Patents

Literature

77 results about "Tensile ductility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High Early Strength Engineered Cementitious Composites

ActiveUS20070181040A1High early-strengthLarge capacitySolid waste managementClimate change adaptationTensile strainCement composites

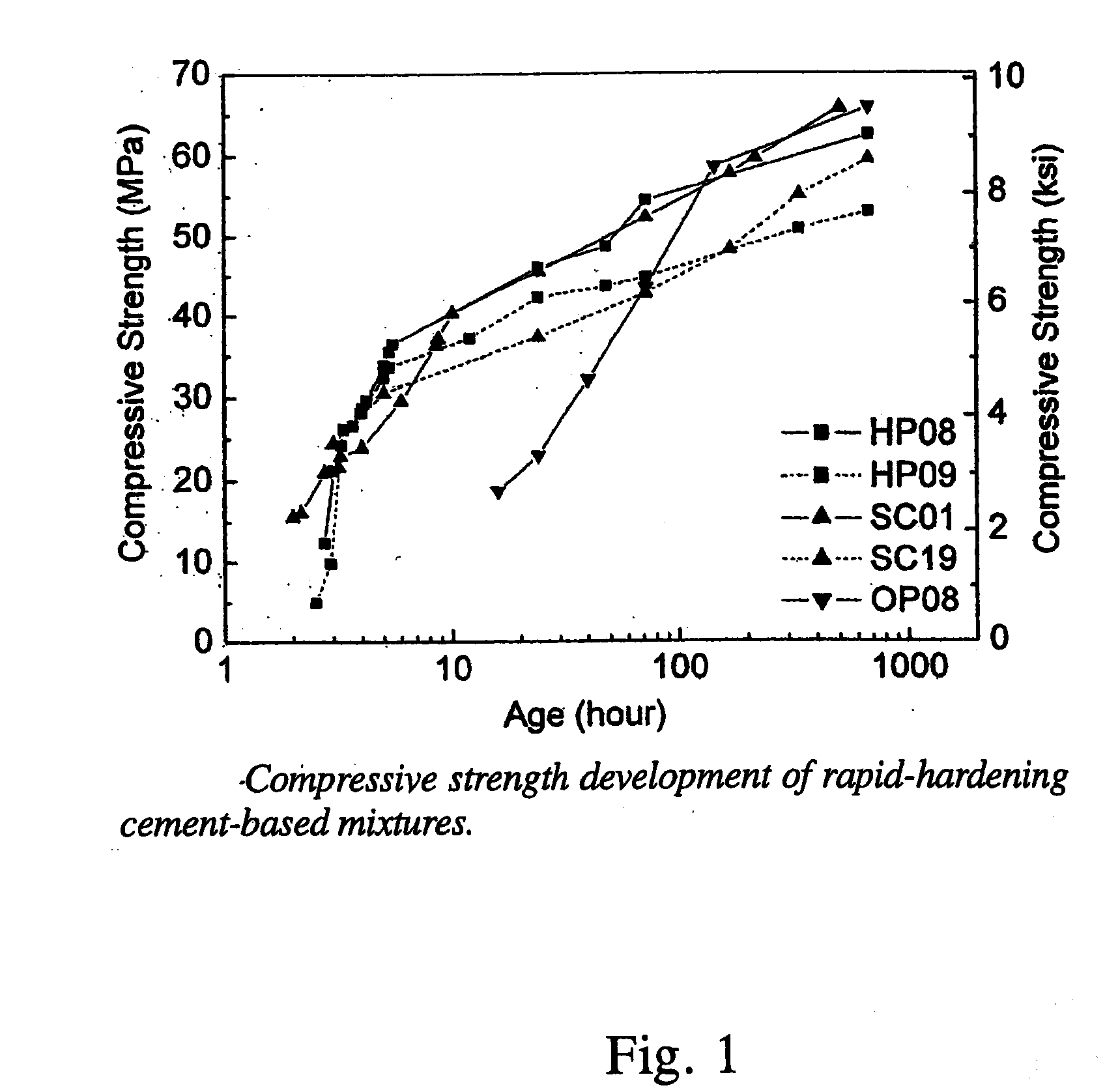

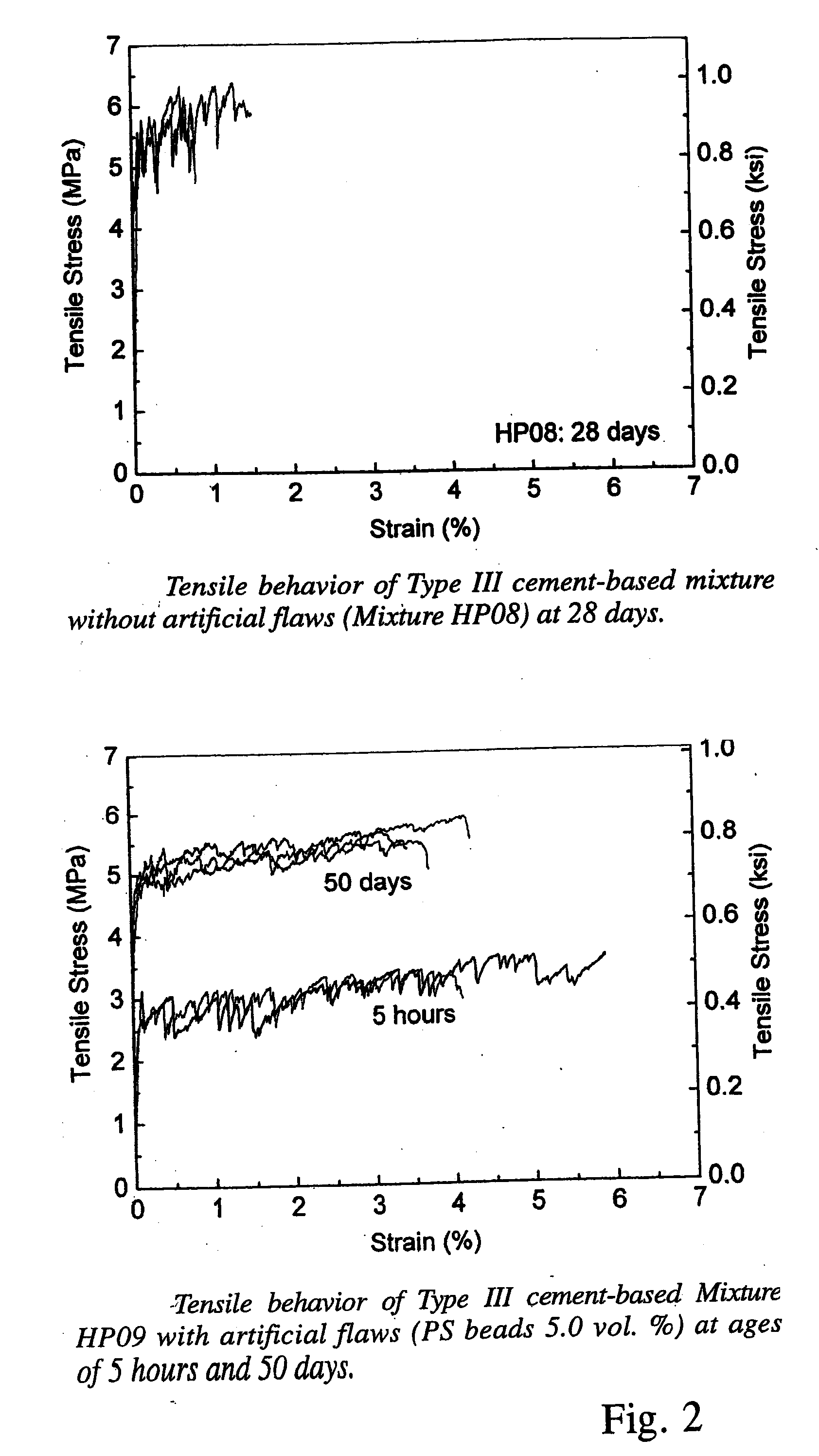

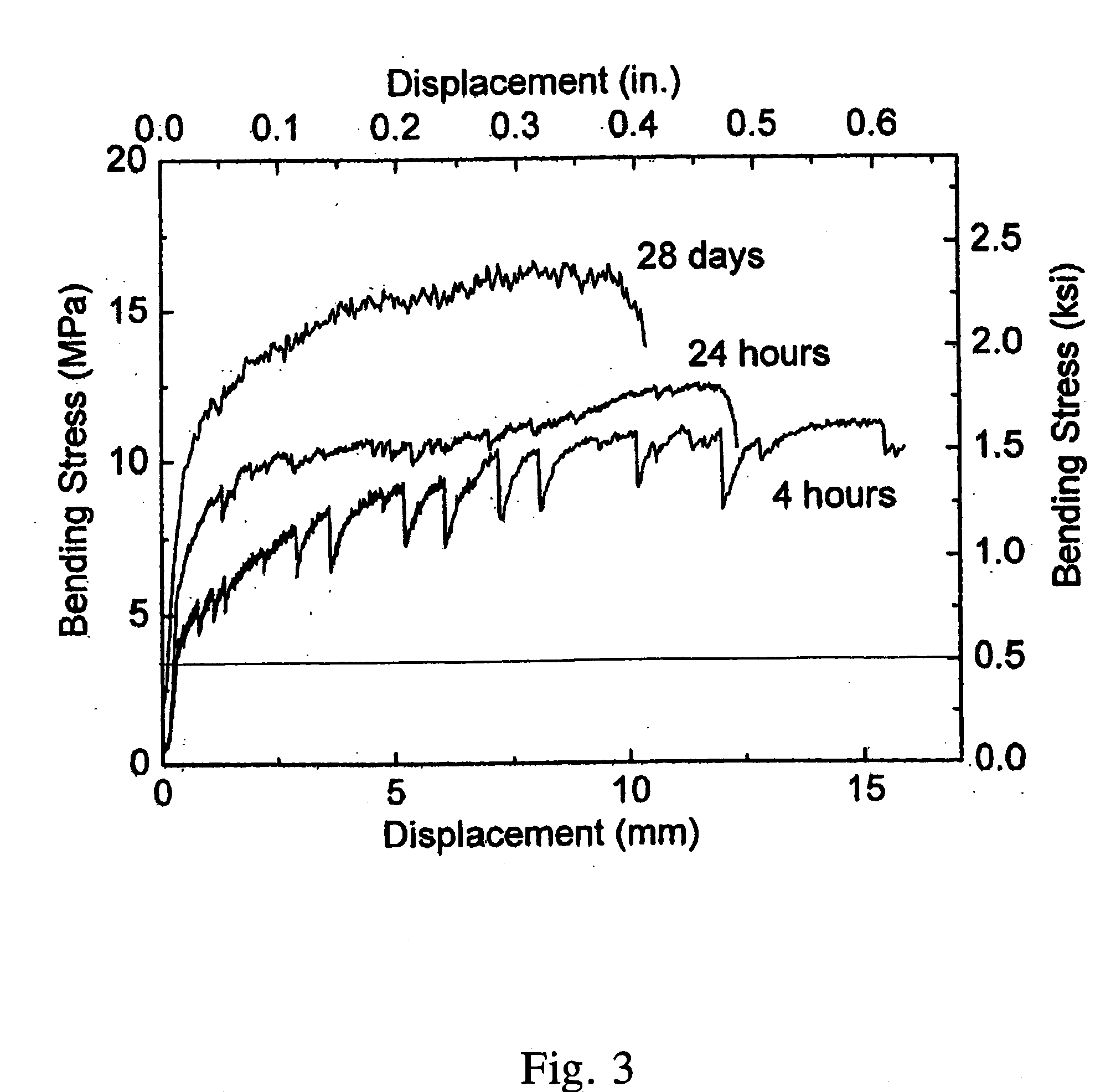

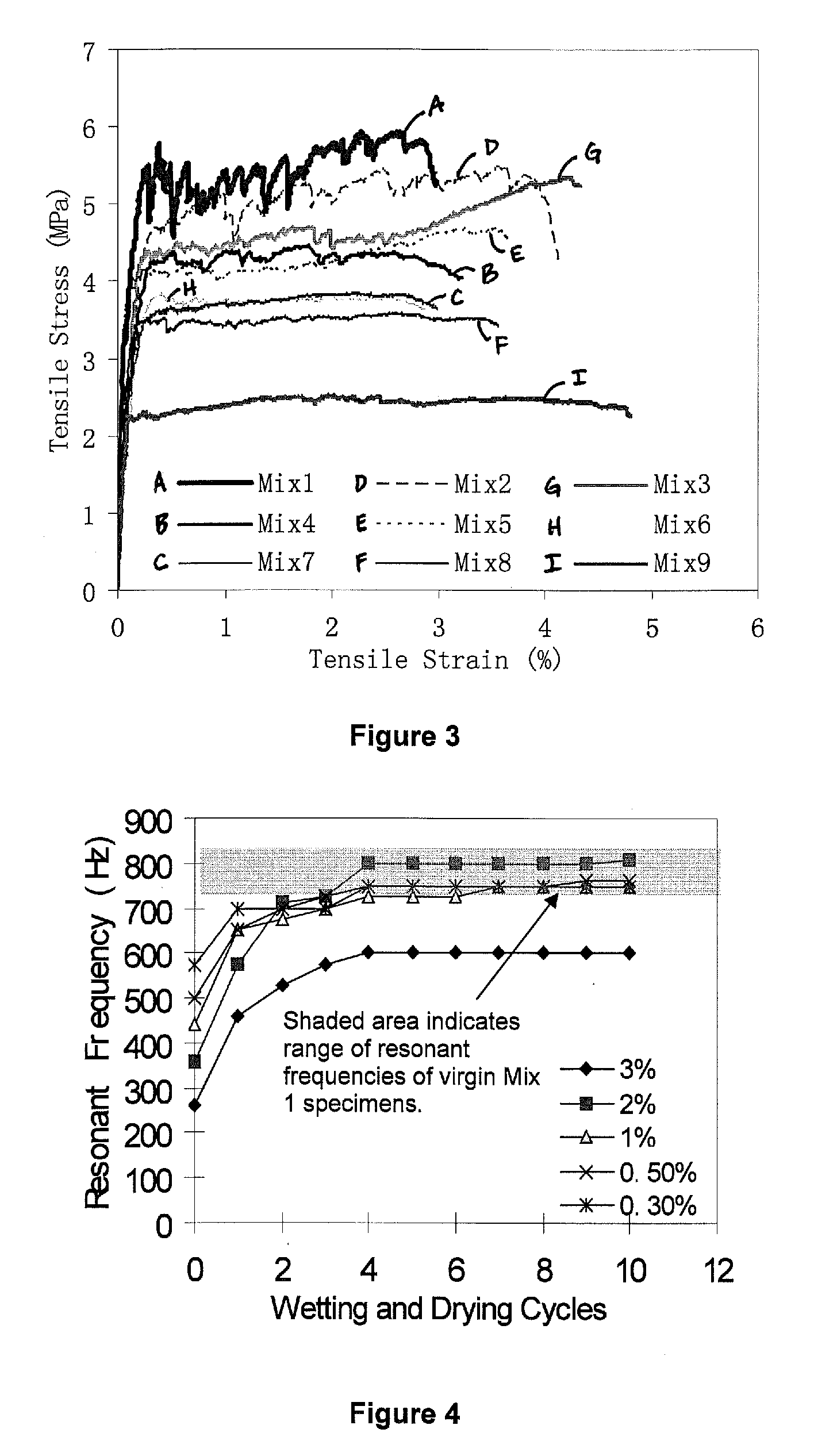

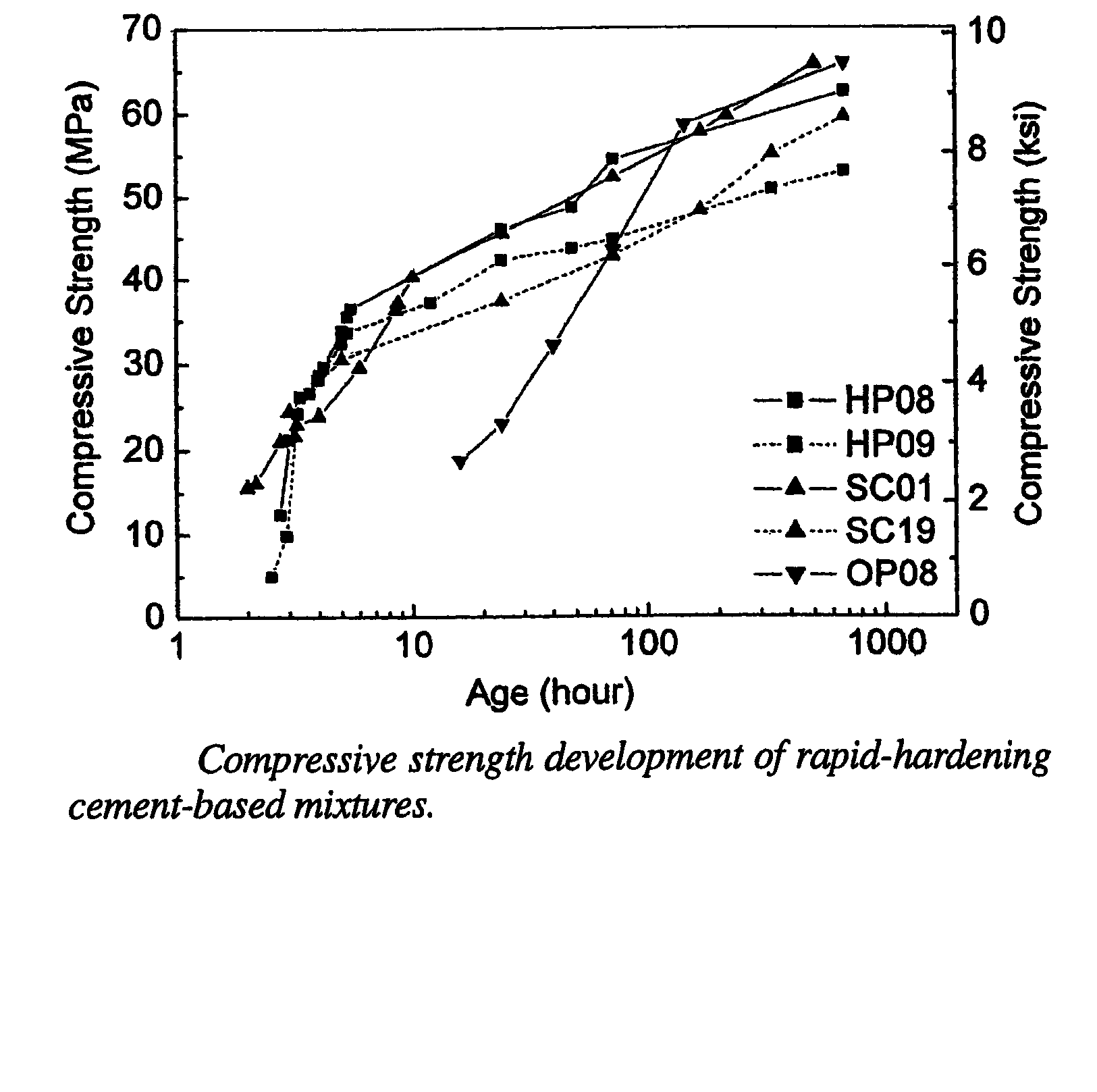

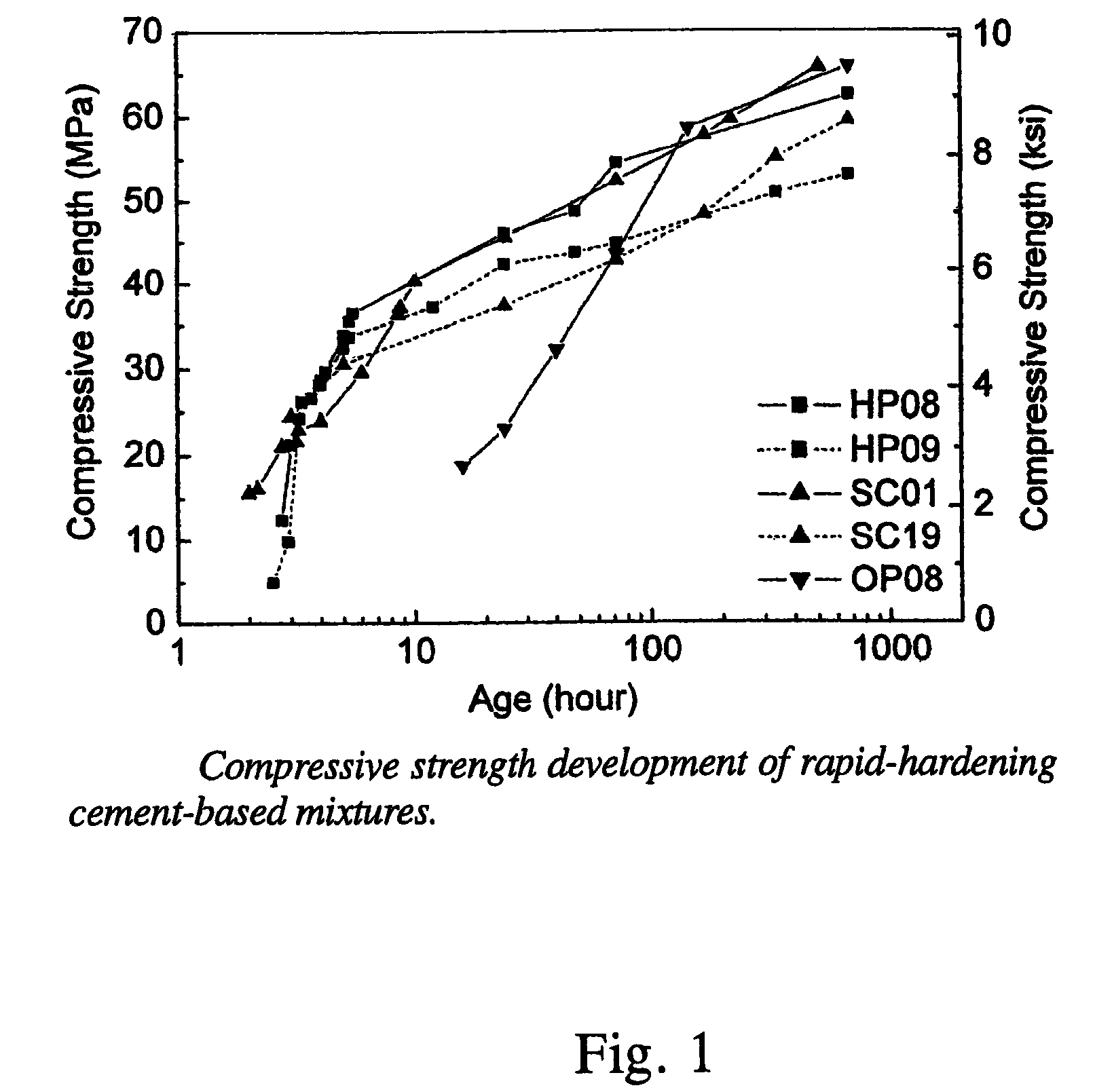

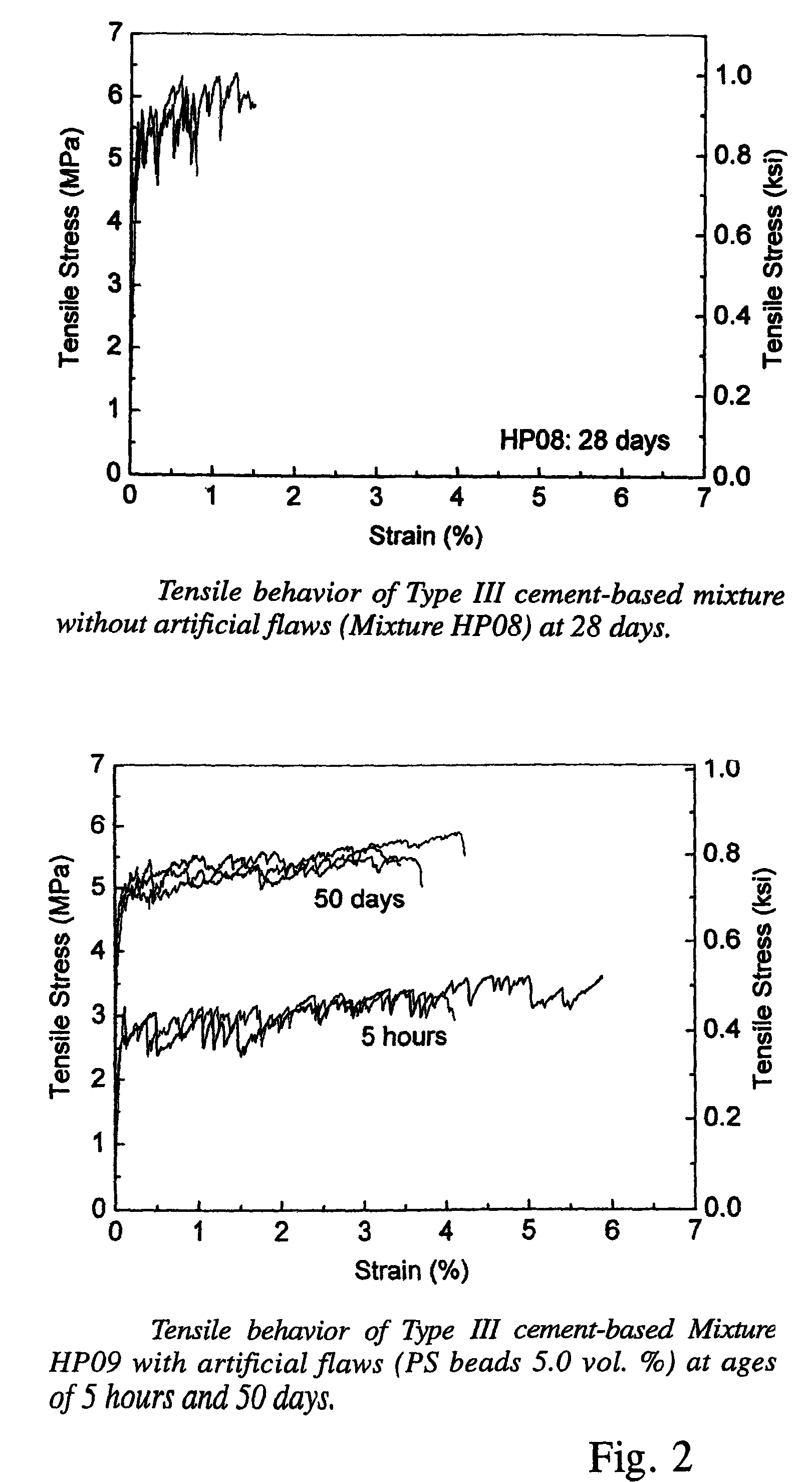

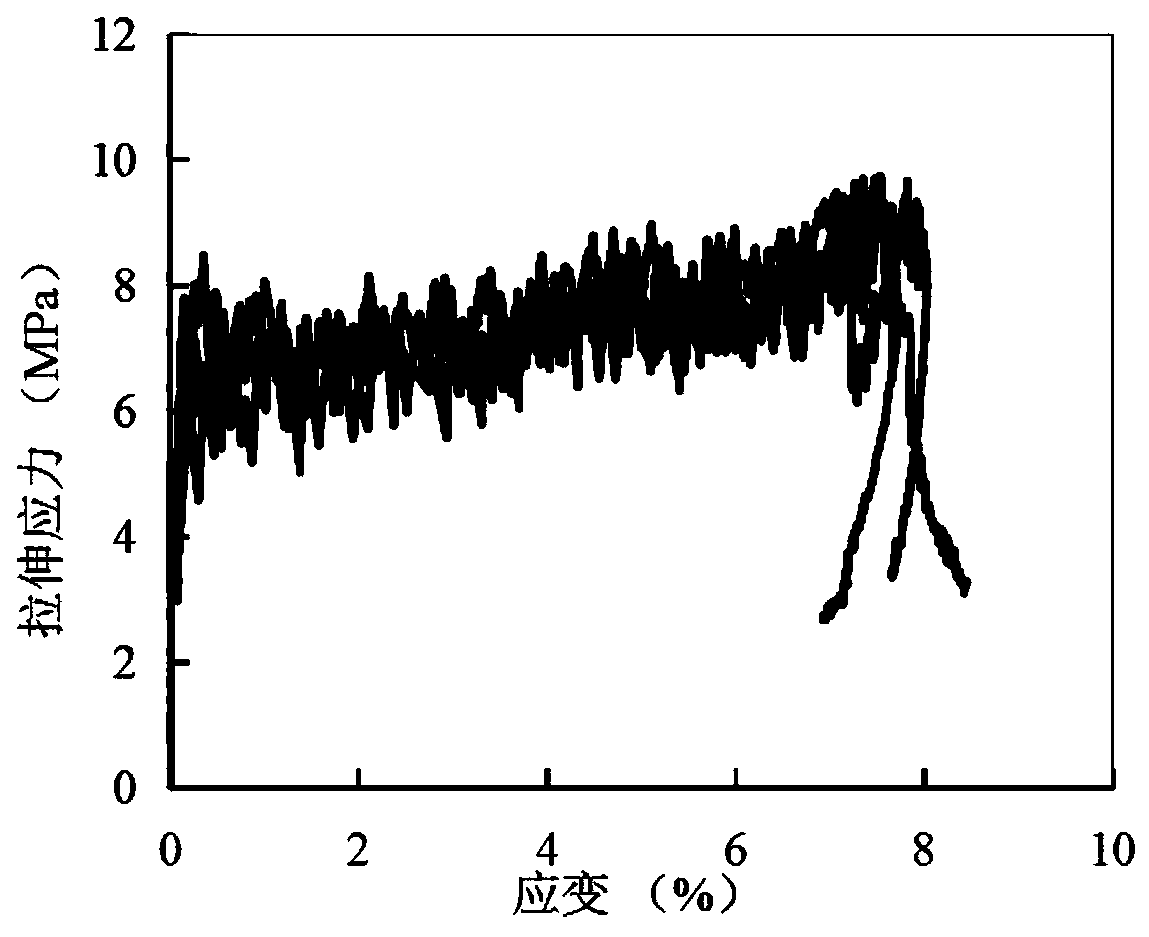

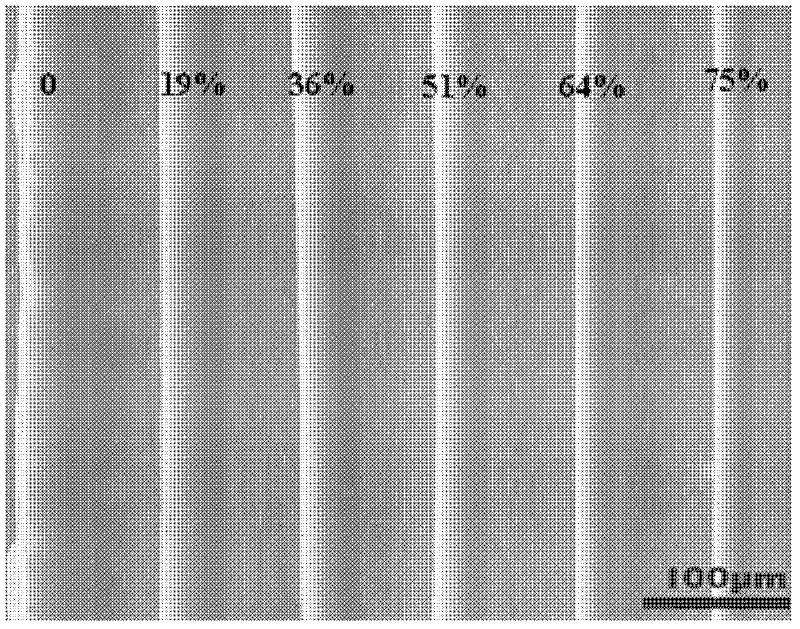

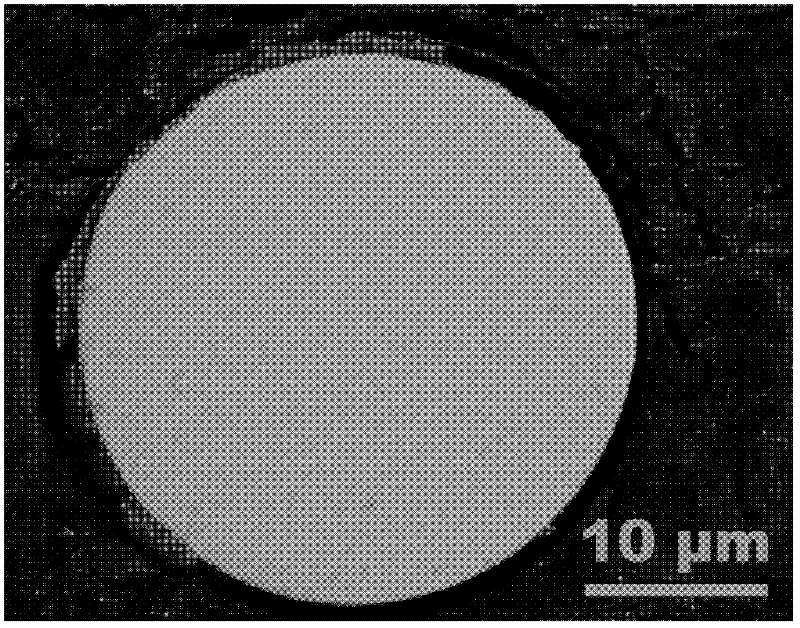

Rapid repair and retrofit of existing infrastructures demand durable high early strength materials that not only deliver sufficient strength within a few hours of placement but also significantly prolong the maintenance interval. The invention comprises a class of newly developed polyvinyl alcohol (PVA) fiber-reinforced high early strength engineered cementitious composites (ECC) materials featuring extraordinary ductility. The tailoring of preexisting flaw size distribution through non-matrix interactive crack initiators in the composite matrix results in high tensile ductility. The resulting high early strength ECC materials are capable of delivering a compressive strength of 21 MPa (3.0 ksi) within 4 hours after placement and retaining long-term tensile strain capacity above 2%.

