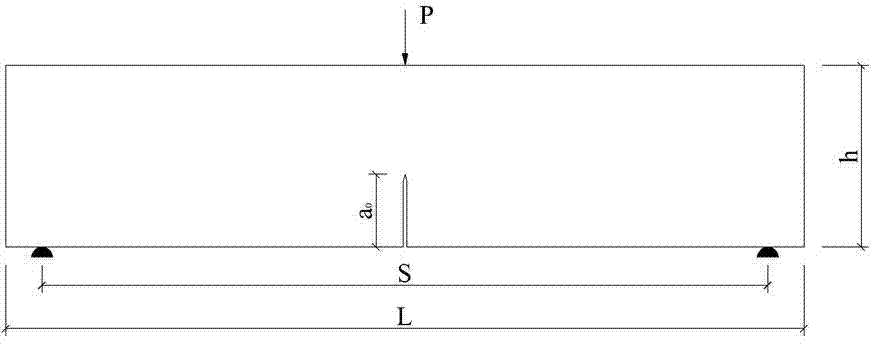

Method for testing fracture toughness of rattan canes based on three-point bending mode

InactiveCN104568605AImprove test accuracyImprove accuracyMaterial strength using steady bending forcesCritical loadStress strength

The invention provides a method for testing the fracture toughness of rattan canes based on a three-point bending mode. The method comprises the following steps: preparing a sample, and regulating a water content rate so as to obtain a sample of which the water content rate is 10-12%; recording a load-crack opening displacement (PV) curve, measuring actual crack depths, and calculating critical loads PQ and critical stress intensity factors KQ. According to the method provided by the invention, the crack opening displacement is measured by a C.O.D Gauge, and the test precision is improved. Aiming at the characteristics of the rattan materials, the sampling method for testing the fracture toughness of rattan canes is ensured, and the measured results having high accuracy and good reproducibility are obtained. The calculation method for testing the fracture toughness of rattan cane, provided by the invention, provides qualitative and quantitative bases for the utilization of the rattan canes.

Owner:INT CENT FOR BAMBOO & RATTAN

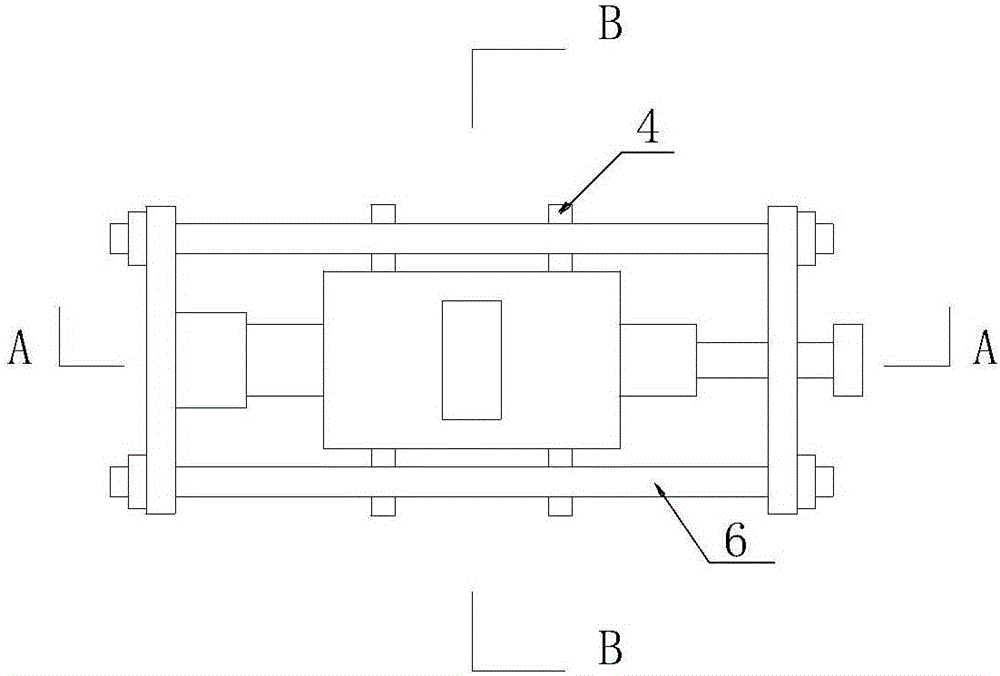

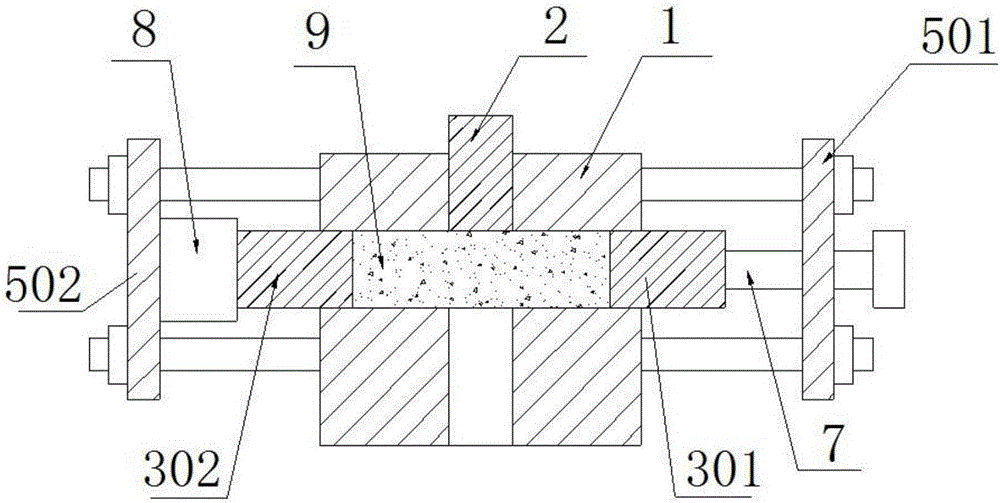

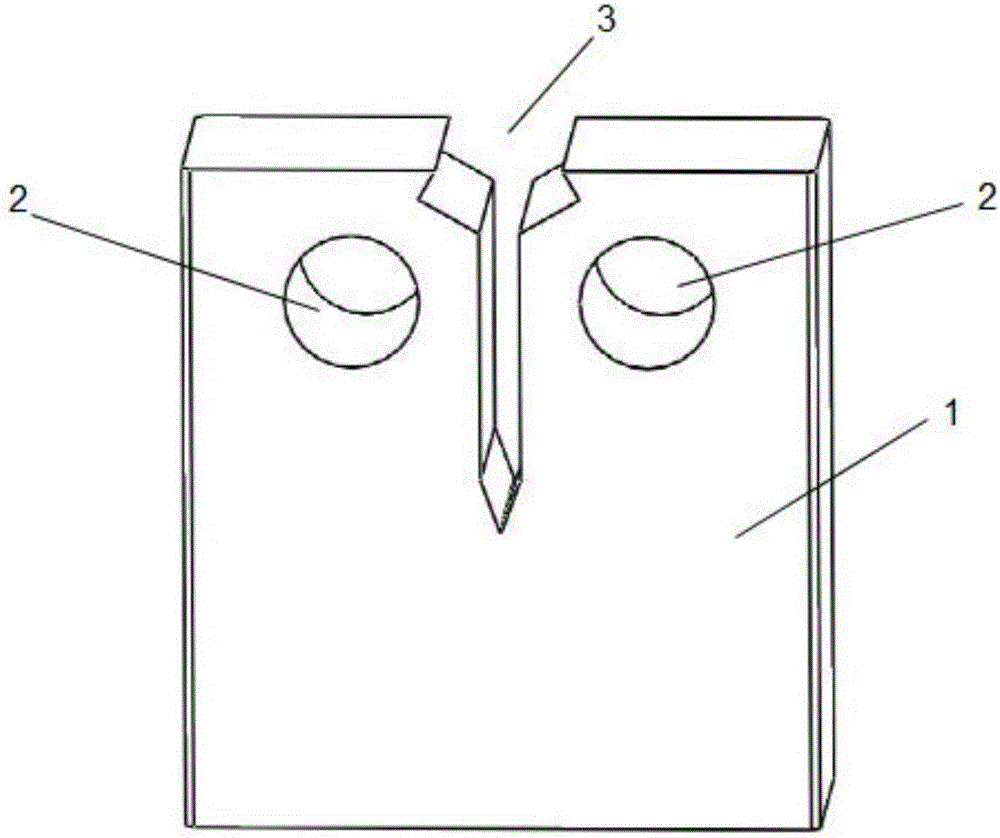

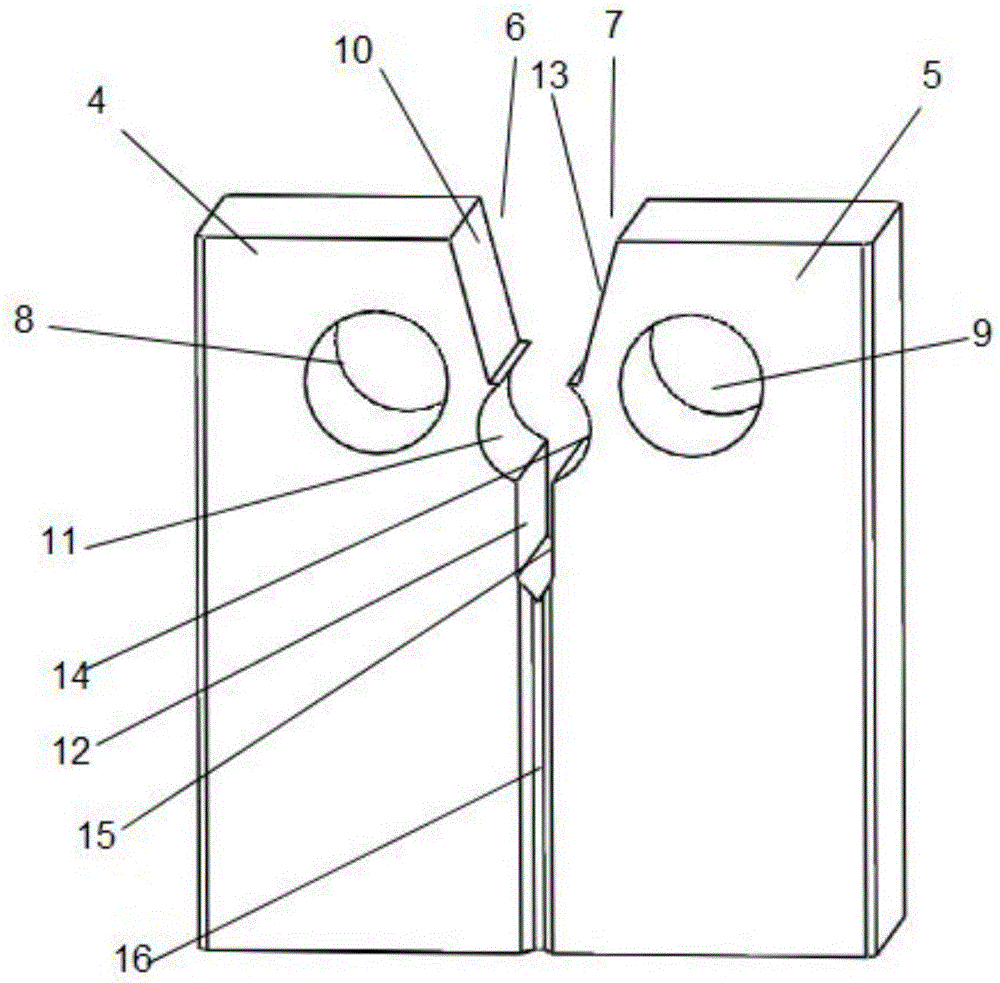

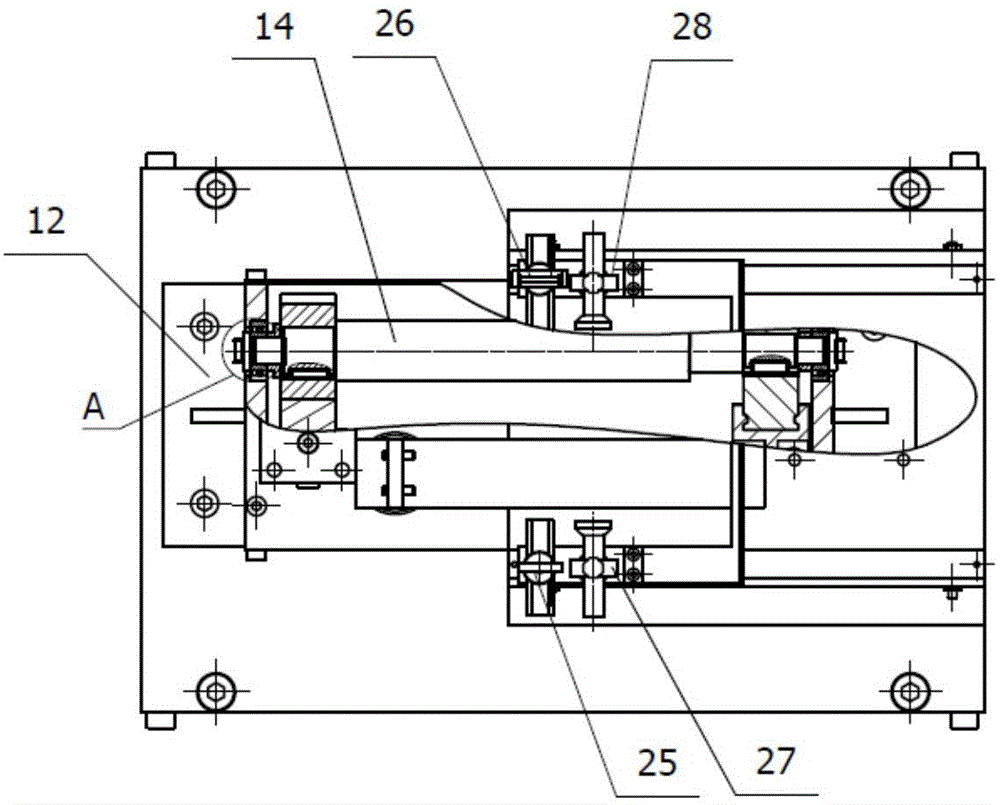

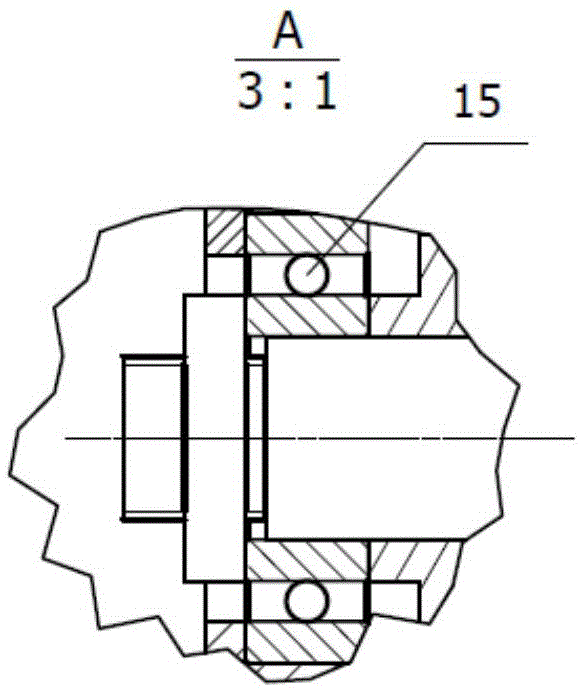

Self-centering double shear test device and type II fracture toughness test method

ActiveCN105784505ASimple structureEasy to manufactureMaterial strength using steady shearing forcesEngineeringRock sample

The invention discloses a self-centering double shear test device which comprises a sample box.A horizontal through hole and a vertical through hole are formed in the sample box and are orthogonal.A first normal pressing block and a second normal pressing block are arranged at the two ends of the horizontal through hole respectively.The first normal pressing block abuts against one end of a position adjusting rod, and the other end of the position adjusting rod is connected with a threaded hole in a first counter-force support through a thread.The second normal pressing block abuts against a normal force loading device which is arranged on a second counter-force support.The first counter-force support and the second counter-force support are connected through a horizontal dowel bar.The invention further discloses a rock sample shear strength parameter test method and a type II fracture toughness test method.The self-centering double shear test device is simple in structure, easy to manufacture and high in applicability, has a self-balancing function, can be easily combined with an existing rock mechanical test system, and can be used for carrying out a rock type II fracture toughness test.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

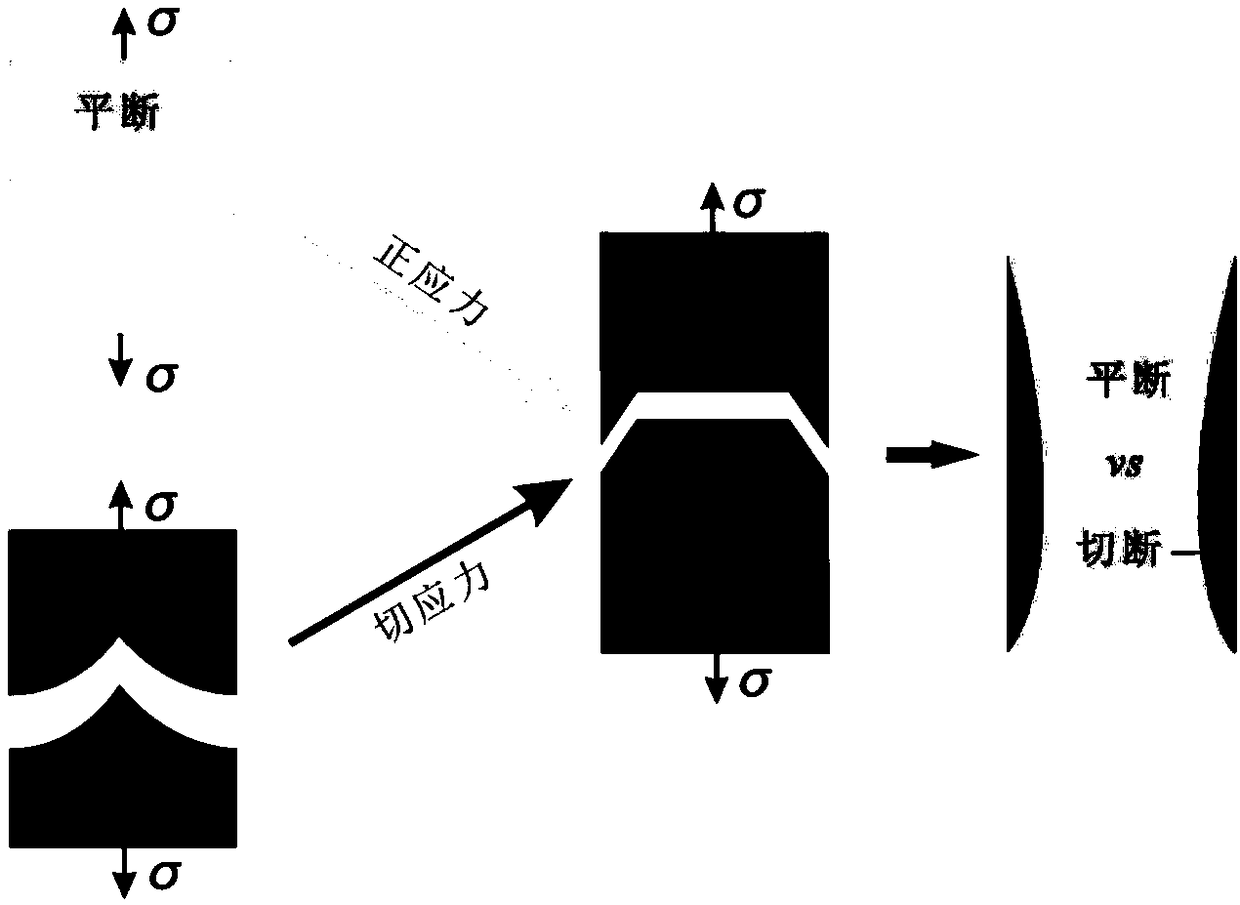

New rock II-type fracture toughness test method

InactiveCN104833590AEnables Mode II Fracture Toughness TestingIncrease the tensile stressPreparing sample for investigationMaterial strength using steady shearing forcesType fractureRock sample

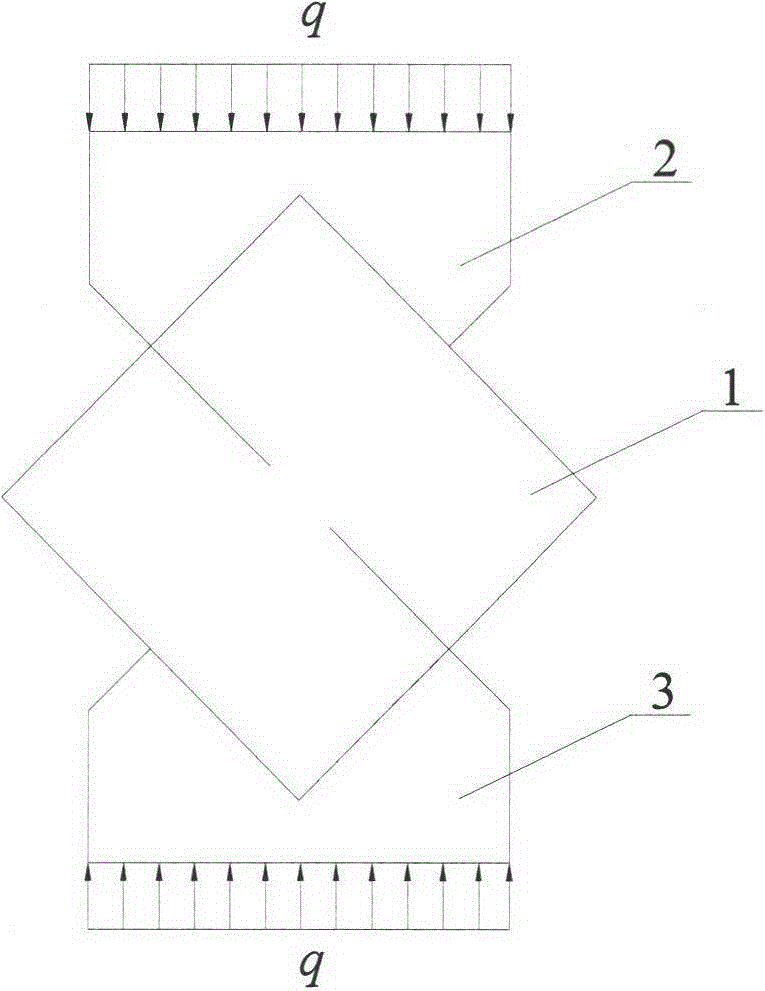

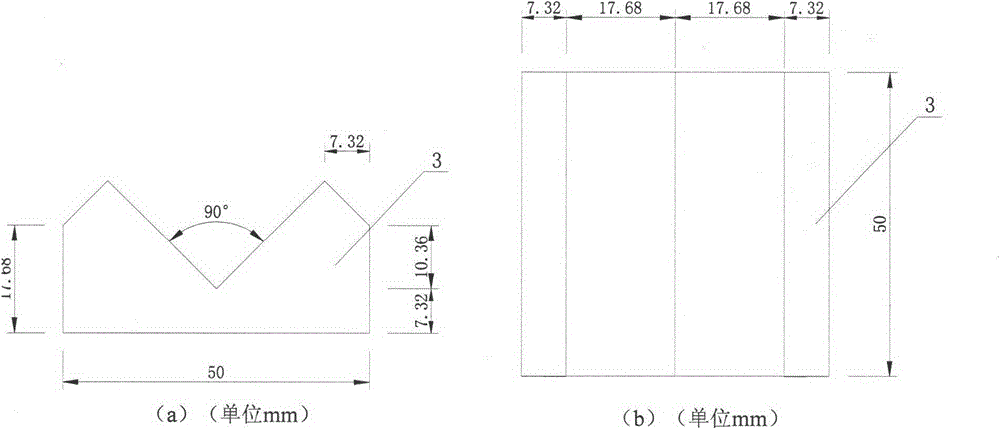

The invention relates to a new rock II-type fracture toughness test method. According to the invention, on the basis of an original shear box test, by means of adjustments of the stress state of a loaded mould and arrangement of a sample to eliminate rotation tendency of the sample, generation of an excessive tensile stress on a crack tip is inhibited, thereby achieving rock II-type fracture toughness test. A test model includes a square rock sample and two steel loading moulds. Straight cracks are pre-formed on the middle parts of the two sides of the square rock sample, wherein the lengths and the widths of the two straight cracks are equal to each other. The two straight cracks are arranged symmetrically. The loading moulds can achieve 45-degree loading of the sample with a loading end surface being flat and smooth. The widths of two contact surfaces between the loading moulds and the square rock sample are both half of the side length of the sample. An upper end and a lower end of the whole system are subjected to a uniform load. The method enables processing of the rock sample and the loading moulds to be more convenient, is simplified in test process, ensures accuracy of test data, is suitable for the II-type fracture toughness test of various rocks, and provides basis for researching the II-type fracture of rocks and a problem of composite fracture mainly comprising II-type fracture.

