Hybrid fiber toughened ultrahigh-strength and ultrahigh-ductility cement-based material

A technology of cement-based materials and hybrid fibers, applied in the field of materials science, can solve problems such as only focusing on strength, and achieve good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 525 ordinary Portland cement: 1250 parts, silica fume: 291 parts, mineral powder: 200 parts, quartz sand: 407.8 parts, water: 201 parts, steel fiber: 7.5 parts, ultra-high molecular weight polyethylene fiber: 12.5 parts.

[0027] First add the solid mixture into the stirring pot, and dry stir for 3 minutes at a slow speed (revolution 62±5r / min, rotation 140±5r / min) until uniform. Then add the water reducer and aqueous solution into the stirring pot, stir quickly (revolution 125±10r / min, rotation 285±10r / min) for 5 minutes, add the fiber in the stated proportion, and stir for another 6 minutes until the ultra-high molecular weight polyethylene fiber Disperse evenly to obtain a super-high-strength and super-high-ductility cement-based material toughened by hybrid fibers. Finally, the slurry is put into a mold for molding and cured at room temperature for 28 days.

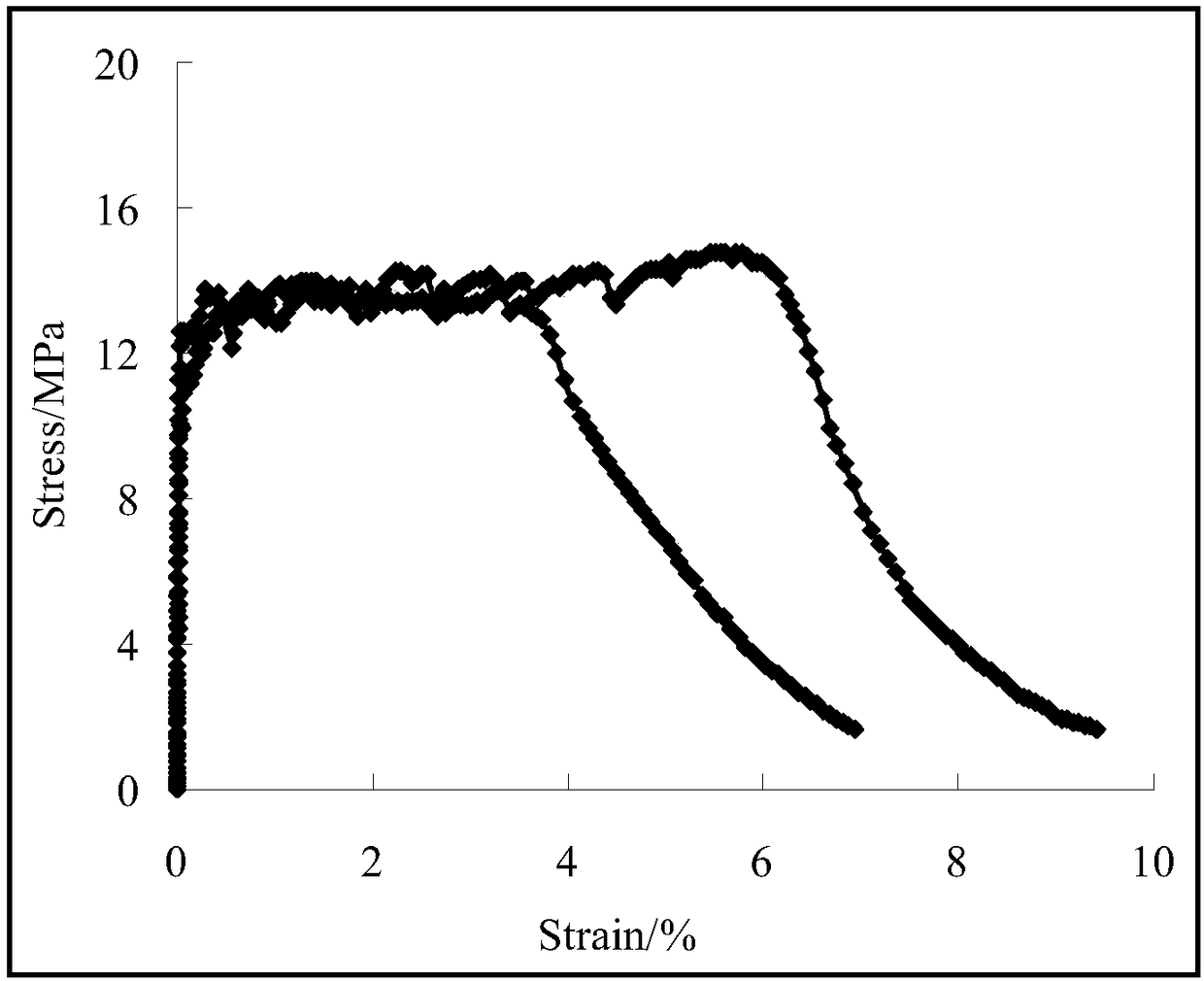

[0028] figure 1 Schematic diagram of the relationship between stress-strain and age of the ultra-high-stren...

Embodiment 2

[0030] 525 ordinary Portland cement: 700 parts, silica fume: 230 parts, mineral powder: 750 parts, quartz sand: 500 parts, water: 230 parts, steel fiber: 5 parts, ultra-high molecular weight polyethylene fiber: 15 parts.

[0031] First add the solid mixture into the stirring pot, and dry stir for 3 minutes at a slow speed (revolution 62±5r / min, rotation 140±5r / min) until uniform. Then add the water reducer and aqueous solution into the stirring pot, stir quickly (revolution 125±10r / min, rotation 285±10r / min) for 5 minutes, add the fiber in the stated proportion, and stir for another 6 minutes until the ultra-high molecular weight polyethylene fiber Disperse evenly to obtain a super-high-strength and super-high-ductility cement-based material toughened by hybrid fibers. Finally, the slurry is put into a mold for molding and cured at room temperature for 28 days.

[0032] The properties of the material at 3 days are as follows: the tensile strength is 8.6 MPa, and the ultimate s...

Embodiment 3

[0034] A hybrid fiber-reinforced ultra-high-strength and ultra-high ductility cement-based material, including the following components and raw materials in parts by weight: 525 ordinary Portland cement: 700, silica fume: 200, mineral powder: 200, quartz sand: 400 , water: 200, polycarboxylate superplasticizer: 20, ultra-high molecular weight polyethylene fiber: 5, ultra-high-strength steel fiber: 39.

[0035] Among them, the ultra-high molecular weight polyethylene fiber used has a length of 6mm, a diameter of 15μm, a tensile strength of 1800MPa, an elastic modulus of 40GPa, an ultimate elongation of 2%, and an aspect ratio greater than 400. The ultra-high-strength steel fiber is a straight fiber with a length of 6mm and a diameter of 0.115mm. The tensile strength is 2700MPa, the elastic modulus is 200GPa, and the ultimate elongation is 2%. The mesh number of quartz sand is 70 mesh, and the ratio of mortar to sand is not more than 0.5, so as to control the fracture toughness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com