Owner:RGT UNIV OF MICHIGAN

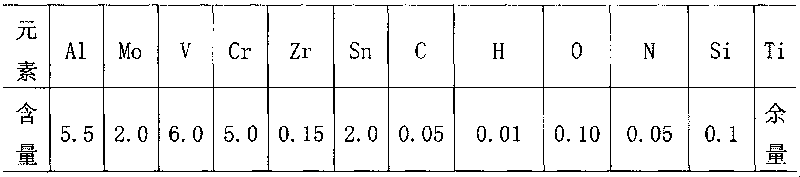

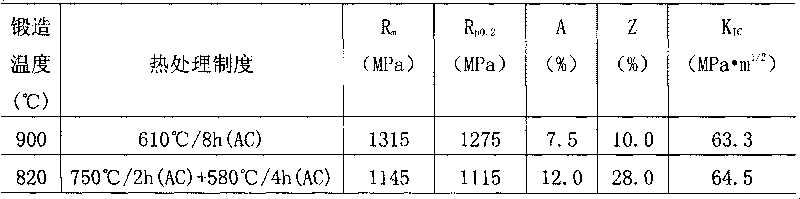

Novel high strength and toughness titanium alloy

The invention relates to a novel high strength and toughness titanium alloy which includes (by weight percent): 2.0-5.5 % of Al, 2.0-8.0 % of Mo and 2.0-6.0 % of V, wherein the ratio of Mo to V is 1 / 3-4. The titanium alloy contains 2.0-5.0 % of Cr or Cr and Fe (at most 0.9 % of Fe), the relationship k beta =CMo / 11+CV / 14.9+CCr / 6.5+CFe / 5 is satisfied and the value is 0.85-1.4. The titanium alloy also contains less than or equal to 0.10% of Si, less than or equal to 0.10% of O and less than or equal to 0.01% of H, the content of the rest components is controlled according to that of normal titanium alloy, and the allowance is Ti. The titanium alloy can also contain one or two of the neutral elements of Zr, Hf, Sn, each of which accounts for 0.15-3.5%. The titanium alloy has strong hardenability and good structure stability under high temperature, and segregation and fragile intermetallic compounds can be prevented. The titanium alloy has good pressure workability and welding property and has good tensile ductility and forgeability.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