Owner:吴礼舟

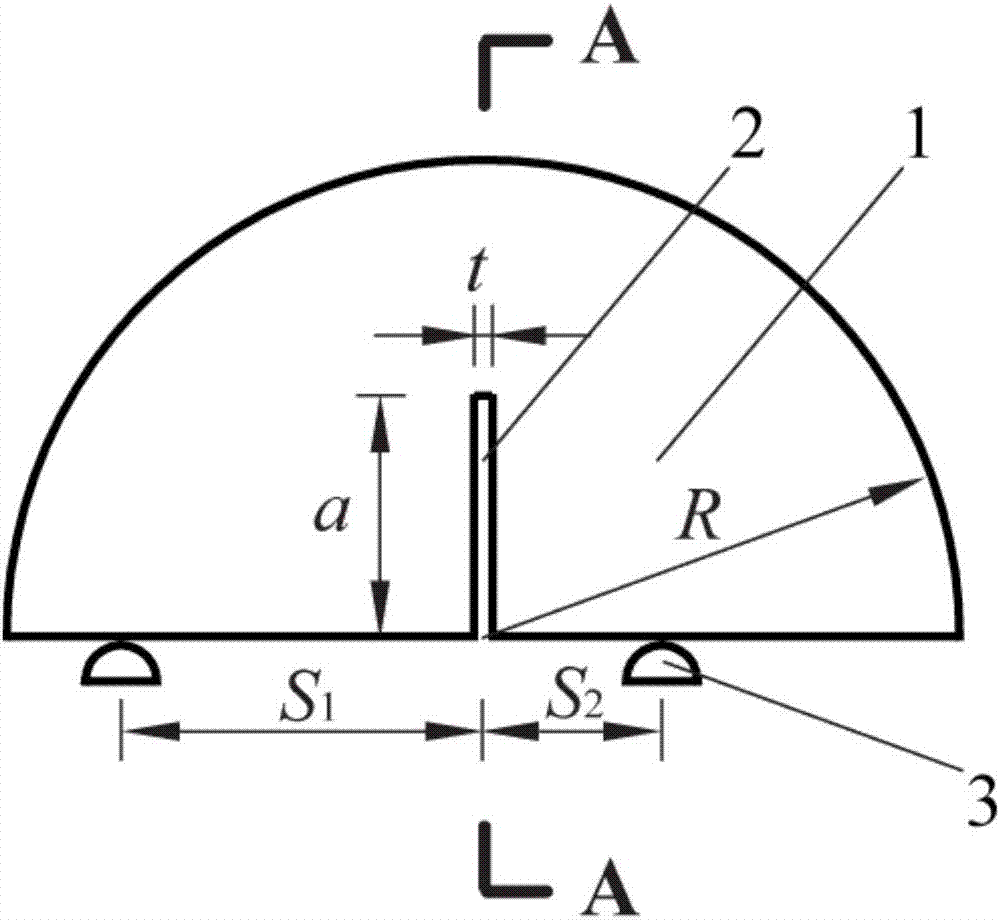

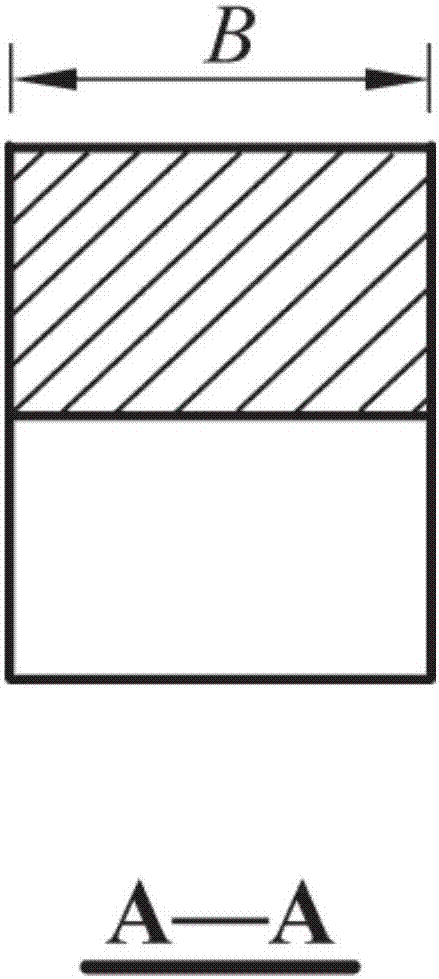

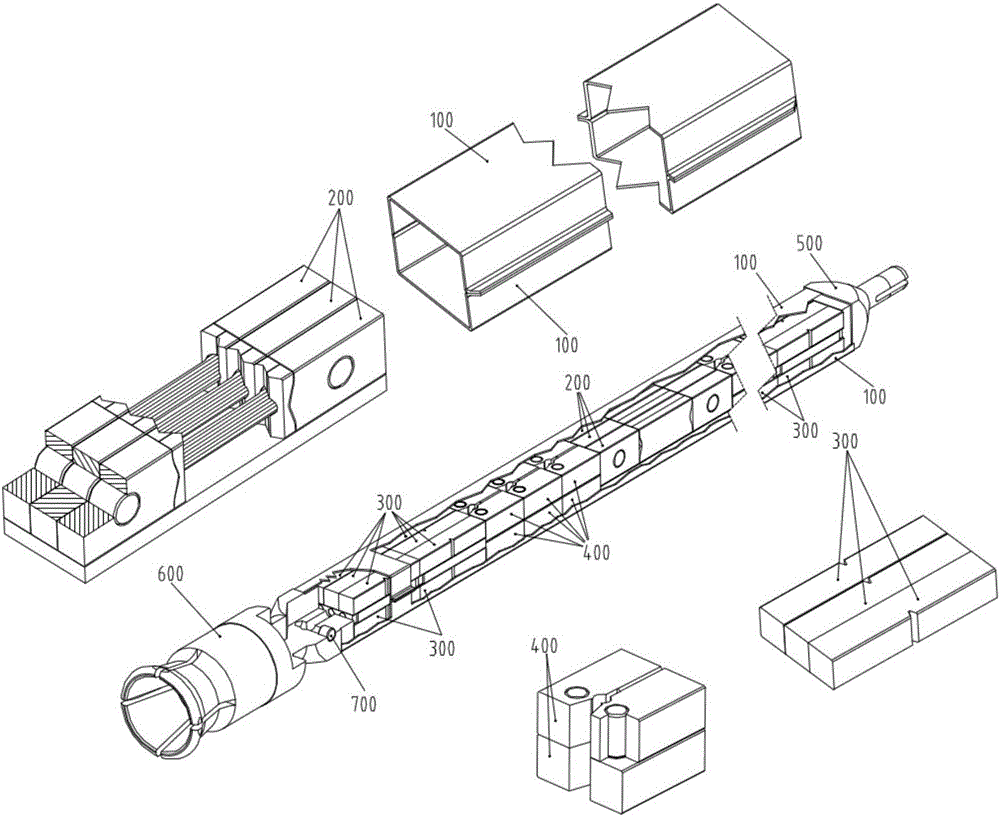

Test piece assembly for testing rock I-II compound dynamic fracture toughness and testing method

InactiveCN106932253ASimple structureReduce processing difficultyPreparing sample for investigationStrength propertiesEngineeringTest fixture

The invention discloses a test piece assembly for testing rock I-II compound dynamic fracture toughness and a testing method. The test piece assembly comprises a test piece body with a groove and a loading platform, and cylindrical pressing heads supporting and abutting against the test piece body. The test piece body is a semi-disc-shaped plate, the groove stretches into a test piece from the straight side plane of the semi-disc-shaped test piece along the axial symmetry surface of the semi-disc-shaped test piece, the loading platform is located in the center of the arc surface of the semi-disc-shaped test piece, and the table plane is parallel to the straight side plane of the test piece. The pressing heads are straight arc cylindrical surface pressing heads. During testing, the two cylindrical pressing heads are located on the two sides of the groove respectively, the test piece assembly is arranged between an incidence rod and a transmission rod of a Hopkinson pressure bar testing device, the test piece is collided through an impact bar of the testing device, and the I-II compound dynamic fracture toughness of the rock test piece is tested through strain signals. The preparation process of the rock I-II compound dynamic fracture toughness testing test piece and the testing process of the rock I-II compound dynamic fracture toughness are greatly simplified.

Owner:SICHUAN UNIV

Test piece and method for testing fracture toughness of hybrid mode of double-material interface

ActiveCN103616299ASimple geometryMaterial strength using steady bending forcesMaterials testingEngineering

The invention discloses a test piece for testing the fracture toughness of a double-material interface in a hybrid mode. The test piece comprises a cuboid, wherein the cuboid consists of two first material blocks and a second material block which are combined closely in common; the two first material blocks are respectively and closely arranged at the two sides of the second material block, the closely-combined surface between one first material block and the second material block is vertical to the horizontal surface, and an included angle is formed between the closely-combined surface of the other first material block and the second material block and the horizontal surface; the combined surface forming the included angle with the horizontal surface is provided with prefabricated cracks. The invention also discloses a manufacturing method of the test piece and a test method simultaneously. The test piece and the manufacturing and testing methods disclosed by the invention have the advantages that the three-point bending test piece with a double-material inclined notch is used for testing the fracture toughness of the hybrid-mode interface, the geometrical shape of the test piece is simple, and a fracture toughness value in the range of 0-90 degrees can be obtained by adopting a three-point bending method on a common material testing machine, so that the test piece is especially suitable for fragile materials.

Owner:SHANDONG UNIV

Self-weight influence-free concrete material fracture toughness testing method

ActiveCN103698224AIncreased testable sizeMake up for the inaccurate determination of crack initiation and instability toughness valueMaterial strength using steady bending forcesTest beamEngineering

The present invention relates to a self-weight influence-free concrete material fracture toughness testing method, and belongs to the technical field of physical measurements. The determination method comprises: 1) erecting a test beam on two rolling bearings of the current three-point bending beam test device, and arranging a load measurement device and a strain measurement device on the test beam; 2) measuring the applied maximum load Fmax through the load measurement device, and measuring an initiation fracture load FQ through the strain measurement device; and 3) calculating an unstable toughness and an initiation fracture toughness. With the self-weight influence-free concrete material fracture toughness testing method, influence of the member self-weight on the testing result is eliminated so as to accurately determine the concrete initiation fracture and unstable toughness and meet the initiation fracture and unstable toughness determination requirements of the concrete material (including hydraulic concrete) of the high crack-depth ratio or large size specimen.

Owner:NANJING HYDRAULIC RES INST

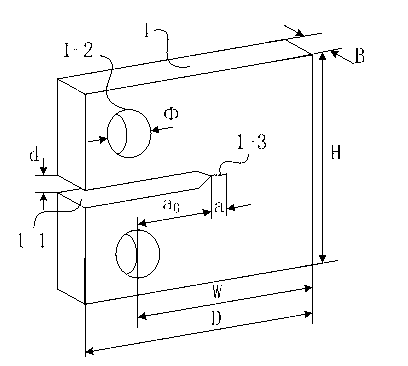

Artificial heart valve pyrolytic carbon and testing method for fracture toughness of pyrolytic carbon composite material

InactiveCN103234823AGuaranteed feasibilityGuaranteed reliabilityMaterial strength using tensile/compressive forcesCritical loadPyrolytic carbon

The invention relates to an artificial heart valve pyrolytic carbon and a testing method for the fracture toughness of a pyrolytic carbon composite material. A testing method for the fracture toughness of the pyrolytic carbon composite material has not been brought forward yet. The testing method provided by the invention comprises the following steps: preparing a plurality of compact tension C(T) specimens from heart valve pyrolytic carbon or a composite material thereof and prefabricating sharp cracks on each specimen, wherein the specimen is of a specification as recommended by American ASTM standard E399, a gap is processed at the central part of the specimen, and upper and lower ends of the gap are respectively provided with a loading hole; then respectively clamping the two loading holes of the gap by using clamps and erecting an extensometer on an open end of the gap; and starting a loading platform to apply an upward load increasing at a uniform speed until the specimens fracture, determining critical load and effective crack length of each specimen, calculating fracture toughness according to the critical load and the effective crack length and taking a mean value as a fracture toughness test value of the heart valve pyrolytic carbon or the composite material thereof. The method provided by the invention can accurately determine fracture toughness of pure pyrolytic carbon and a pyrolytic carbon composite material.

Owner:HANGZHOU DIANZI UNIV

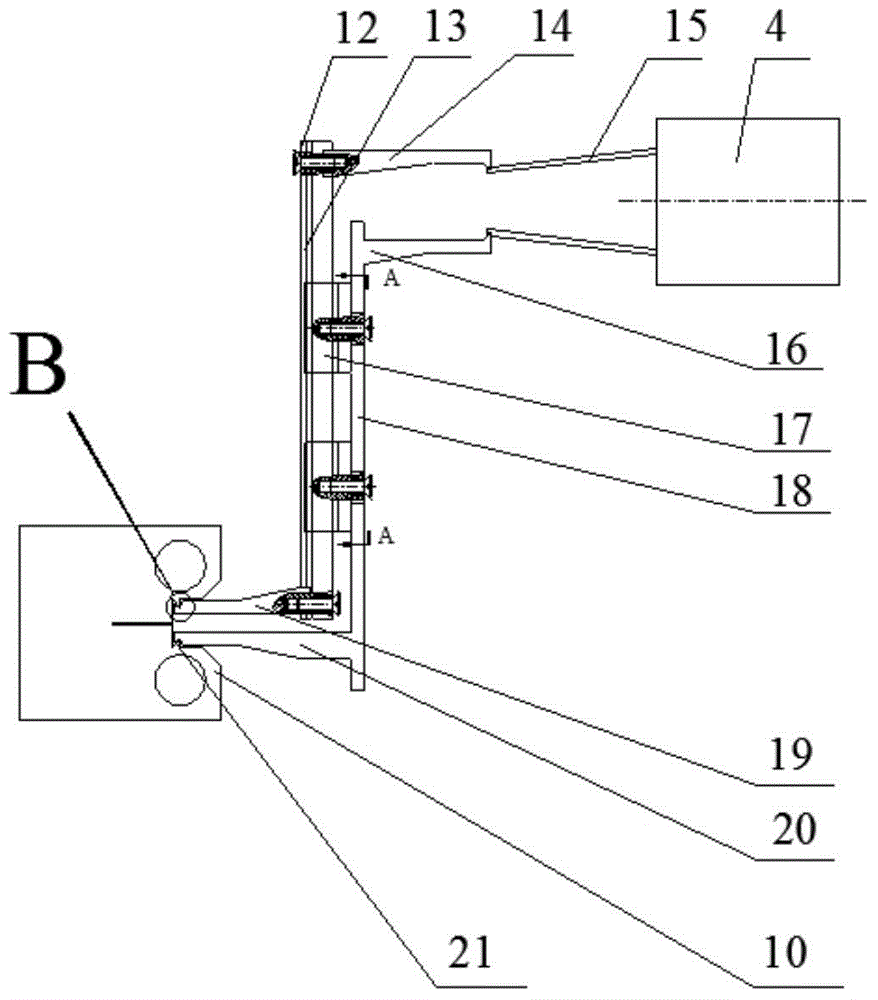

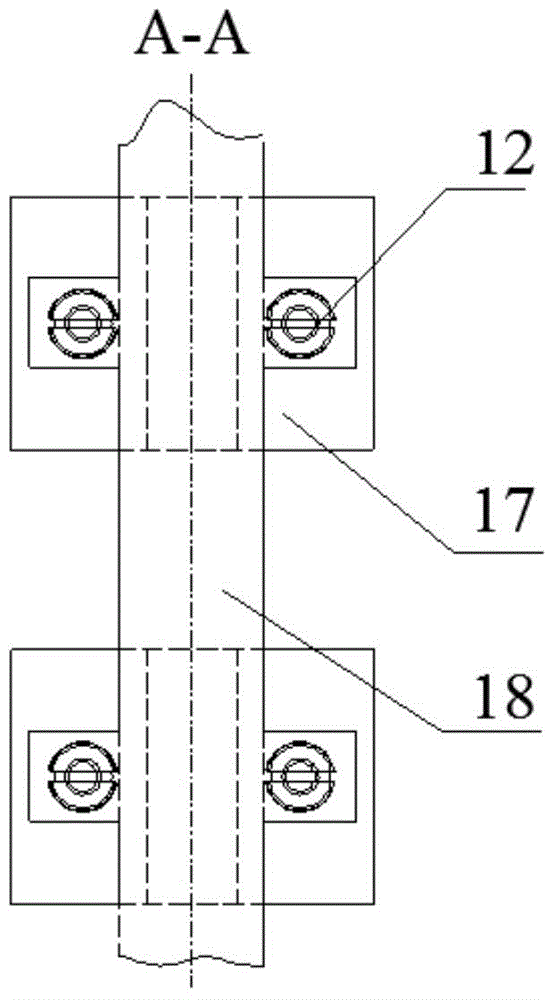

Device and method for testing breaking tenacity of compact tension specimen in low-temperature environment

ActiveCN103954512AAccurate measurementAvoid damageInvestigating material ductilityLiquid mediumEngineering

The invention provides a device and a method for testing breaking tenacity of a compact tension specimen in a low-temperature environment. The device comprises an insulated container for containing low-temperature liquid medium, upper and lower clamps and a displacement transmitting mechanism, wherein a specimen is soaked in low-temperature liquid medium and comprises a crack mouth in a horizontal orientation; the upper and lower clamps are connected with the specimen, respectively arranged at two sides of the crack mouth, and respectively connected with upper and lower pistons of a tensile testing machine; the displacement transmitting mechanism comprises two vertical guide rails which are parallel and slide oppositely; upper and lower blades are respectively arranged at two ends of the each vertical lead rail; the upper blades of the two vertical guide rails are oppositely arranged to form an upper tool edge connected with an extensometer; the lower blades of the two vertical guide rails are arranged oppositely to form a lower tool edge connected with the crack mouth, so that a loaded line displacement of the specimen is transferred to the extensometer above the liquid level of the low-temperature liquid medium, so as to accurately measure the loaded line displacement. Meanwhile, the extensometer is prevented from directly contacting the low-temperature liquid medium to be easily damaged, and the device and the method are simple and reliable in structure, and convenient to install and operate.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

