Device and method for measuring I-type creep fracture toughness and fracture toughness of rock

A creep fracture and fracture toughness technology, applied in the field of rock performance test research, to achieve the effect of simplifying test operation, ensuring accuracy and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

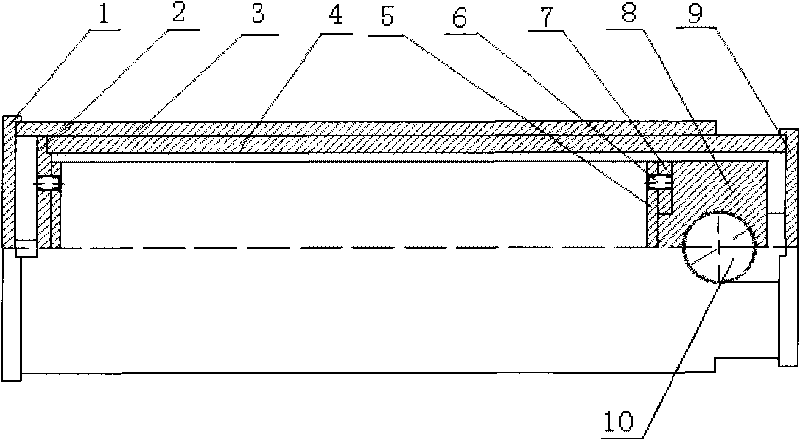

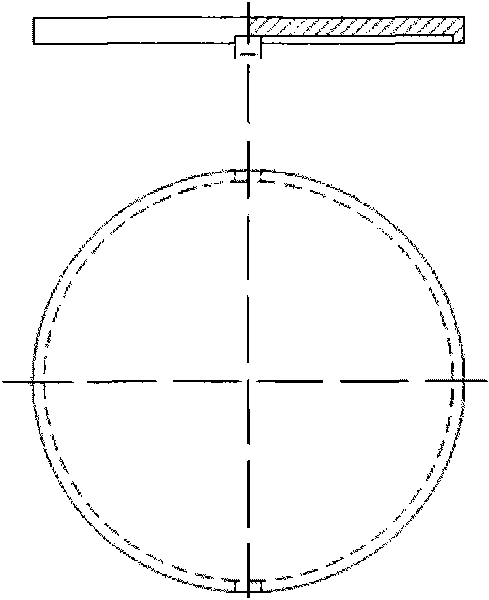

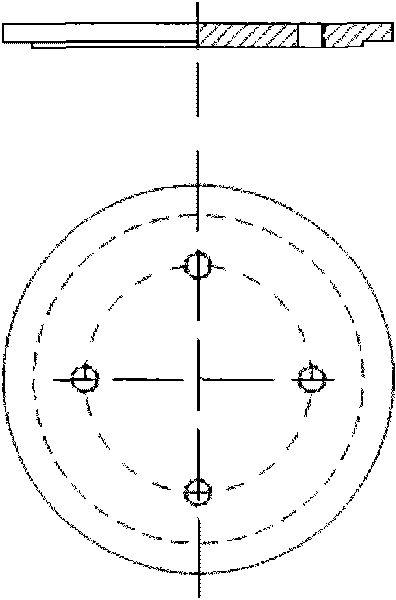

[0019] Such as figure 1 The shown device for testing the rock type I creep fracture toughness and fracture toughness consists of an upper top cover 1, a lower top cover 2, an outer sleeve 3, an inner sleeve 4, a pull pad 5, a connecting bolt 6, and a connecting ring 7 , hanger block 8, lower bottom cover 9, finale 10 constitute, upper top cover 1 and lower bottom cover 9 sections are a circular top cover, and upper top cover 1 is as figure 2 The shape shown is a groove shape, which together with the outer sleeve 3 forms a fully enclosed cylindrical structure. Lower top cover 9 such as image 3 Shown is a round convex cap with bolt holes arranged evenly around the circumference. Both the outer sleeve 3 and the inner sleeve 4 have a circular cross-section, which is a hollow cylinder shape, and connecting holes are left in the upper and lower cross-sections respectively. Arrange the connecting bolt holes, connect the connecting ring with the bolt 6, and form an integral struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com