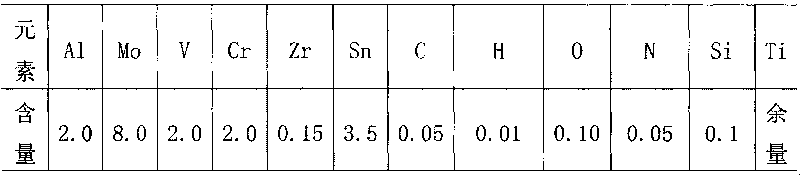

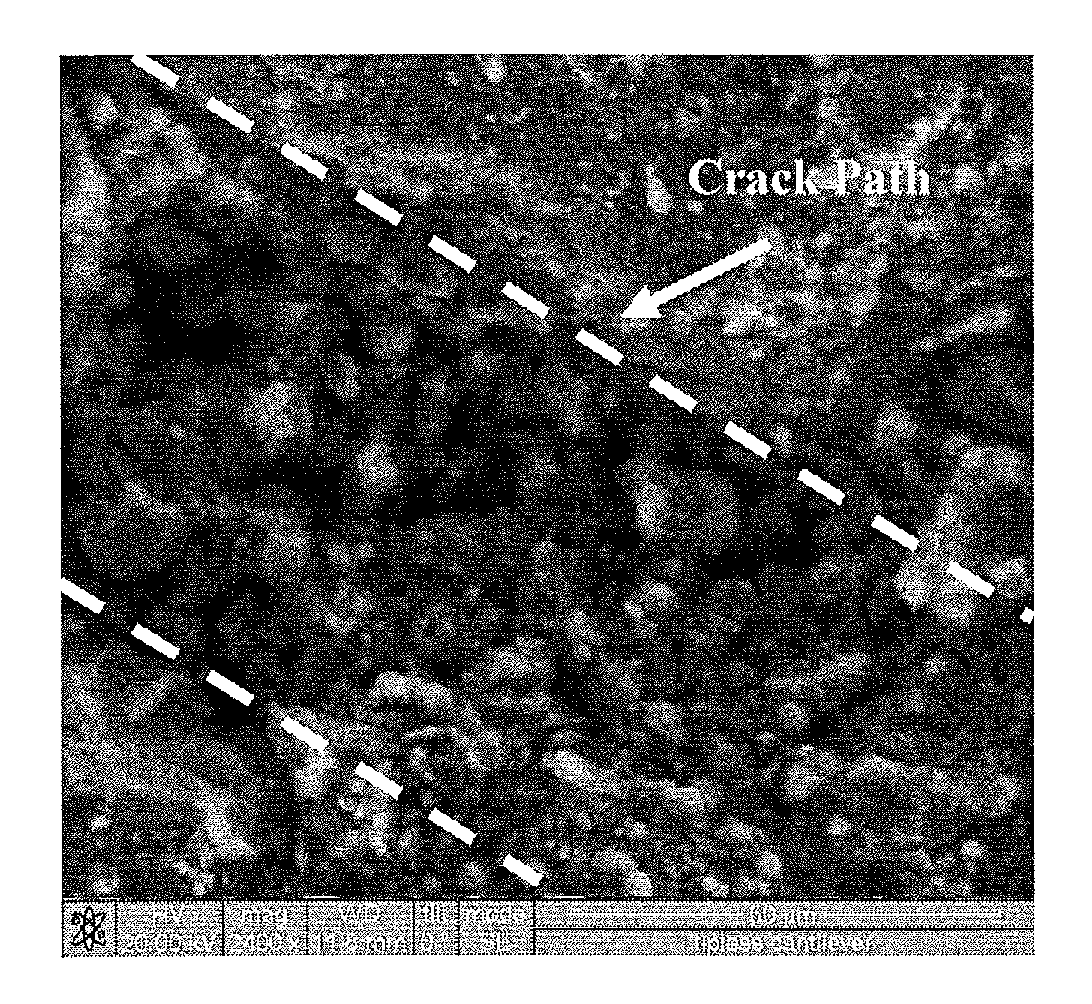

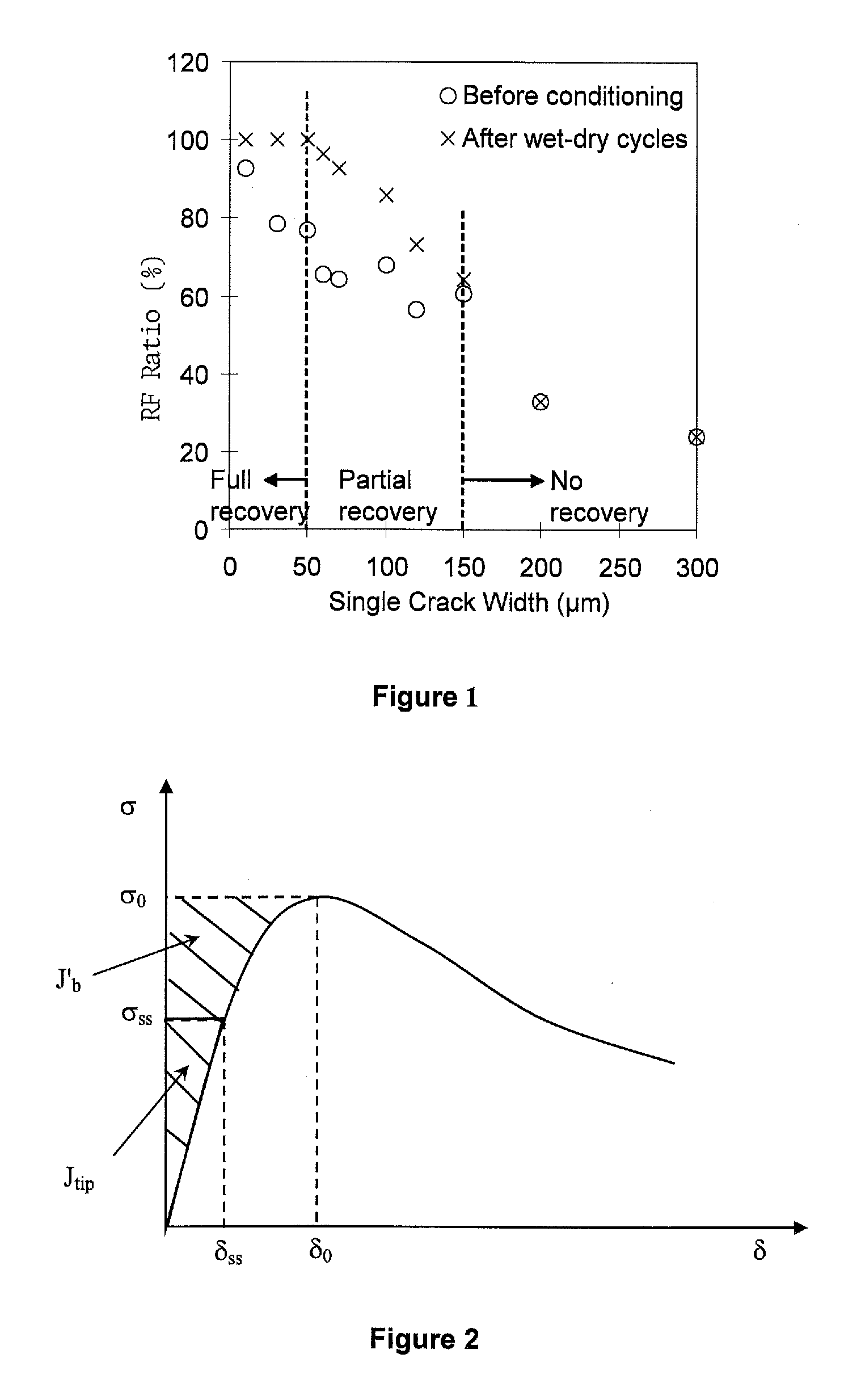

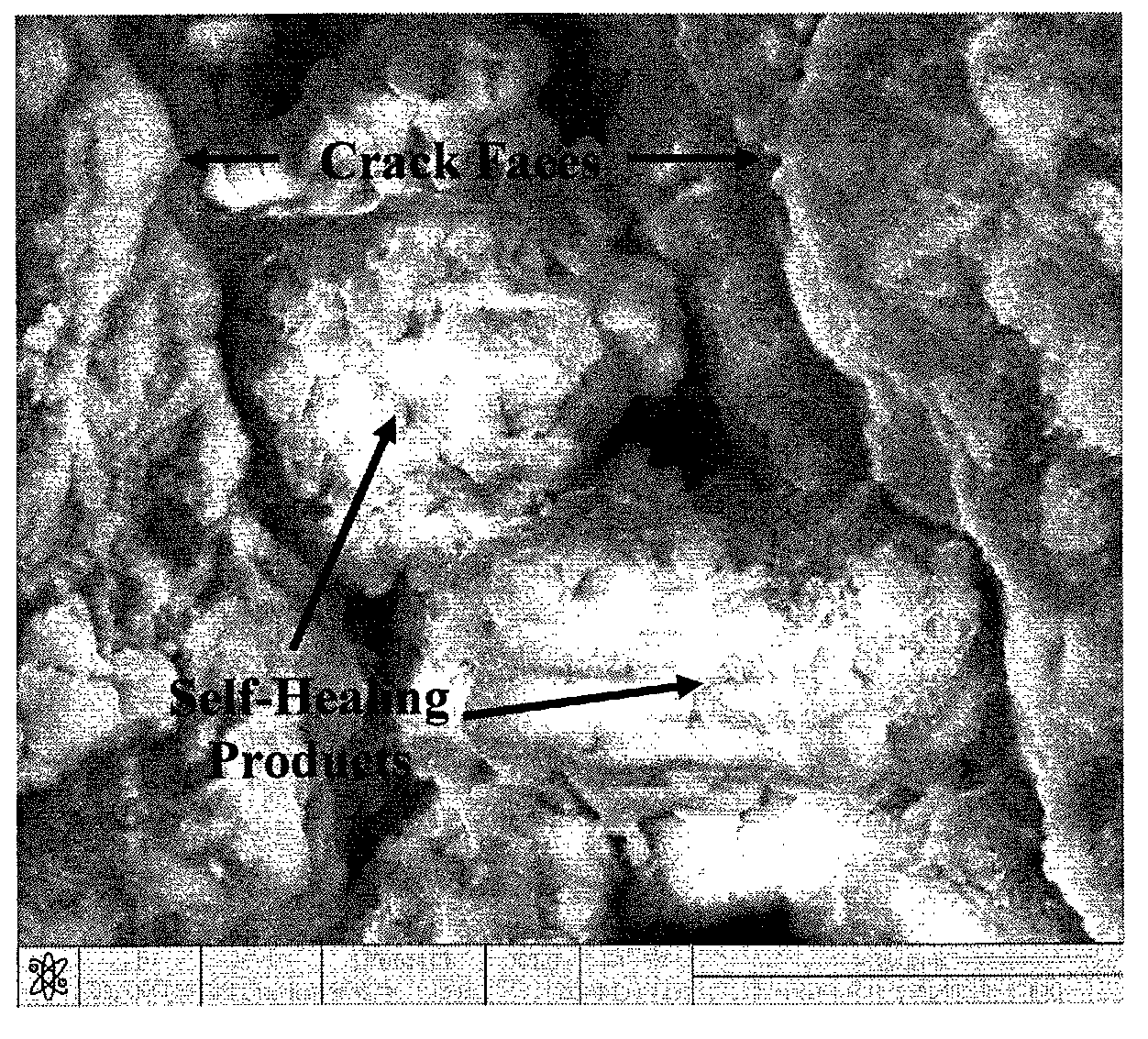

Engineered self healing cementitious composites

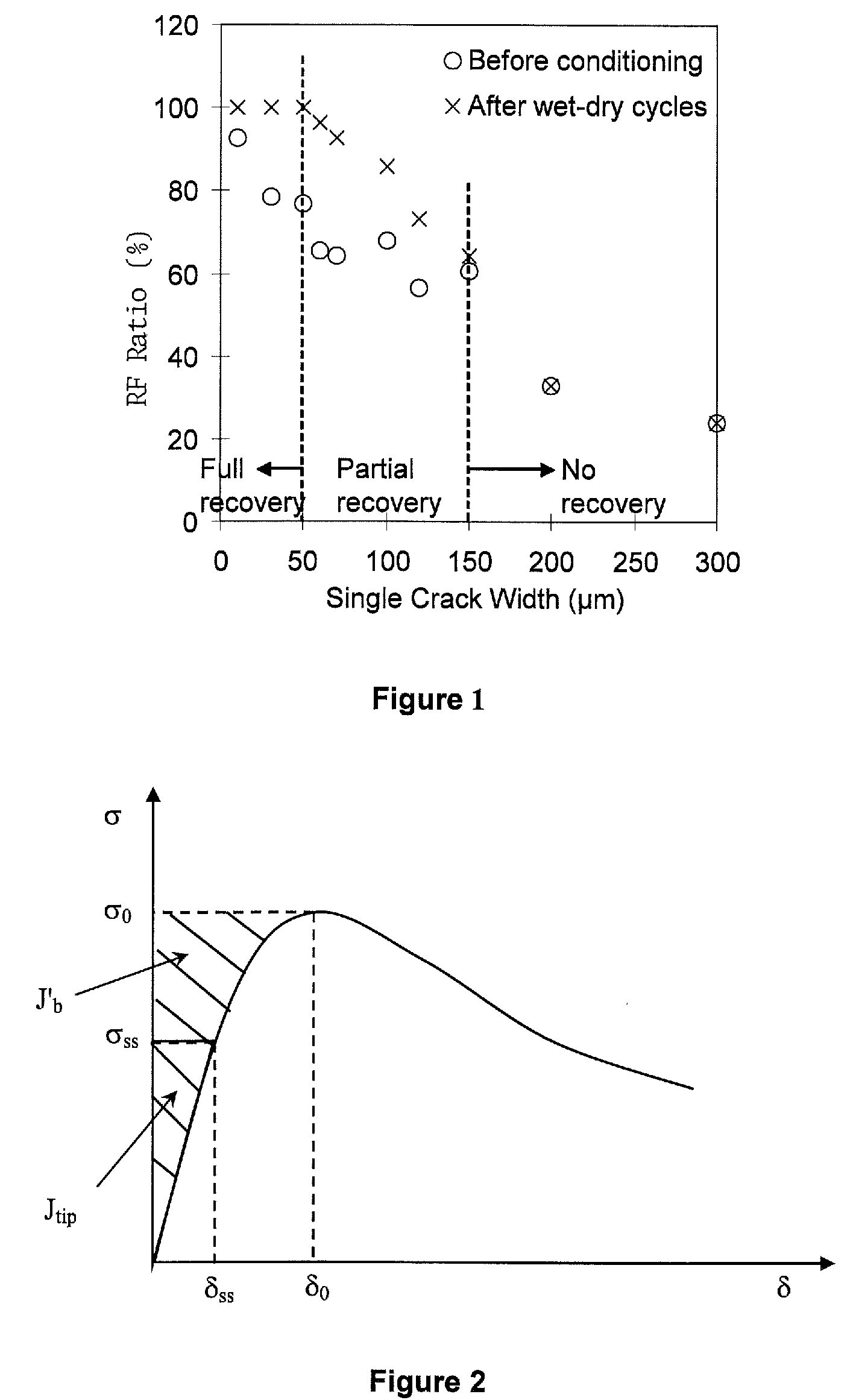

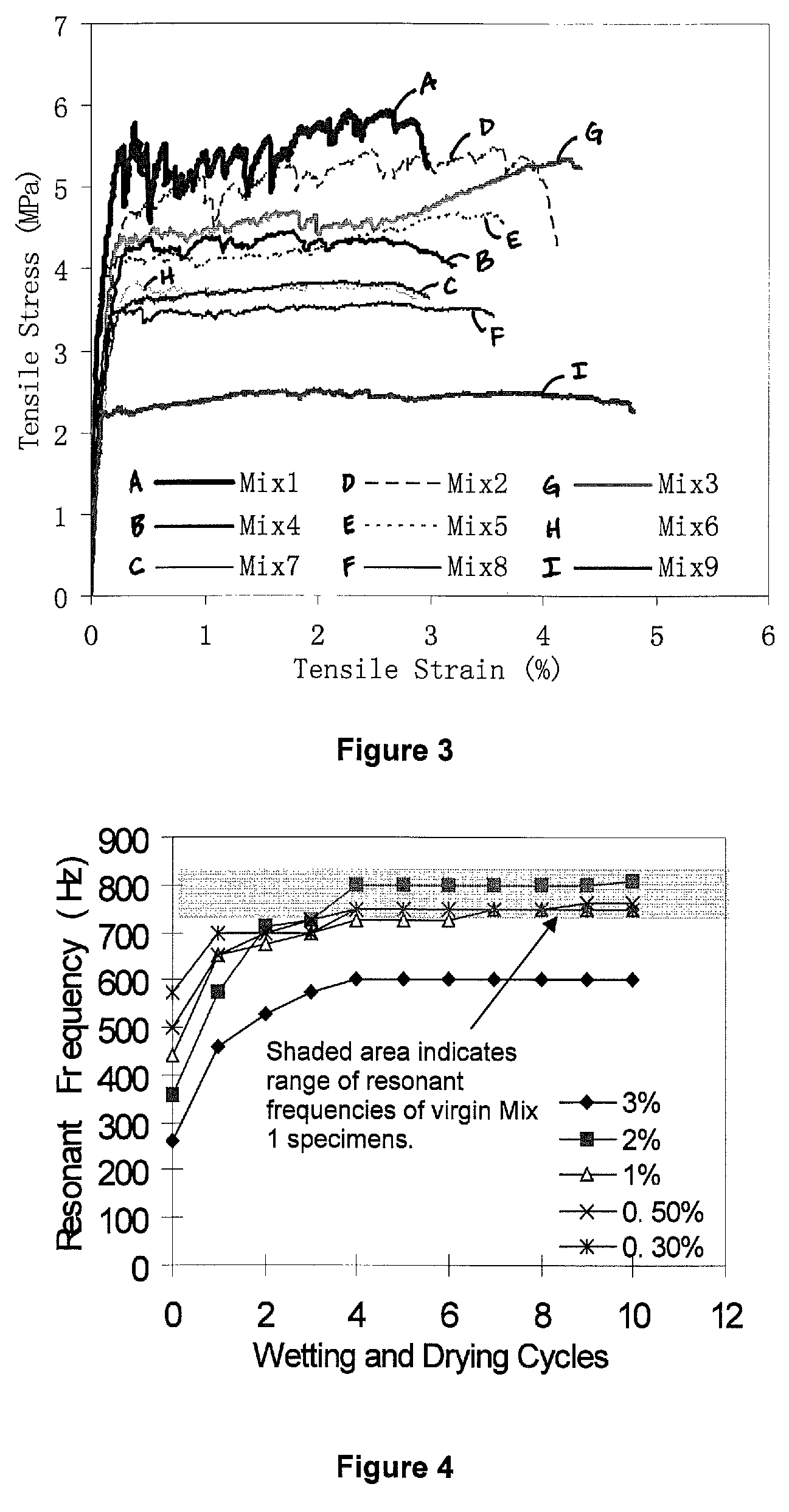

ActiveUS20080261027A1Highly controlled crack widthPreferable flowabilitySolid waste managementSynthetic resin layered productsSelf-healingCement composites

Cementitious composites engineered for self-healing, combining self-controlled tight crack width and extreme tensile ductility. Self-healing takes place automatically at cracked locations without external intervention. In the exemplary embodiment, fiber-reinforced cementitious composites with self-controlled tight crack width less than 50 μm and tensile ductility more than 2% are prepared. Self-healing in terms of mechanical and transport properties recovery of pre-damaged (by pre-cracking) composite is revealed in a variety of environmental exposures, include wetting and drying cycles, water permeation, and chloride submersion.

Owner:RGT UNIV OF MICHIGAN

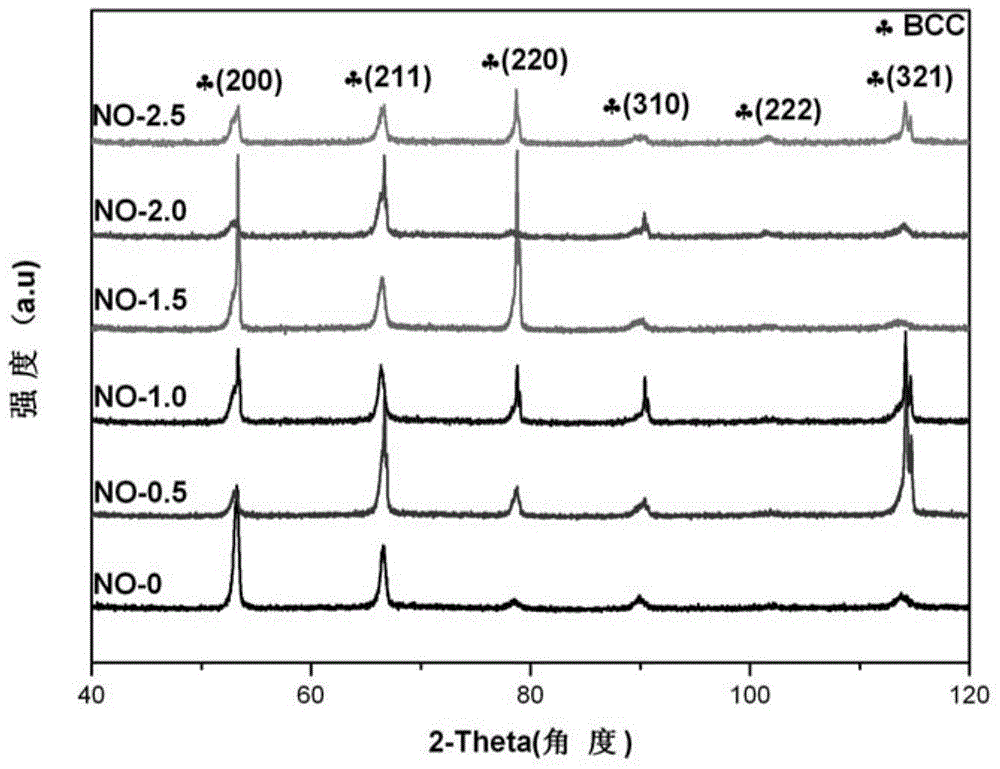

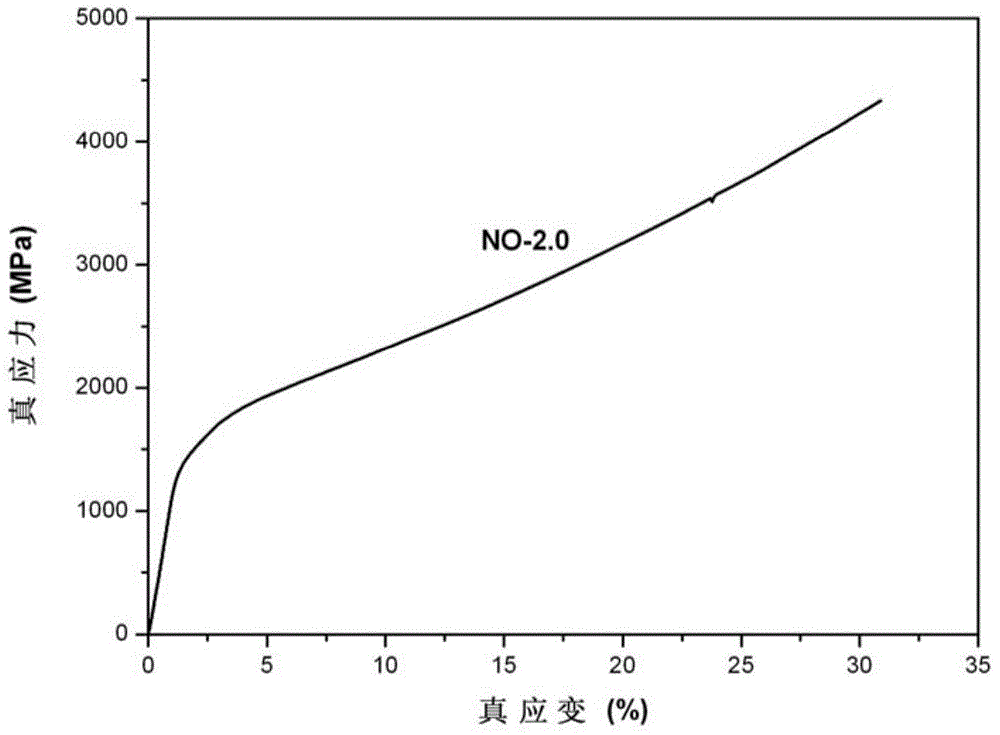

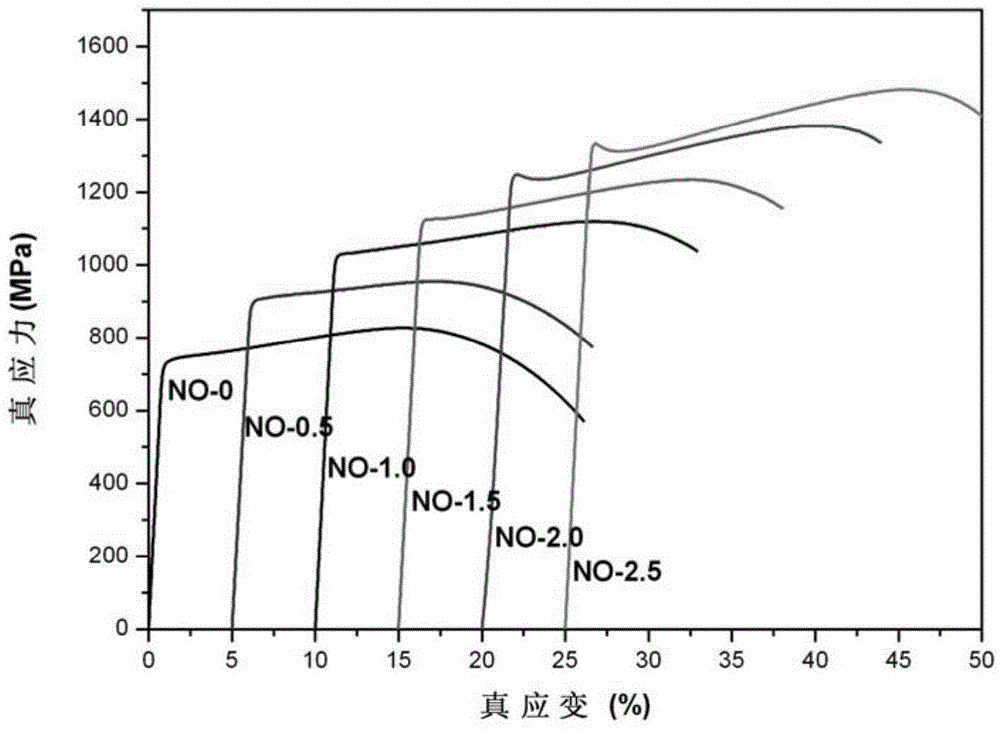

TiZrHfNb based high-entropy alloy with nitrogen and oxygen alloyed together and preparation method thereof

ActiveCN105671404AWide range of ingredientsWide range of preparation conditionsHigh entropy alloysOxygen

The invention relates to TiZrHfNb based high-entropy alloy with nitrogen and oxygen alloyed together and a preparation method thereof. Particularly, the tensile strength and tensile ductility of the alloy are remarkably improved by simultaneously microalloying N and O elements. The preparation method includes the following steps that metal raw materials of Ti, Zr, Hf and Nb are accurately weighed according to the molar ratios after oxide skin is removed; other added elements are accurately weighed according to the molar ratios after oxide skin is removed and the elements are washed with alcohol; the N element is added in the form of nitride, and the O element is added in the form of oxide; and target alloy is smelted in a nonconsumable vacuum arc furnace or cold crucible shower furnace, and the alloy is obtained through vacuum suction casting or casting equipment. The tensile property of the high-entropy alloy is improved remarkably by simultaneously adding the N and O elements, the tensile strength of (TiZrHfNb)97.5(NO)2.5 based high-entropy alloy reaches 1300 MPa, meanwhile, the tensile ductility exceeds 15%, the work-hardening rate is low, and the comprehensive tensile property is excellent.