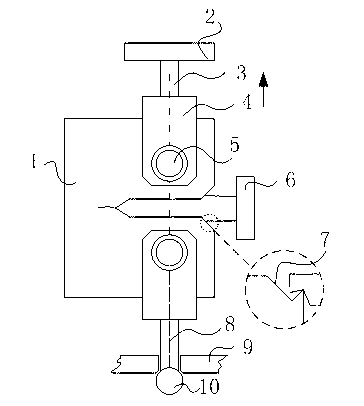

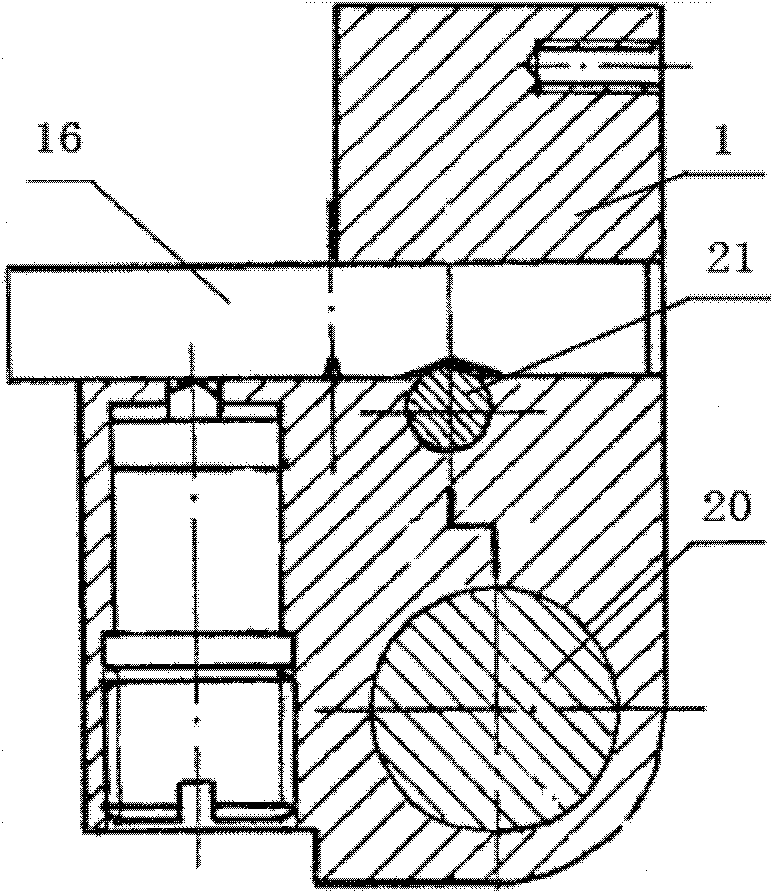

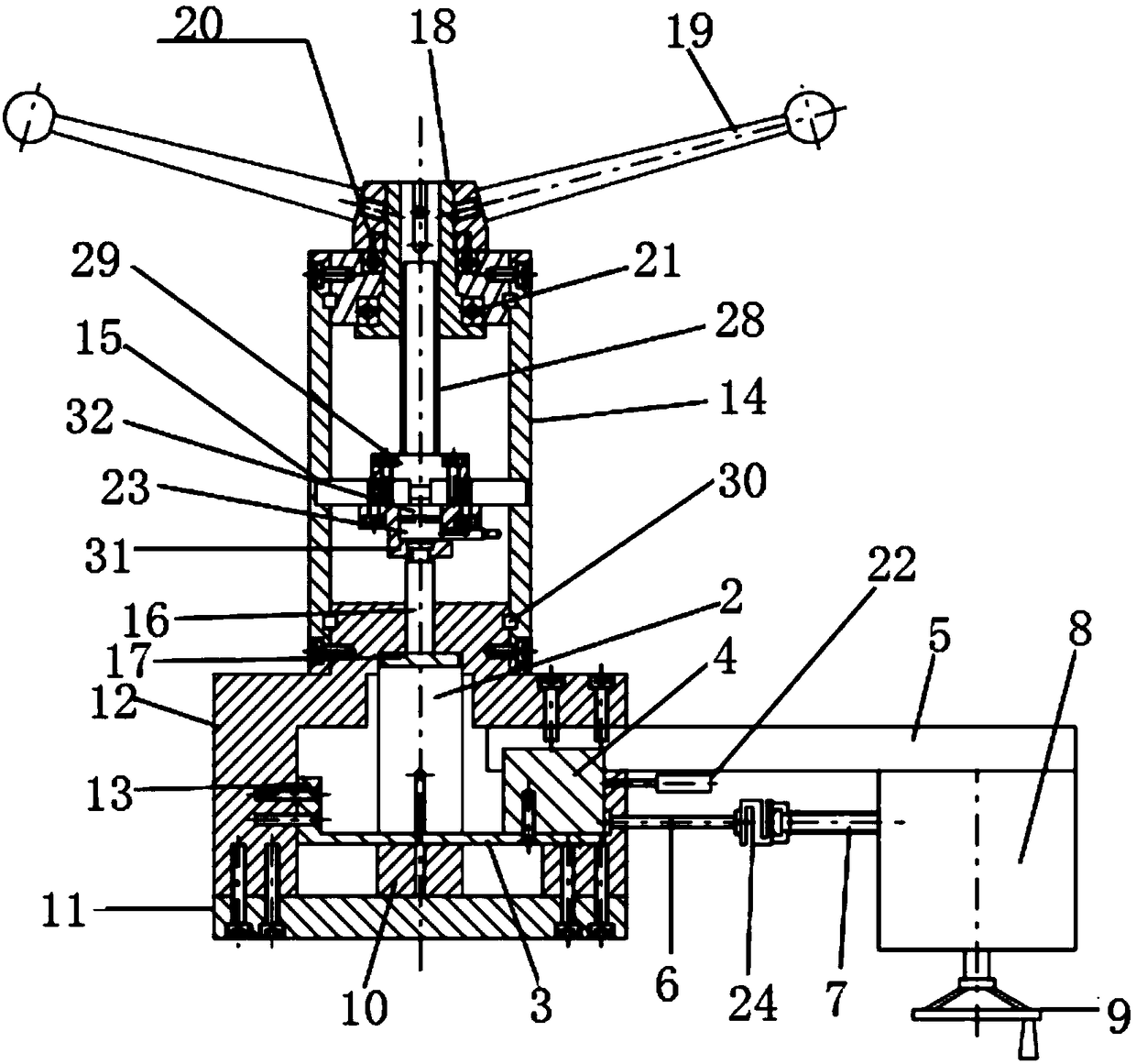

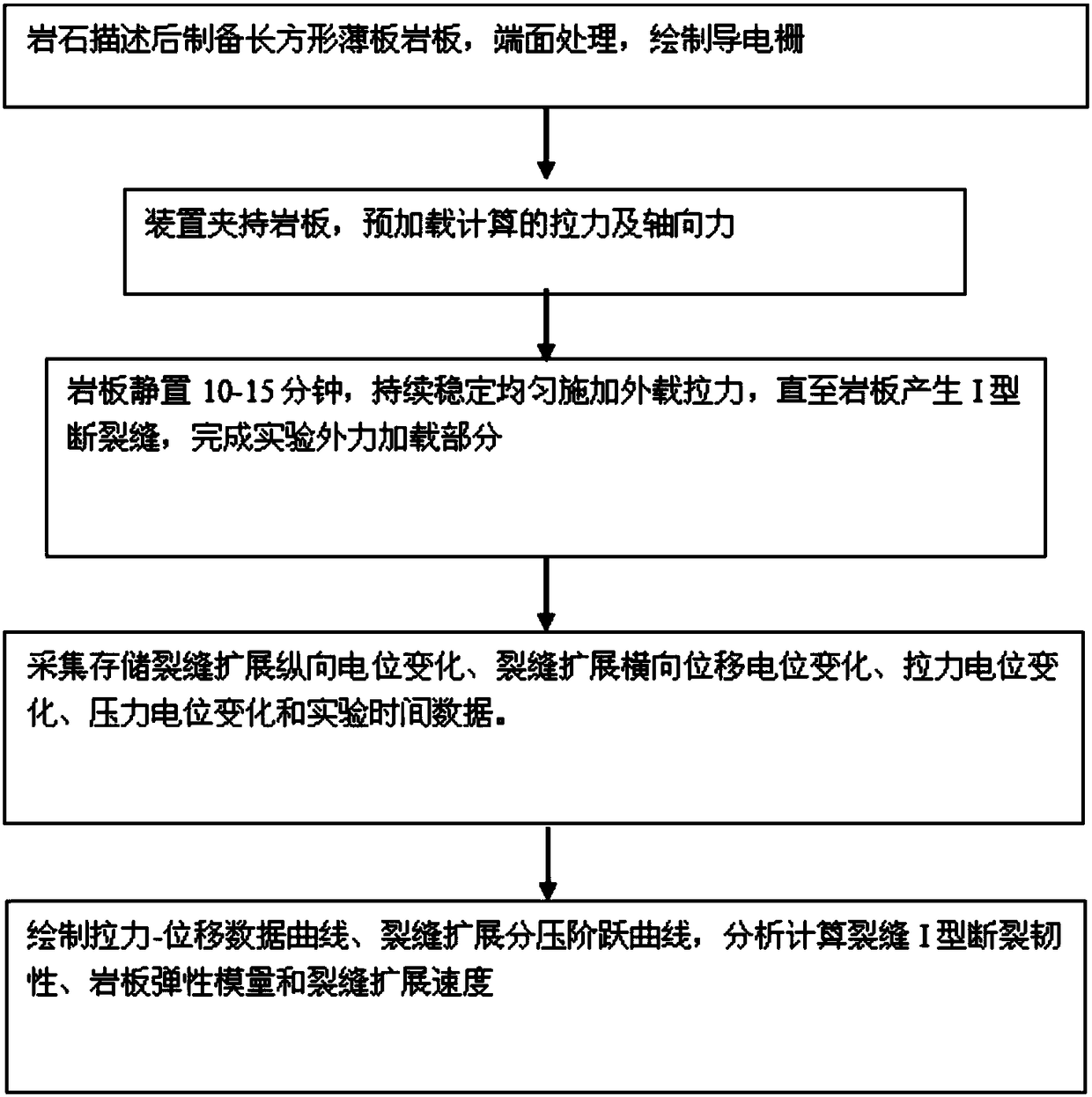

Device and method for measuring I-type creep fracture toughness and fracture toughness of rock

InactiveCN101710042ASimple test operationGuaranteed accuracyInvestigating material ductilityFracture testEnvironmental geology

The invention relates to a device and a method for measuring the I-type creep fracture toughness and the fracture toughness of rock. A rock single axle tensile creep fracture test and a conventional fracture test are carried out on the device for measuring the I-type creep fracture toughness and the fracture toughness of rock, thus the I-type creep fracture toughness and the fracture toughness of rock are measured. The measuring method comprises the steps of: transferring a pressure applied by the exterior into a tensile force of the interior of a rock test piece so as to realize the single axle tension of the rock test piece. The invention enables the operation of the indoor measuring method of rock fracture toughness to be simpler, guarantees the accuracy of the measured data of the test and has rather high precision, therefore having excellent using and popularizing values.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

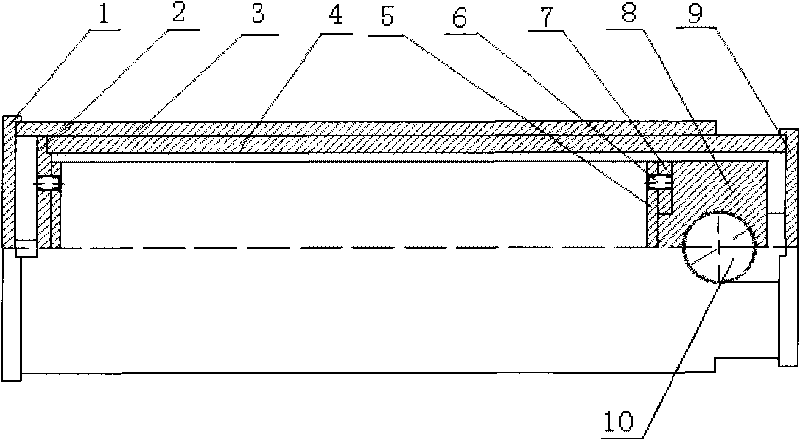

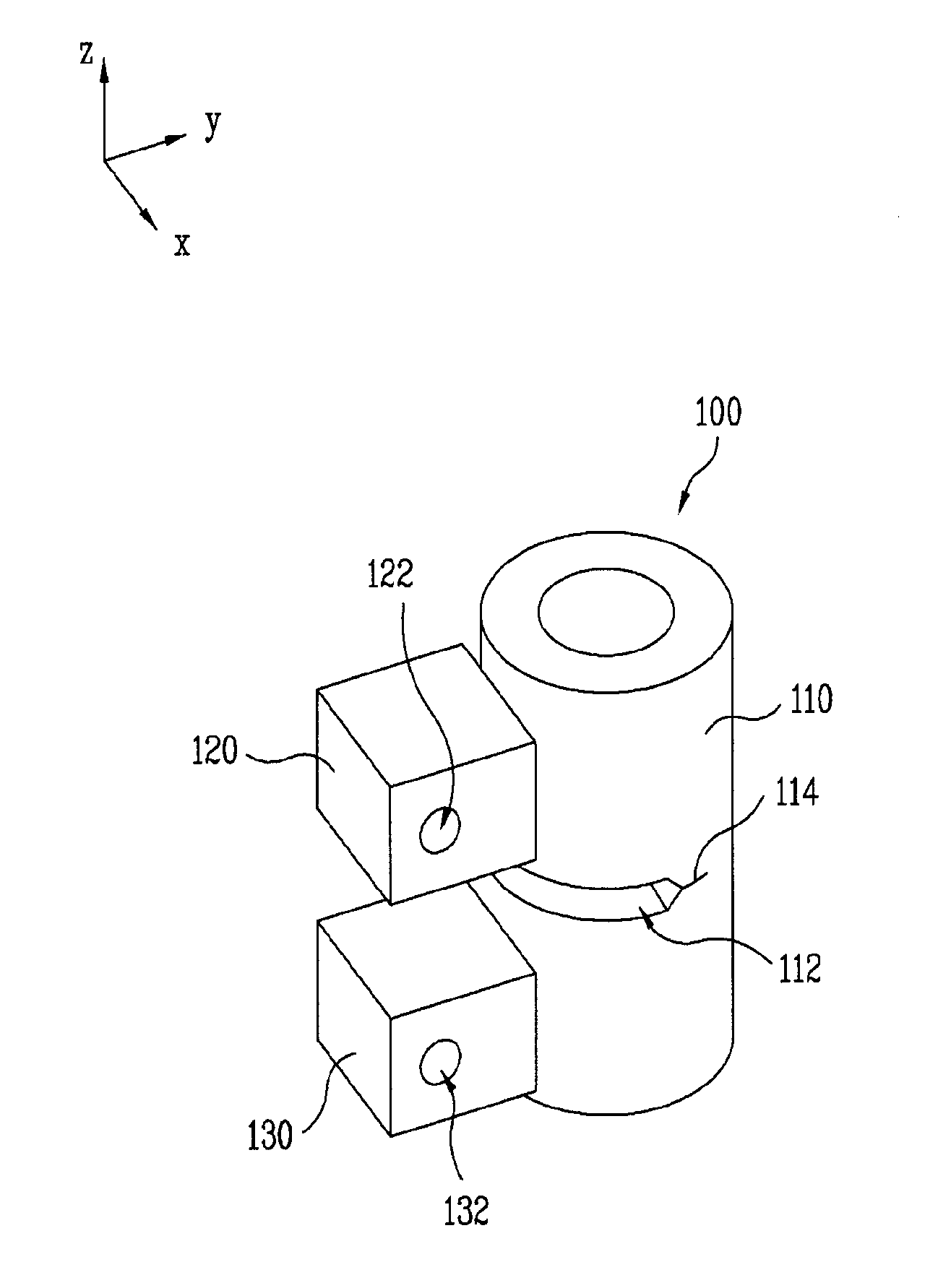

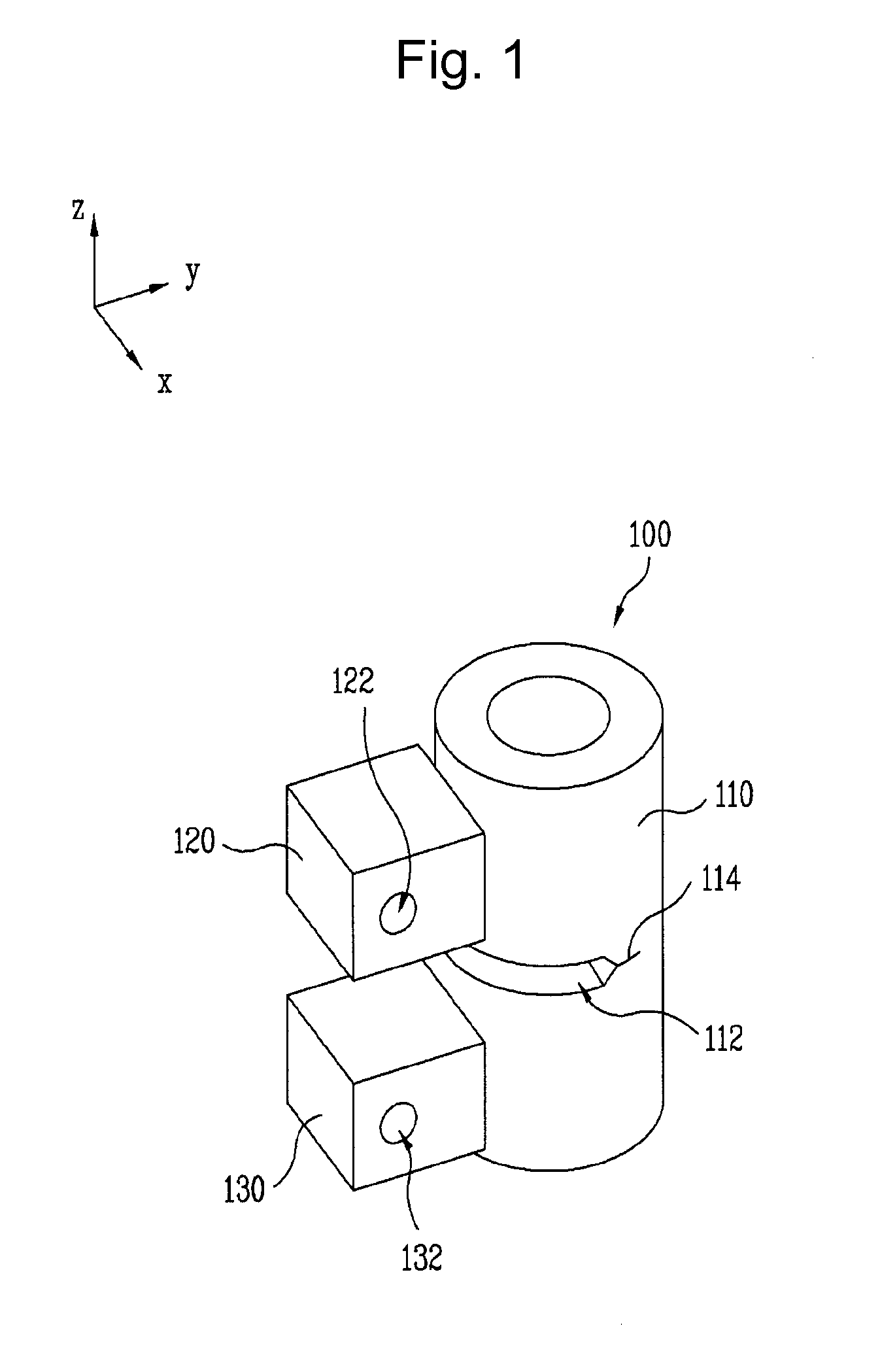

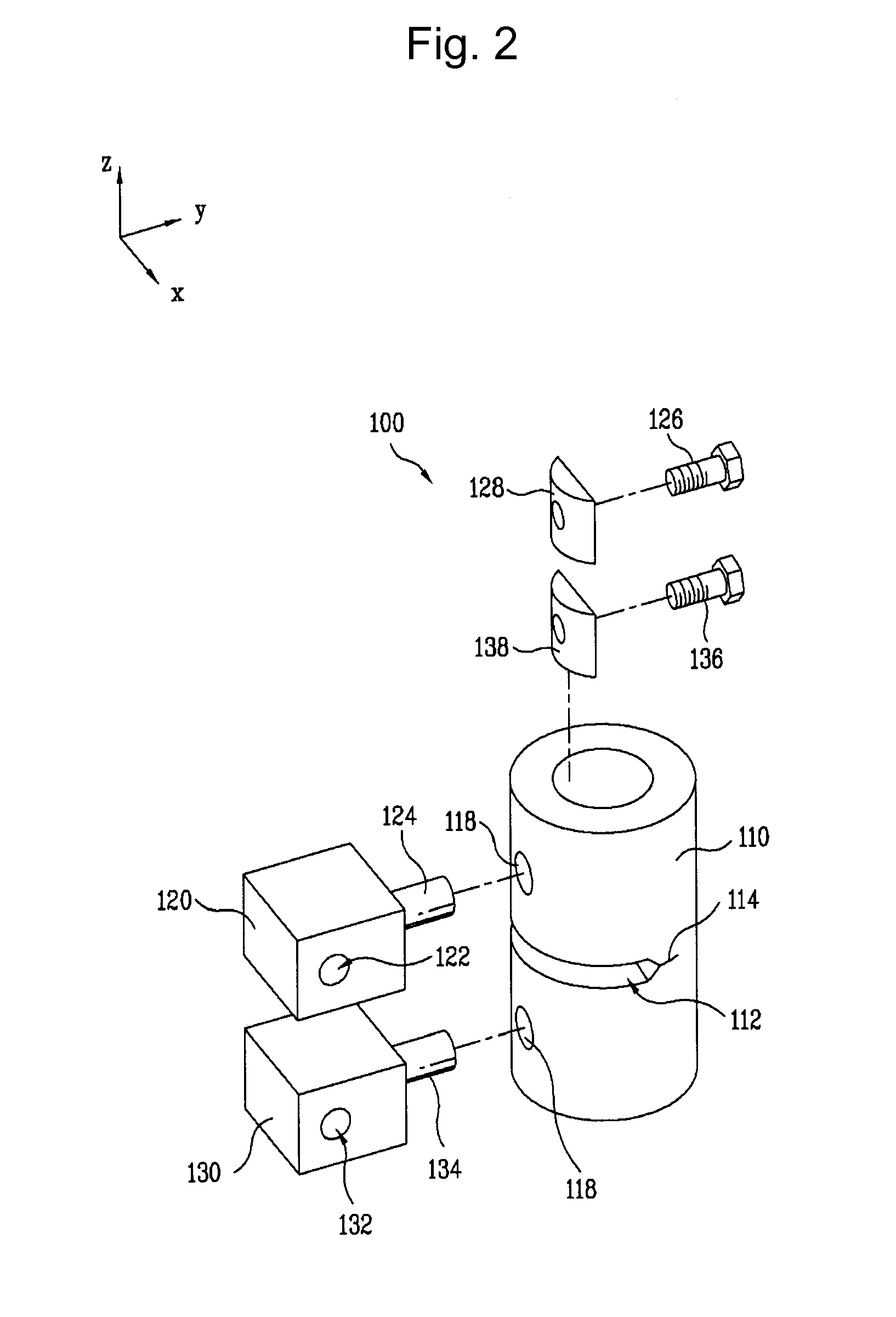

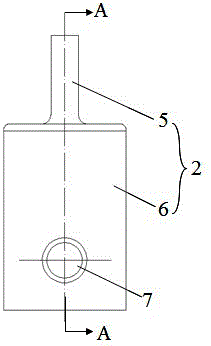

Compact pipe specimen

InactiveUS20110094307A1Large bending loadSolve large capacityMaterial strength using steady bending forcesEngineeringPhysical property

A compact pipe specimen applicable to a fracture toughness test used to evaluate physical properties of a pipe material is provided. The compact pipe specimen includes: a pipe having a notch portion formed in a circumferential direction and a crack portion formed at the edge of the notch portion; and first and second jigs having openings to which a pressurizing unit is coupled so as to cause a bending load on the pipe, having the notch portion therebetween, and attached to the exterior surface of the pipe, respectively. It is unnecessary to correct the influence of a constraint effect due to varying sizes and shapes of the specimen. There is no restriction to the curvature and thickness of a pipe. A fracture behavior of a pipe crack portion can be precisely simulated.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

