New rock II-type fracture toughness test method

A technology of fracture toughness and new method, applied in the field of geotechnical engineering, can solve the problems of large gap, large tensile stress at the crack tip, complicated processing of loading molds, etc., and achieve the effect of simple and reasonable structure, simple operation and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] The specific implementation method comprises the following steps:

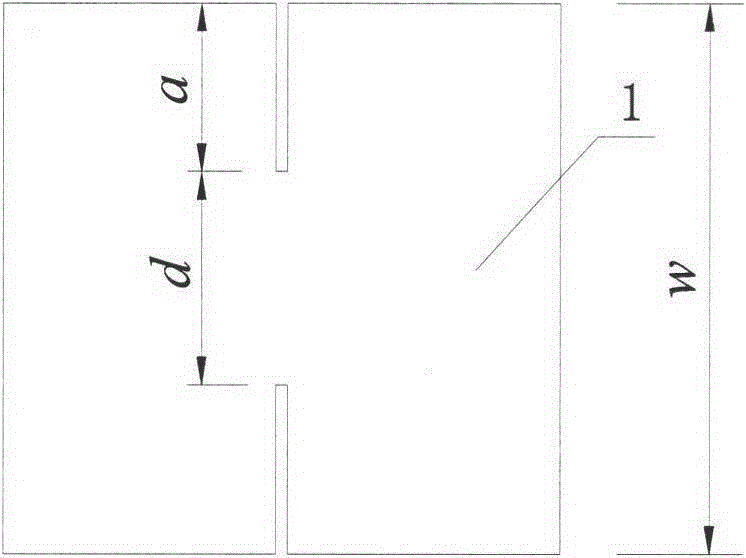

[0026] 1. First, the rock sample to be tested is made into a 50mm×50mm×50mm square sample according to the "Engineering Rock Mass Test Method Standard", and the rock surface around the test body needs to be processed and leveled.

[0027] 2. Use milling machines, diamond saw blades and other tools to process double-sided symmetrical prefabricated straight cracks on the square sample. The crack width is required to be less than or equal to 1.0mm, and the crack length is processed according to the design length of the test plan. The two crack ends use diamonds less than 0.3mm The sawing wire is processed into crack tips for secondary processing. For rocks with different strengths, the dimensionless length (a / w) must be greater than a certain value, otherwise the rock sample will be crushed.

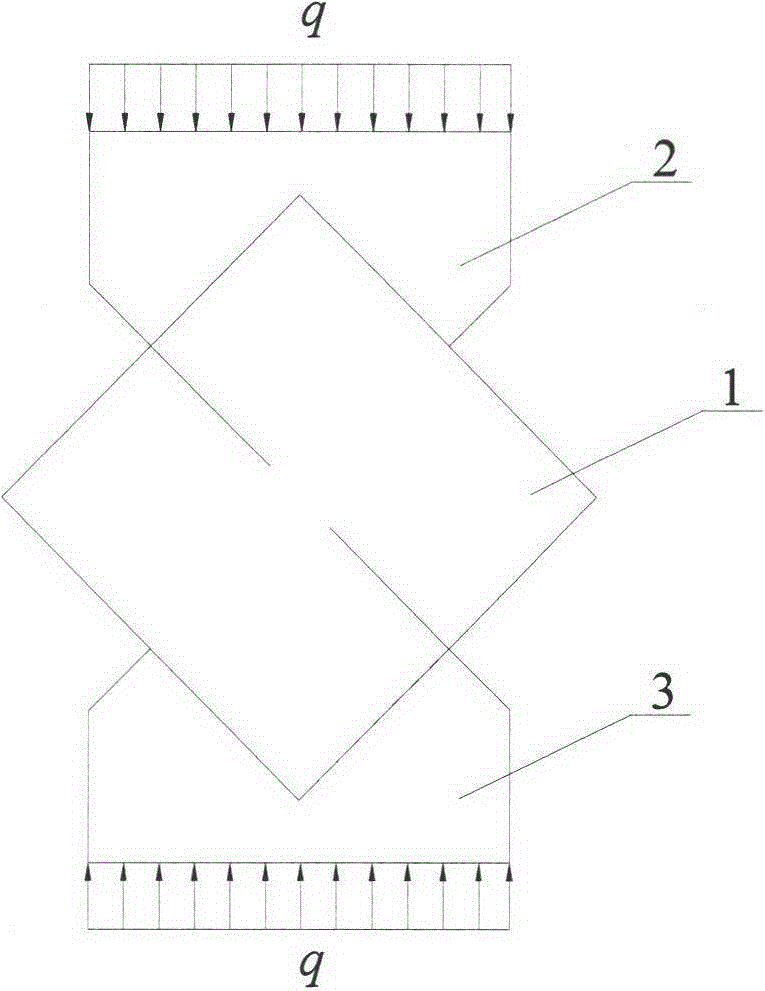

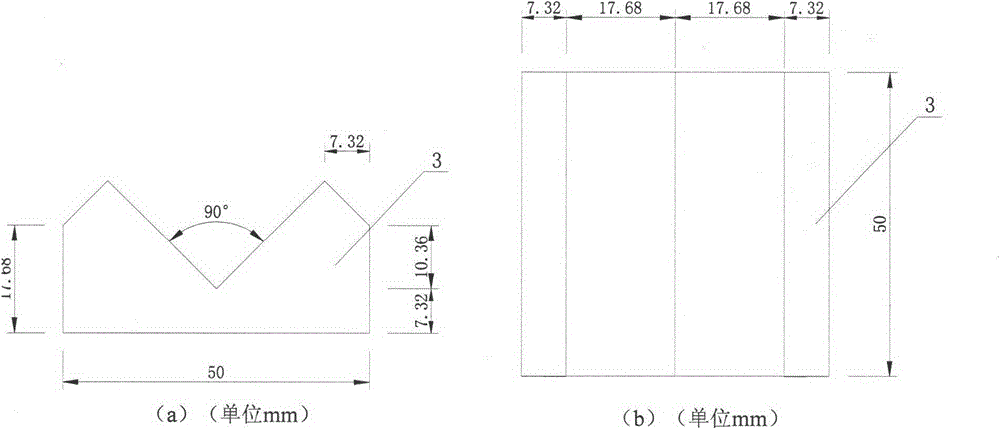

[0028] 3. Place the square rock sample with double-sided prefabricated straight cracks between two steel loading m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com