Owner:UNIV OF SCI & TECH BEIJING

Strain hardening brittle matrix composites with high strength and high tensile ductility

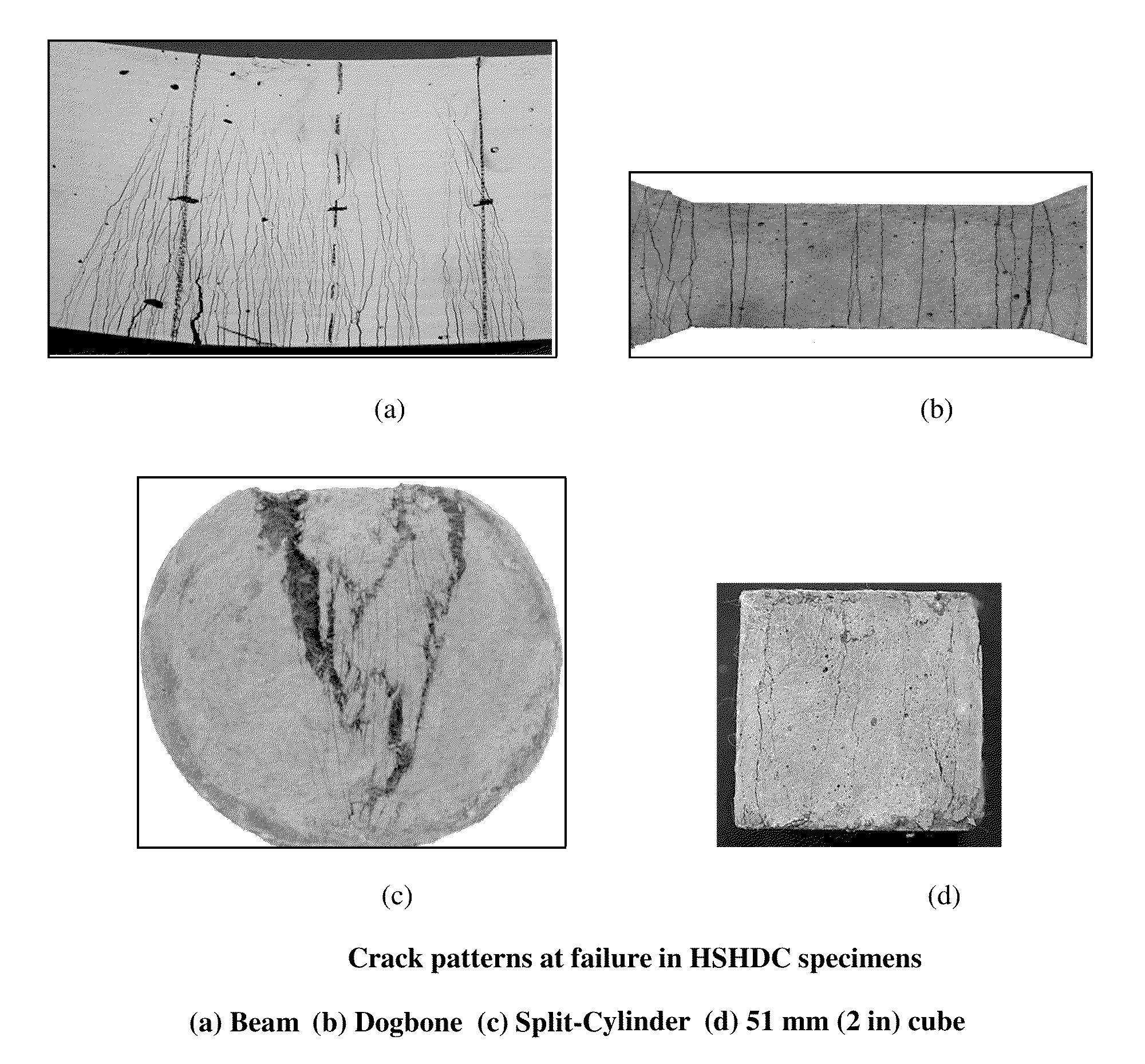

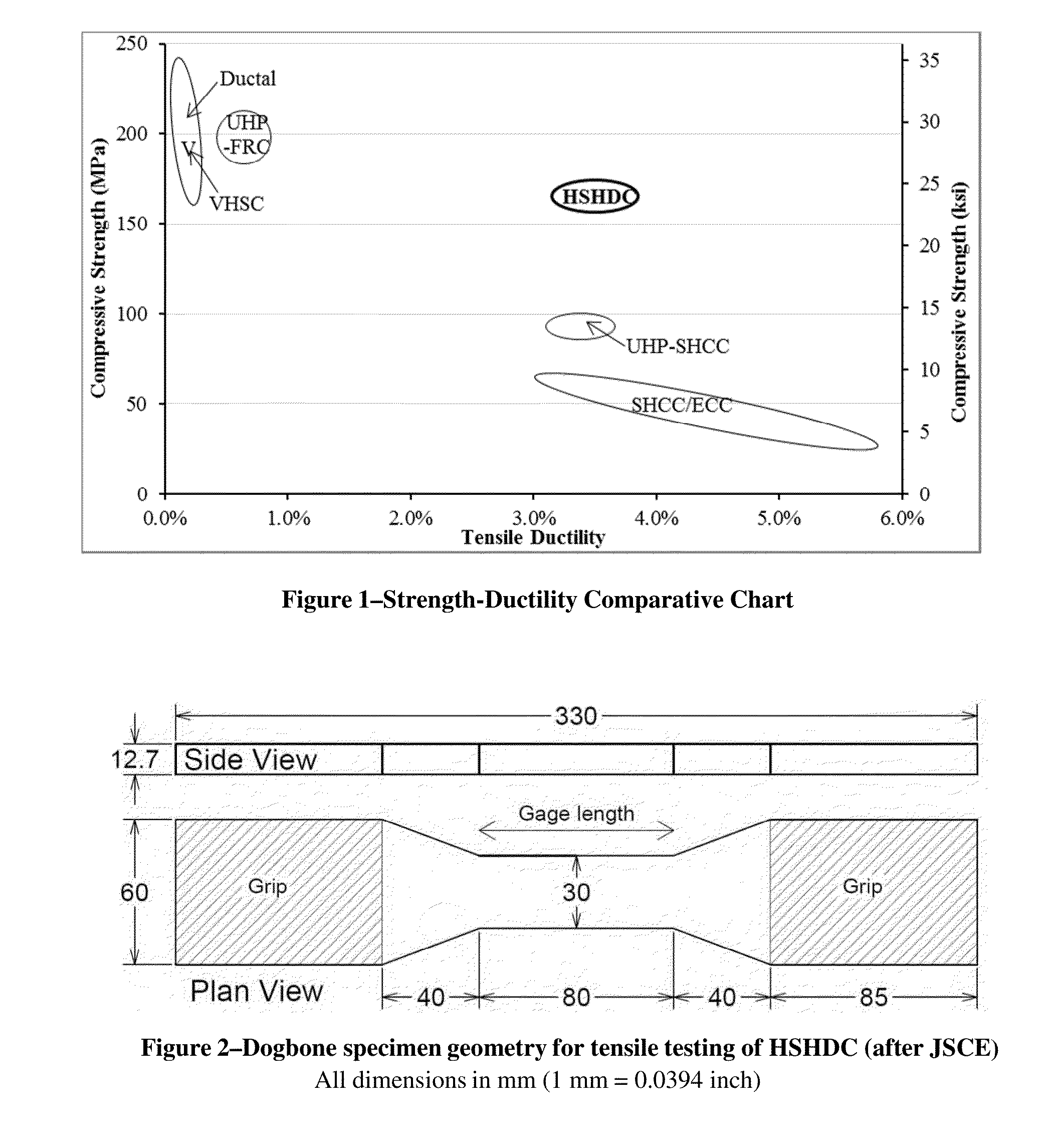

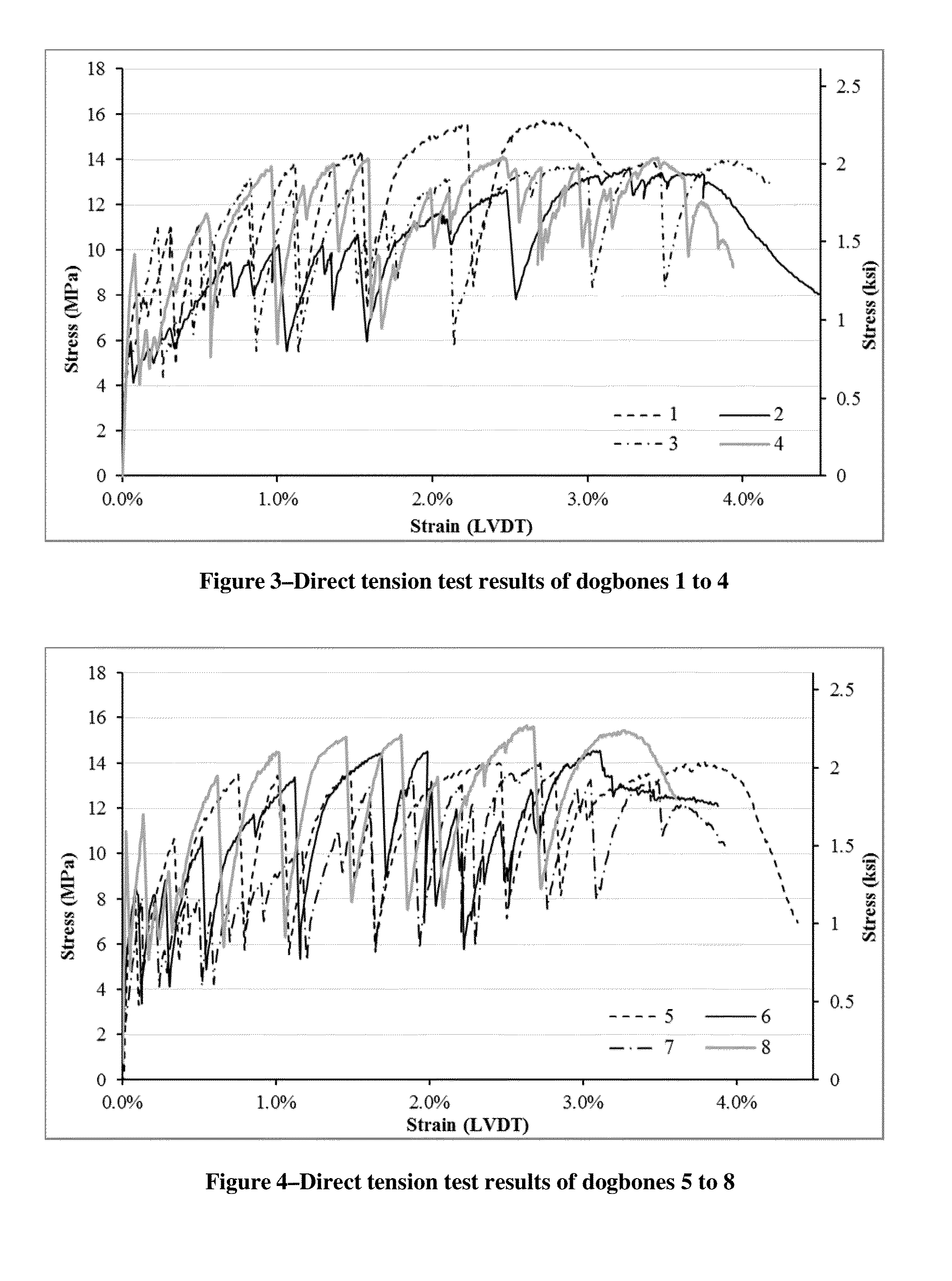

InactiveUS20130012625A1Increase deflectionEnhance load bearing and energy absorption capacitySolid waste managementPolymer scienceEnergy absorption

A new class of ultra-high performance concrete with very high strength and very high tensile ductility (High Strength High Ductility Concrete) is provided that represents the culmination of two high performance cement-based composite systems, namely those of very high strength, and those of very high tensile ductility into a single composite system. The integration of high strength and ductility has been attained via the adoption of micromechanical analysis and design of fiber reinforced brittle matrix composites. In doing so, the new High Strength High Ductility Concrete material dramatically increases the energy absorption capabilities of structural systems employing this material, making it a very good candidate material where hurricanes, earthquake, impact and blast loads are a concern.

Owner:RGT UNIV OF MICHIGAN

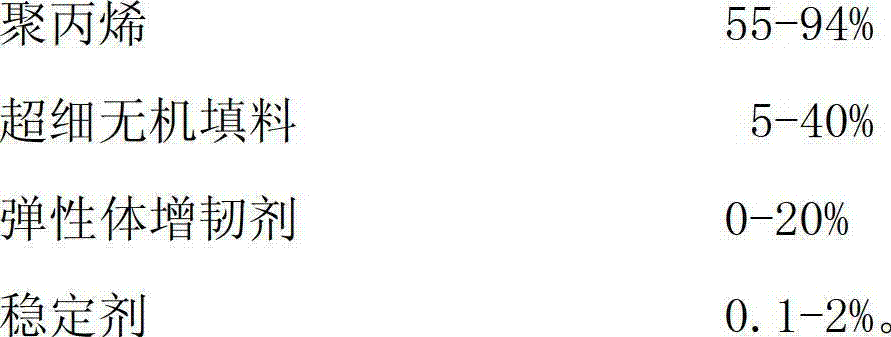

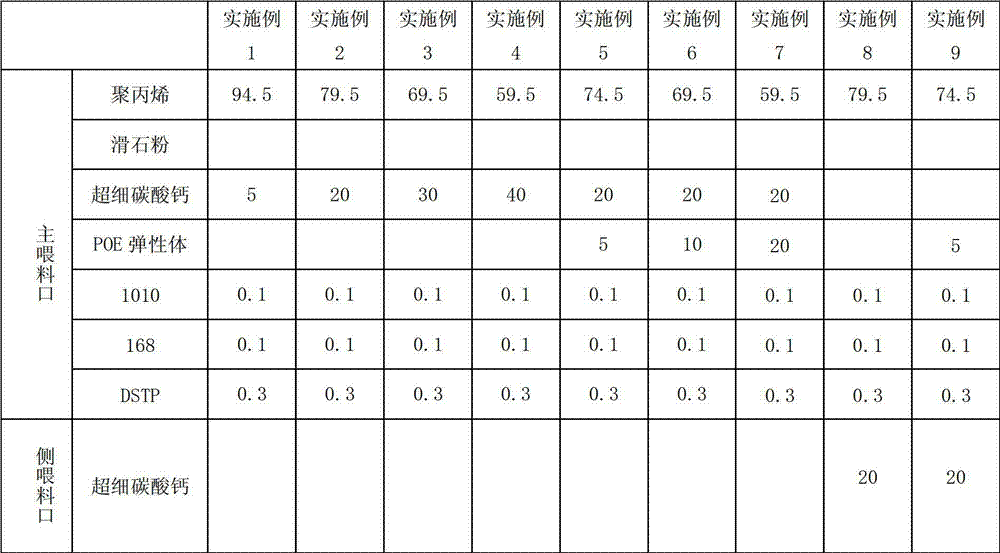

Polypropylene composite material with high strength and high elongation at break and preparation method thereof

InactiveCN103044769AImprove impact toughnessIncreased tensile elongation at breakElastomerPolypropylene composites

The invention discloses a polypropylene composite material with high strength and high elongation at break. The polypropylene composite material is prepared from the following raw materials in percentage by weight: 55-94% of polypropylene, 5-40% of ultrafine inorganic filler, 0-20% of elastomeric toughener and 0.1-2% of stabilizer. The polypropylene composite material disclosed by the invention has the following advantages: 1) the ultrafine calcium carbonate spherical filler is used for filling so as to modify the polypropylene material; and then compared with traditional talc powder-modified polypropylene, the polypropylene composite material has obviously higher impact toughness and especially has sufficient anti-bending performance and good rigid-tough balance; 2) the ultrafine calcium carbonate rigid particles are used for toughening the polypropylene material, the using quantity of a rubber elastomer with high price is greatly reduced, and the polypropylene composite material simultaneously has higher rigidity and tensile ductility; and 3) the sectional feeding way is adopted, the ultrafine calcium carbonate filler is added into an extruding machine at the lower stream of a screw rod, the influence of other components during the melting blending process on the ultrafine spherical particles during shearing and dispersion processes can be avoided to the greatest extent, and the performances of the composite material are further improved.

Owner:SHANGHAI PRET COMPOSITES

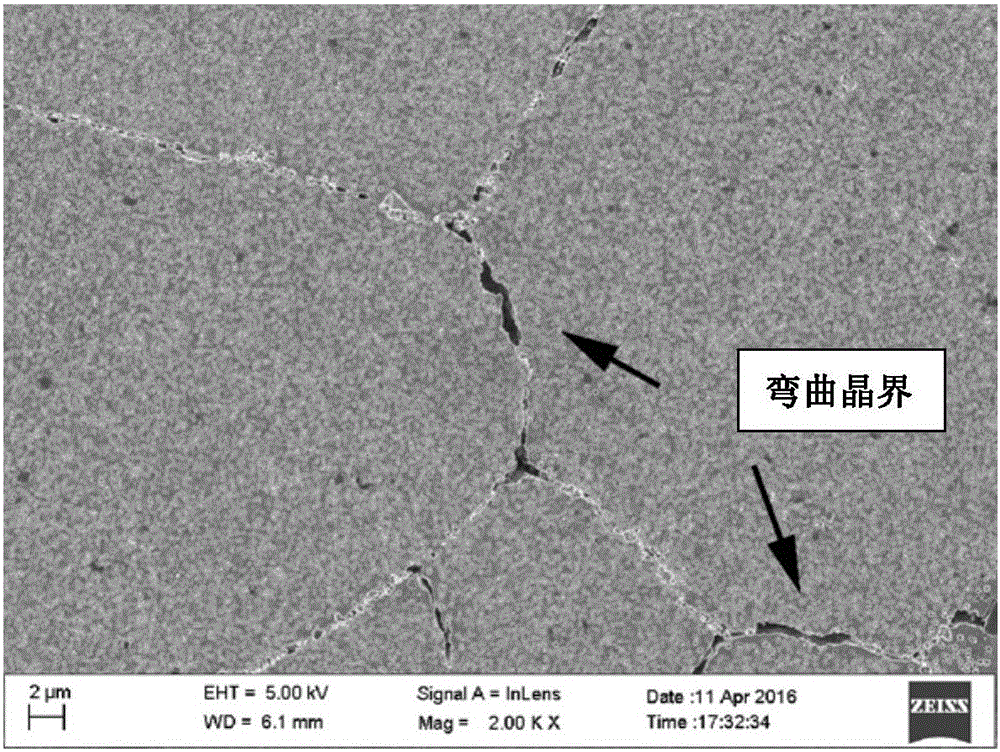

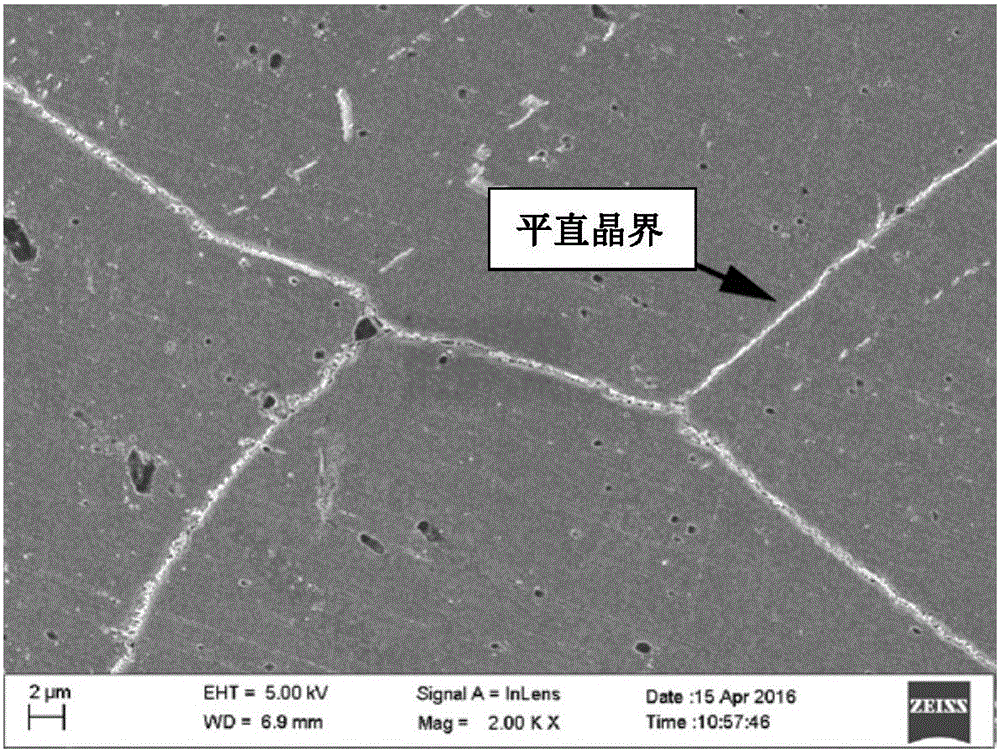

Heat treatment technology for improving high-temperature tensile ductility of Ni-Fe-Cr based deformation high-temperature alloy

ActiveCN106834990AImprove grain boundary strengthImprove tensile plasticitySolution treatmentCarbide

The invention discloses a heat treatment technology for improving high-temperature tensile ductility of Ni-Fe-Cr based deformation high-temperature alloy. The technology includes the steps that heat preservation lasts for 0.5-2h within the temperature range of 1050-1200 DEG C for performing solution treatment; the temperature is lowered to 20-150 DEG C below a gamma' phase precipitation temperature from the solution temperature at the speed of 0.1-20 DEG C / min, and air cooling is conducted to an indoor temperature after heat preservation lasts for 0.5-4h; and heat preservation is performed for 4-30h at the temperature 150-350 DEG C below the gamma' phase precipitation temperature, and air cooling is conducted again to the indoor temperature. According to the heat treatment technology, the method with high-temperature solution, slow cooling and low-temperature aging combined is adopted, the grain size of an obtained alloy structure is moderate, a bent sawtooth crystal boundary is formed among grains, and M23C6-type carbide is evenly distributed on the crystal boundary; and the crystal boundary has a good reinforcement effect under the high-temperature condition, and the high-temperature tensile ductility of the alloy is high.