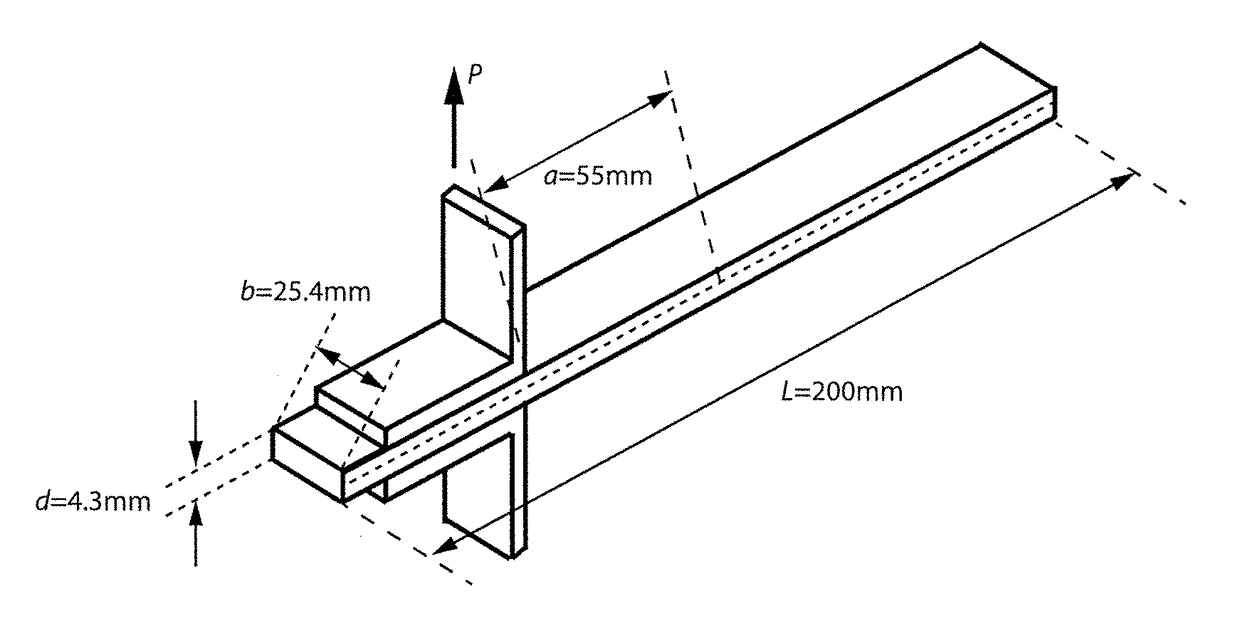

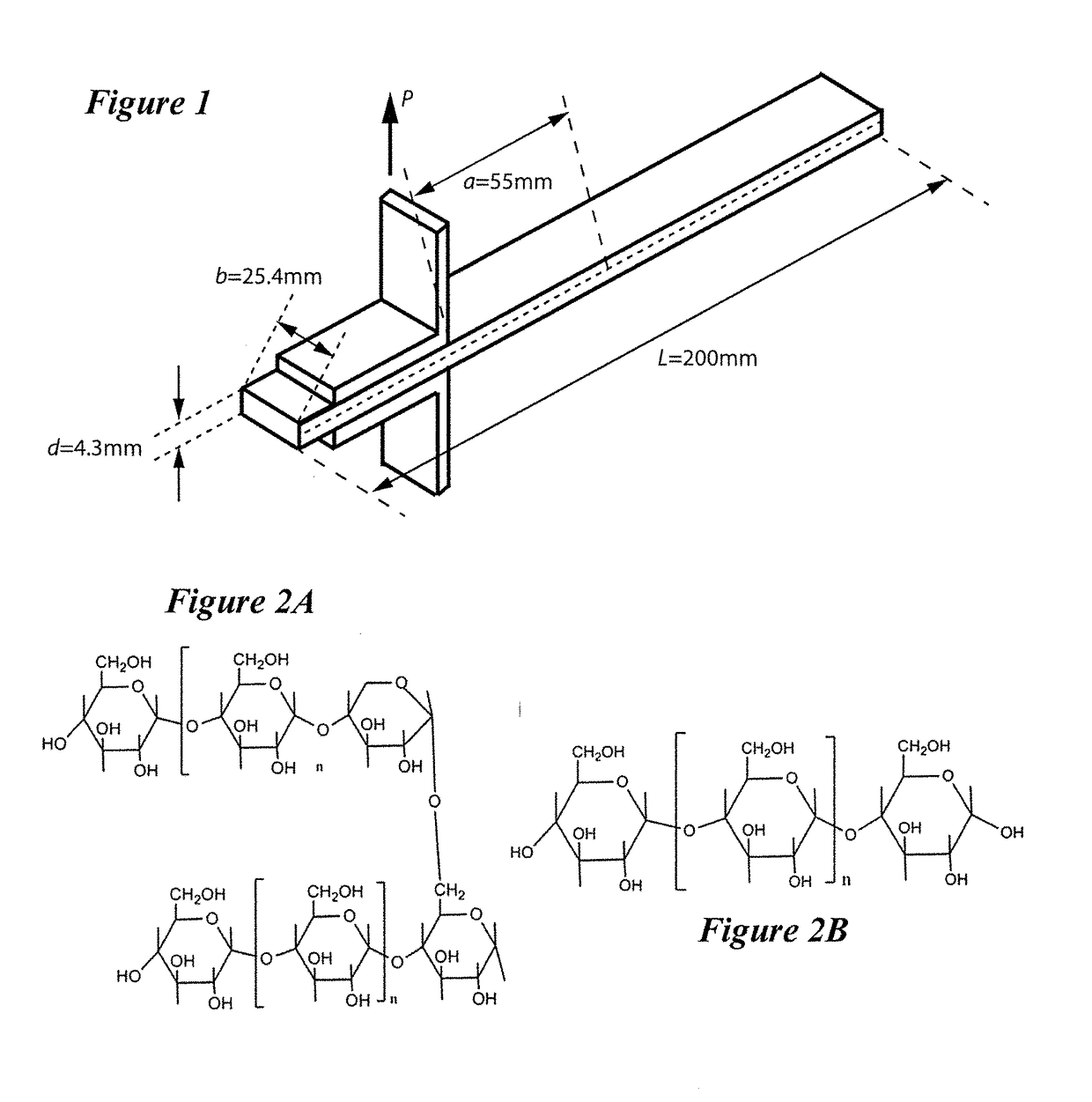

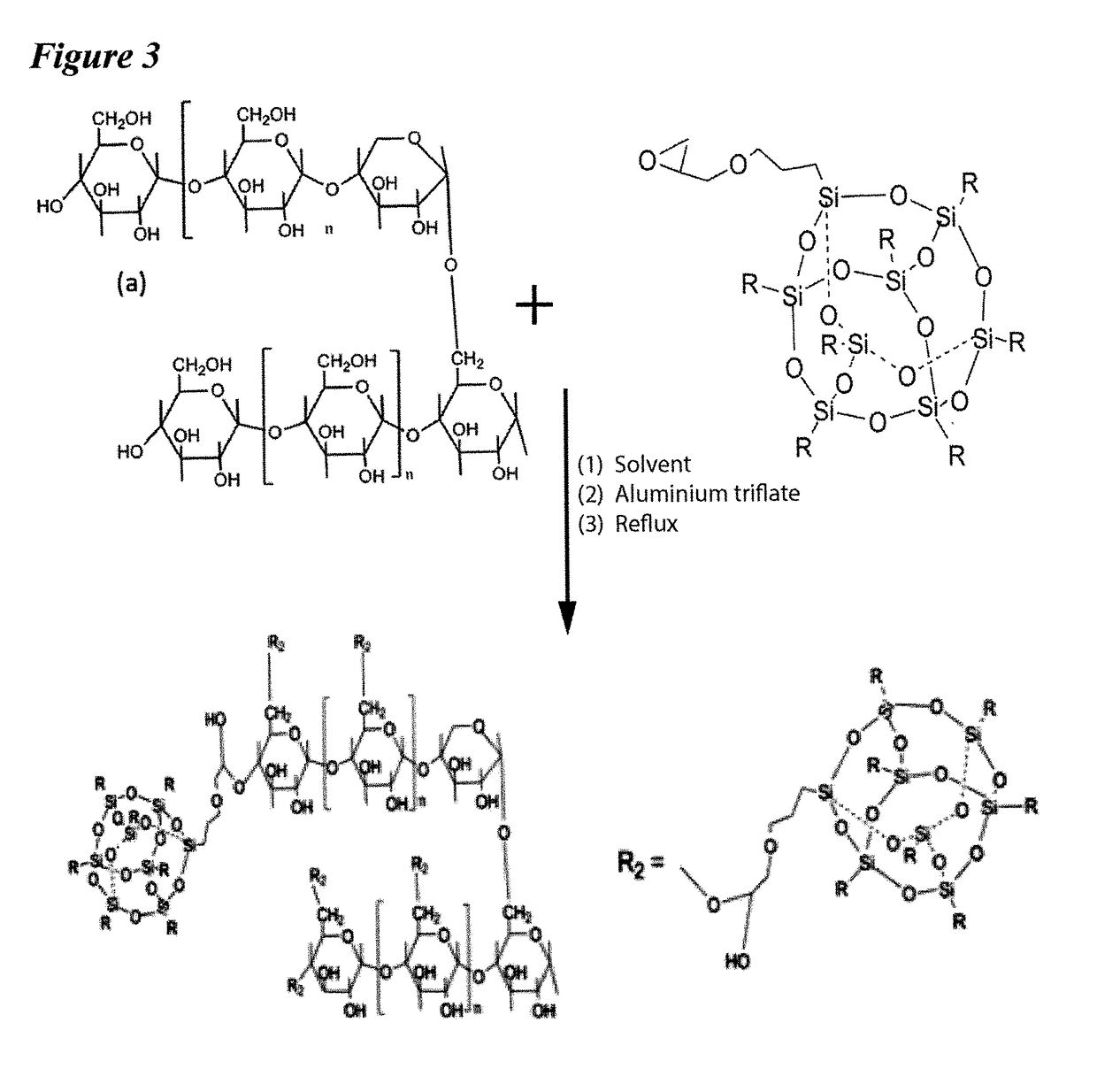

System and method for synthesis of poss-graphene oxide derivatives as effective fillers for developing high performance composites

According to an embodiment, a method for grafting POSS (polyhedral silsesquioxane) nanomaterial to graphene oxide is described for use in preparation of high performance composite materials. In another embodiment, amine functionalized graphene oxide may be particularly suitable. In this embodiment, POSS molecules grafted to amine functionalized graphene oxide are synthesized by reacting graphene oxide with different POSS molecules. The amine functionalized graphene oxide may be dissolved in a solvent and the reaction may include the presence of a catalyst. The resultant POSS grafted graphene oxide / POSS grafted amine functionalized graphene oxide may be mixed with a resin (epoxy) in a masterbatch. The masterbatch may then be packaged and sold. The masterbatch material may then be introduced into the interlaminar area of graphite / epoxy composites. Biodegradability and interlaminar fracture toughness testing results from the use of epoxy based nanocomposites containing POSS modified graphene oxide polymer are expected to improve.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY

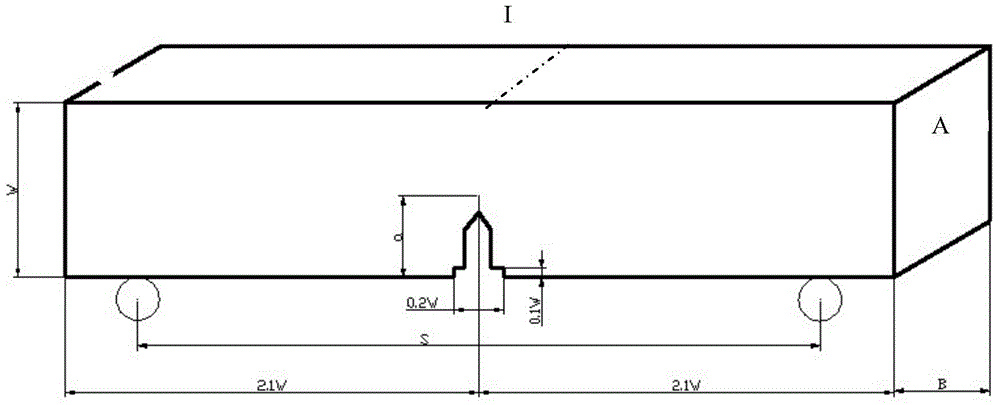

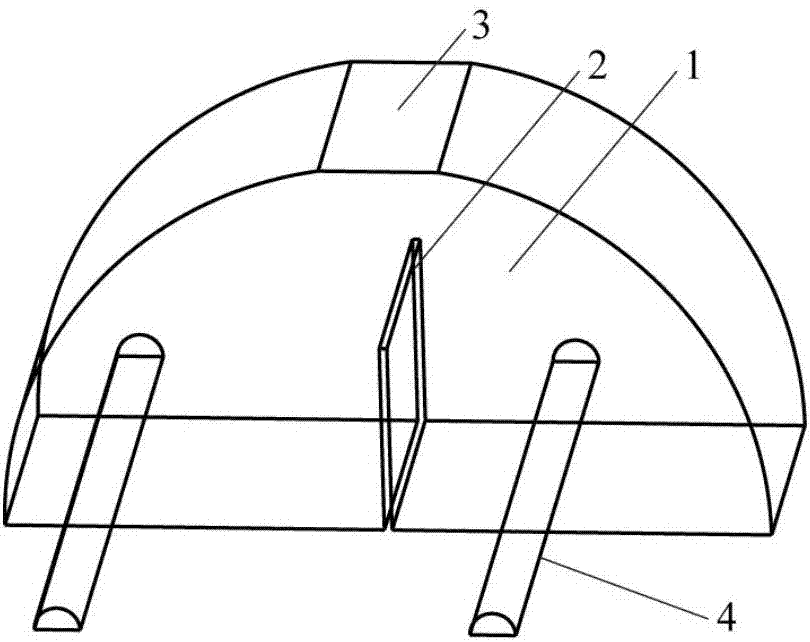

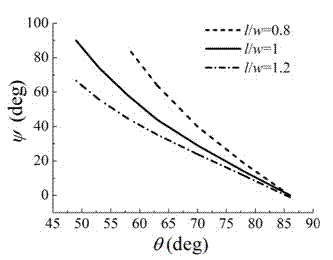

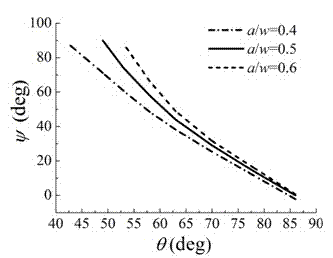

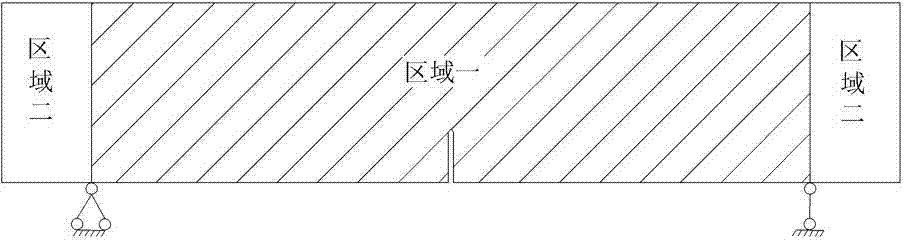

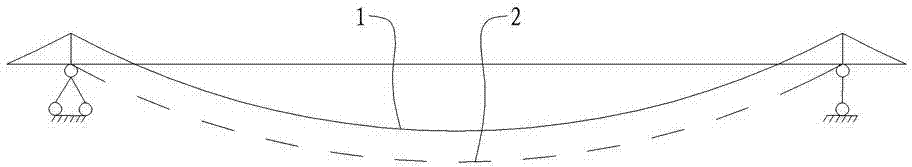

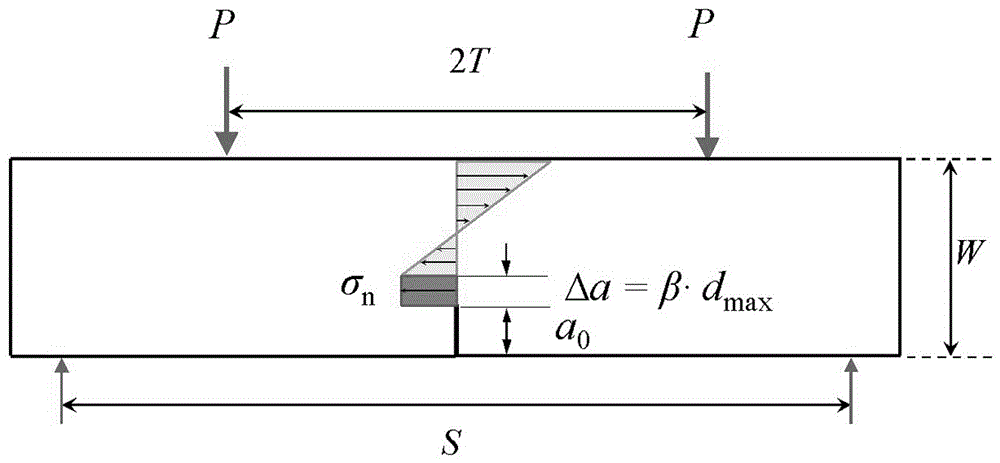

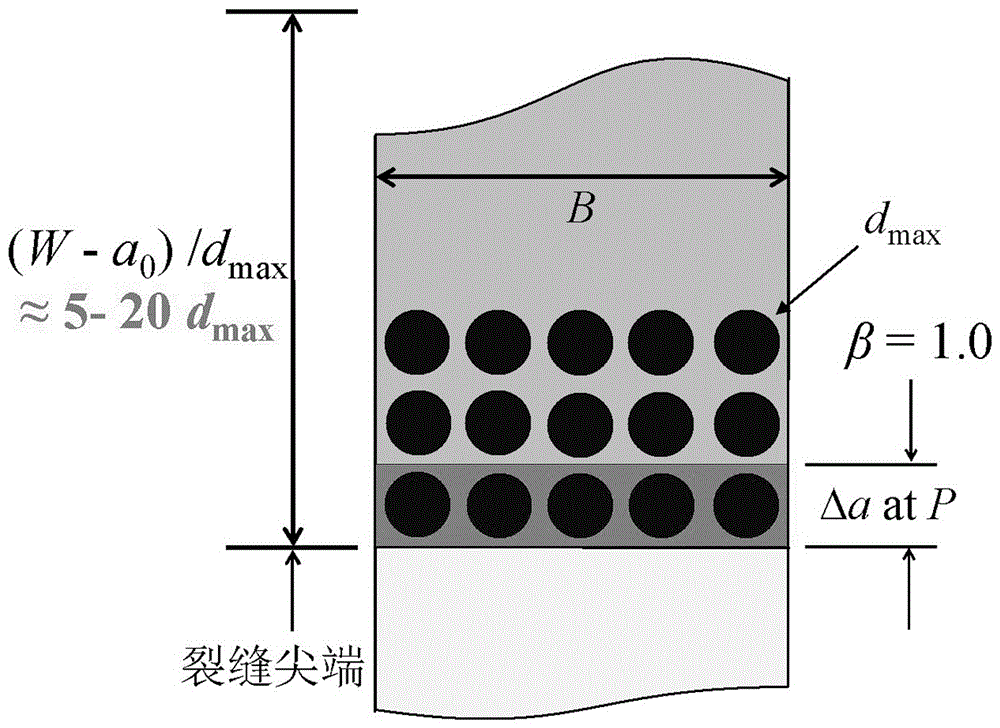

Method for testing rock composite fracture toughness based on asymmetric three-point bending loading of NDB sample

ActiveCN109781548ARich fracture toughness testing technology systemSimple structurePreparing sample for investigationMaterial strength using steady bending forcesNon symmetricEngineering

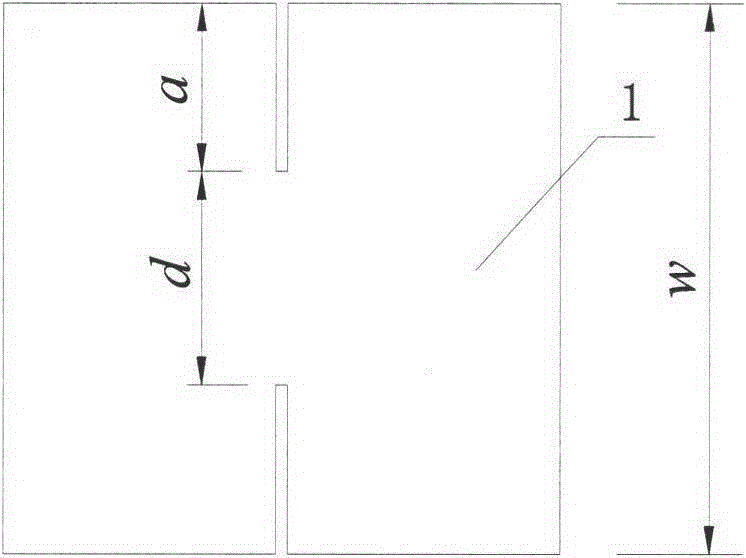

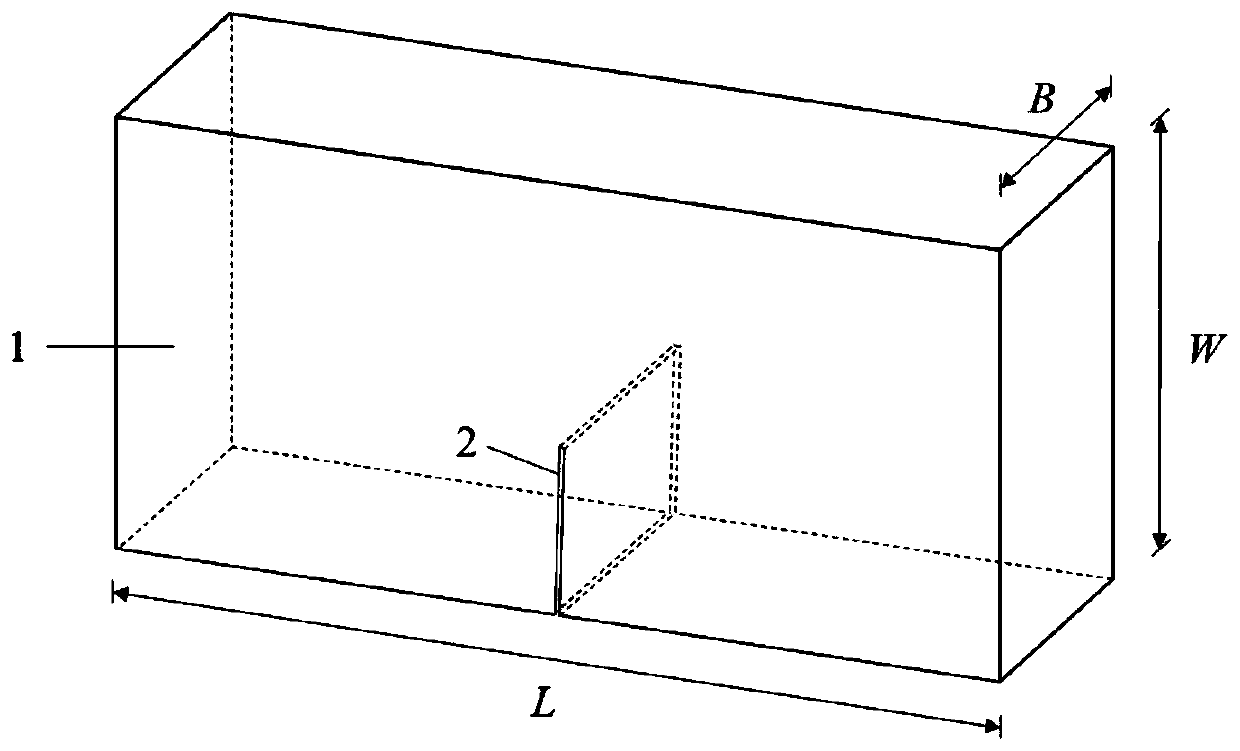

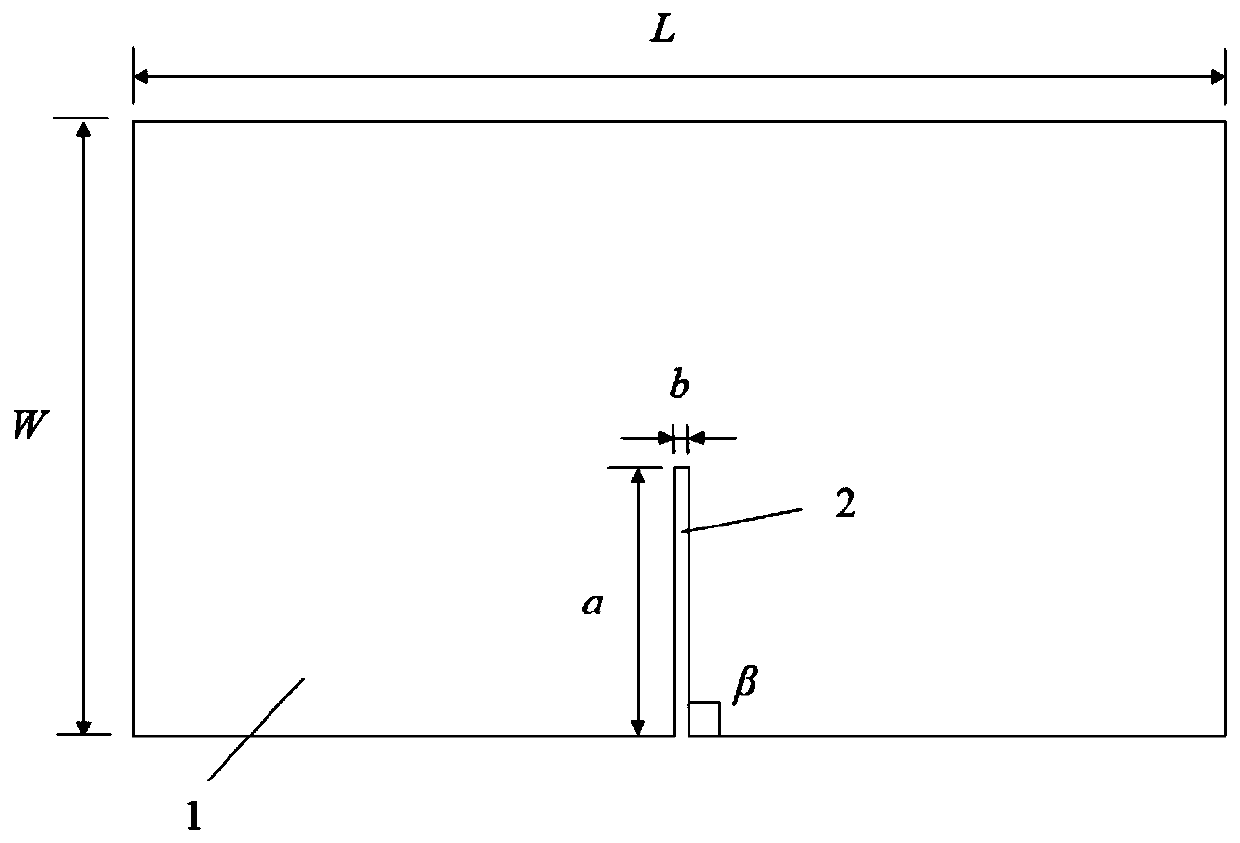

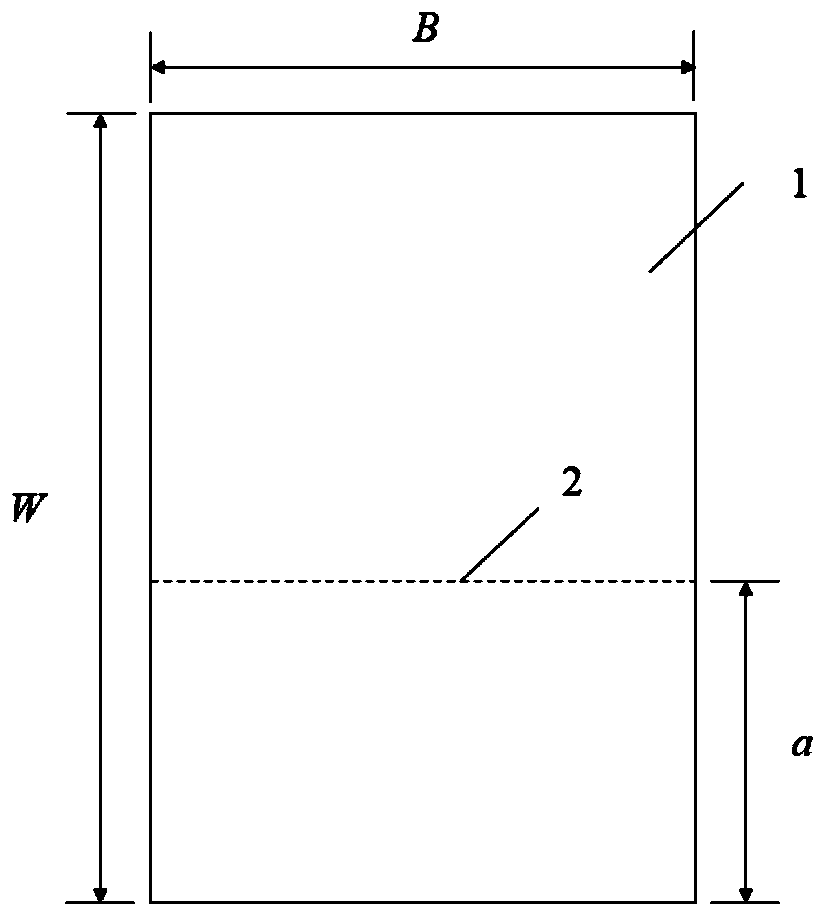

The invention provides a method for testing rock composite fracture toughness based on asymmetric three-point bending loading of an NDB sample, and the method comprises the steps: enabling a test piece body to be a rectangular deep beam (NDB) with a cutting groove, enabling the shape of the test piece body to be a cuboid, prefabricating a cutting groove with the height of a in the middle cross section of the body, extending towards the thickness direction of the body, and penetrating through the front and rear end faces in the body thickness direction; wherein the length L of the test piece body is twice the width W of the test piece body, and the thickness B is not less than 0.8 W. Based on the NDB sample, the invention provides a method for carrying out rock purity type I, rock purity type II and rock purity type I-II composite fracture toughness testing by using asymmetric three-point bending loading, and application of tension and shear load is realized through asymmetric loading.The NDB sample used in the invention has a simple structure and is easy to process by using rock blocks. A clamp used for loading is a common three-point bending clamp, only asymmetric arrangement ofthe supports is needed, experiment loading is quite convenient, and the pure I type, the pure II type and the I-II-type composite fracture toughness of the whole composite loading interval can be achieved.

