Experimental method for testing transformation relationship between pretightening torque and pretightening force of anchor bolt

A test method and pre-tightening force technology, applied in the direction of measuring torque/torsion force, force/torque/power measuring instrument, force sensor related to bearings, etc. during tightening, so as to achieve the test operation process is simple and easy, and the test method is scientific and reasonable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

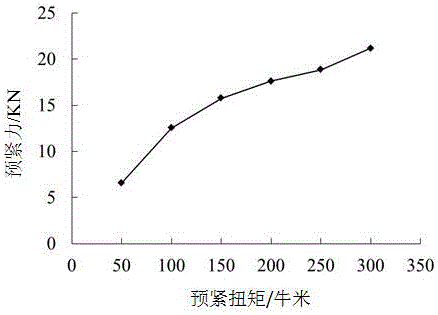

Embodiment 1

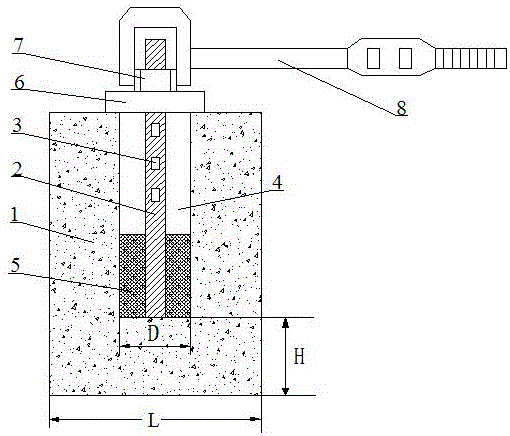

[0028] a. Pouring a cuboid concrete sample 1 with a size of 30 cm×30 cm×120 cm. The material used in concrete sample 1 and its ratio are water:cement:quartz sand=0.36:1:1; after concrete sample 1 is cured for 14 days , drill a bolt hole 4 with a diameter D of 30 mm and a depth of 1000 mm on its central axis; the bolt 2 used in the test is taken from the coal mine of Jining No. The quantity E is 220GPa, and a strain gauge 3 is pasted every 10cm on the free section of the anchor rod body, a total of 5 strain gauges.

[0029] b. Pour the anchoring agent 5 into the bolt hole 4. The anchoring agent 5 used in the test is cement mortar of water: cement: fine sand = 0.5: 1: 0.6, and the anchoring length is 0.5m; after the anchoring agent 5 is poured, quickly put The anchor rod 2 is inserted into the anchor rod borehole 4 and fully contacted with the anchoring agent 5; the finished anchoring material sample is kept in a cool place for 14 days.

[0030] c Install the backing plate 6 an...

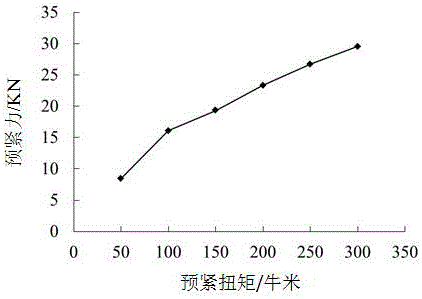

Embodiment 2

[0036] a. Pouring a cuboid concrete sample 1 with a size of 30 cm×30 cm×120 cm. The material used in concrete sample 1 and its ratio are water:cement:quartz sand=0.36:1:1; after concrete sample 1 is cured for 14 days , drill a bolt hole 4 with a diameter D of 30 mm and a depth of 1000 mm on its central axis; the bolt 2 used in the test is taken from the coal mine of Jining No. The quantity E is 220GPa, and a strain gauge 3 is pasted every 10cm on the free section of the anchor rod body, a total of 5 strain gauges.

[0037] b. Pour the anchoring agent 5 into the bolt hole 4. The anchoring agent 5 used in the test is cement mortar of water: cement: fine sand = 0.5: 1: 0.6, and the anchoring length is 0.5m; after the anchoring agent 5 is poured, quickly put The anchor rod 2 is inserted into the anchor rod borehole 4 and fully contacted with the anchoring agent 5; the finished anchoring material sample is kept in a cool place for 14 days.

[0038] c Apply butter to the thread at ...

Embodiment 3

[0044] a. Pouring a cuboid concrete sample 1 with a size of 30 cm×30 cm×120 cm. The material used in concrete sample 1 and its ratio are water:cement:quartz sand=0.36:1:1; after concrete sample 1 is cured for 14 days , drill a bolt hole 4 with a diameter D of 30 mm and a depth of 1000 mm on its central axis; the bolt 2 used in the test is taken from the coal mine of Jining No. The quantity E is 220GPa, and a strain gauge 3 is pasted every 10cm on the free section of the anchor rod body, a total of 3 strain gauges.

[0045] b. Anchoring agent 5 is poured into the bolt hole 4. The anchoring agent 5 used in the test is cement mortar of water: cement: fine sand = 0.5: 1: 0.6, and the anchoring length is 0.8m; after the anchoring agent 5 is poured, quickly put The anchor rod 2 is inserted into the anchor rod borehole 4 and fully contacted with the anchoring agent 5; the finished anchoring material sample is kept in a cool place for 14 days.

[0046] c Install the backing plate 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com