Owner:HUANENG POWER INT INC +1

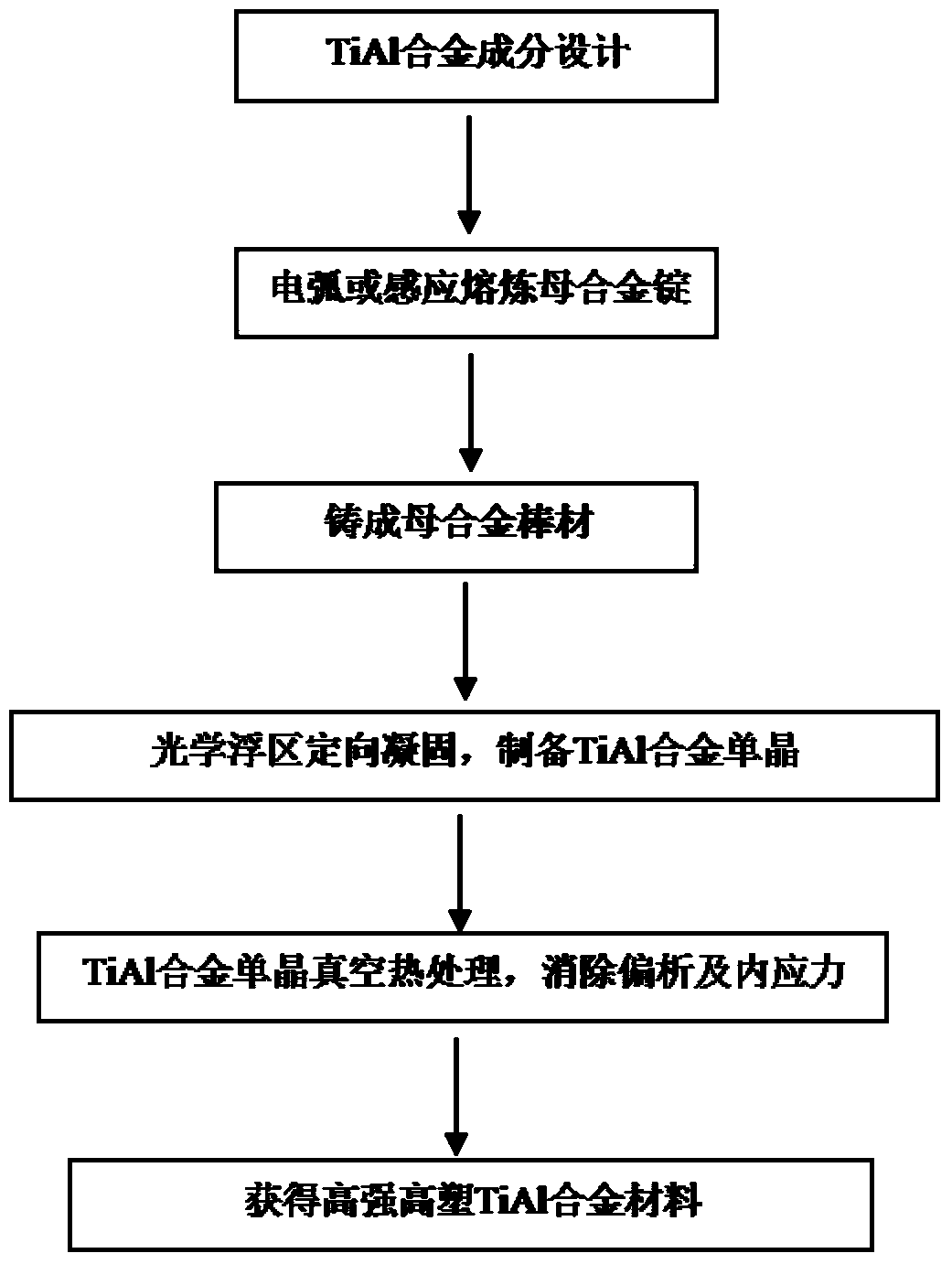

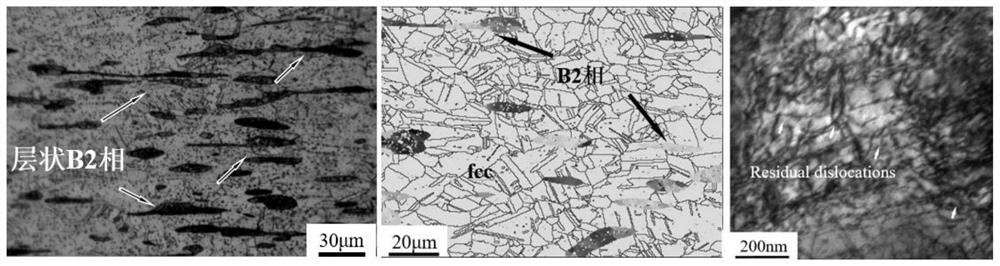

High-strength high-ductility TiAl alloy material and preparation method thereof

ActiveCN104278173AImprove mechanical properties at room temperatureImprove room temperature brittlenessPolycrystalline material growthEutectic material solidificationStress reliefTensile ductility

The invention discloses a high-strength high-ductility TiAl alloy material and a preparation method thereof. The high-strength high-ductility TiAl alloy material comprises Ti, Al and Nb, wherein the atomic percent is (44-51)Ti-(43-47)Al-(6-9)Nb. The preparation method of the high-strength high-ductility TiAl alloy material comprises the following steps of carrying out electromagnetic induction suspension smelting on a TiAl alloy mother alloy ingot by adopting a water-cooled copper crucible, and carrying out suction casting to obtain a mother alloy rod; carrying out directional solidification on the mother alloy rod by adopting a four-mirror optical floating region directional solidification furnace, controlling the orientation of a TiAl alloy lamella, and acquiring a PST crystal; carrying out heat treatment and stress relief annealing on the PST crystal in an alpha single-phase region through a vacuum heat treatment furnace, and removing B2-phase segregation and residual stress to finally form the high-strength high-ductility TiAl alloy material. The high-strength high-ductility TiAl alloy material prepared through the method disclosed by the invention prevents the pollution of the water-cooled copper crucible on a TiAl alloy in a melting process, overcomes the defects of nonuniform component property and complicated processing of the traditional seed crystal method, is enhanced in strength and obtains outstanding room temperature tensile ductility.

Owner:NANJING UNIV OF SCI & TECH

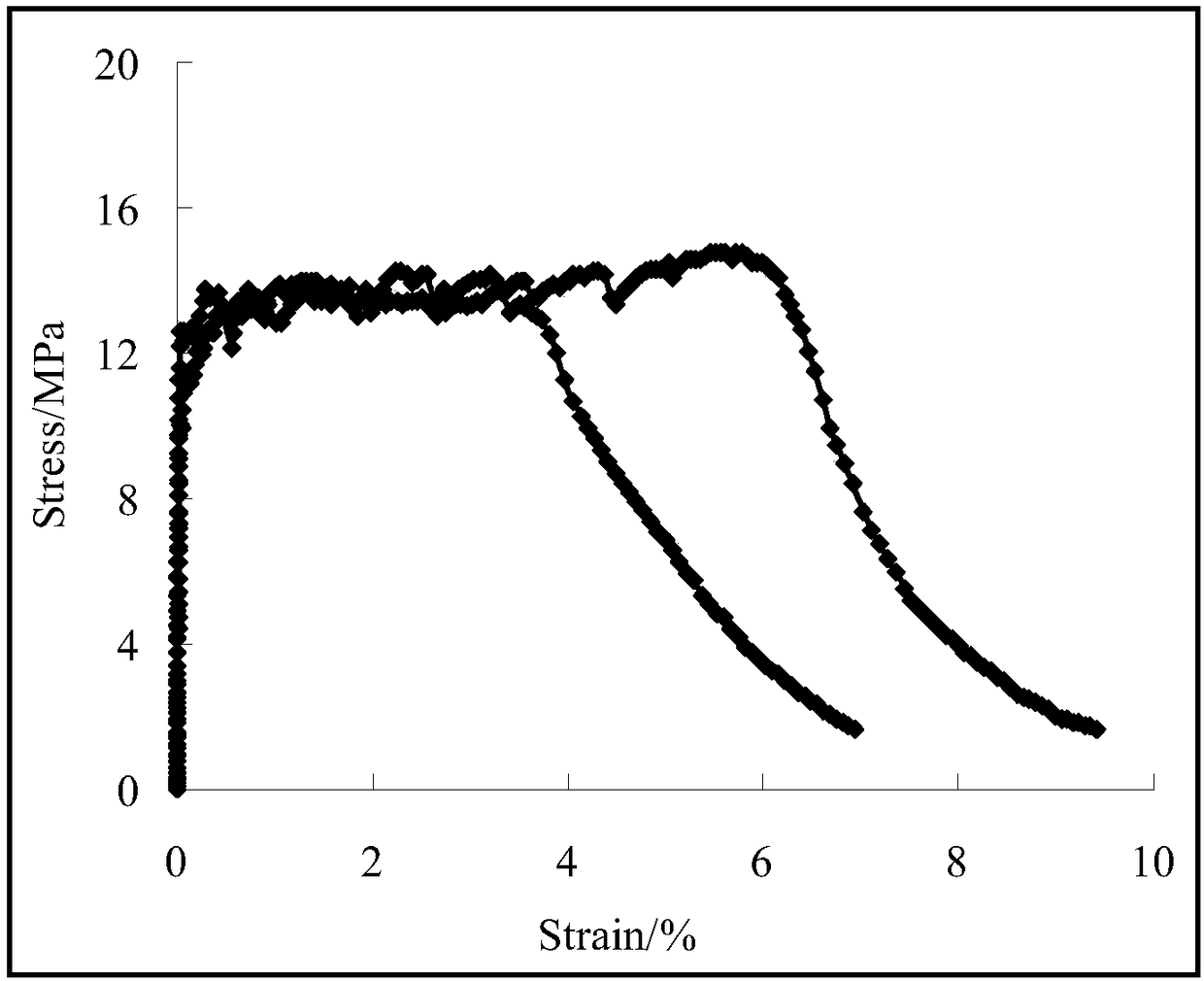

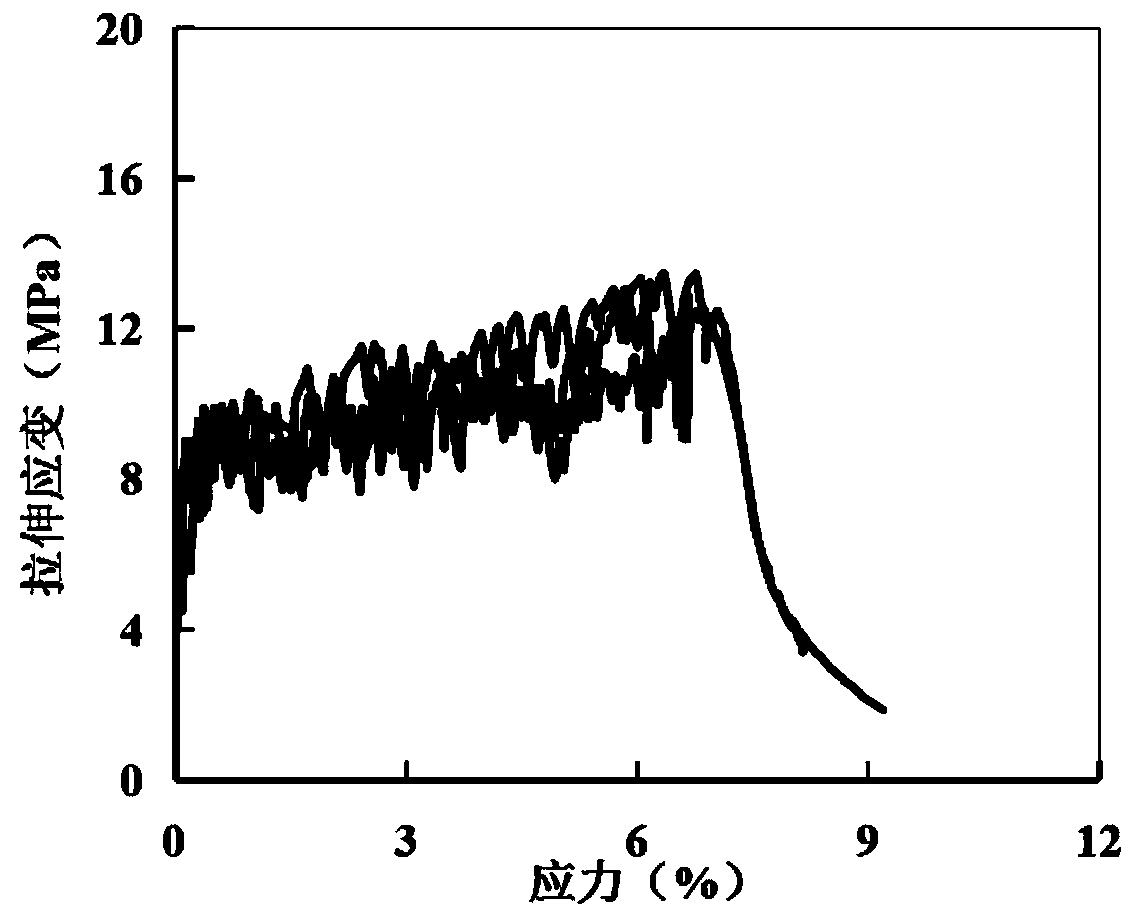

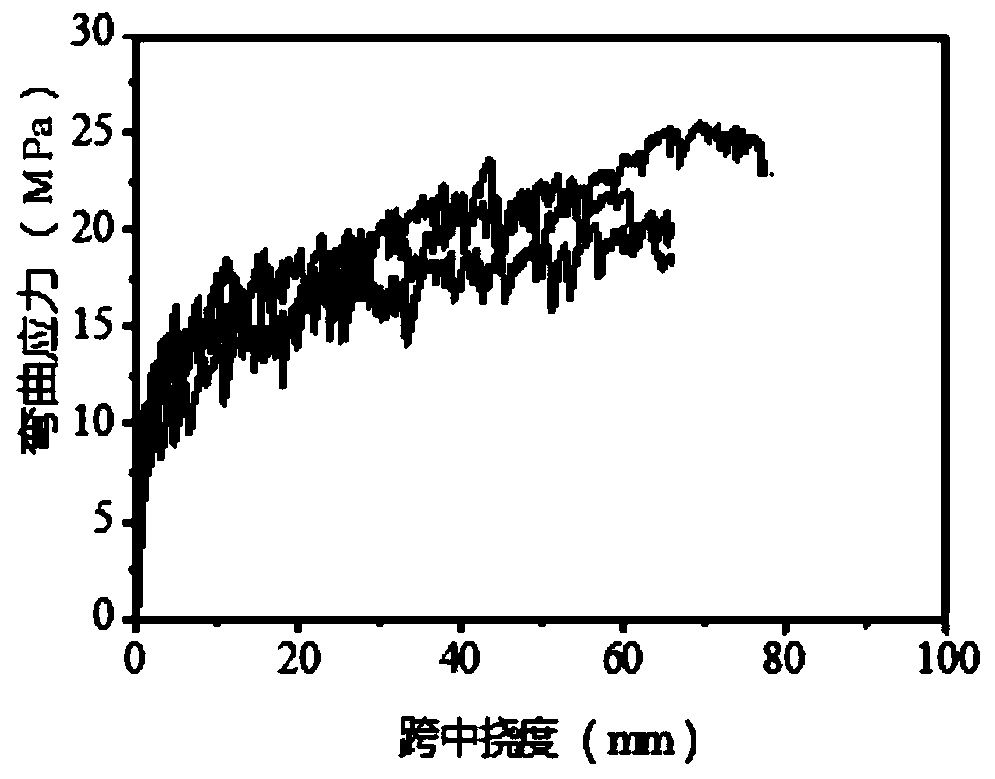

Hybrid fiber toughened ultrahigh-strength and ultrahigh-ductility cement-based material

The invention relates to a hybrid fiber toughened ultrahigh-strength and ultrahigh-ductility cement-based material which comprises the following ingredients in parts by weight: 700-1250 parts of 525 ordinary Portland cement, 200-300 parts of silica fume, 200-750 parts of mineral powder, 400-500 parts of quartz sand, 200-230 parts of water, 20-30 parts of a polycarboxylic acid high efficiency waterreducer, 5-20 parts of ultra-high molecular weight polyethylene fiber and 39-117 parts of ultrahigh-strength steel fiber. Compared with the prior art, the cement-based composite with maximum compressive strength of 200MPa, direct tension strength near 15MPa, tensile ductility near 10% and slump of greater than 180mm is obtained by mixed use of the ultra-high molecular weight polyethylene fiber and the steel fiber, and can be pumped and cast in place.

Owner:TONGJI UNIV

Engineered self healing cementitious composites

ActiveUS7572501B2Reduce capacityReduce stiffnessSolid waste managementSynthetic resin layered productsSelf-healingCement composites