Owner:SICHUAN UNIV

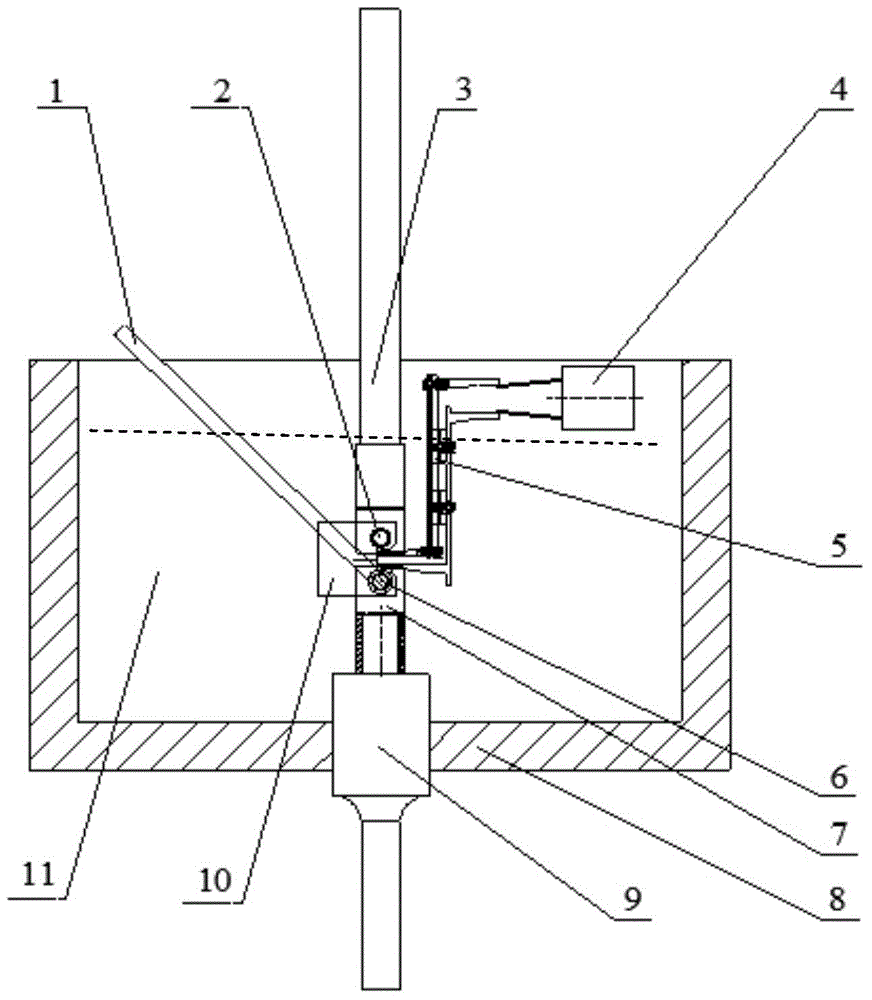

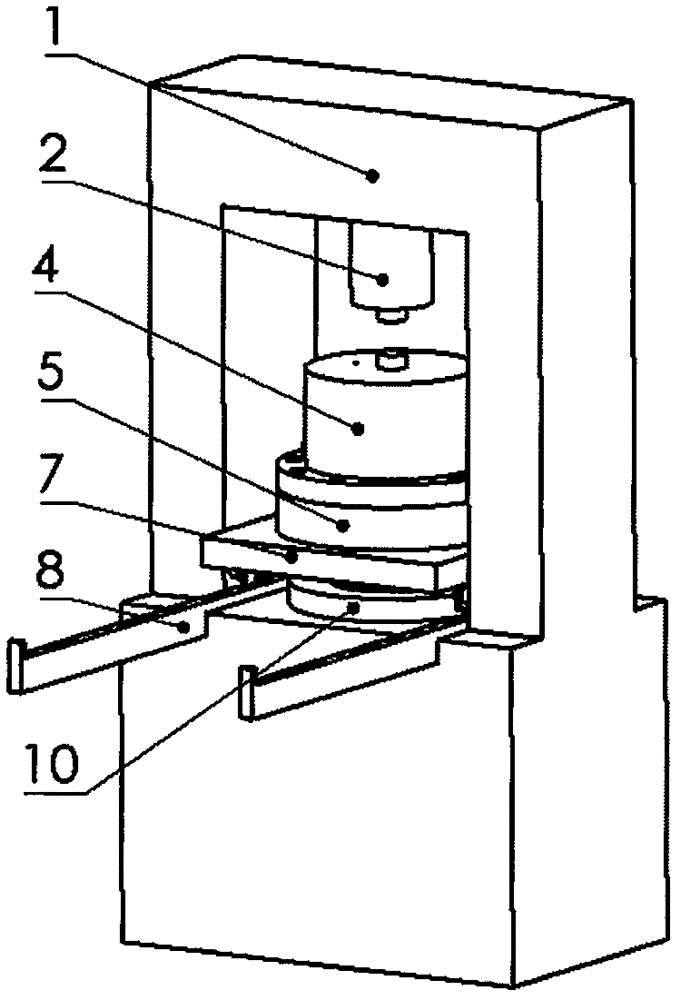

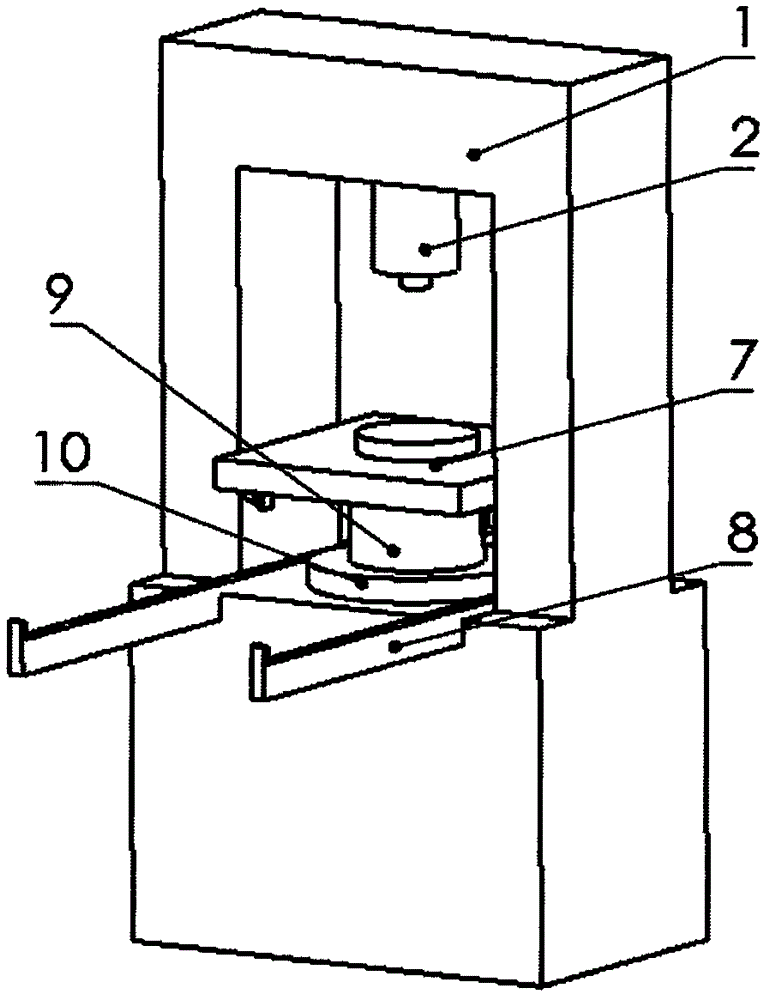

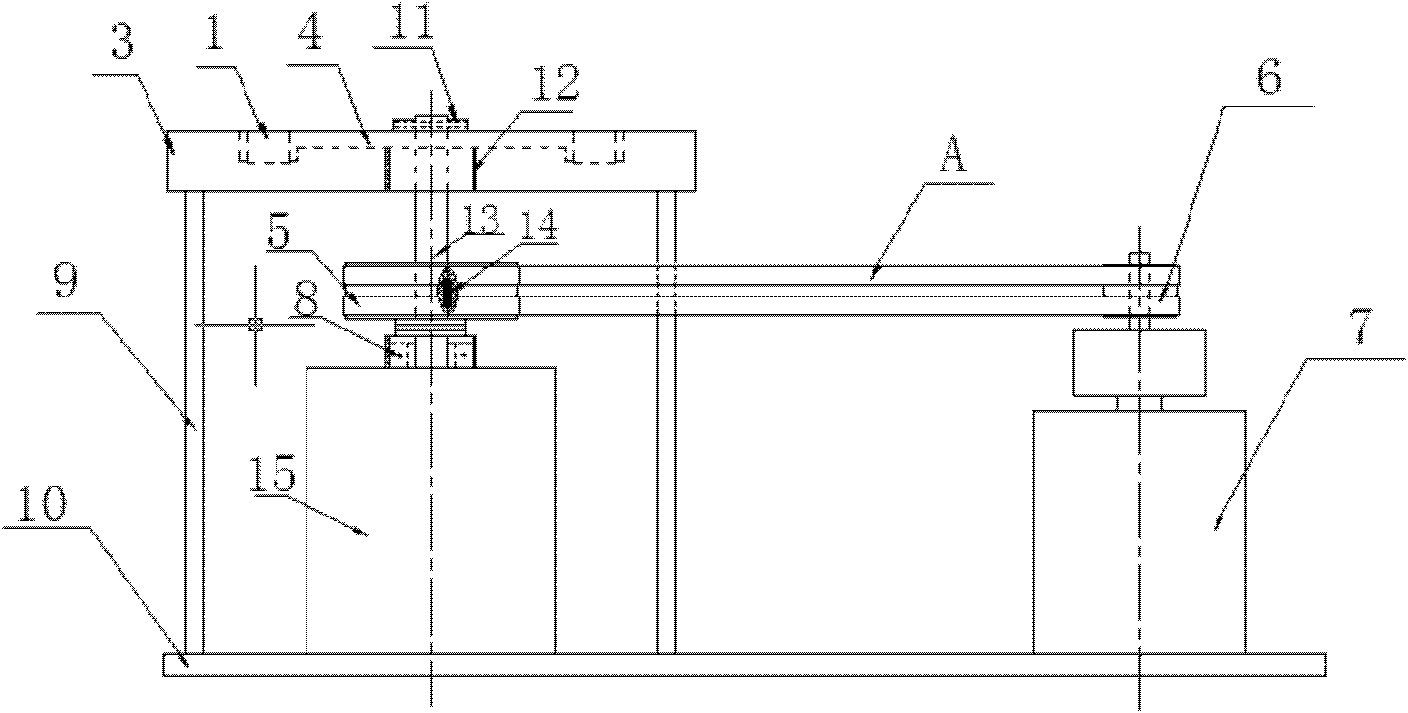

Experimental device for testing fracture toughness of rocks under pore pressure condition

ActiveCN106644740AFracture toughness is accurateThe result is accurateMaterial strength using tensile/compressive forcesHydraulic cylinderArtificial materials

The invention relates to an experimental device for testing fracture toughness of rocks under a pore pressure condition. The experimental device comprises a testing machine, a confining pressure cavity and a clamping clamp. The testing machine comprises a testing machine rigid frame, a rigid frame pressing head, a trolley, a sliding rail, a hydraulic shaft and a hydraulic cylinder; the confining pressure cavity comprises a confining pressure barrel pressing head, a confining pressure barrel, a confining pressure barrel base and a positioning rod; the clamping clamp comprises a clamping base, a stand column, a supporting plate, a supporting roller, a pore pressure end socket, a compaction part, an upper cover plate, a clamp pressing head, an upper ring, a fixed bolt, a probe and a lower plate. The experimental device is simple in structure, convenient to operate and high in practicability, can be used for carrying out a fracture toughness test on rock materials and artificial materials under confining pressure-containing, high-temperature and pore pressure-containing conditions; an obtained result is more accurate, and accurate fracture toughness parameters are provided for calculation of hydraulic fracture models of oilfields and research institutes.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for the interlayer interface fracture toughness of ballastless track

InactiveCN111189694AOvercome limitationsPreparing sample for investigationMaterial strength using tensile/compressive forcesMeasuring instrumentTrackway

The invention relates to a method for testing the interlayer interface fracture toughness of a ballastless track. The method comprises the following steps: (1) manufacturing a concrete test block of adouble-layer concrete layer structure containing interlayer cracks; (2) mounting the concrete test block on a testing machine, and mounting at least one of a displacement sensor, a strain gauge and the like, pre-pulling the concrete test block, and the pre-pulling load being a failure load with the value range of (0-20%); (3) adjusting a measuring instrument, carrying out formal testing, controlling the load speed to be 0.1-1mm / min until the test piece is damaged, and recording the damage load and the fracture position; and (4) processing a test result, and solving the fracture toughness. Thetest result is processed according to a formula, and the toughness of the concrete interlayer crack is calculated and is accurate to 0.1 J / mm < 2 >. According to the method, the fracture toughness ofthe interlayer interface of the ballastless track is measured based on an energy method, the method is suitable for elastoplasticity and different material combinations, and a judgment basis can be provided for the interlayer hydraulic splitting opportunity of the CRTS I-type double-block ballastless track in a tunnel.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

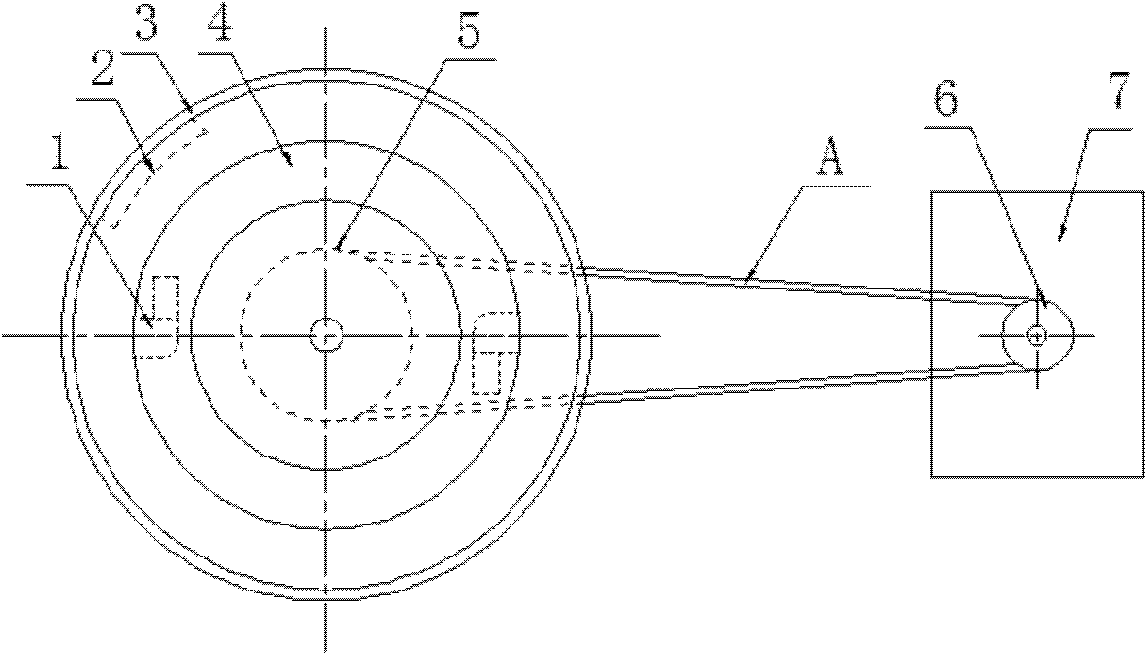

Method and device for simulating multi-rush fracture toughness of well drilling working condition

InactiveCN102305746AThe test results are close toRealistic behavior reflecting dynamic breaksMaterial strength using repeated/pulsating forcesEdge surfaceWell drilling

The invention discloses a method and device for simulating the multi-rush fracture toughness of a well drilling working condition. The invention is characterized in that the rotating characteristics of a rotating body are utilized to cause a test piece fixed at the outer edge of the rotating body to attack a chopping block fixed at the outer edge surface of an adjacent rotating body at a certain period and frequency, thus the aim of carrying out a low-load multi-rush experiment in accordance with vibration characteristics of a drilling column is achieved. In the device, whether a well drilling liquid is injected into a mud groove can be optional in the test, thus the underground environment under the working conditions of a mud drilling well and an air drilling well can be simulated, and the fracture condition of a drilling column material under the underground low-load multi-rush action is truly reflected. The device has a simple structure and low manufacturing cost and can be applicable to testing and studying on multi-rush fracture toughness of the drilling column material.

Owner:SOUTHWEST PETROLEUM UNIV

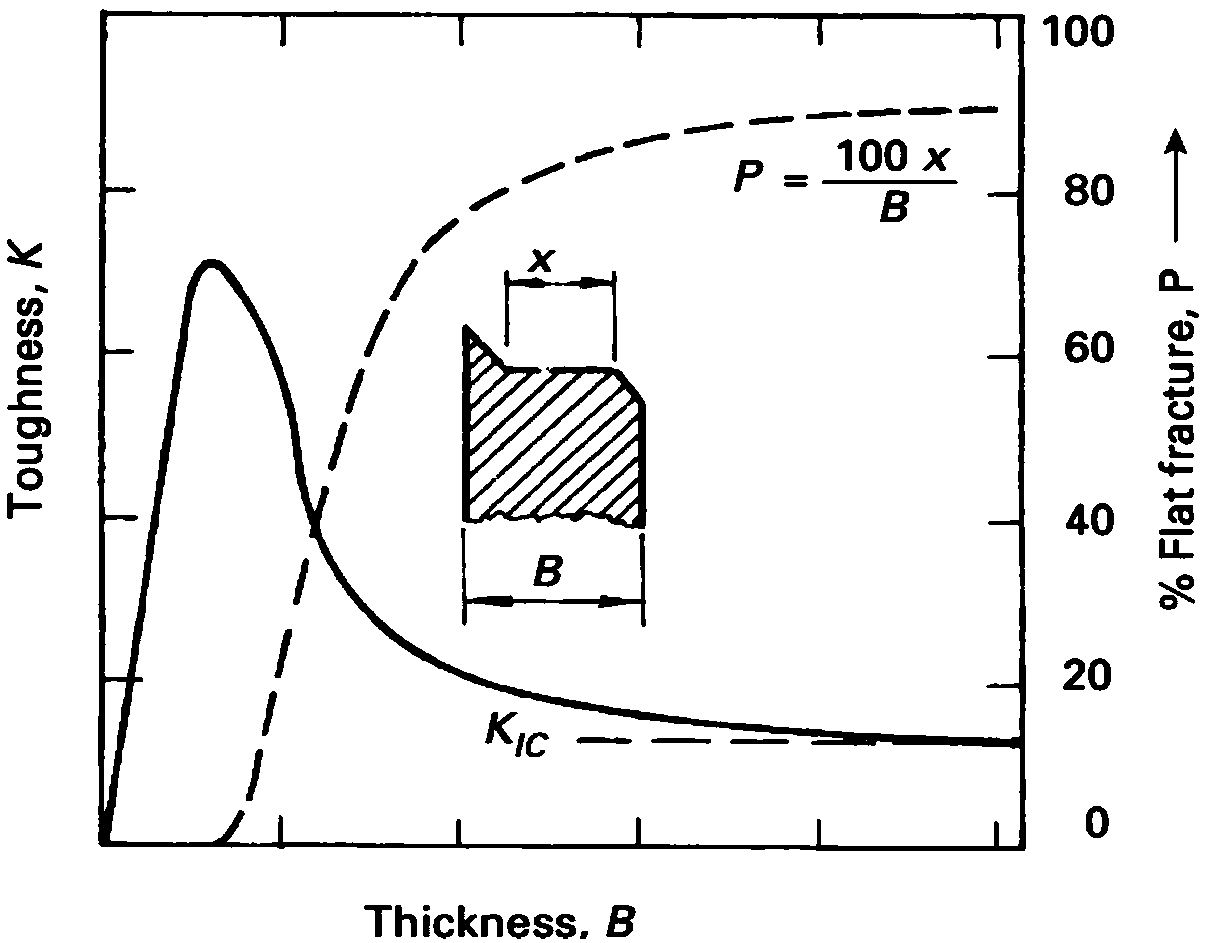

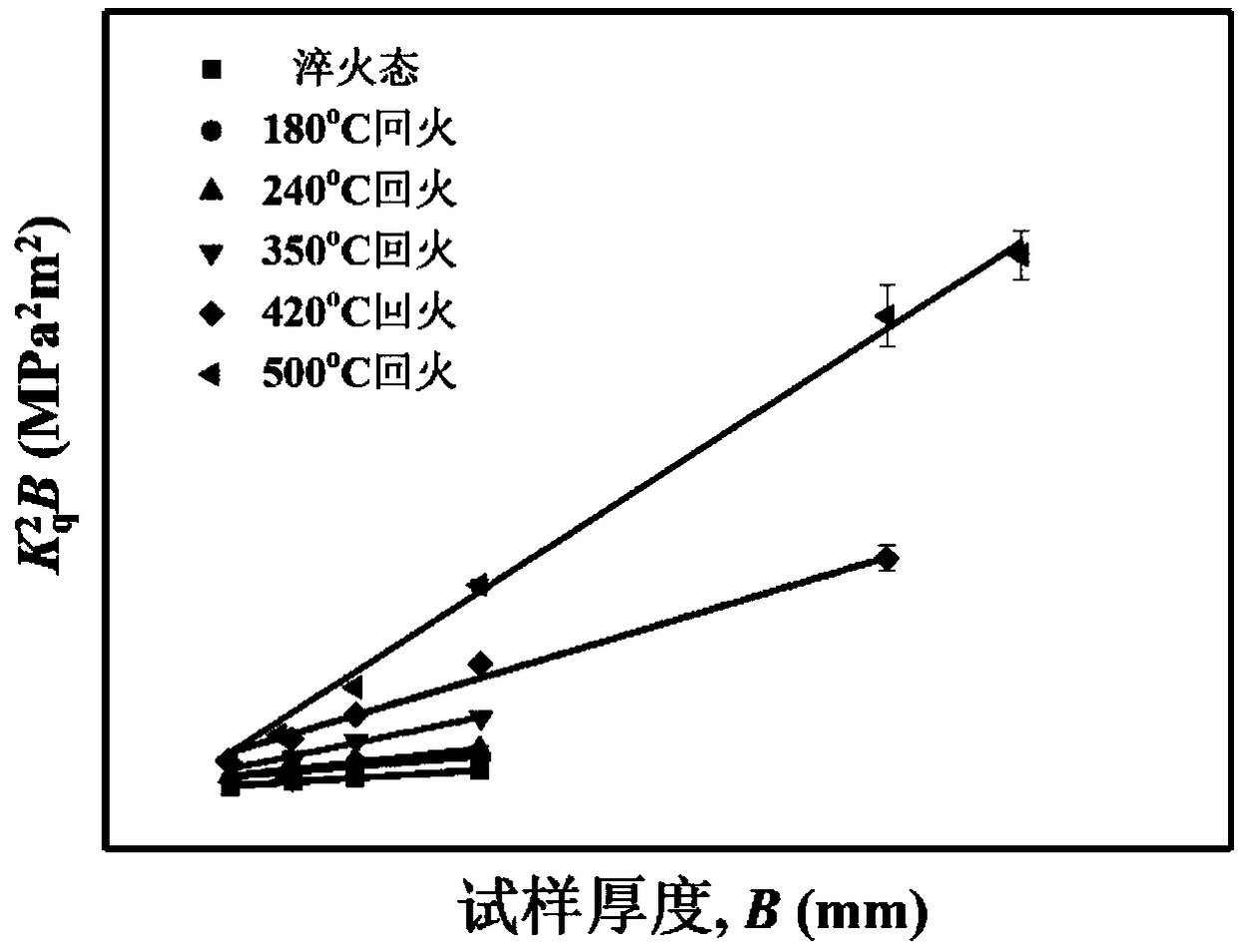

Method for estimating plane-strain fracture toughness of metal material

ActiveCN108844806AEasy to measureSimple and fast estimationForce measurementStrength propertiesAviationSmall sample

The invention discloses a method for estimating plane-strain fracture toughness of a metal material, and belongs to the technical field of fracture toughness of metal materials. The method comprises three steps: performing a fracture toughness experiment on a small sample to obtain an experimental value Kq, performing linear fitting on Kq2B and specimen thickness B and performing accurate calculation through straight line slope to obtain KIC. According to the method, the plane-strain fracture toughness of the material can be measured simply and effectively, so that the experiment cost is greatly reduced; in addition, as the KIC of materials (such as amorphous alloys or nano-metal materials) cannot be measured due to a preparation process or relatively high toughness of the materials, accurate parameters can be provided through the method, so that a strong basis is provided for material selection, and particularly, a theoretical basis is provided for the damage tolerance design of a component of the aviation manufacturing industry.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Sample component and method for nuclear power plant reactor pressure container irradiation inspection test

ActiveCN106644681AOptimal adjustment of loading quantityConsiderable loading spacePreparing sample for investigationMaterial strength using tensile/compressive forcesReduction ratioIrradiated materials

The invention discloses a sample component and method for a nuclear power plant reactor pressure container irradiation inspection test. The component comprises a tensile sample, an impact sample and a compact tensile sample, wherein the tensile sample is used for acquiring the tensile strength, the yield strength, the elongation and the cross section reduction ratio of irradiated materials, the impact sample is used for acquiring impact toughness of the irradiated materials, the compact tensile sample is used for acquiring fracture toughness of the irradiated materials and provided with notches, circular portions and side grooves which are sequentially formed in a first side face and a second side face from top to bottom, and the notch with an isosceles trapezoidal section, the circular portions and the notch with a V-shaped bottom jointly form an extensometer placement space. The method includes the steps of sample preparation, sample loading, sample testing and result evaluation. Arrangement of a bent sample is canceled, the quantity proportion of the other samples is optimized, the shape of the compact tensile sample is optimally improved, and test failure risks in fracture toughness testing are decreased.

