A drop point detection device and detection method for ointment for cables

A detection device and ointment technology, applied in the field of cable materials, can solve problems such as visual fatigue and insecurity, and achieve the effects of low labor intensity, accurate recording, and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

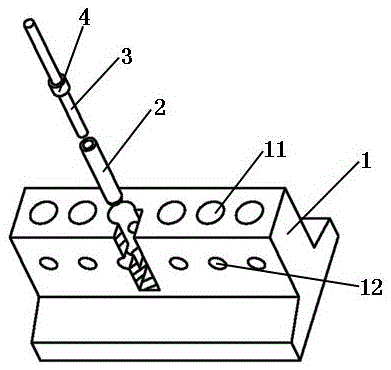

[0024] please see figure 1 ,refer to Figure 4 and Figure 5 , a drop point detection device for cable ointment is characterized in that it includes a housing 1, a heating device 16 located inside the housing, and a power connection line; the upper part of the housing is in the shape of a cuboid, and the vertical direction on the cuboid has A plurality of container lumens 11 that are not connected to each other. The horizontal direction on the cuboid has a plurality of observation holes 12 that are corresponding to the container cavity and are not connected to each other. The corresponding observation holes are connected to the container cavity. The cavity and the observation hole are both straight holes, and the observation hole runs through the front and rear sides of the cuboid in the horizontal direction; on the orthographic projection of the front side of the cuboid, the observation hole is located in the middle and lower part of the corresponding container cavity; the h...

Embodiment 2

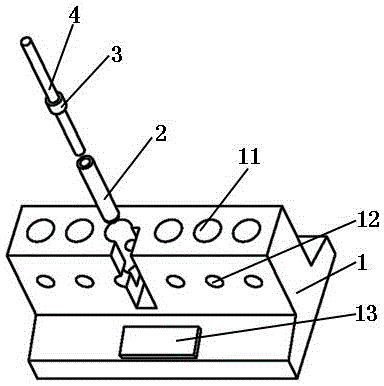

[0026] please see figure 2 ,refer to Figure 4 and Figure 5 , a drop point detection device for cable ointment, characterized in that it includes a housing 1, a heating device 16 located inside the housing, a display and setting device 18, a power connection line, and a display on the housing and the operation panel 13; the top of the housing is in the shape of a cuboid, the vertical direction on the cuboid has a plurality of chambers 11 that are not connected to each other, and the horizontal direction on the cuboid has a plurality of observation chambers that are corresponding to the chambers and are not connected to each other. Hole 12, the corresponding observation hole is connected with the container cavity, the container cavity and the observation hole are straight holes, and the observation hole runs through the front and rear sides of the cuboid in the horizontal direction; on the orthographic projection of the front side of the cuboid , the observation hole is loc...

Embodiment 3

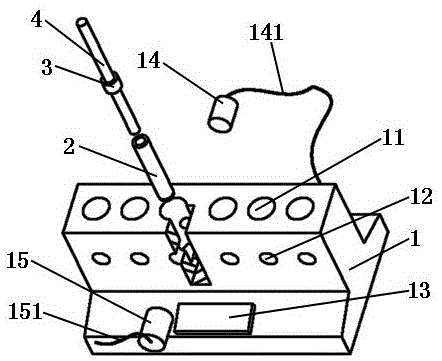

[0028] please see image 3 ,refer to Figure 4 and Figure 5 , a drop point detection device for cable ointment, is characterized in that it includes a housing 1, a heating device 16 positioned inside the housing, a display and setting device 18, a power connection line, a temperature detection device 19, a computing and Control device 17, signal transmitting device 14 and signal receiving device 15 located outside the housing, display and operation panel 13 located on the housing; the upper part of the housing is in the shape of a cuboid, and the vertical direction on the cuboid has a plurality of non-communicating holding tubes Cavity 11, the horizontal direction on the cuboid has a plurality of observation holes 12 corresponding to the container cavity and not communicating with each other, the corresponding observation holes are connected to the container cavity, and both the container cavity and the observation hole are straight holes , the observation hole runs through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com