Owner:RGT UNIV OF MICHIGAN

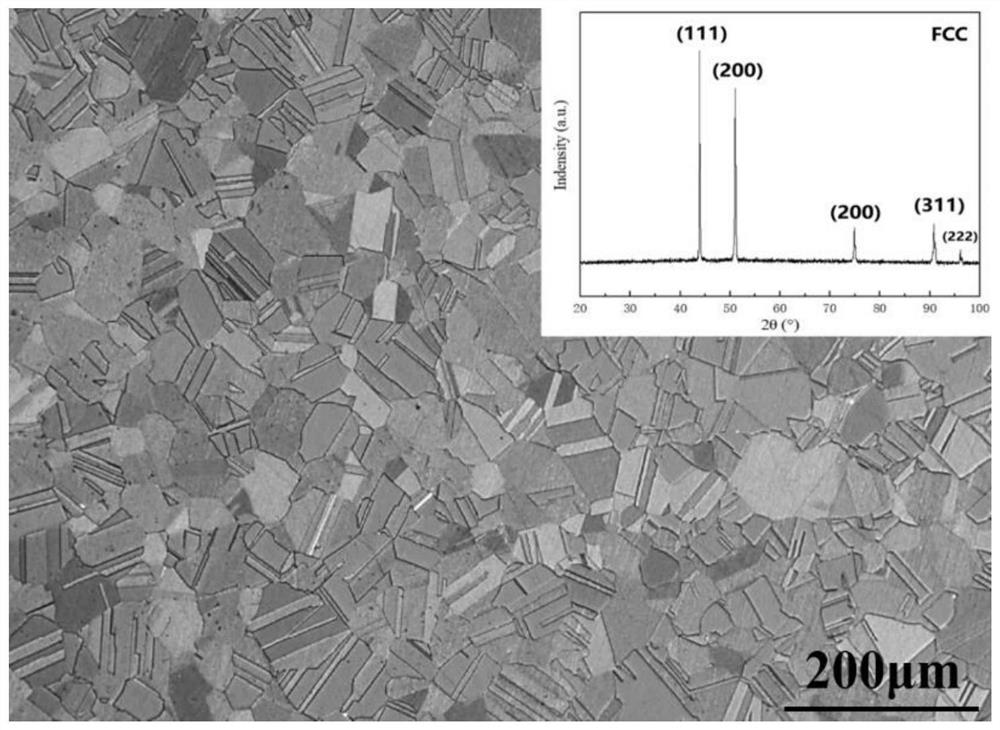

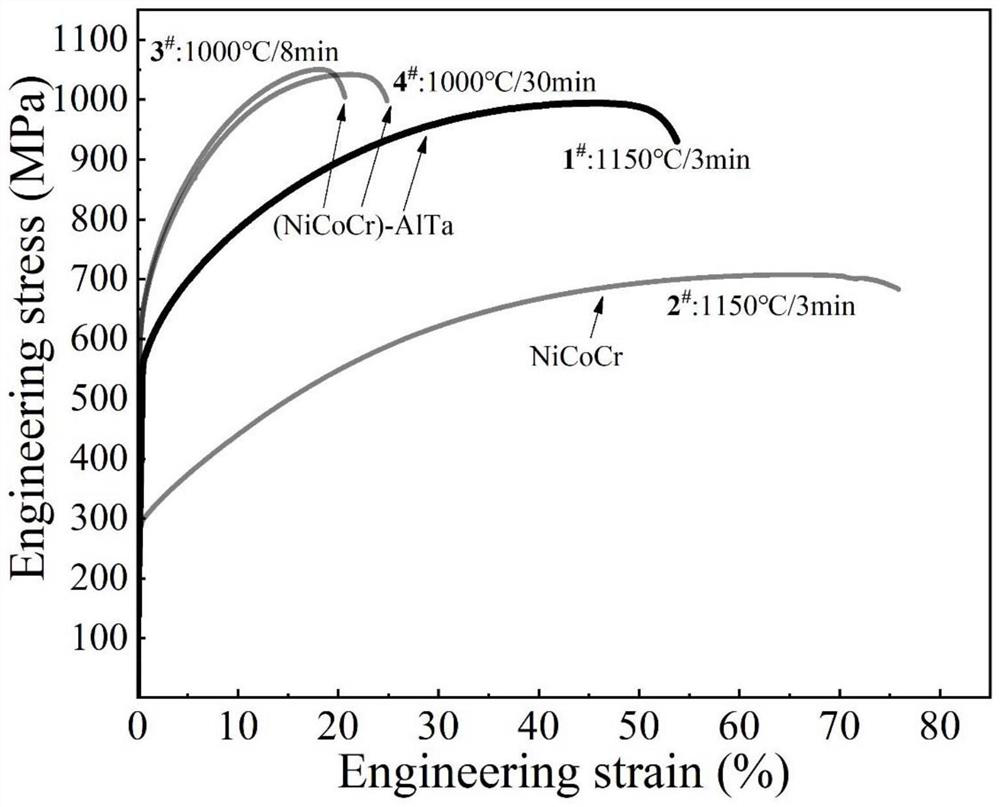

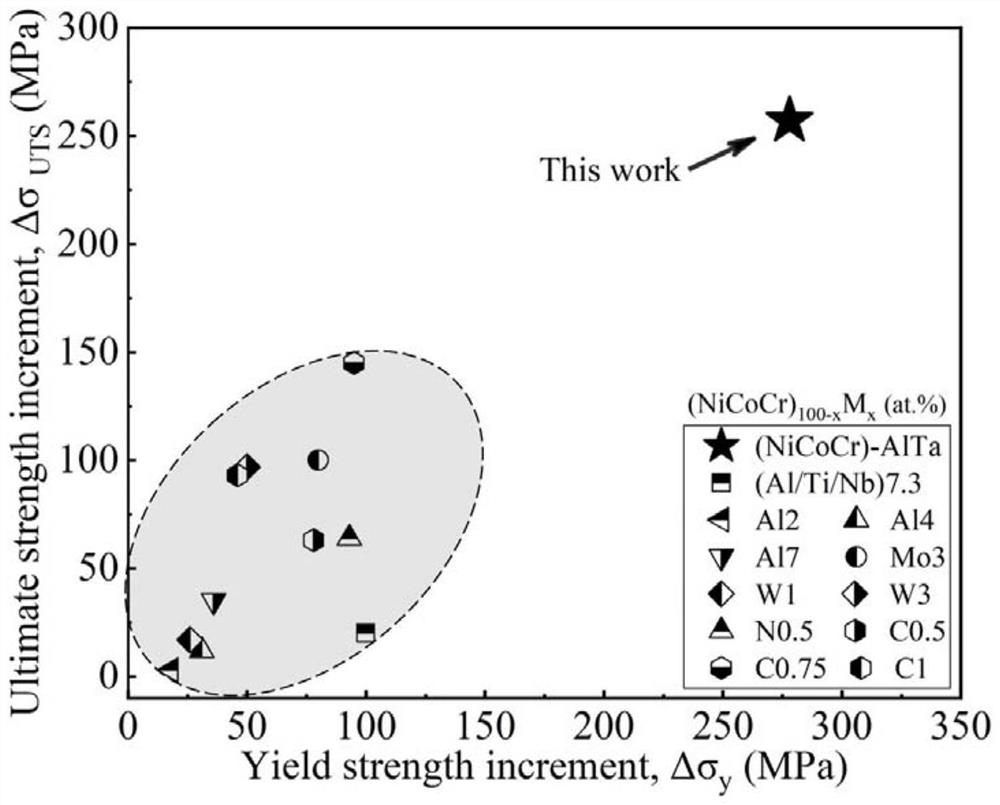

NiCoCr-based medium entropy alloy with excellent strength plasticity matching and preparation method

ActiveCN111893363AHigh strengthGood mechanical properties at room temperatureSolid solution strengtheningTensile ductility

The invention provides a NiCoCr-based medium entropy alloy with excellent strength plasticity matching and a preparation method. According to the NiCoCr-based medium entropy alloy with the excellent strength plasticity matching and the preparation method, microalloying treatment is performed by utilizing Al and Ta elements, and the alloy can obtain excellent strength-plasticity combination after being subjected to a simple deformation heat treatment process; and by means of Al / Ta element alloying, the grain size is reduced, the twin crystal content is increased, and a remarkable solid solutionstrengthening effect is generated, the lattice friction force is greatly increased, but the alloy still maintains a fcc matrix, so that the alloy still has good toughness while the alloy strength isimproved. The NiCoCr-based medium entropy alloy has excellent room-temperature mechanical properties, the NiCoCr medium entropy alloy yield strength is improved by 106% to be about 635 MPa, the tensile strength is improved by 35% to be about 1000 MPa, and meanwhile, the NiCoCr-based medium entropy alloy has a tensile ductility of 52% at the same time. Based on the above characteristics, the NiCoCr-based medium entropy alloy with the excellent strength plasticity matching is made to have a great competitive advantage in single-phase fcc high / medium entropy alloys and have the engineering application foreground extremely.

Owner:XI AN JIAOTONG UNIV

Expanding and extruding connection method for mechanical connection of plastic pipes

InactiveCN102032413ALifetime SynchronizationFirmly connectedJoints with sealing surfacesPipe connection arrangementsEngineeringTensile ductility

The invention relates to an expanding and extruding connection method for mechanical connection of plastic pipes, specifically comprising the following steps of: (1) expanding the inner diameter of each plastic pipe connection part by 10-25 percent by using a pipe expander and utilizing the stretching ductility of the plastic pipes; and (2) connecting the plastic pipes by adopting a plastic expanding and extruding connector comprising a plastic connector and a plastic nut, sleeving the plastic nut on the plastic pipe, inserting an insertion part of the plastic connector to a connection part of the plastic pipes, fastening the plastic nut on an outer thread of the plastic connector, enabling ribbed edges to clamp the inner wall of the connection part of the plastic pipes, and storing an extruded deformation part of the plastic pipeline into a concave ring. The expanding and extruding connection method of the invention is convenient, concise and reliable to connect various plastic pipelines.

Owner:上海三山信邦科技有限公司

Production method of complete biodegradable aliphatic polyester

The invention discloses a production method of complete biodegradable aliphatic polyester. The production method comprises the following three steps: (1) an esterification phase that: aliphatic dibasic acid monomer and aliphatic dibasic alcohol monomer are added to a reactor according to certain proportions, an esterification catalyst is added, and a normal-pressure esterification reaction is carried out under the protection of an inert gas; (2) a pre-concentration phase that: when the esterification reaction is completely finished, a main catalyst is added, and the mixture is subject to a reaction for 1 to 2 hours; (3) a concentration phase: an auxiliary catalyst is added, and the mixture is subject to a reaction for 4 to 9 hours, such that aliphatic ???? with a weight average molecular weight greater than 150 thousands is obtained. The polyester product provided by the present invention has good heat stability, stretching ductility, environment friendly performance and a good color, and can be biodegraded.

Owner:ZHEJIANG BILI PACKAGING

High early strength engineered cementitious composites

ActiveUS7799127B2High early-strengthLarge capacitySolid waste managementClimate change adaptationTensile strainCement composites

Rapid repair and retrofit of existing infrastructures demand durable high early strength materials that not only deliver sufficient strength within a few hours of placement but also significantly prolong the maintenance interval. The invention comprises a class of newly developed polyvinyl alcohol (PVA) fiber-reinforced high early strength engineered cementitious composites (ECC) materials featuring extraordinary ductility. The tailoring of preexisting flaw size distribution through non-matrix interactive crack initiators in the composite matrix results in high tensile ductility. The resulting high early strength ECC materials are capable of delivering a compressive strength of 21 MPa (3.0 ksi) within 4 hours after placement and retaining long-term tensile strain capacity above 2%.

Owner:RGT UNIV OF MICHIGAN

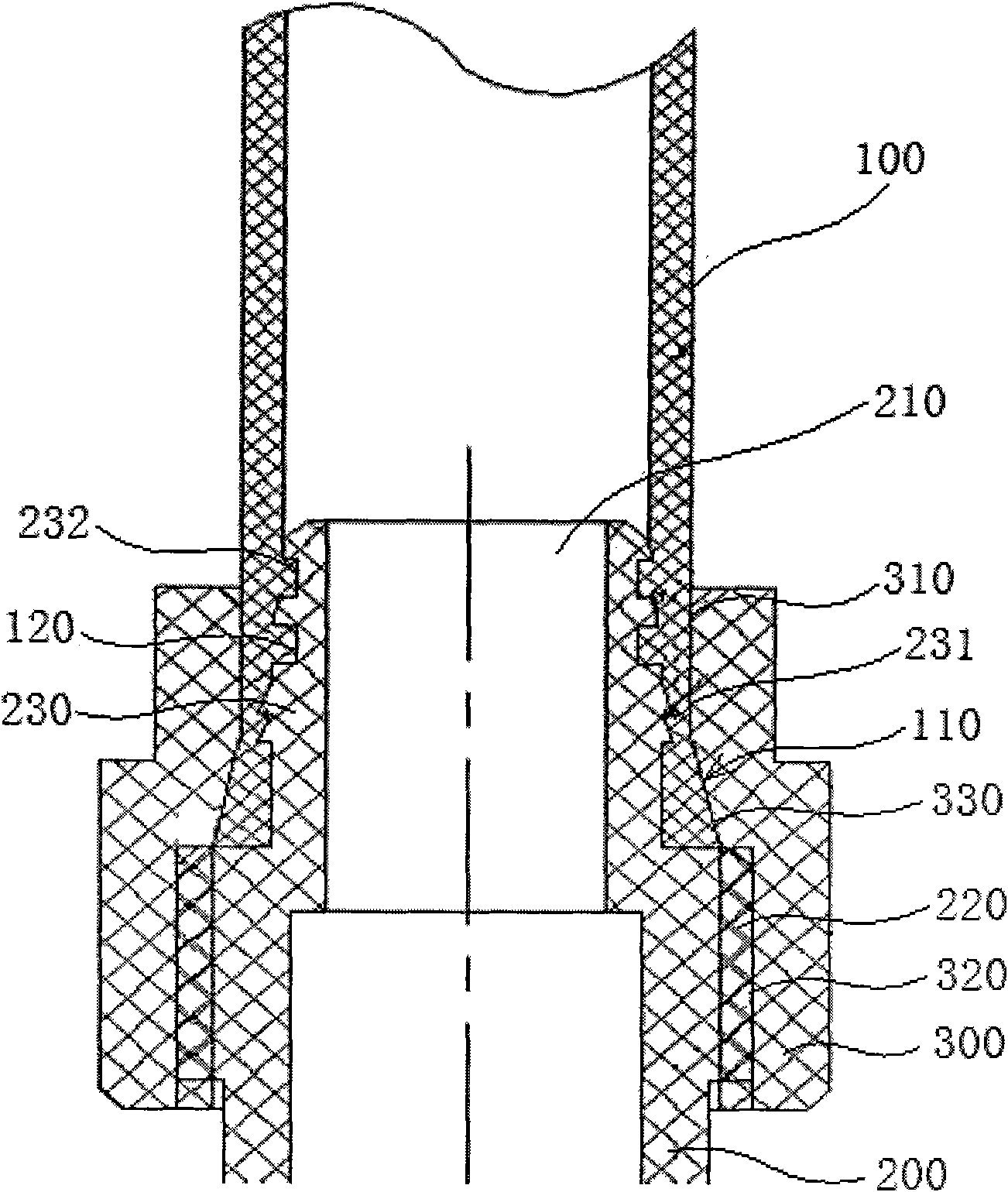

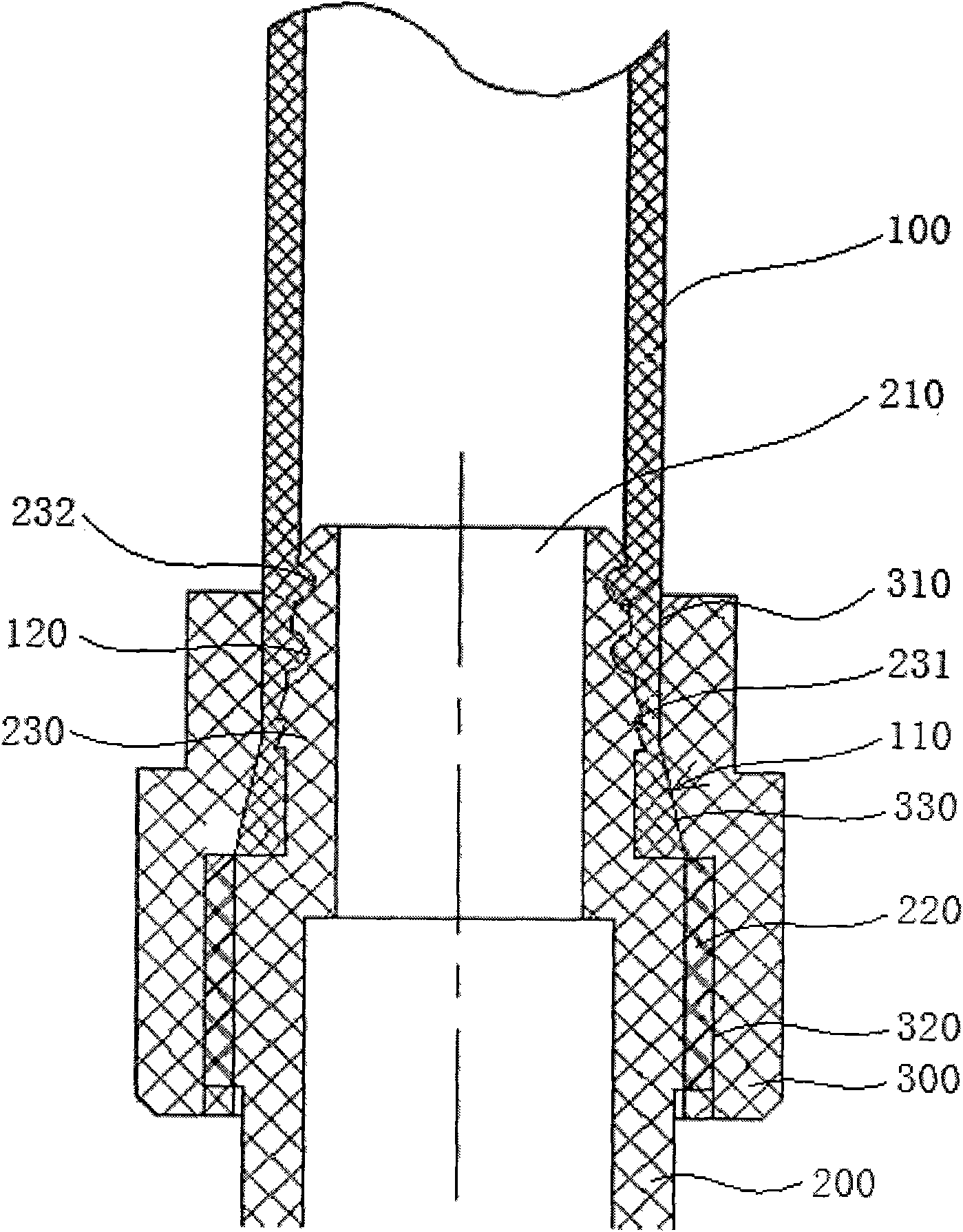

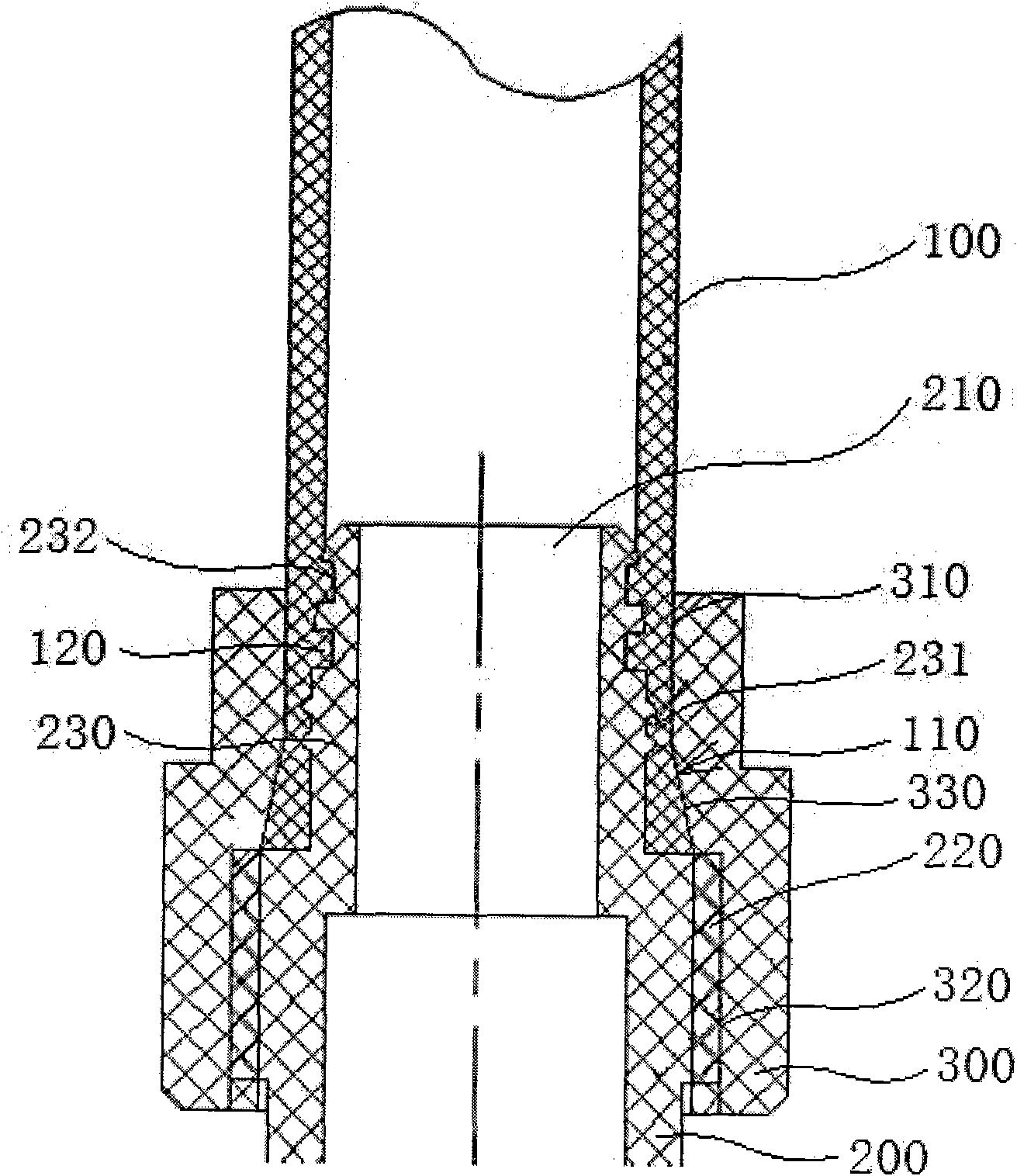

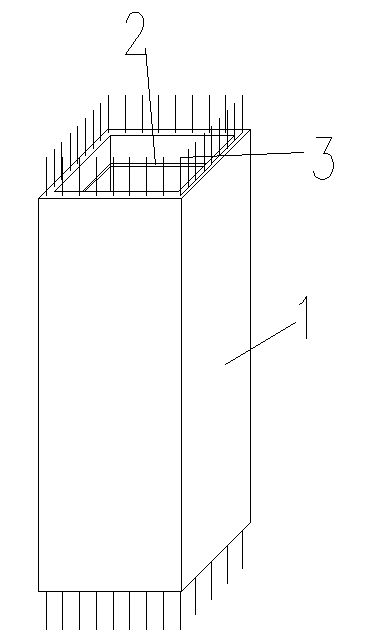

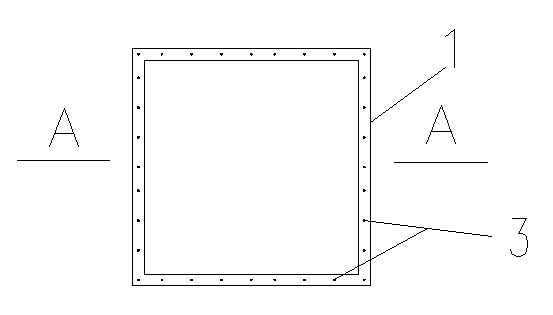

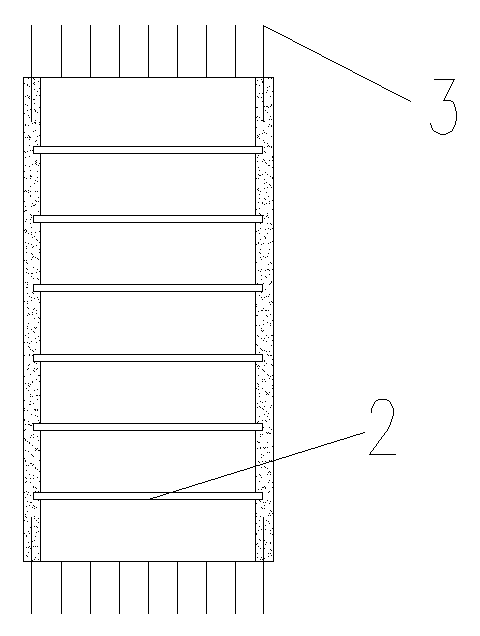

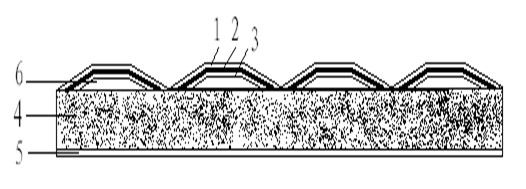

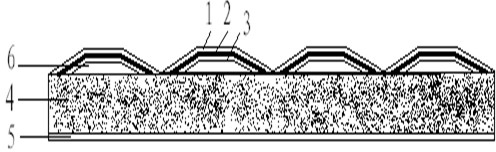

Highly durable permanent column template

InactiveCN103225398AIncreased durabilityHigh tensile ductilityClimate change adaptationForms/shuttering/falseworksEngineeringChloride ion penetration

The invention discloses a highly durable permanent column template. The column template comprises a column template body and is characterized in that the column template body is a thin-walled cylinder; grooves are formed in the surface on the inner side of the thin-walled cylinder; and reinforcement bars are embedded in the two ends of the thin-walled cylinder. The shape of the cross section of the column template body is the same with that of a column to be poured and is circular, rectangular or polygonal; the cross section size and the height of the column template body are the same with those of the column to be poured; and the thickness of the column template body is that of the protective layer of the column to be poured. The grooves are circularly formed in the surface on the inner side of the thin-walled cylinder of the column template body. The reinforcement bars are embedded in the thin-walled cylinder for 15 cm to 20 cm and extend out of the two ends of the thin-walled cylinder for 15 cm to 20 cm. The column template body is prefabricated with ECC (Engineered Cementitious Composites). The highly durable permanent column template has the advantages of high tensile ductility and excellent creak control capability, is superior to common concrete in chloride ion penetration resistance and water penetration resistance, can improve the durability of concrete structures, facilitates the construction, and shortens the construction time.