Owner:中广核工程有限公司 +1

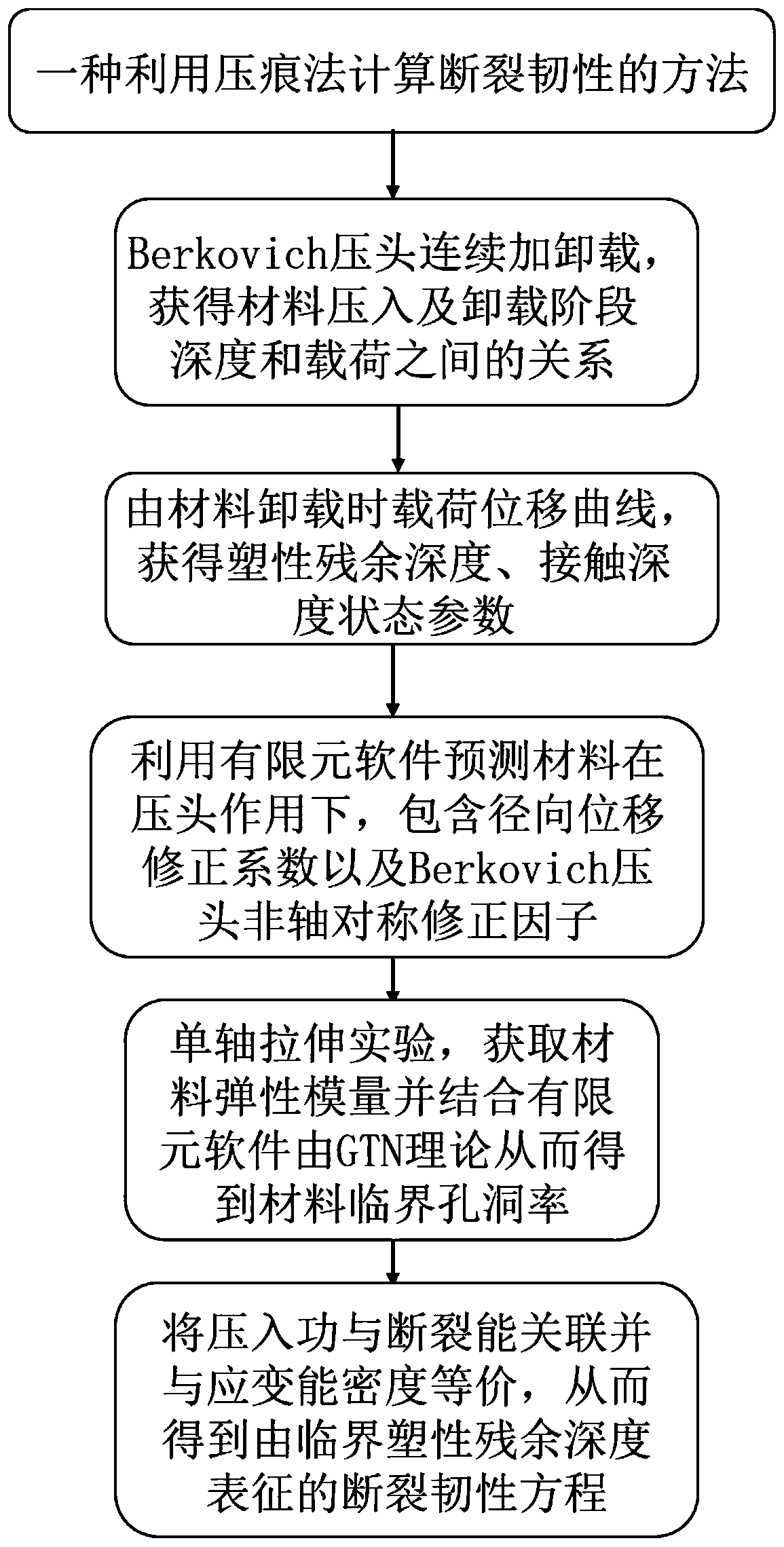

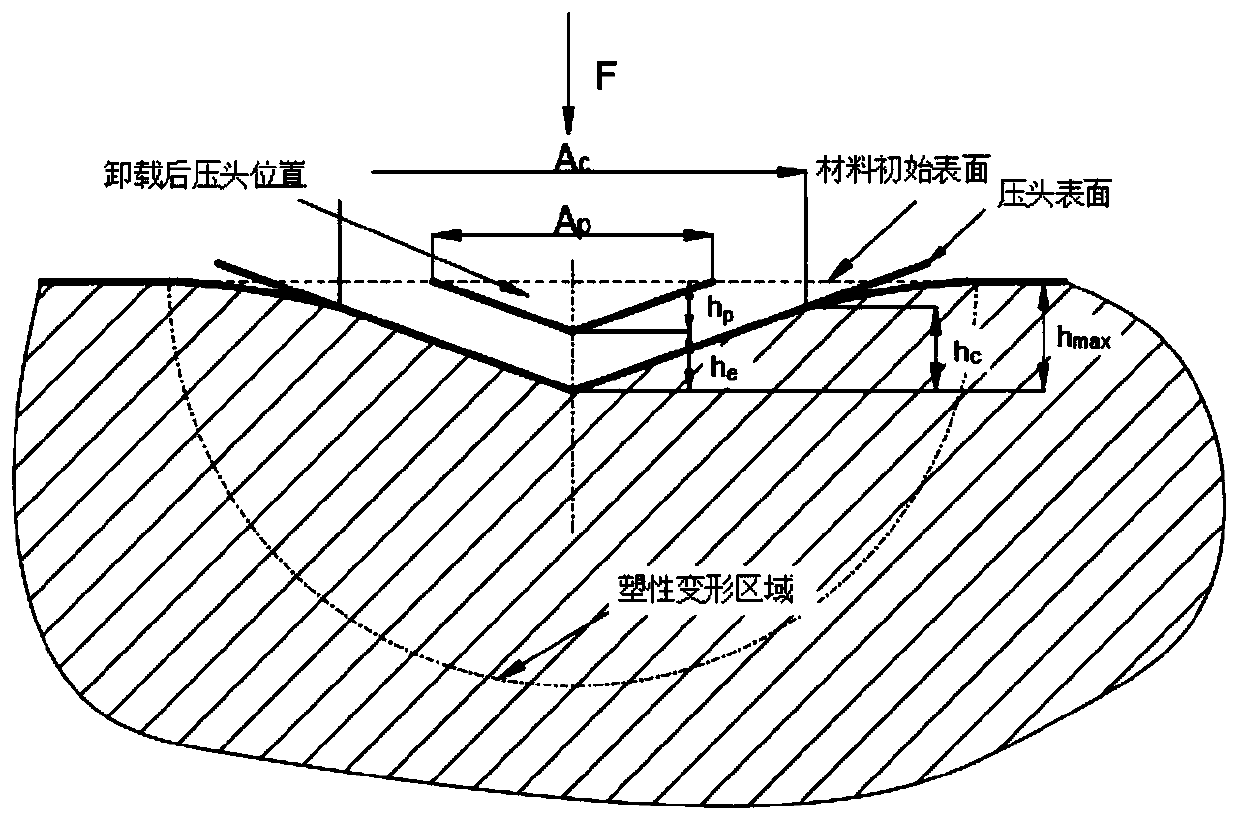

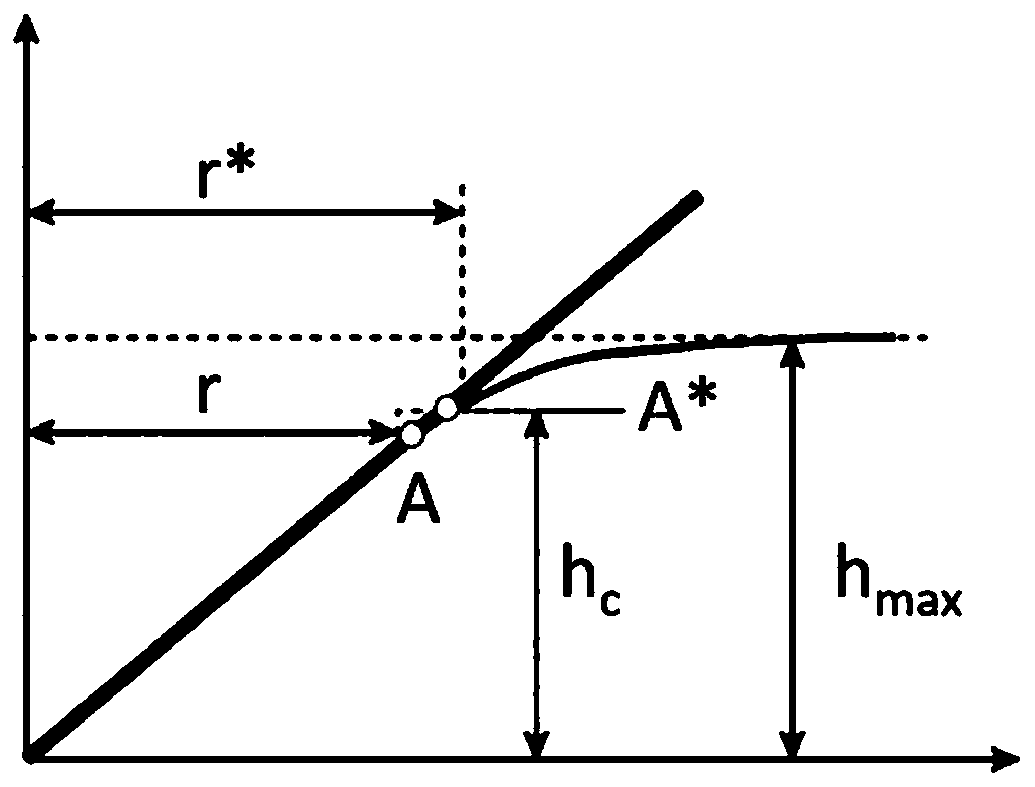

Method for calculating fracture toughness through indentation method

ActiveCN109900554ALow damage fracture toughness valueReduce consumptionMaterial strength using tensile/compressive forcesInvestigating material hardnessState parameterStrain energy

The invention belongs to the technical field of fracture toughness test and provides a method for calculating fracture toughness through an indentation method. The method comprises the following steps: 1) obtaining relationship between depth and load during material pressing-in and unloading stages; 2) obtaining plastic residual depth and contact depth state parameters according to a load-displacement curve during material unloading; 3) predicting a radial displacement correction factor and a Berkovich pressing head non-axisymmetric correction factor of the material under the function of a pressing head by utilizing finite element software; 4) carrying out material uniaxial tension experiment to obtain material elasticity modulus, and obtaining critical hole rate of the material based on the GTN theory with the help of the finite element software; and 5) associating indentation work with fracture energy and carrying out equivalence with strain energy density to obtain a fracture toughness equation characterized by the critical plastic residual depth. The fracture toughness test method can quickly obtain the elastic modulus and the fracture toughness value of the material at low loss through a small-range indentation experiment of the material.

Owner:江苏嘉易安科技有限公司

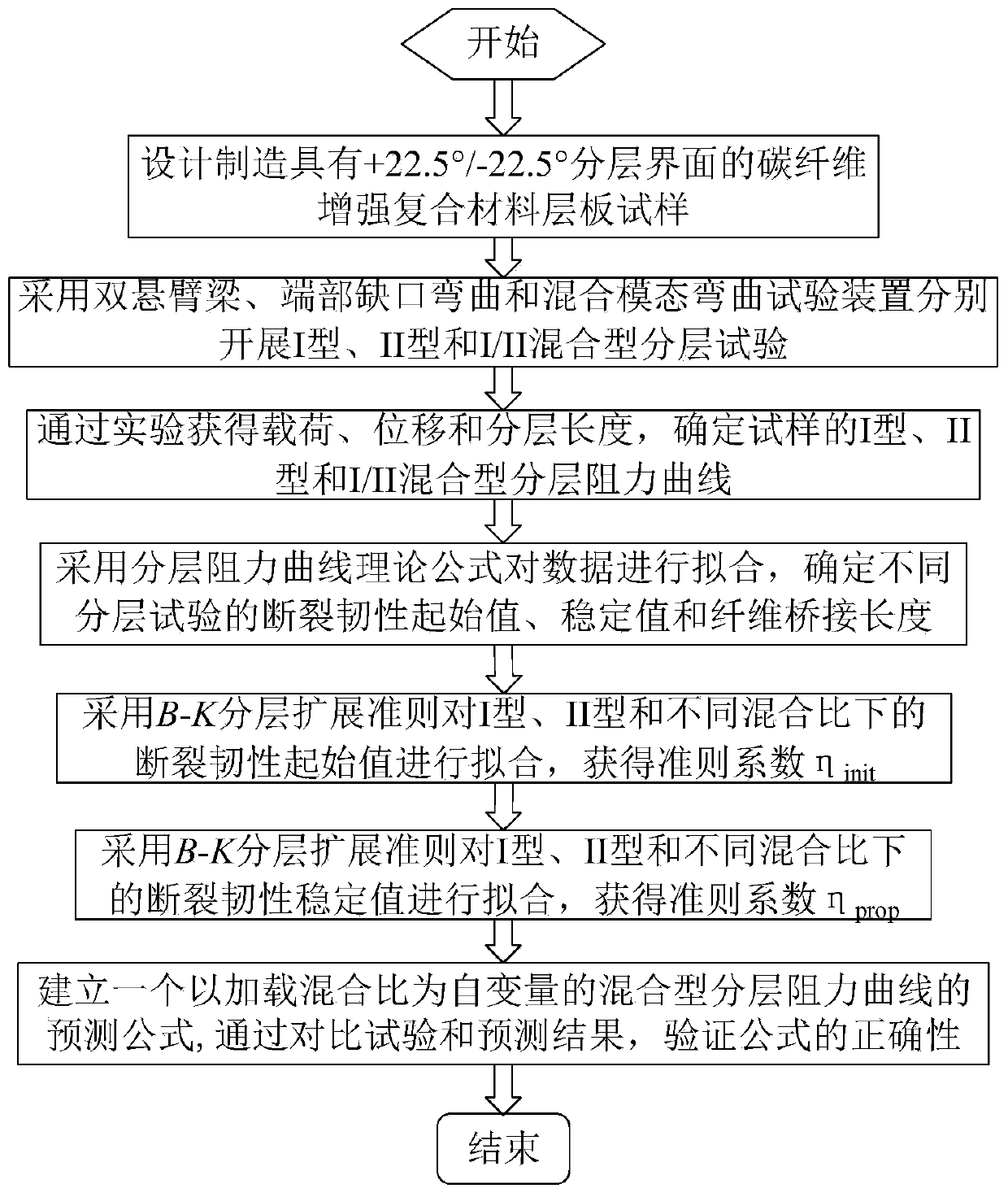

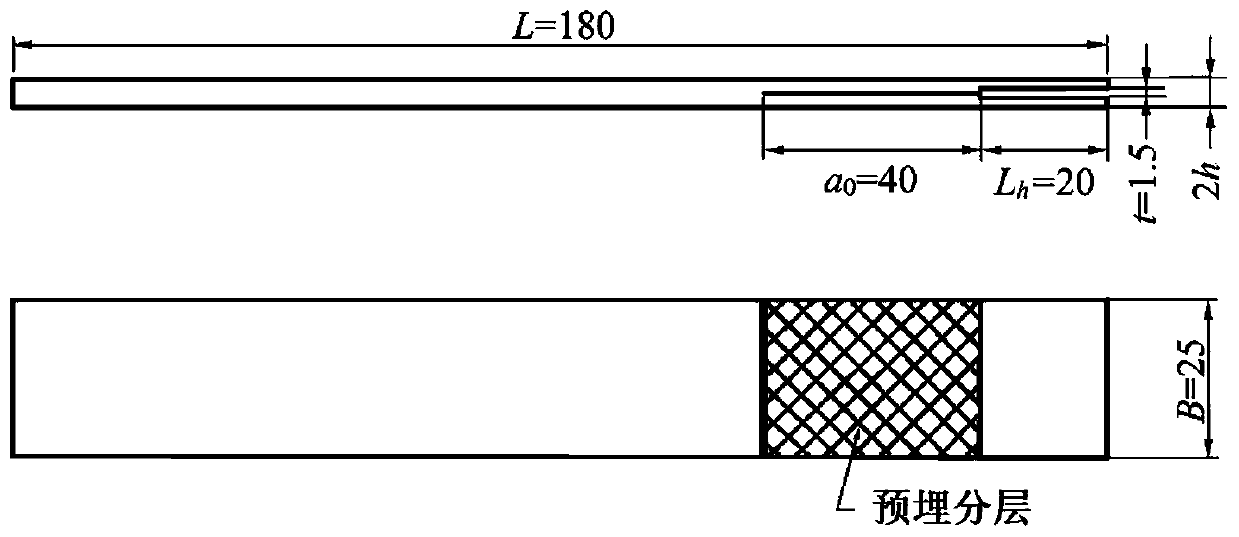

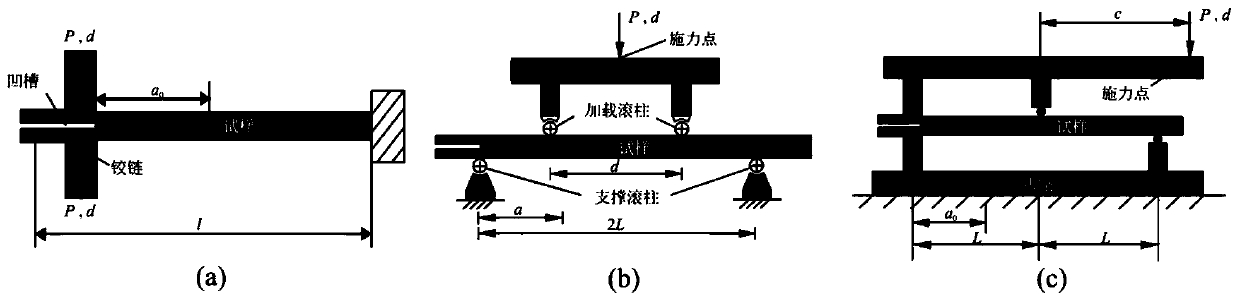

Prediction method for mixed type delamination resistance curve of composite

InactiveCN109991077APromote engineering applicationReduce workloadMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesHybrid typeFiber-reinforced composite

The invention relates to a prediction method for a mixed type delamination resistance curve of a composite. The prediction method comprises the following steps: (1) designing and manufacturing a carbon fiber reinforced composite laminate sample; (2) respectively carrying out an I type delamination experiment, an II type delamination experiment and an I / II mixed type delamination experiment by adopting a double cantilever beam, an end part notch bending device and a mixed mode bending device; (3) determining an I type delamination resistance curve, an II type delamination resistance curve and an I / II mixed type delamination resistance curve of the sample; (4) fitting data by adopting a delamination resistance curve theoretical formula, and determining fracture toughness initial values and stable values as well as fiber bridging lengths of different delamination experiments; (5) respectively fitting the fracture toughness initial values and stable values at different mixing ratios by adopting a B-K criterion, so that criterion coefficients etainit and etaprop are obtained; and (6) establishing a mixed type delamination resistance curve prediction formula with a loading mixing ratio as an independent variable. The prediction method provided by the invention predicts a delamination resistance curve at any other mixing ratio by virtue of delamination fracture toughness testing on acarbon fiber reinforced composite laminate at a specific mixing ratio, is convenient for engineering application and can reduce experimental cost.

