Method for determining fracture toughness and tensile strength of brittle material through two-point loading test piece

A brittle material, fracture toughness technology, applied in the analysis of materials, strength properties, preparation of test samples, etc., can solve the problems of increasing the cost of test sample production and test workload, and difficulty in completing sample preparation and test work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

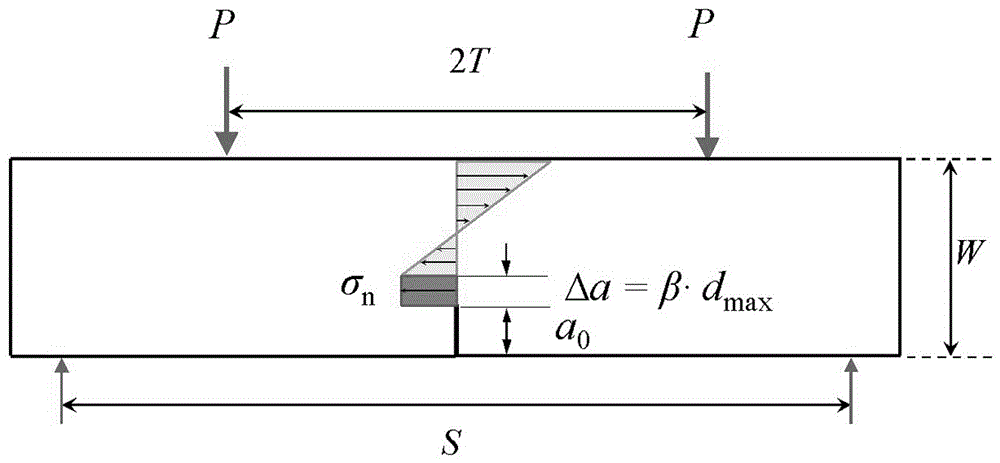

[0040] Example 1: For the concrete specimen of the two-point loading type used in the test of this example, the maximum particle size of the concrete aggregate is d max = 13mm, L × B × W = 806.4 × 152 × 203.2 mm, initial seam height ratio α =a 0 / W=0.30, 0.35, 0.40, 0.45, 0.50, W / d max =15.6.

[0041] see figure 1 , considering that concrete is a quasi-brittle material, the stress distribution at the peak load P is as follows figure 1 As shown, the corresponding crack extension Δa=β·d max . Based on formula (2), the nominal strength σ of each specimen can be calculated from the measured peak load n .