Owner:CHINA MCC17 GRP

Lightweight high-strength high-ductility mortar and preparation method thereof

The invention provides a lightweight high-strength high-ductility mortar and a preparation method thereof. The mortar comprises cement, silica fume, slag powder, recycled powder, fly ash floating beads, glass microbeads, recycled rubber powder, a water reducing agent, water, ultrahigh-molecular-weight polyethylene fibers and polyester fibers. The preparation method comprises the following steps of: mixing the cement, the silica fume, the slag powder, the recycled powder, the fly ash floating beads, the glass microbeads and the recycled rubber powder under stirring to obtain a first mixture; adding the mixed liquid of the water reducing agent and the water into the first mixture and carrying out stirring to obtain a second mixture; adding the ultrahigh-molecular-weight polyethylene fibers and the polyester fibers into the second mixture and carrying out stirring to obtain a third mixture; and finally, subjecting the third mixture to vibration molding and maintenance. The mortar of the invention has the characteristics of light weight, high compressive strength, high tensile strength, excellent energy-dissipating capacity, high stretching charge mass ratio and ultra-high tensile ductility, thereby significantly reducing the deadweight of materials and structures and maintaining sufficient bearing capacity.

Owner:TONGJI UNIV

Composite aluminum film elastic flashing and preparation method thereof

ActiveCN102168474AImprove water resistanceHigh strengthRoof covering using flexible materialsPolyesterPolyethylene terephthalate glycol

The invention relates to composite aluminum film elastic flashing and a preparation method thereof. The composite aluminum film elastic flashing comprises five layers of a substrate, butyl rubber, a polyethylene terephthalate (PET) polyester film, aluminum foil and polyurethane from bottom to top. The preparation method for aluminum foil comprises the following steps of: selecting the aluminum foil appropriately, coating the polyurethane on one surface of the aluminum foil, and combining the PET polyester film with the other surface of the aluminum foil; and slitting to form the composite aluminum film elastic flashing with fan-shaped aluminum foil folds with the appropriate butyl rubber belt by an extrusion mode. The composite aluminum film elastic flashing has the characteristics of superior ageing resistance, lasting bonding performance and excellent stretching ductility, and can be constructed smoothly at the temperature of between -10 and 80 DEG C.

Owner:上海昇慧材料科技有限公司

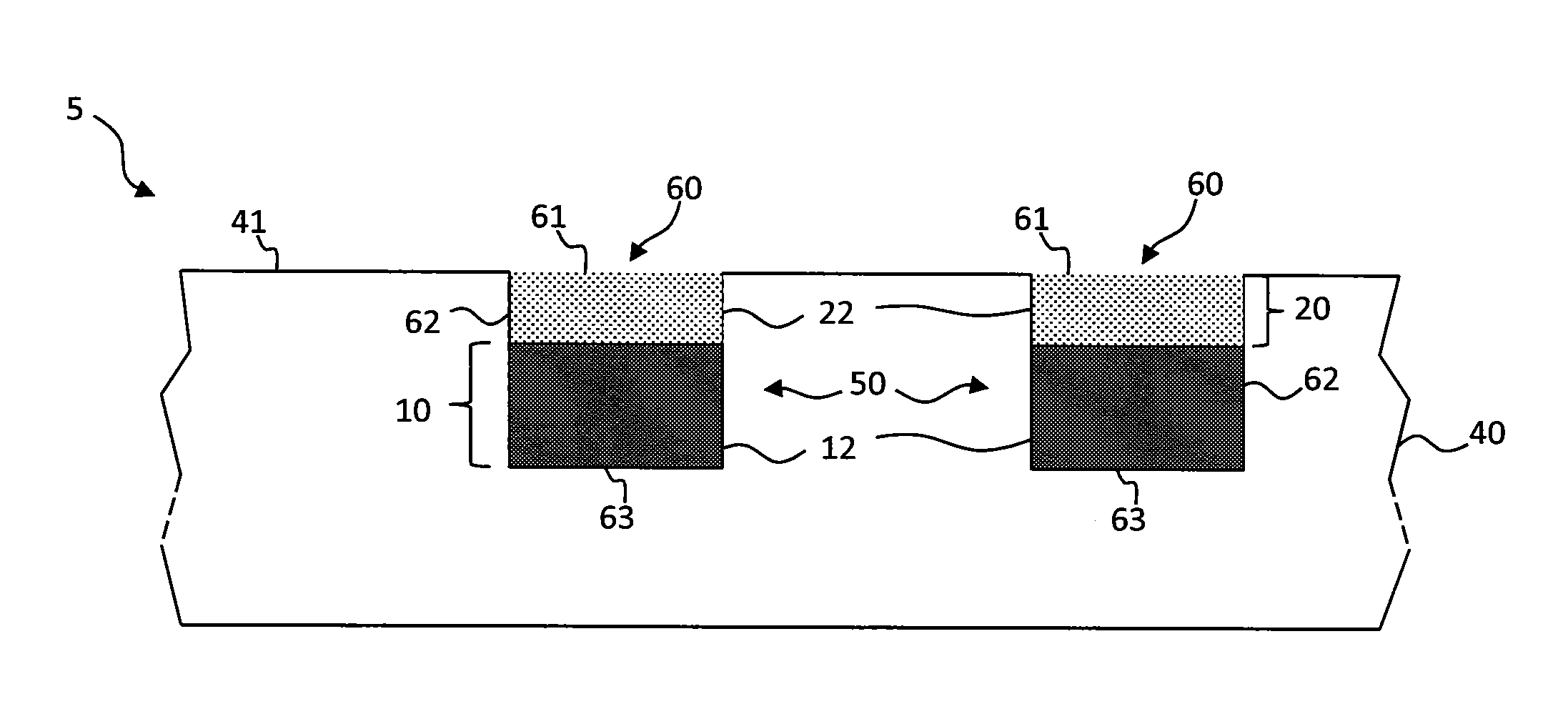

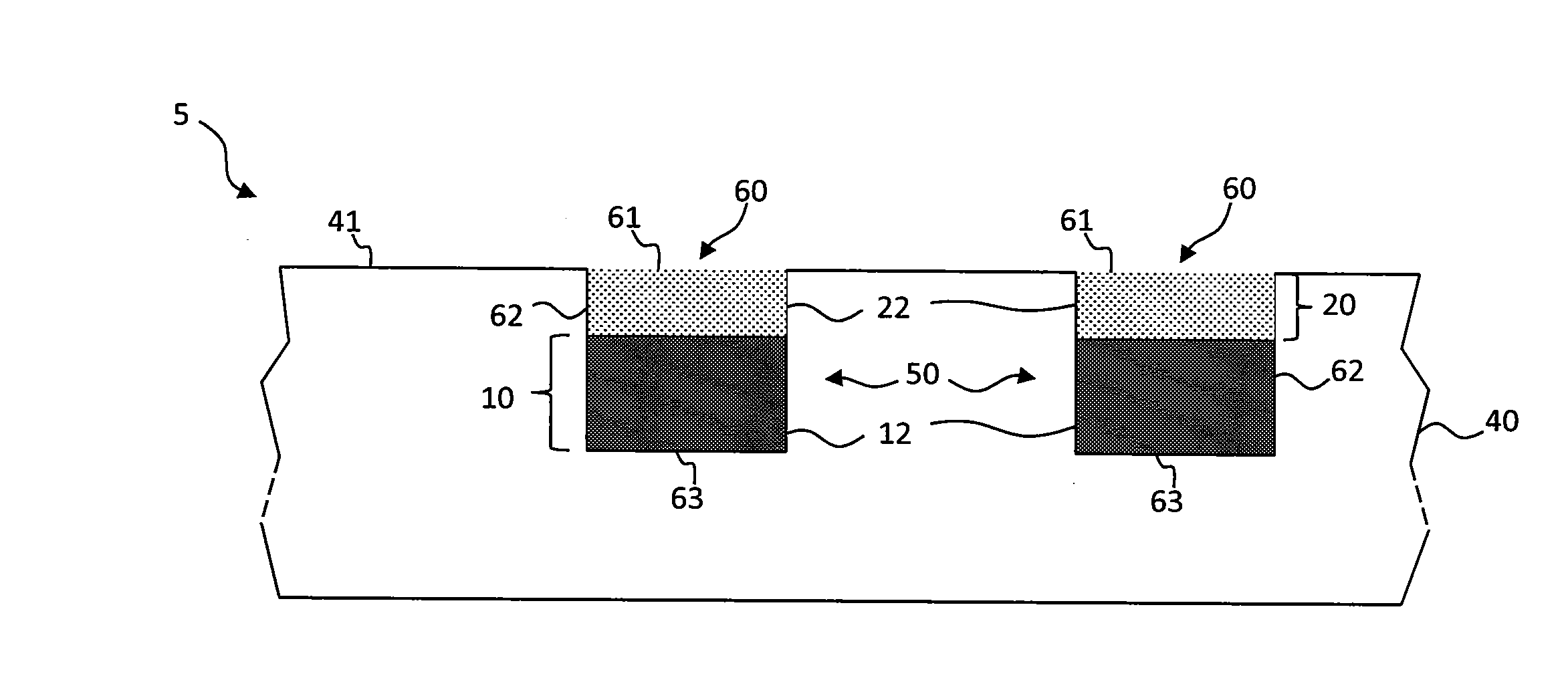

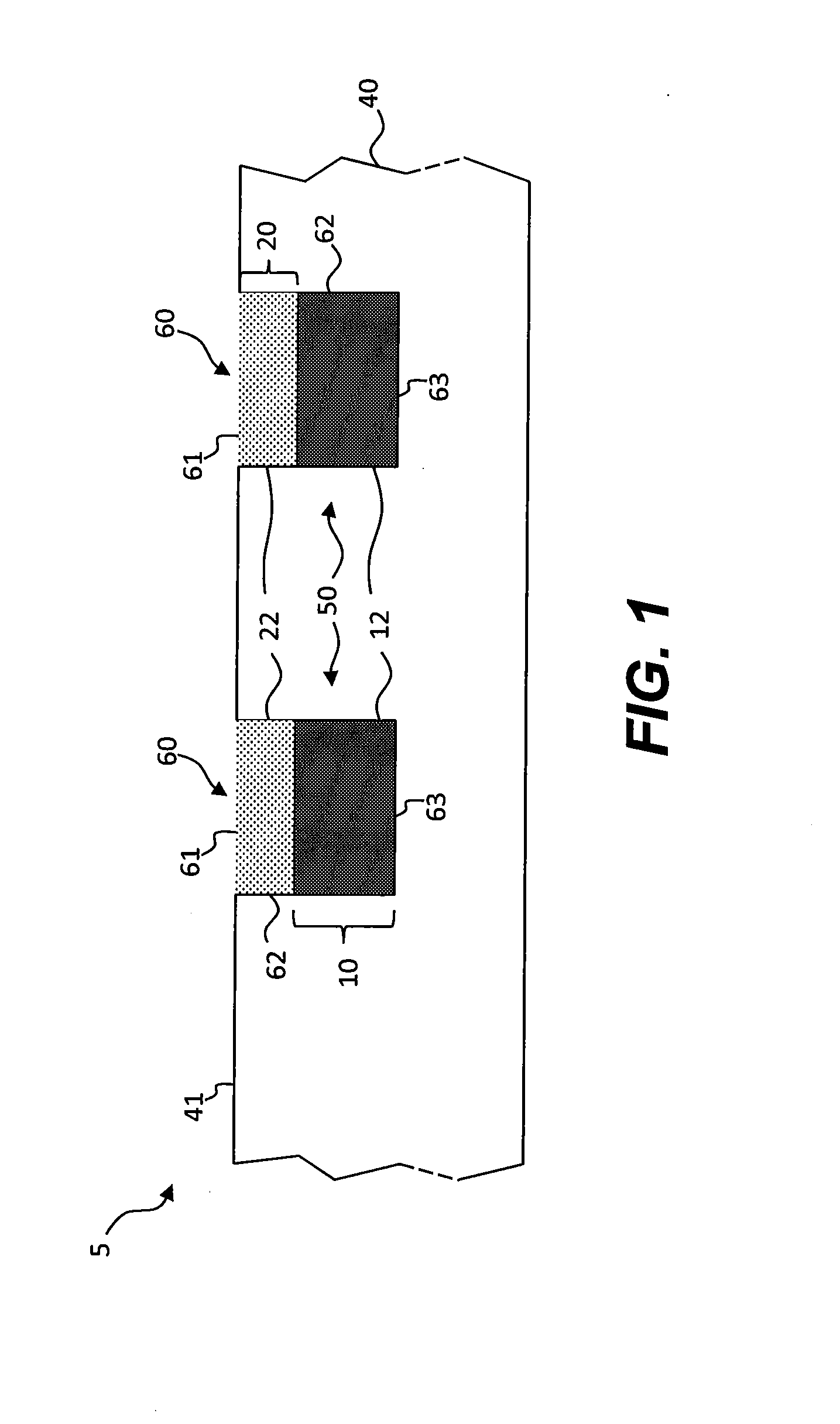

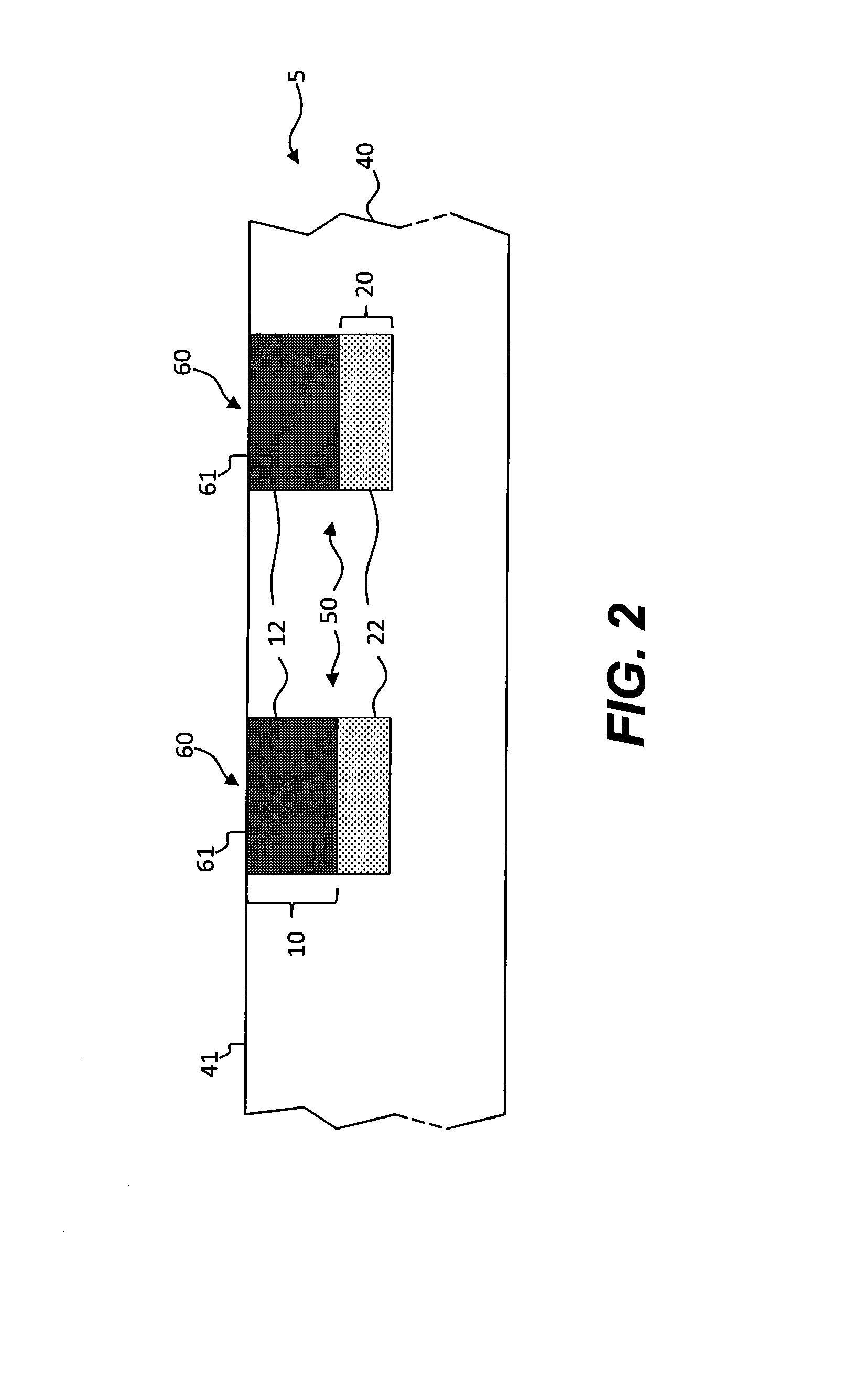

Making multi-layer micro-wire structure

ActiveUS20150310967A1Improve conductivityImprove robustnessPrinted circuit aspectsPretreated surfacesConductive materialsTensile ductility