Owner:CHONGQING UNIV

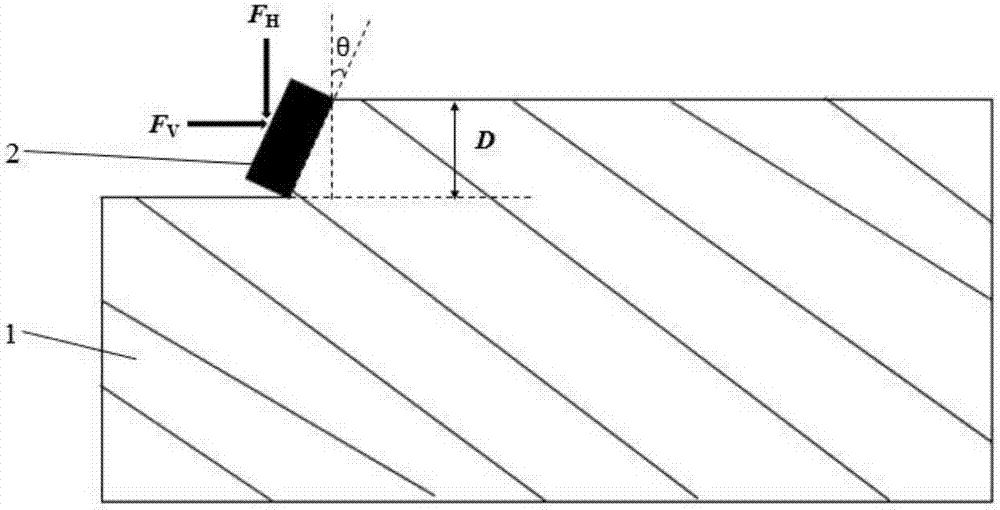

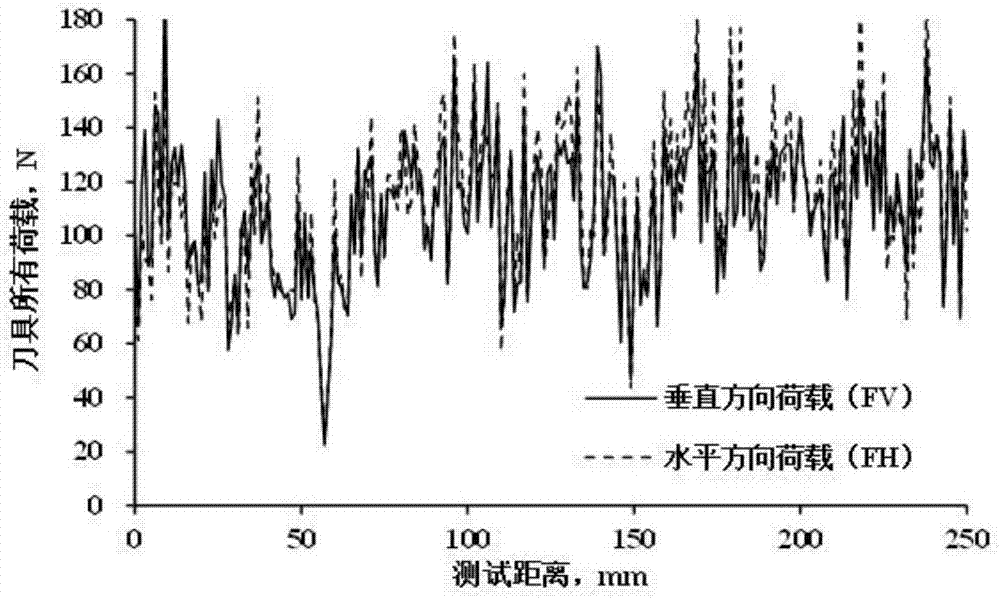

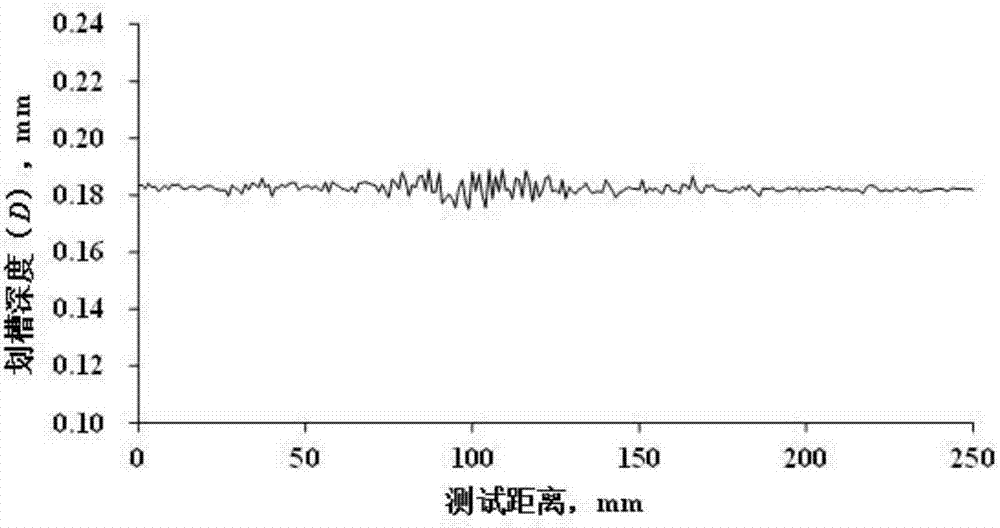

Method for calculating fracture toughness of shale based on scratch experiment

InactiveCN107063905ADoes not affect other test analysisReduce the difficulty of sample preparationPreparing sample for investigationInvestigating material hardnessExperimental testingRock core

The invention discloses a method for calculating fracture toughness of shale based on scratch experiment. The method is characterized by monitoring loads in horizontal and vertical directions of a cutter in a scratch experiment process and the depth of a scratch groove on the surface of a rock core, substituting the loads and the depth of the scratch groove on the surface of the rock core into a shale fracture toughness calculation model, and calculating the fracture toughness of the shale. Compared with the existing rock fracture toughness experiment test method, the method has the following advantages: (1) the rock core is low in sample preparation difficulty, and the test analysis process is fast and concise; (2) only the shallow surface of the rock core is broken in the test process; the subsequent application is not influenced, and the consumption of the rock core is low; and (3) the tested rock core is large in size and characterization dimension, randomness and discreteness of test results can be greatly reduced, and a fracture toughness curve profile continuous in the long axis direction of the rock core can be obtained. The fracture toughness testing method can provide more effective experiment support for shale gas well fracturing process design and is a worthily-popularized experiment test method of fracture toughness of the shale.

Owner:SOUTHWEST PETROLEUM UNIV

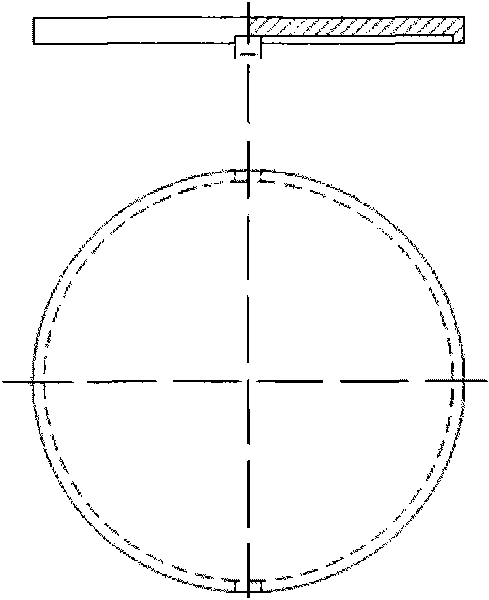

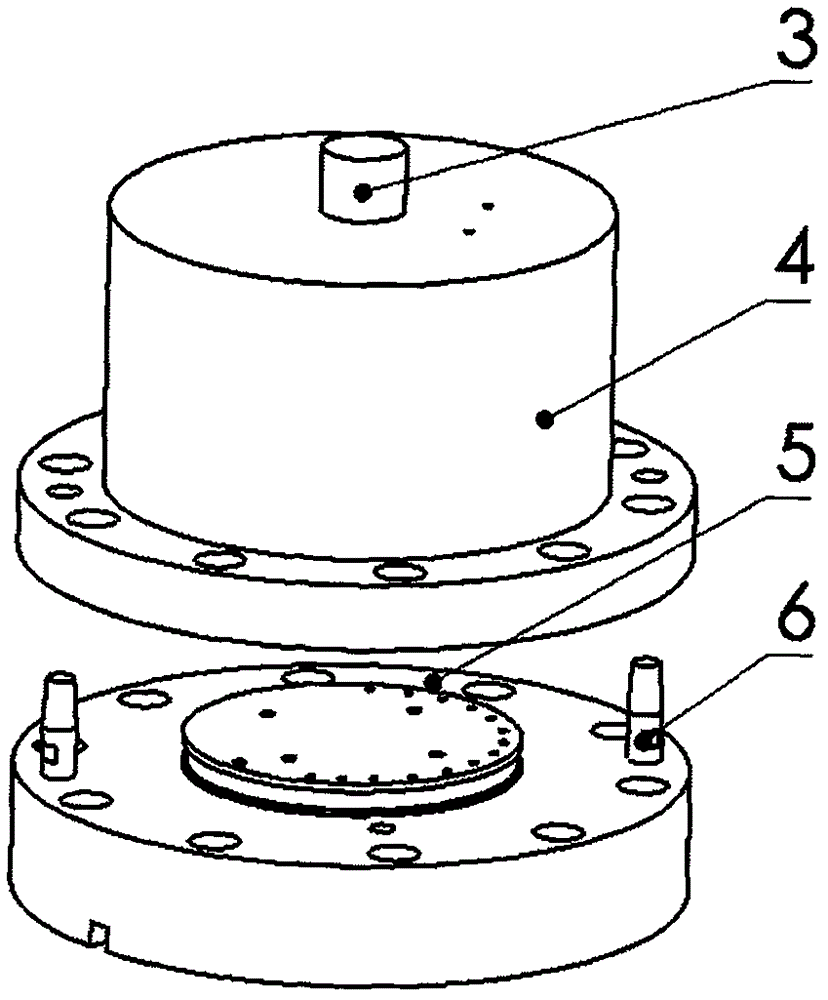

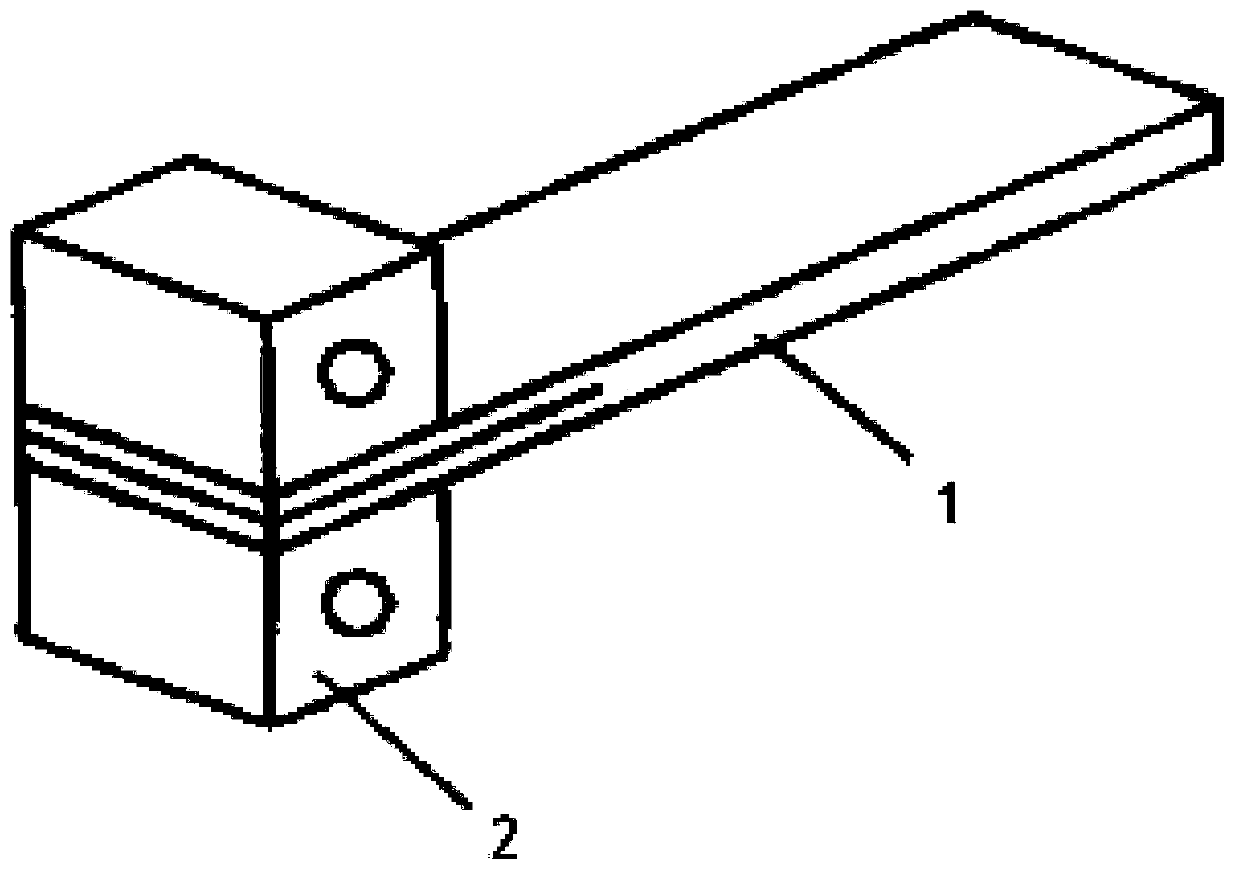

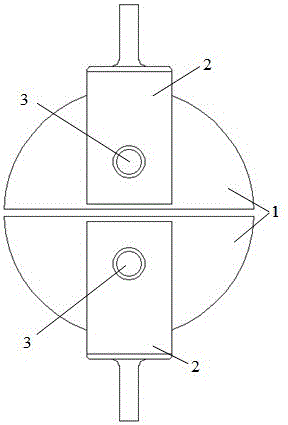

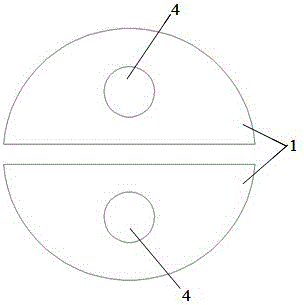

Device and test method for testing circumferential fracture toughness of thin-wall pipe

InactiveCN106053232AAccurate hoop fracture toughnessAvoid Specimen DefectsMaterial strength using tensile/compressive forcesDirect testTensile testing

The invention discloses a device and test method for testing circumferential fracture toughness of a thin-wall pipe. The device comprises a disc-shaped clamping device, two connecting devices and fixing pins for fixing the clamping device and the connecting devices; the clamping device is divided into two semicircular slices with different sizes, and fixing holes are formed in both of the semicircular slices; each connecting device comprises a connecting handle and a Pi-shaped connector, the connecting handle is fixed with the center of a cross beam of the connector, and pin holes are formed in both of two side walls of the connector. The method comprises the following steps of: (i) measuring the size of the thin-wall pipe; (ii) mounting the device; (iii) prefabricating cracks;(iv) testing the circumferential fracture toughness; and (v) calculating the circumferential fracture toughness. According to the invention, annular specimen cracks are prefabricated without loss, the fracture toughness is tested through a simple tension test to avoid specimen defects brought about in a specimen bending process, and the circumferential fracture toughness of the thin-wall metal pipe can be accurately and directly tested.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

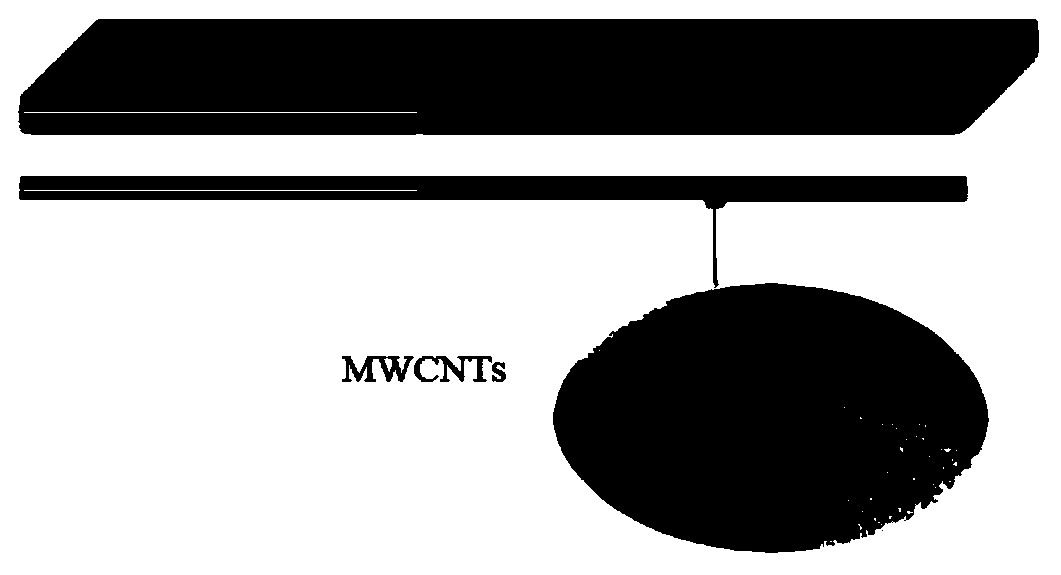

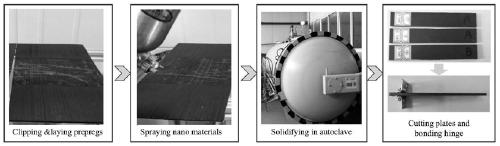

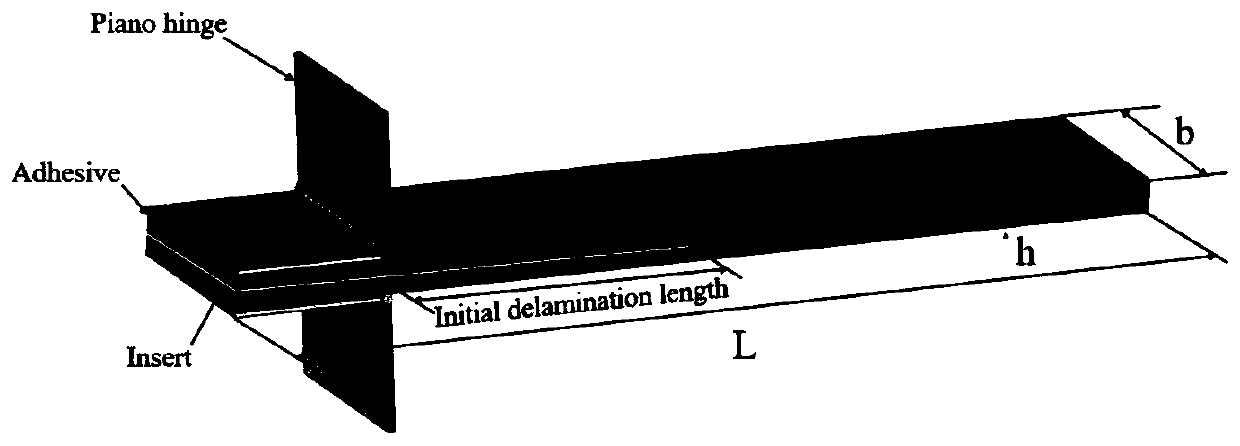

Method for toughening composite interlayers by using multiwalled carbon nanotubes

The invention belongs to the fields of preparation and mechanical properties of carbon fiber / resin-based laminated composite materials, and relates to a method for toughening composite interlayers byusing multiwalled carbon nanotubes (MWCNTs). The method comprises the steps that the multiwalled carbon nanotubes low in cost are used as a toughening material for the composite prepreg interlayers, after cutting of prepreg is completed, the multiwalled carbon nanotubes are quantitatively put into acetone or ethyl alcohol liquid in proportion, fully dispersed through ultrasonic waves and uniformlysprayed to the surface of each layer of the prepreg by using an air pressure gun, after the acetone or the ethyl alcohol is completely volatilized, the prepreg is laid and then fed into a hot-press tank for heating and pressurizing solidification, and finally, the prepreg is cut into DCB and ENF standard samples for I and II fracture toughness testing. The testing results show that when the spraying surface density is 1 g / m<2>, GIC and GIIC of the material are remarkably improved, the interlayer toughness of a composite laminated structure is improved, and the deficiency of the interlayer performance of the laminated composite material is made up for.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