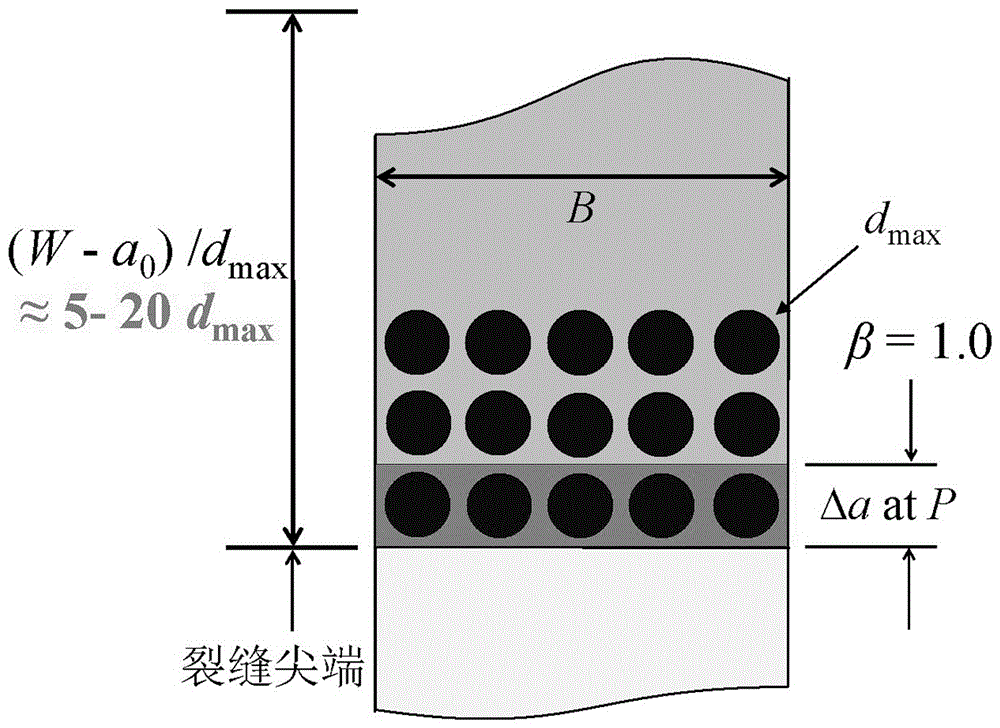

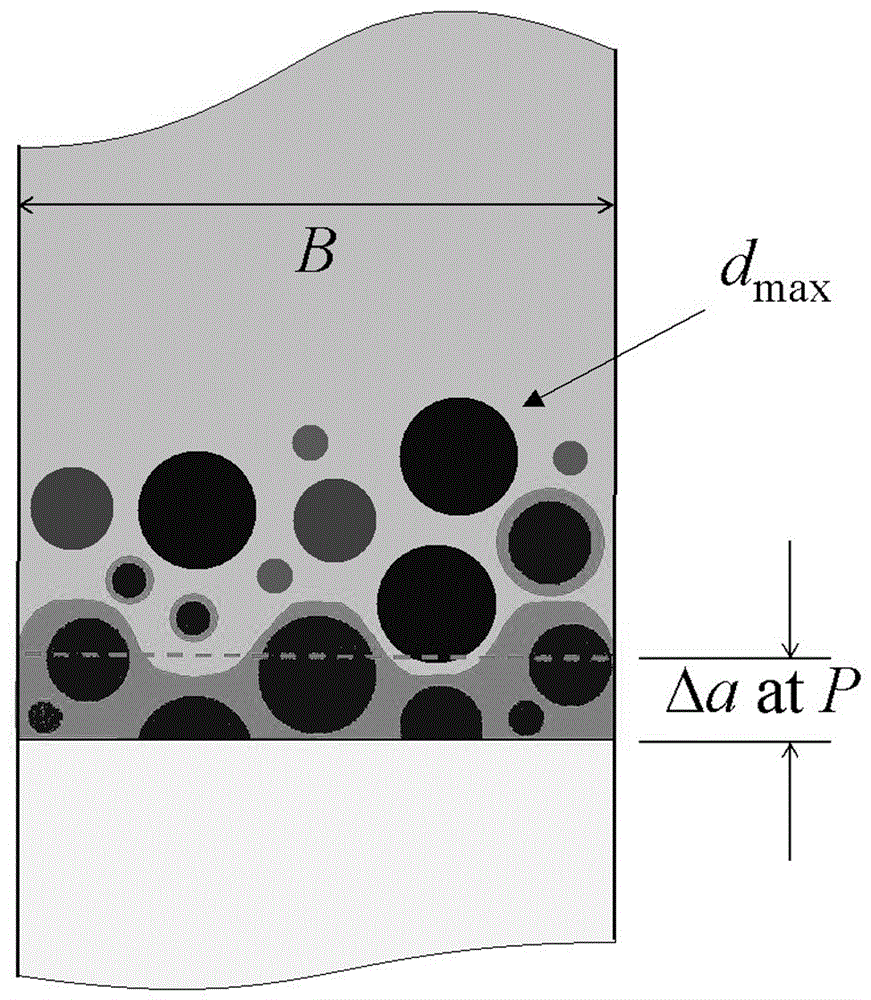

[0042] Considering β=1.0 from a statistical point of view, the average value of the fracture toughness and tensile strength of concrete can be calculated, see figure 2 . Considering the discreteness of the concrete test results and solving it accurately, β=0.2, 0.4, 0.6, 0.8, 1.0, 1.2, 1.4... can be calculated to obtain the exact values of the fracture toughness and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com