Integrated pressing method of combined-type silkworm breeding frames

A combined and silkworm frame technology, which is applied to frames, other household appliances, household appliances, etc., can solve the problems of low utilization rate of factory space, low mechanical properties of small bamboo baskets, inconvenient stacking of small bamboo baskets, etc., and achieve excellent silkworm rearing effect , Excellent effect of silkworm rearing and ideal space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

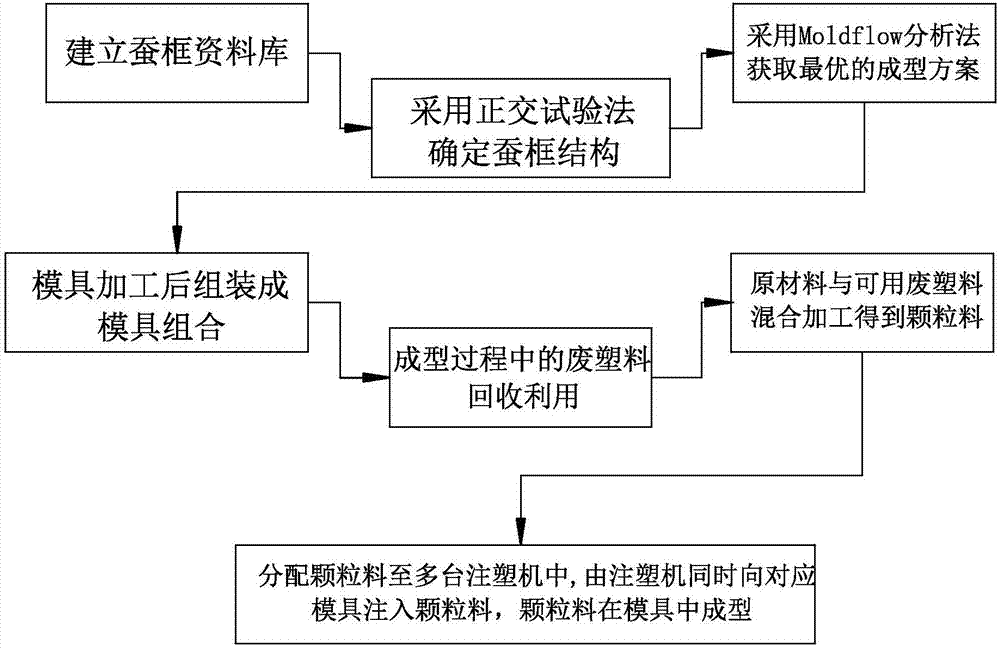

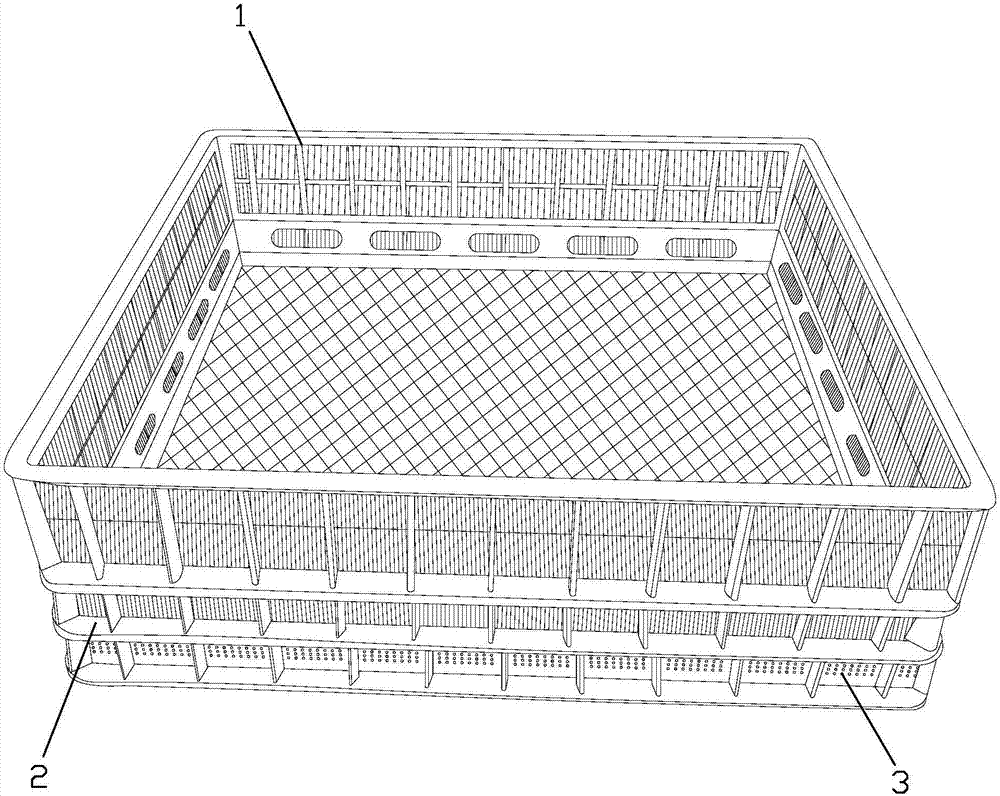

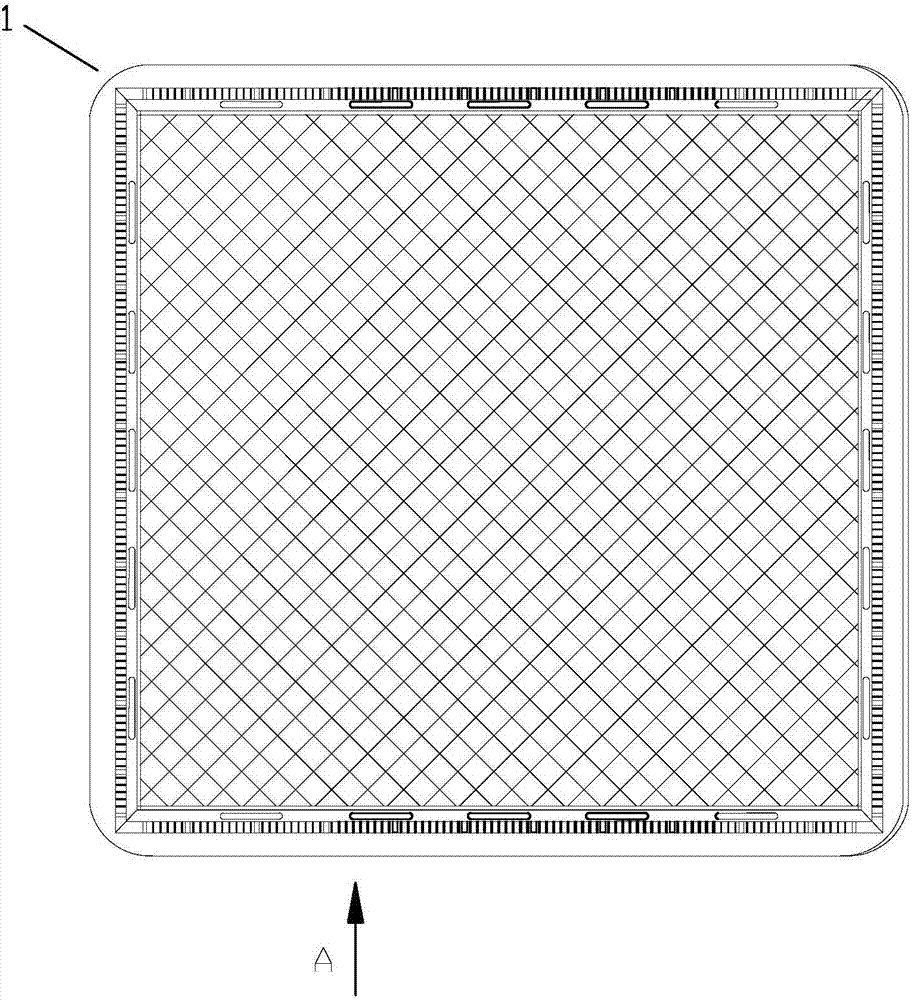

[0048] Such as Figures 1 to 9 As shown, the present invention is an integrated pressing method of a combined sericulture frame, which is realized through the following steps:

[0049] (1) Silkworm frame structure design:

[0050] Establish 5 groups of combined sericulture frame structures, and mark the 5 groups as test group 1, test group 2, test group 3, test group 4 and test group 5; among them, the sample in test group 1 is sample 1 , the sample in test group 2 is sample 2, the sample in test group 3 is sample 3, the sample in test group 4 is sample 4, and the sample in test group 5 is sample 5; The specific structure of the sample is shown in Table 1:

[0051] Table 1 Structural features of sample 1 to sample 5

[0052]

[0053] Sample 1, sample 2, test 3, sample 4 and sample 5 are manufactured and molded to detect the mechanical properties of each sample; Adult rate, mechanical properties and the test results of adult rate are shown in Table 2:

[0054] Table 2 M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com