Method and device for testing bonding strength of anchoring interface of anchoring system

An interface bonding and anchoring system technology, applied in the field of geotechnical engineering, can solve the problem of inability to accurately calculate the bonding strength of the first and second anchoring interfaces, the inability to obtain the bonding strength of the first anchoring interface, and the inability to obtain the second anchoring interface Bond strength and other issues, to achieve the effect of simple and easy test operation process, scientific and reasonable test method, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

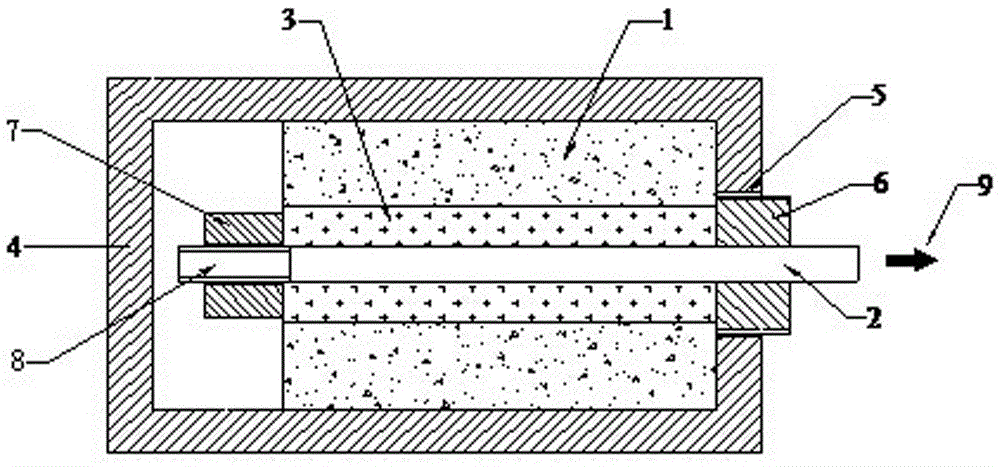

[0039] A. Pour a cuboid anchoring sample 1 with a size of 20cm×20cm×25cm. The material and proportion of anchoring sample 1 are water:cement:quartz sand=0.4:1:1; after 14 days of curing for anchoring sample 1, The central axis is drilled with a diameter of 30mm and a bolt hole of 250mm in length; making a bolt 2 with a diameter of 10mm and a total length of 60cm, and the length of the extension section 8 in the bolt 2 is 10cm; placing the bolt 2 on the bolt In the center of the drill hole, pour anchoring agent 3 into the borehole of the anchor rod. The material used for anchoring agent 3 and its ratio are water: cement = 0.5:1; so far, it is composed of anchoring sample 1, anchor rod 2 and anchoring agent 3. test sample.

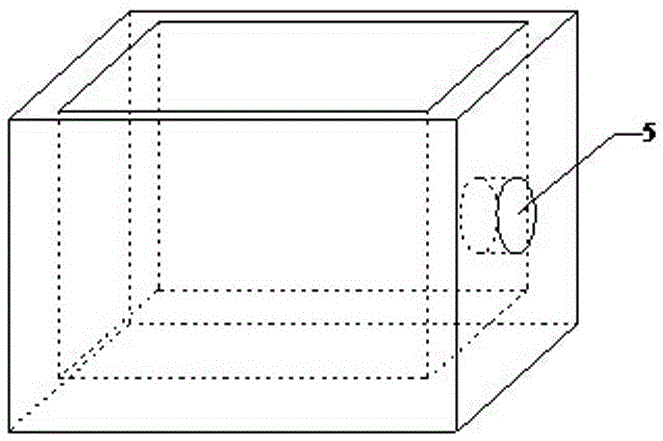

[0040] B. After the anchoring agent 3 is solidified, the test sample is placed in the sample chamber 4, and the anchor rod 2 passes through the limiting hole 5, such as figure 2 As shown, the internal size of the sample chamber 4 is 20cm×20cm×45cm, and t...

Embodiment 2

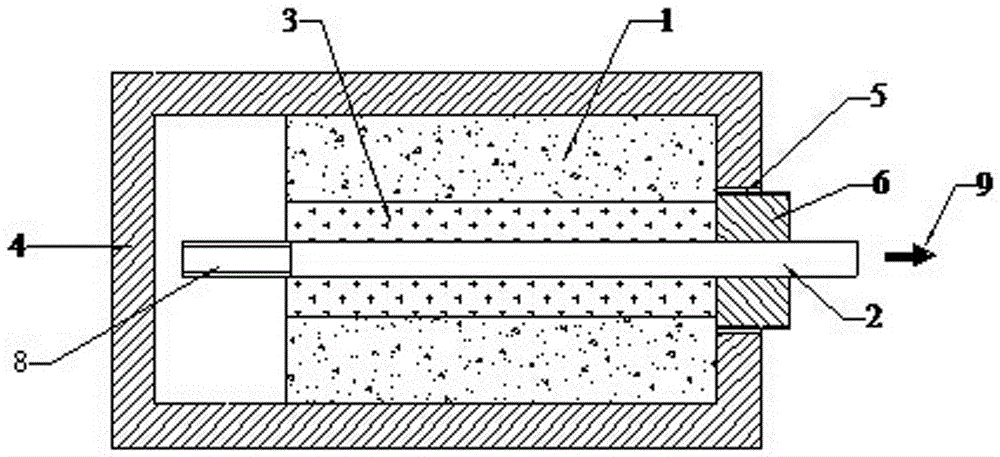

[0045] A. Pour a cuboid anchoring sample 1 with a size of 20cm×20cm×25cm. The material and proportion of anchoring sample 1 are water:cement:quartz sand=0.4:1:1; after 14 days of curing for anchoring sample 1, The central axis is drilled with a diameter of 30mm and a bolt hole of 250mm in length; making a bolt 2 with a diameter of 10mm and a total length of 60cm, and the length of the extension section 8 in the bolt 2 is 10cm; placing the bolt 2 on the bolt In the center of the drill hole, pour anchoring agent 3 into the borehole of the anchor rod. The material used for anchoring agent 3 and its ratio are water: cement = 0.5:1; so far, it is composed of anchoring sample 1, anchor rod 2 and anchoring agent 3. test sample.

[0046] B. After the anchoring agent 3 is solidified, the test sample is placed in the sample chamber 4, and the anchor rod 2 passes through the limiting hole 5, such as figure 2 As shown, the internal size of the sample chamber 4 is 20cm×20cm×45cm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com