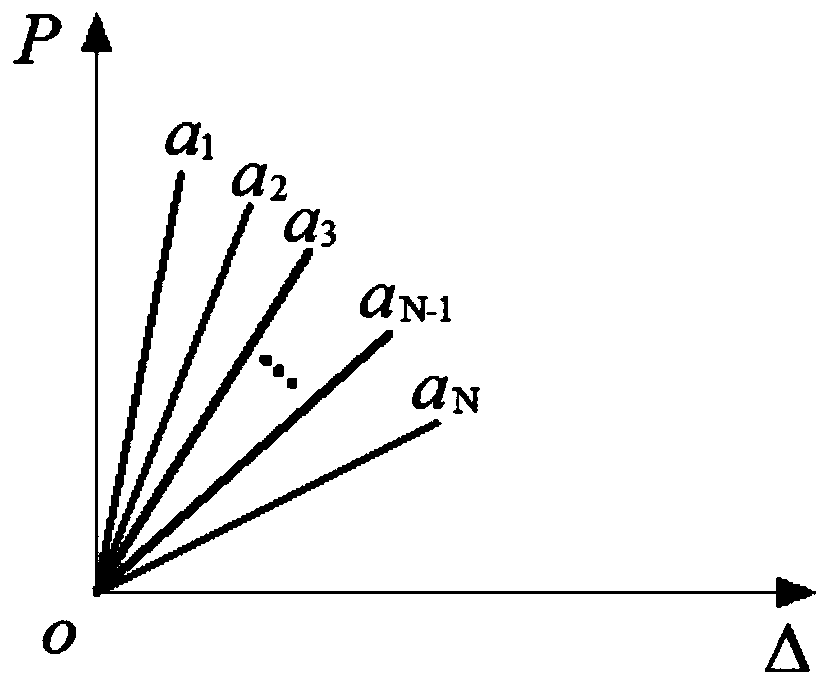

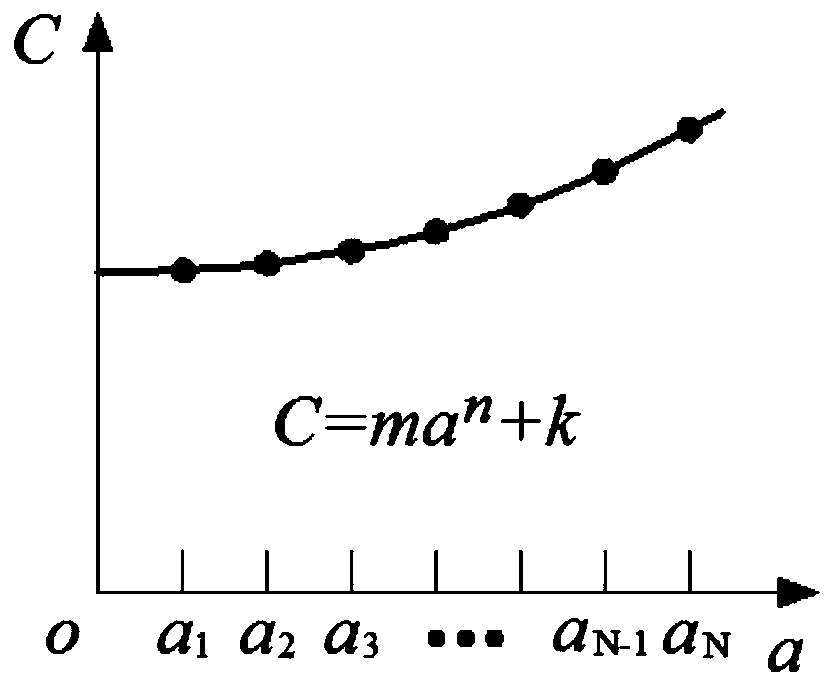

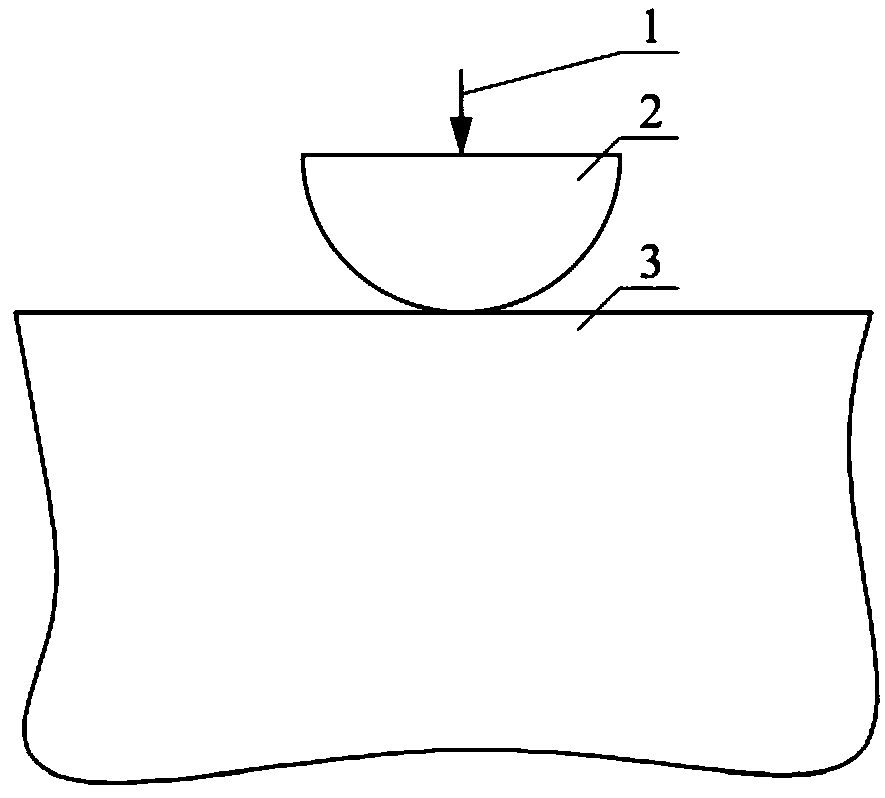

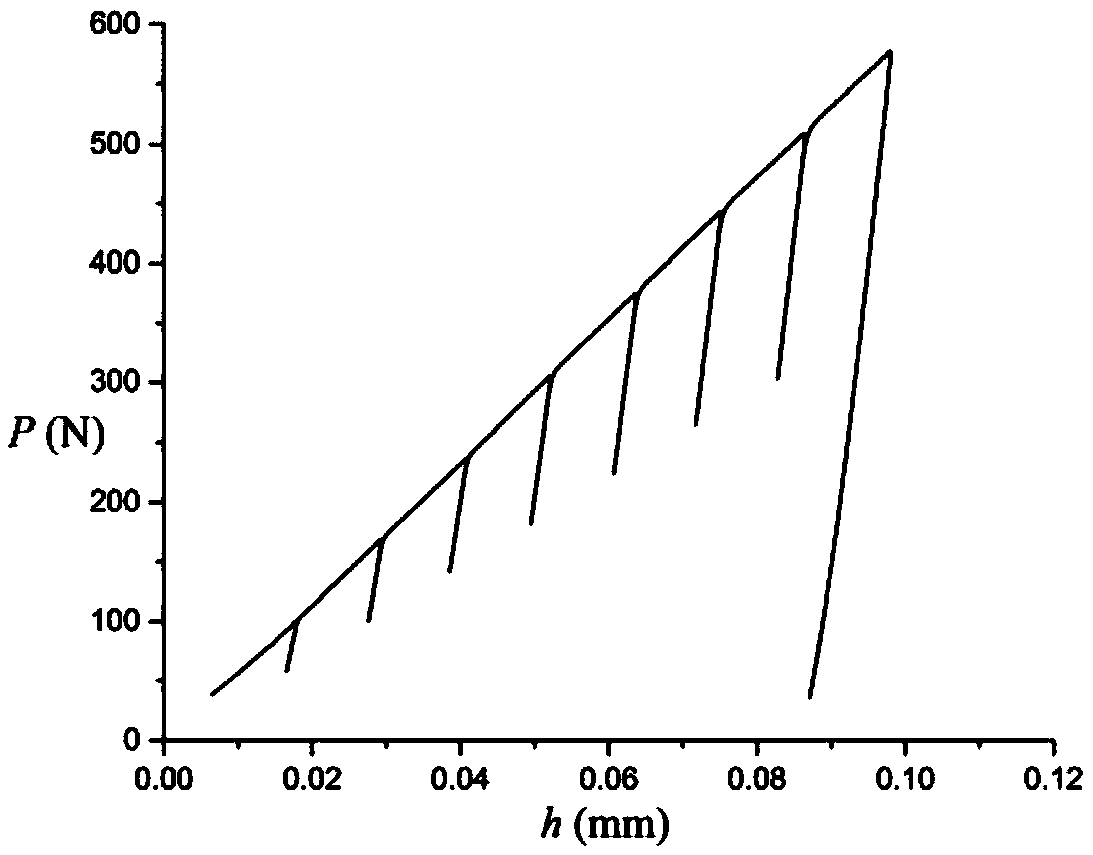

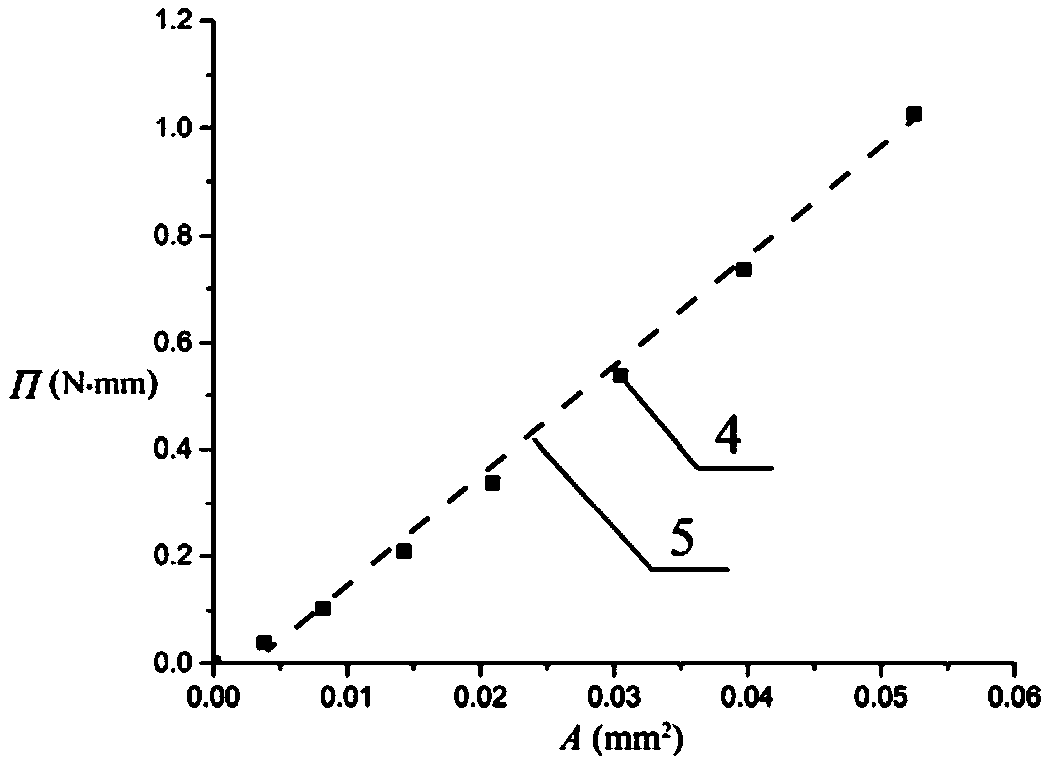

Method for obtaining fracture toughness of material by repeatedly loading and unloading spherical indenter and pressing-in

ActiveCN108982261APromote popularizationEfficient use ofMaterial strength using repeated/pulsating forcesInvestigating material hardnessTest requirementsTest material

The invention relates to the field of materials, in particular to the filed of new methods for testing mechanical property slight damages of service materials, weld materials and new materials, in particular to a method for obtaining fracture toughness of a material by repeatedly loading and unloading a spherical indenter and pressing-in. The method comprises the steps of: using a spherical indenter of hard material, conducting press-in test on the surface of a smoothed tested material through a method of N times of repeatedly loading and unloading to obtain a continuous indentation load P-indentation depth h curve of the tested material, and then acquiring the fracture toughness of the material through application of the method. The method overcomes the deficiencies that an existing spherical indenter press-in test technology requires an extra destructive uniaxial tensile test or relies on certain materials, and the test method is simple, convenient, and accurate, has good universality, and is beneficial to the popularity and application of the spherical indenter press-in test technology. The method for obtaining the fracture toughness of the material by repeatedly loading and unloading the spherical indenter and pressing-in is suitable for occasions that sampling is difficult to perform according to requirements of a conventional fracture toughness test, especially for the deterioration of material properties of bridges, ships, and the like, and the need to discuss the difference of fracture toughness of local materials.

Owner:SHANDONG UNIV

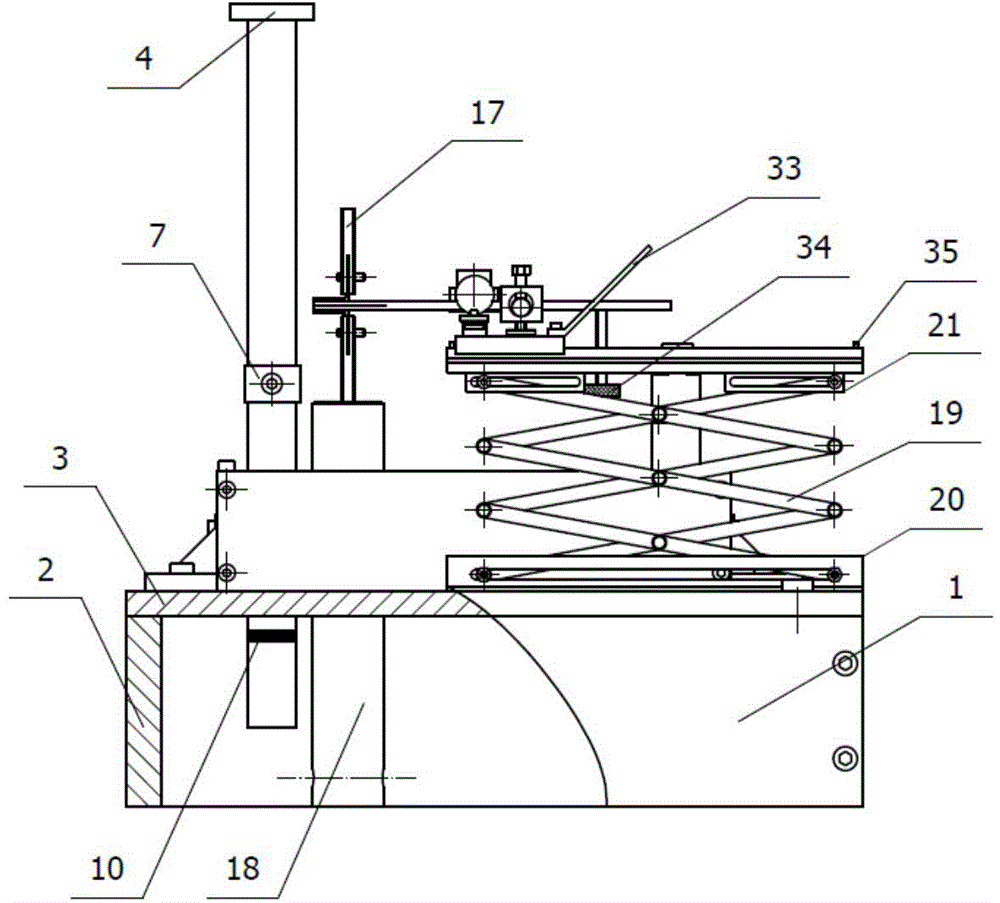

Clamp for testing I type interlayer fracture toughness of composite material

ActiveCN105784468AReduce labor intensityImprove test efficiencyStrength propertiesRepeatabilityUltimate tensile strength

The invention discloses a clamp for testing I type interlayer fracture toughness of a composite material. The clamp can effectively solve the problems that the repetitive operation is too much, the labor strength is large, the test preparation time is long, and thus operators may get fatigue easily. The clamp is made of a base, a transmission device, a clamping device, and an observation platform. The clamp is characterized in that the observation platform and a sample can be elevated synchronously; an observation device and an illumination device can be arranged; the extension situation of cracks in the front side and the rear side can be observed at the same time, and the end portions of the sample can be supported during the whole process.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for determining fracture toughness and tensile strength of brittle material through two-point loading test piece

ActiveCN105865896ALoose detection conditionsOvercome resiliencePreparing sample for investigationStrength propertiesRegression analysisUltimate tensile strength

The invention discloses a method for determining the facture toughness and the tensile strength of a brittle material through a two-point loading test piece. The method comprises the following steps: preparing a test piece, cutting a crack, performing two-point static force loading, recording peak load, calculating nominal strength sigma n, calculating an equivalent crack length ae, and the like; finally, performing regression analysis and simultaneously obtaining the tensile strength ft and the fracture toughness KIC of the brittle material. The method disclosed by the invention is simple in form; the test is easy to operate; the accuracy is enough; the result reasonability is easy to judge. The facture toughness KIC and the tensile strength ft of the brittle material can be determined at the same time by the peak load of a small-sized two-point loaded test piece which is loaded at two points.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

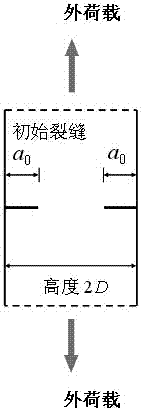

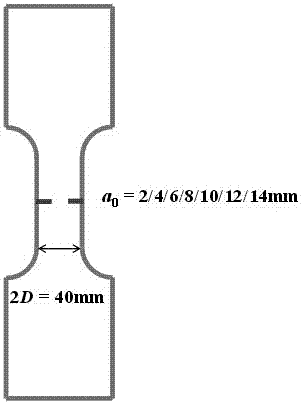

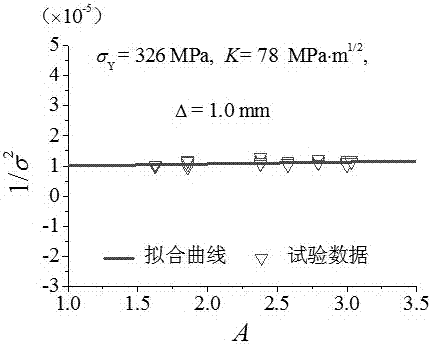

Method for determining fracture toughness and strength by using double-cut small-sized specimens

ActiveCN107121337AEasy to judge the rationality of the resultsImprove stabilityMaterial strength using tensile/compressive forcesRegression analysisUltimate tensile strength

The invention discloses a method for determining fracture toughness and strength by using double-cut small-sized specimens. The method comprises the following steps: pouring the specimens, cutting out cracks, loading a static force, recording the peak loads, calculating the nominal strengths sigman, calculating geometric parameters A of the specimens, and finally performing regression analysis to obtain the fracture toughness K and the tensile strength f of a material without a size effect. Based on an idea of progressive extrapolation as well as theoretical analysis in elastoplastic fracture mechanics, material parameters of infinitely large slab specimens (the material parameters of the infinitely large slabs have no size effect) are extrapolated from experimental data of finite-size specimens, so that the fracture toughness and the strength of the material without the size effect can be determined only according to the key loads F of the small-sized specimens; strict current domestic and foreign specifications on the sizes and the types of the specimens, loading conditions and the like are not required to be met, and the stability of the double-sided tensile specimens is better than that of the single-sided tensile specimens, so that operation is easier.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

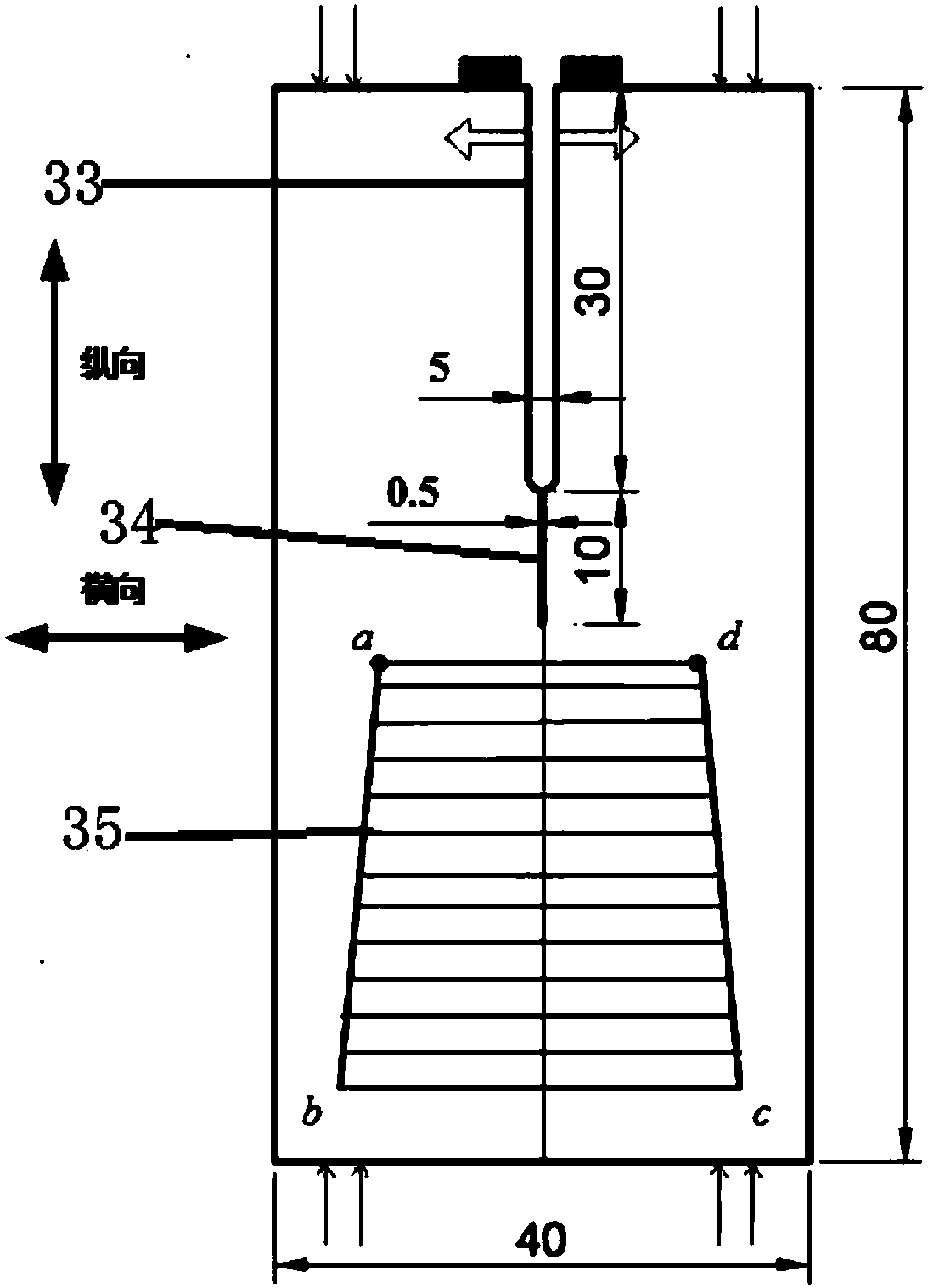

DCB (double-cantilever beam) fracture toughness testing device

ActiveCN108303314AEasy to operateSimple structurePreparing sample for investigationMaterial strength using tensile/compressive forcesPressure transmissionCollection system

The invention discloses a DCB (double-cantilever beam) fracture toughness testing device. The device comprises a mechanical transmission system, an electronic collection system and a data terminal processing system, wherein the electronic collection system is connected with the mechanical transmission system and the data terminal processing system; the mechanical transmission system comprises a sample clamping component, a tension transmission mechanism and a pressure transmission mechanism; the electronic collection system comprises a potential data collection card, an LVDT (linear variable differential transformer) displacement sensor, a pressure sensor and a tension sensor; the data terminal processing system is used for processing, filtering and sampling the collected data. The DCB fracture toughness testing device is simple, easy to understand and convenient to operate, a test result is accurate, data such as extension speed, cracking displacement, extension length and the like ofa type I fracture can be recorded and measured effectively, and a method foundation is provided for design research of rock fracture toughness.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Slotting cutter, equipment and slotting method for testing fracture toughness of graphite material

ActiveCN108453906AImprove reliabilityCalculation of Toughness ParametersPreparing sample for investigationWorking accessoriesNumerical controlGraphite

The invention provides a slotting cutter, equipment and a slotting method for testing fracture toughness of a graphite material. The slotting cutter for testing the fracture toughness of the graphitematerial is included. The slotting cutter for testing the fracture toughness of the graphite material comprises a cutter handle and a blade. The cutter handle is coaxially connected with a main shaftof a numerical control machine tool, and the blade rotates to perform numerical control slotting on a graphite material sample clamped and fixed by a fixture on a worktable instead of manual slotting,the influence of manual slotting on the accuracy of the test results is avoided, the technical problem of inaccuracy, caused by manual slotting, of graphite material fracture toughness testing is solved, the consistency of graphite sample material slotting is ensured, and the testing accuracy of the graphite material sample during fracture toughness testing is improved; and besides the numericalcontrol machine tool drives the specific slotting cutter to perform full-automatic slotting on the graphite material sample, the slotting speed and efficiency of the slotting cutter are far higher than the speed of manual slotting, and the testing efficiency is improved.

Owner:赛迈科先进材料股份有限公司

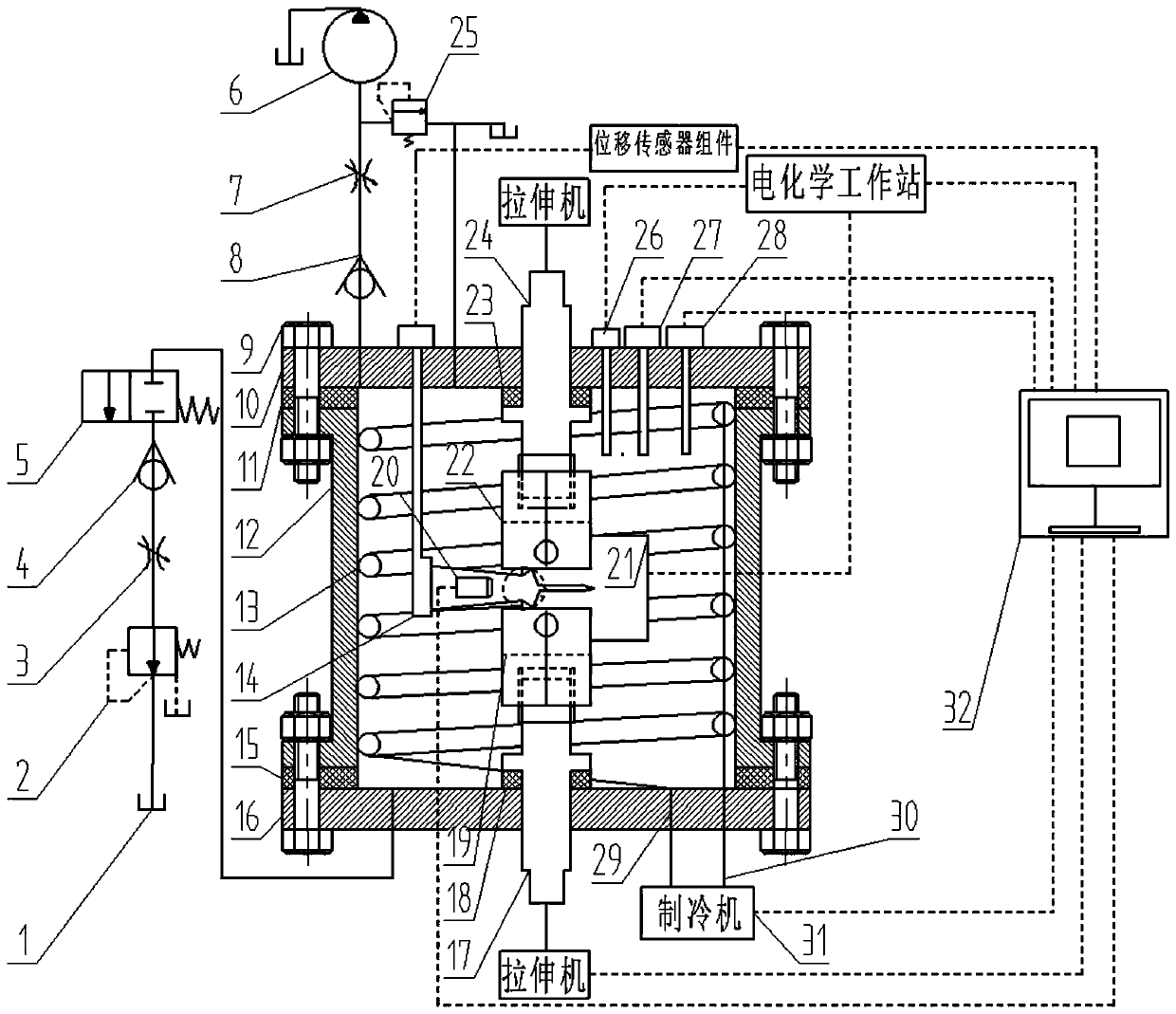

Fracture toughness testing device under low temperature high pressure hydrogen charged environment and method thereof

InactiveCN110018060AAvoid error effectsIncrease authenticityMaterial strength using tensile/compressive forcesElectricityTest sample

The invention provides a fracture toughness testing device under a low temperature high pressure hydrogen charged environment. The device comprises a sealed box body and a tensile device. The tensiledevice is set on the sealed box body. The device also comprises a refrigeration assembly, a liquid pressurization assembly, an electrochemical assembly, a detection assembly and an industrial personalcomputer. The liquid pressurization assembly is used for supplying a high pressure electrolyte solution to the interior of the sealed box body. The refrigeration assembly is used for cooling the electrolyte solution. The electrochemical assembly is used for generating hydrogen on a surface of a tensile test sample. The detection assembly is used for detecting a pressure and a temperature in the sealed box body and an opening crack state of the tensile test sample. The industrial personal computer is used for controlling the refrigeration assembly, the liquid pressurization assembly, the electrochemical assembly and the tensile device through collection and analysis of information of the detection assembly. The device is used for testing fracture toughness under a low temperature high pressure hydrogen rich environment. A relatively systematical and complete testing scheme is formed. A low temperature high pressure hydrogen rich deep sea environment is effectively simulated. Reliability of final testing data is improved.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com