Method for the interlayer interface fracture toughness of ballastless track

A fracture toughness, ballastless track technology, applied in the preparation of test samples, the use of stable tension / pressure test material strength, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

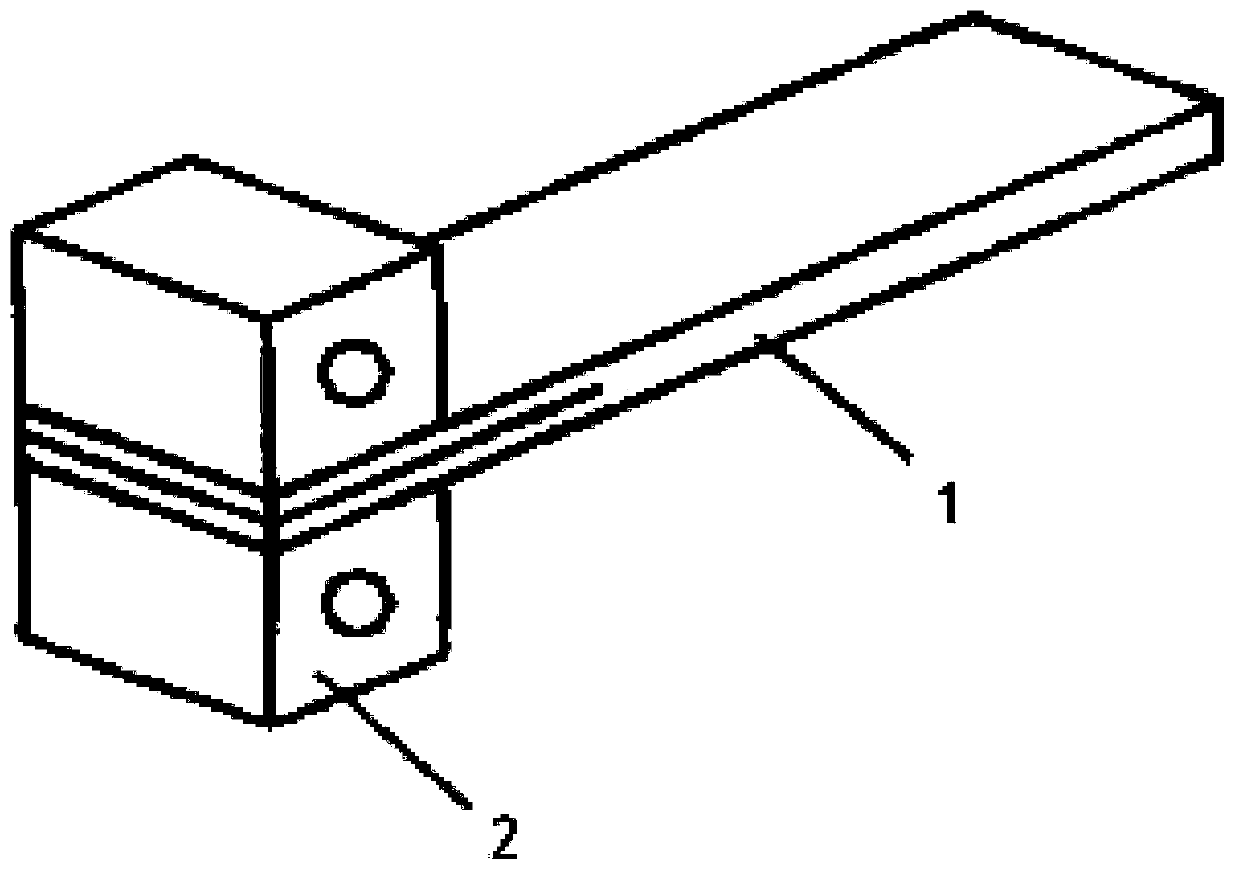

[0052] (1) Test piece production: pouring such as figure 1 The double cantilever beam (DCB) test block shown. Make 5 groups of concrete C40-C20 DCB specimens with interlayer cracks, 15 in total. First, mix C40 concrete according to the mix ratio requirements, take the amount of concrete required for 1 / 2 the height of the test piece and put it into the test mold, put it in the curing room to cure the test pieces at the required interval, and then carry out layer treatment according to the construction requirements. Mix C20 concrete according to the mix ratio requirements, put it into the remaining 1 / 2 test mold, and maintain it to the age required by the test.

