Method for estimating plane-strain fracture toughness of metal material

A technology of plane strain and fracture toughness, applied in the analysis of materials, strength characteristics, measuring devices, etc., can solve the problems of large dispersion and achieve the effect of saving experimental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

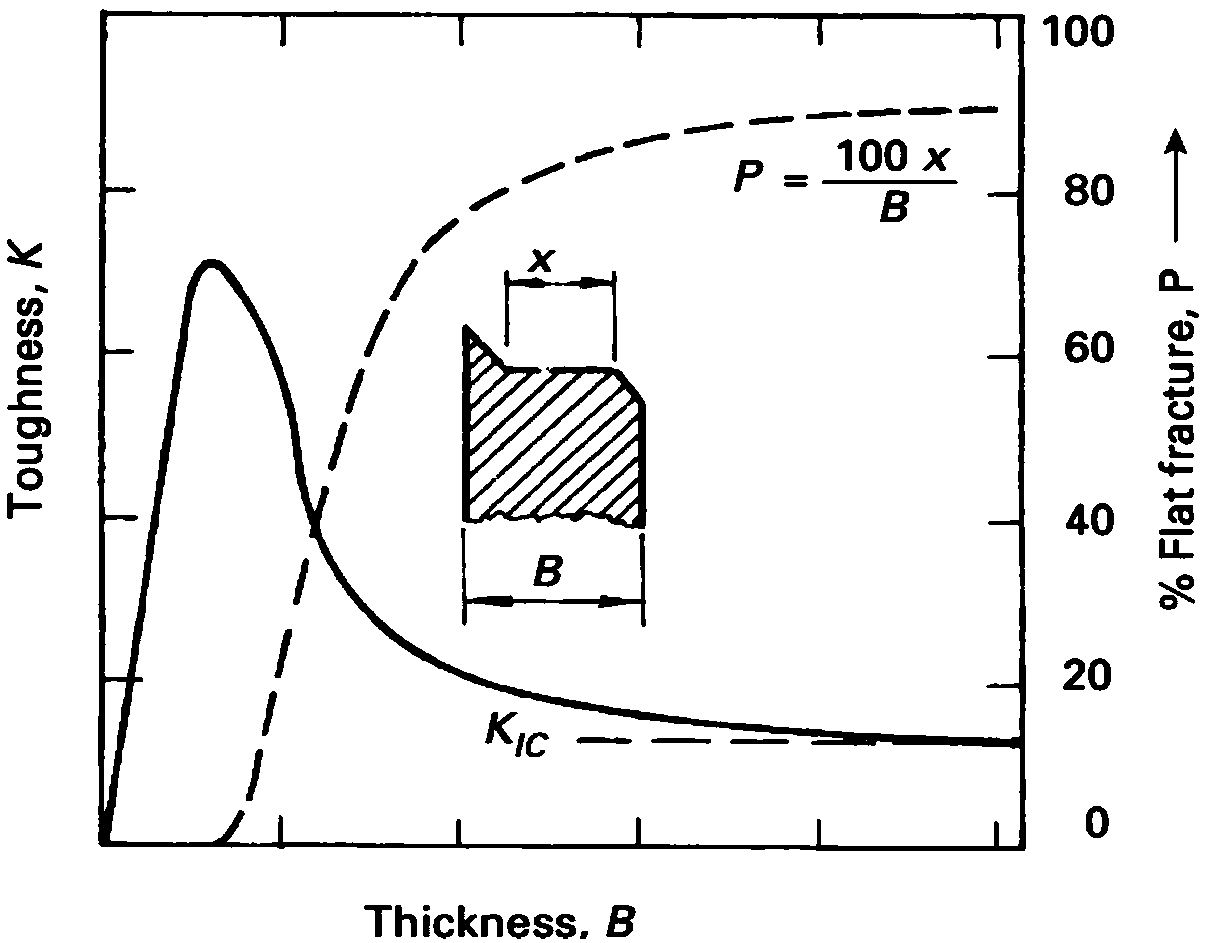

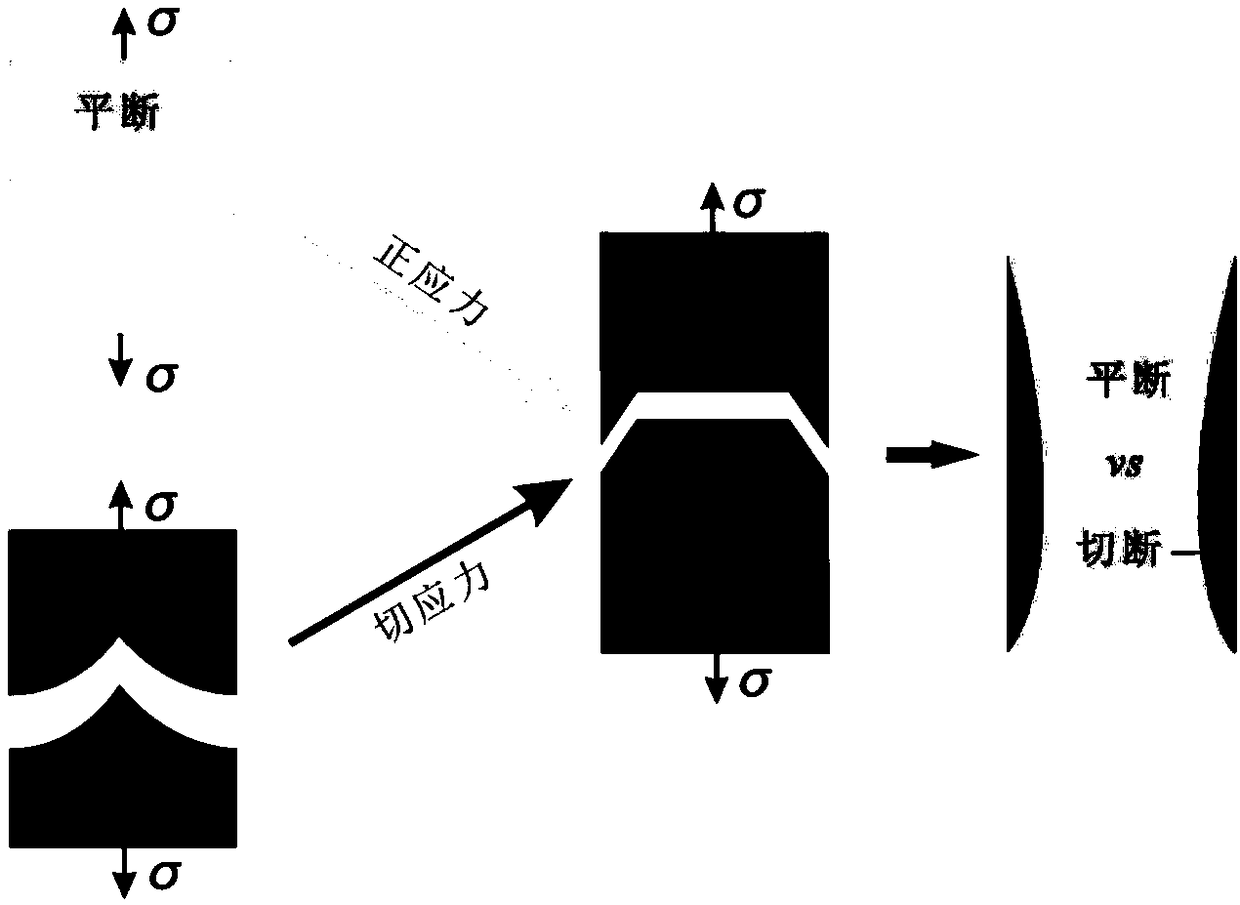

Problems solved by technology

Method used

Image

Examples

Embodiment 1

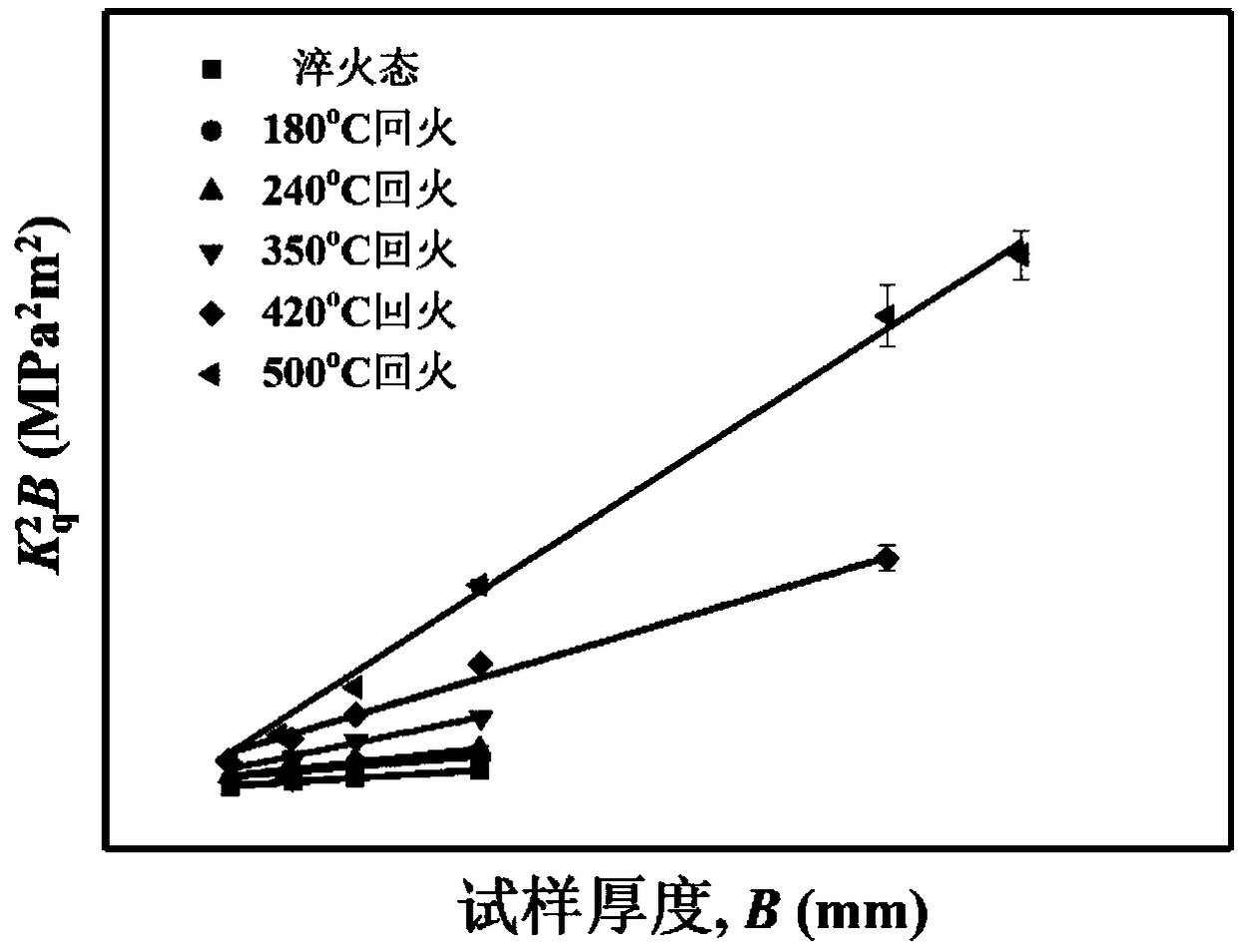

[0066] This embodiment is to adopt the small size sample to predict the plane strain fracture toughness of AISI 4340 steel, and the specific steps are as follows:

[0067] Step 1: Select three-point bending specimens with different thicknesses (4mm, 6mm, 8mm and 12mm) for fracture toughness experiment, and calculate the experimental value K according to the experimental standard q .

[0068] Step 2: Divide K by formula (8) q 2 B is linearly fitted to the sample thickness B.

[0069] Step 3: Calculate K from the linear slope fitted in step 2 IC , estimated and experimental values such as Figure 6 shown.

Embodiment 2

[0071] The present embodiment is to adopt small size sample to predict plane strain fracture toughness of 18Ni maraging steel, concrete steps are as follows:

[0072] Step 1: Select three-point bending specimens with different thicknesses (4mm, 6mm and 25mm) for fracture toughness experiment, and calculate the experimental value K according to the experimental standard q .

[0073] Step 2: Divide K by formula (8) q 2 B is linearly fitted to the sample thickness B.

[0074] Step 3: Calculate K from the linear slope fitted in step 2 IC , estimated and experimental values such as Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com