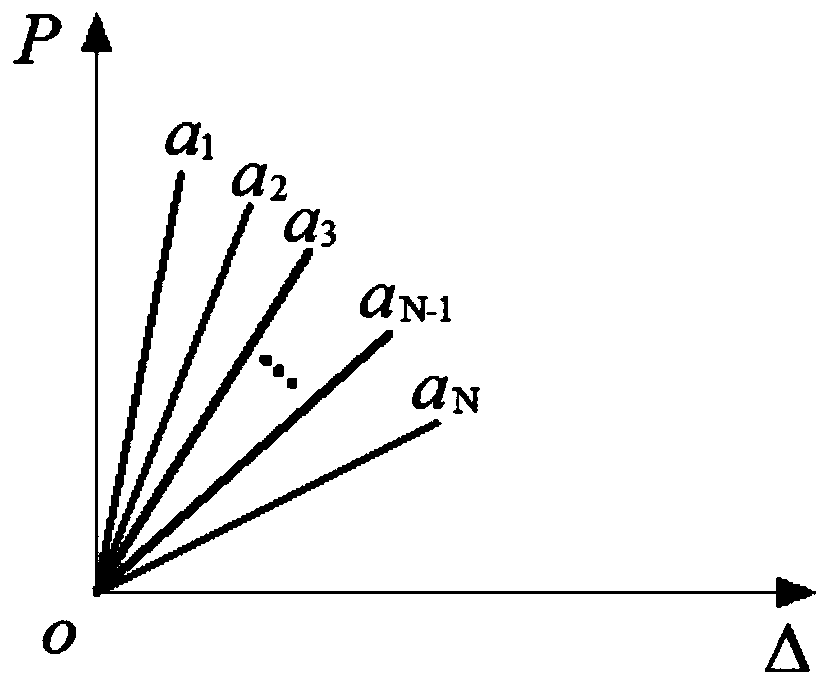

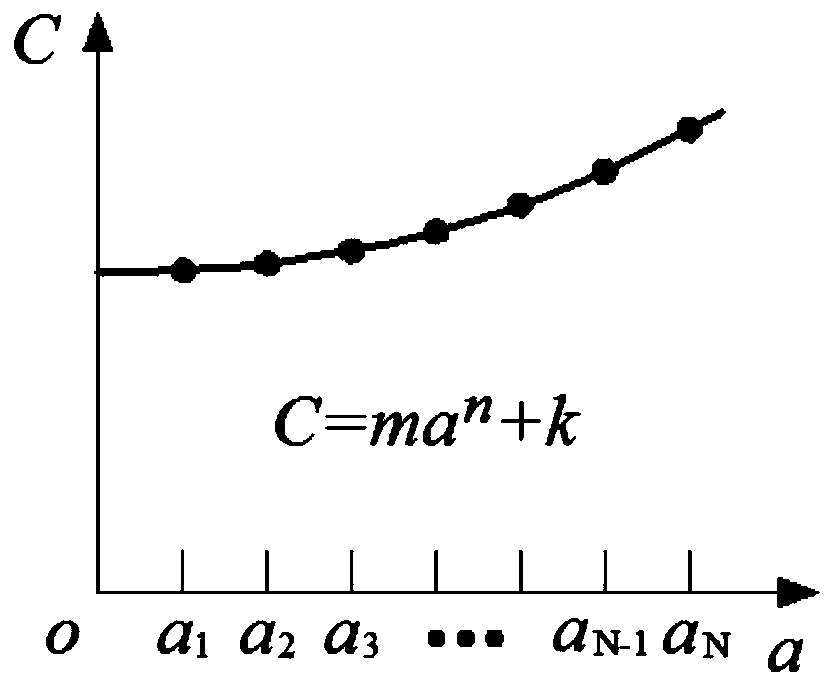

[0053] (2) When the test age is reached, the specimen is taken out from the curing room, and the cross-sectional dimension B of the specimen is measured to an accuracy of 1mm. Such as Figure 4 As shown on the right side of the middle, measure the cross-sectional dimension B of the test piece and the height h of the ...

Embodiment 2

[0059] 1. Production of test pieces

[0060] The test piece manufacturing process and load loading test process are the same as in Example 1, and the load loading instrument and equipment selection is as follows:

[0061] (1) Testing machine: 10kN tensile testing machine or servo program-controlled universal testing machine, the stretching distance is not less than 300mm.

[0062] (2) Mold test: the length of the test piece is 400mm, the interface width is B=50mm, and the initial crack length is a 1 =50, 65, 80, 95, 110mm, the thickness of the upper test piece is h 1 =50mm, the thickness of the lower specimen is h 2 = 50mm. Dimensions of molded specimens such as Figure 4 shown. In order to prevent the specimen from cracking along the vertical direction and provide a loading position for the application of the load, certain steel bars are configured for the specimen.

[0063] (3) Force block: length is 50mm, width is 50mm, thickness is 25mm, and the diameter of the round...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com