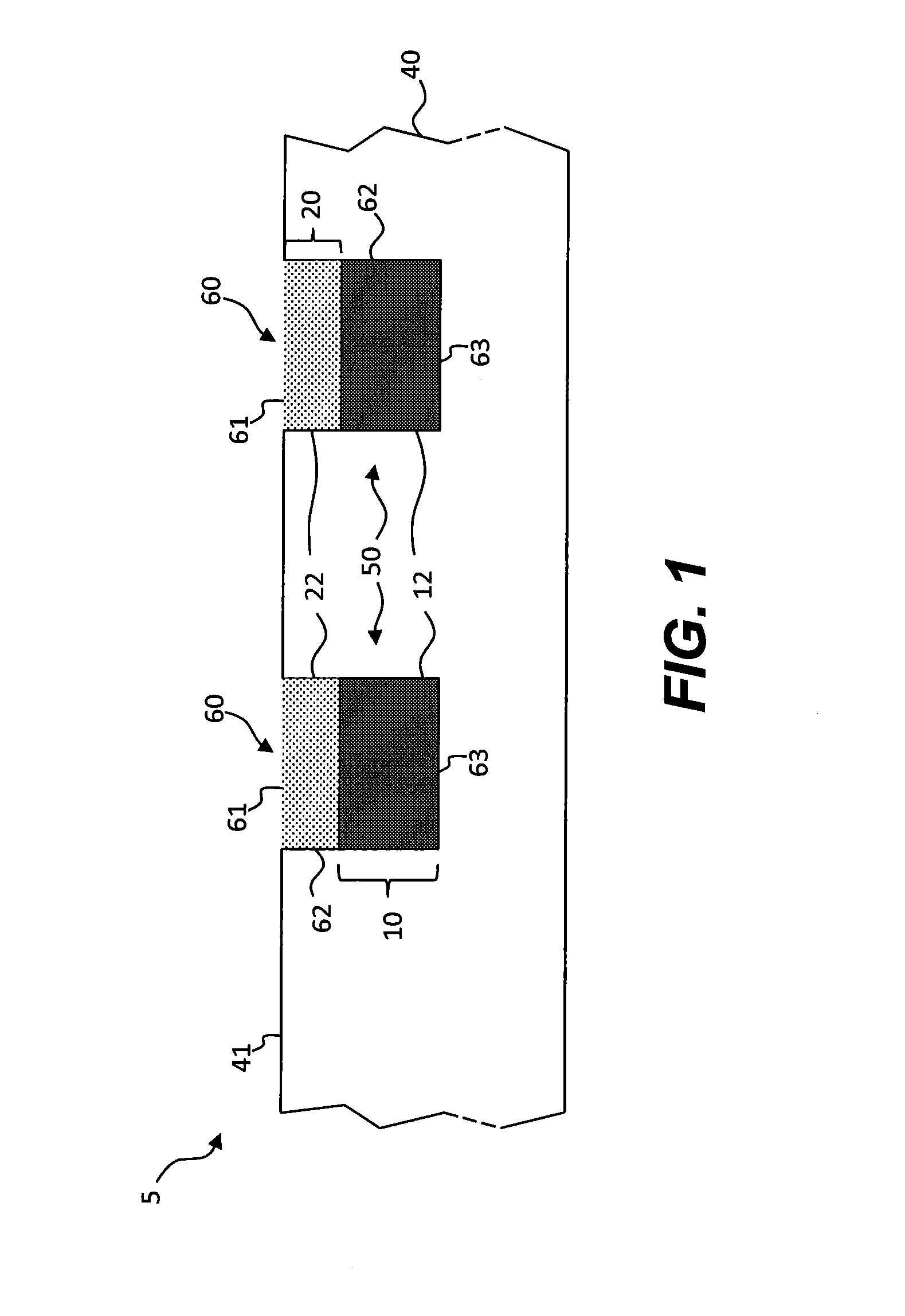

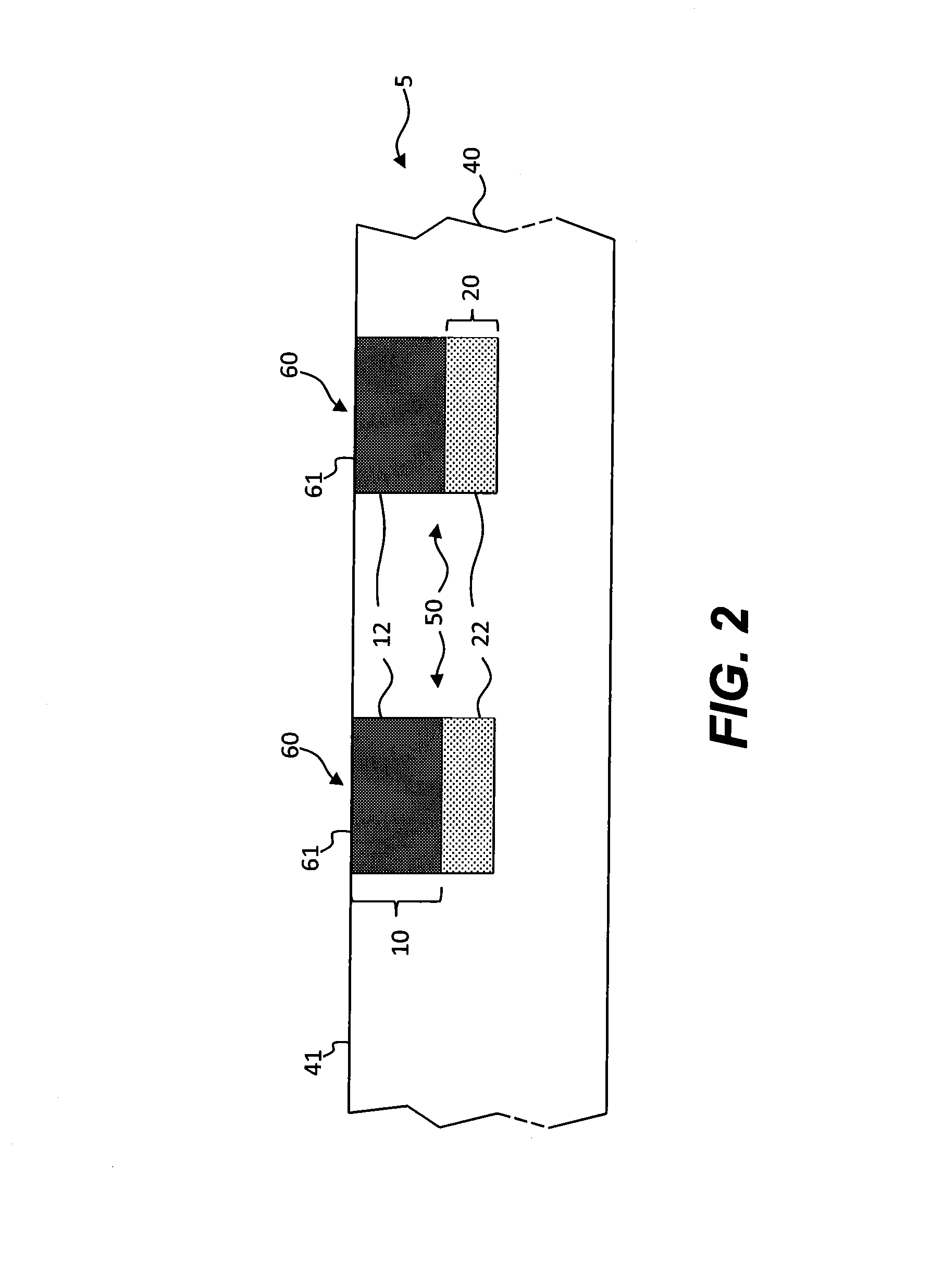

A method of making a multi-layer micro-wire structure resistant to cracking on a substrate having a surface including forming a plurality of micro-channels in the substrate, locating a first electrically conductive material composition forming a first layer in each micro-channel, and locating a second electrically conductive material composition having a greater tensile ductility than the first material composition to form a second layer in each micro-channel and in electrical contact with the first electrically conductive material composition thereby providing an electrically conductive multi-layer micro-wire in each micro-channel that is resistant to cracking.

Owner:EASTMAN KODAK CO

Cobalt-based amorphous nanocrystal biphase metal fiber and preparation method thereof

The invention relates to cobalt-based amorphous nanocrystal biphase metal fiber and a preparation method thereof, and is used for solving the problem that the traditional micro-scale cobalt-based amorphous fiber has poor tensile ductility. The nominal composition of the biphase metal fiber is Co68.15Fe4.35Si12.25B15.25; and 5-85vol% of crystalline phase with size of 4-20 nm is dispersed and distributed on an amorphous substrate of the cobalt-based amorphous nanocrystal biphase metal fiber. The cobalt-based amorphous nanocrystal biphase metal fiber is obtained by carrying out multiple cold drawing treatments on amorphous metal fiber obtained by a precision device for drawing melt into metal wire. According to the invention, the yield strength of the biphase metal fiber is 1208-2108 MPa, the fracture strength is 3044-3976 MPa and the tensile plastic strain is 0.36-1.64%; the preparation method has simple and convenient preparation process; and the application space of the cobalt-based amorphous fiber material is expanded.

Owner:HARBIN INST OF TECH

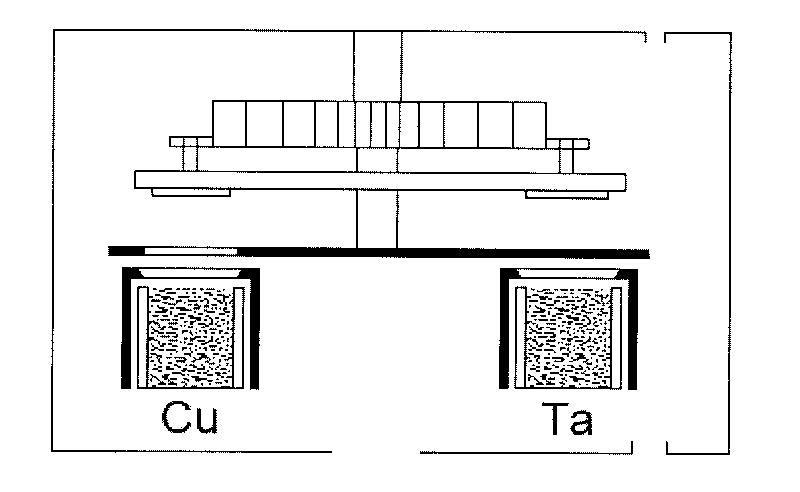

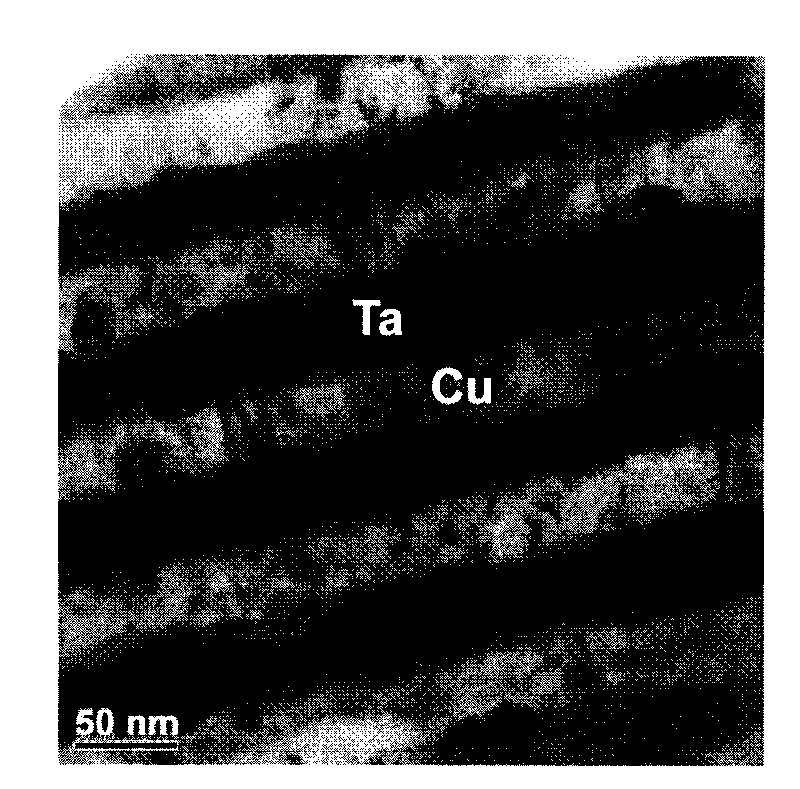

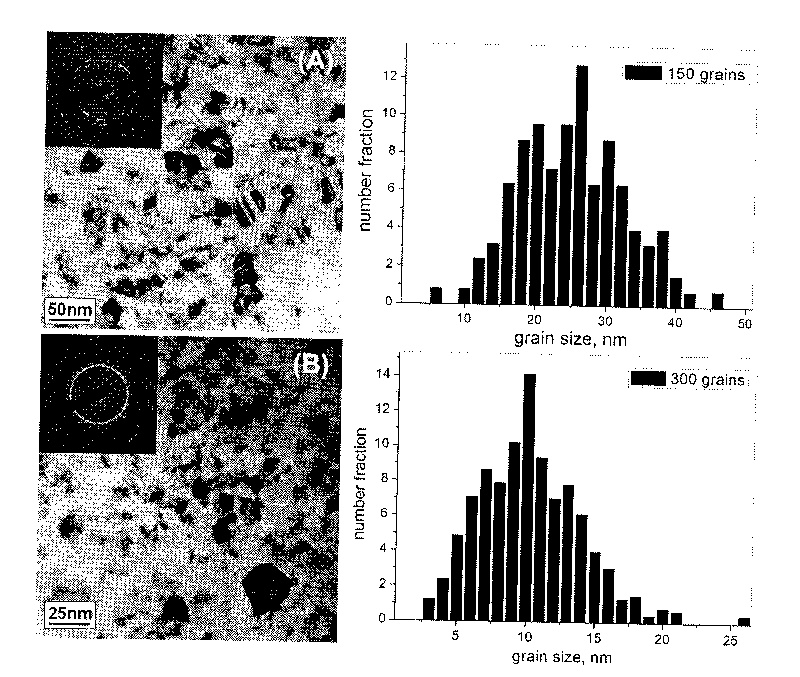

Preparation method of Cu/Ta nanometer multilayer film with crystal particle dimension difference

InactiveCN101748372AHigh hardnessHigh strengthVacuum evaporation coatingSputtering coatingWavelengthTensile ductility

The invention discloses a method for preparing a metal nanometer multilayer film with different crystal particle dimension by adopting magnetic control sputtering technology; the Cu / Ta nanometer multilayer film is alternately composed of a Cu layer and a Ta layer, and the ratio of the thickness of two layers is 1:1, the modulated wave length is 5-140nm, and the total thickness is 1mum; wherein the size of the Cu layer crystal particle dimension is equivalent to the thickness of the film layer, and the size of the Ta layer crystal particle dimension is 1 / 4 of the thickness of the film, and the Cu layer and the Ta layer have obvious crystal particle dimension difference; the hardness of the Cu / Ta nanometer multilayer film is increased by 35 percent compared by the traditional multilayer film material, the stretching extensibility exceeds 5 percent and is far more than that of the traditional multilayer film material. The hardness and the plasticity of the Cu / Ta nanometer multilayer film are optimized on the mechanical property; the metal nanometer multilayer film with different crystal particle dimension can be widely applied to very-large-scale integration circuit devices, protective coatings and functional coatings of various precise instruments and the like.

Owner:山东铭特金属材料科技有限公司

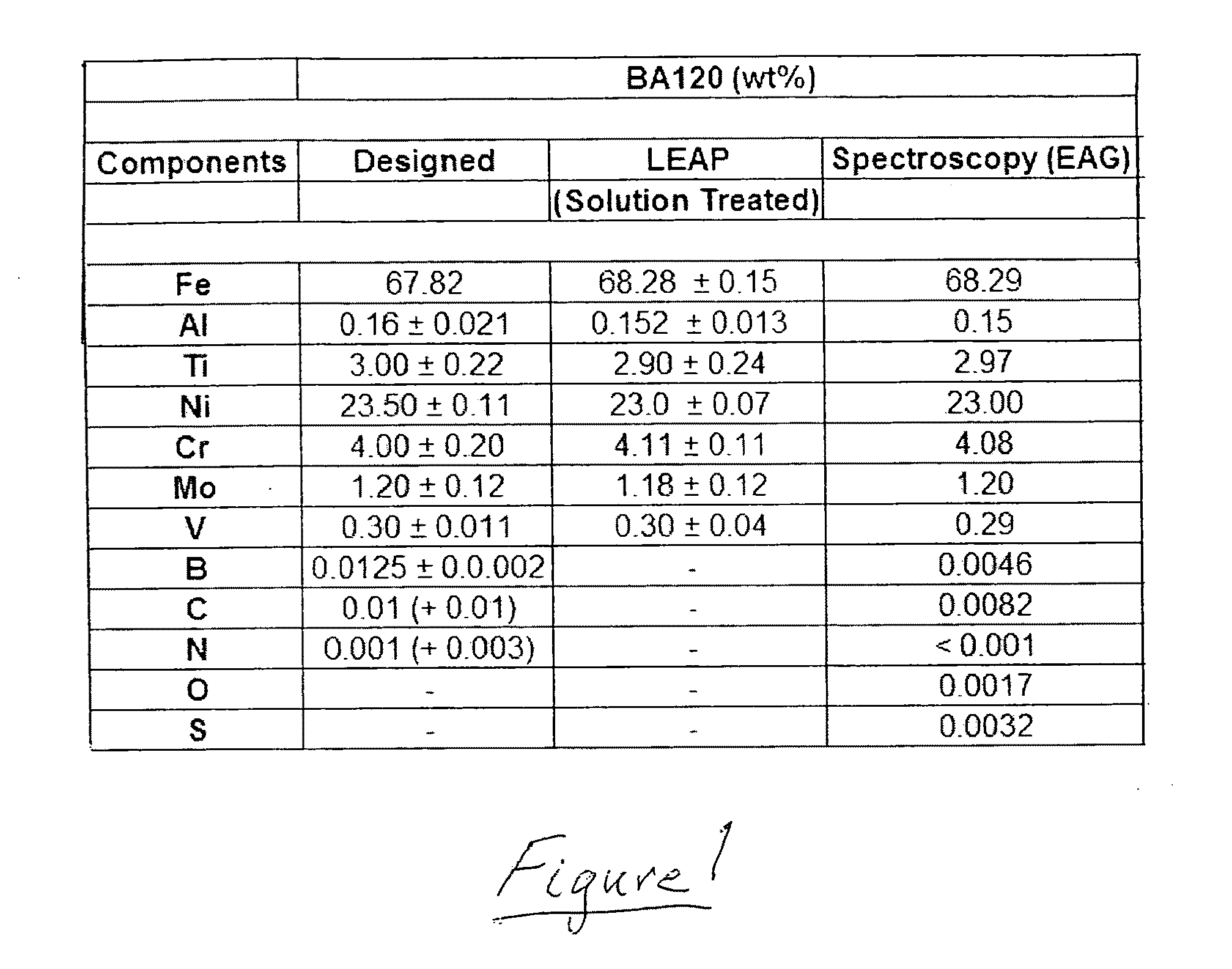

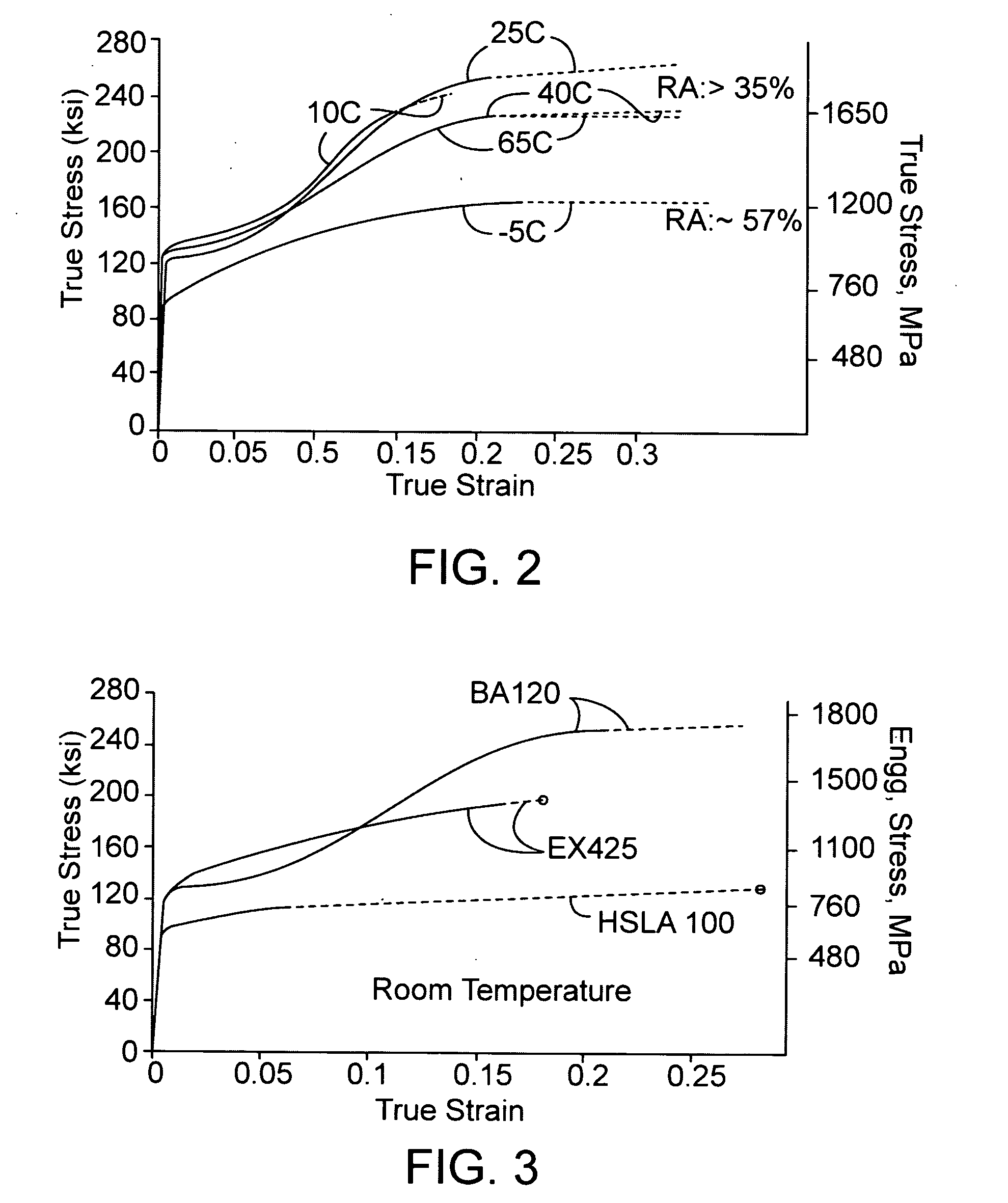

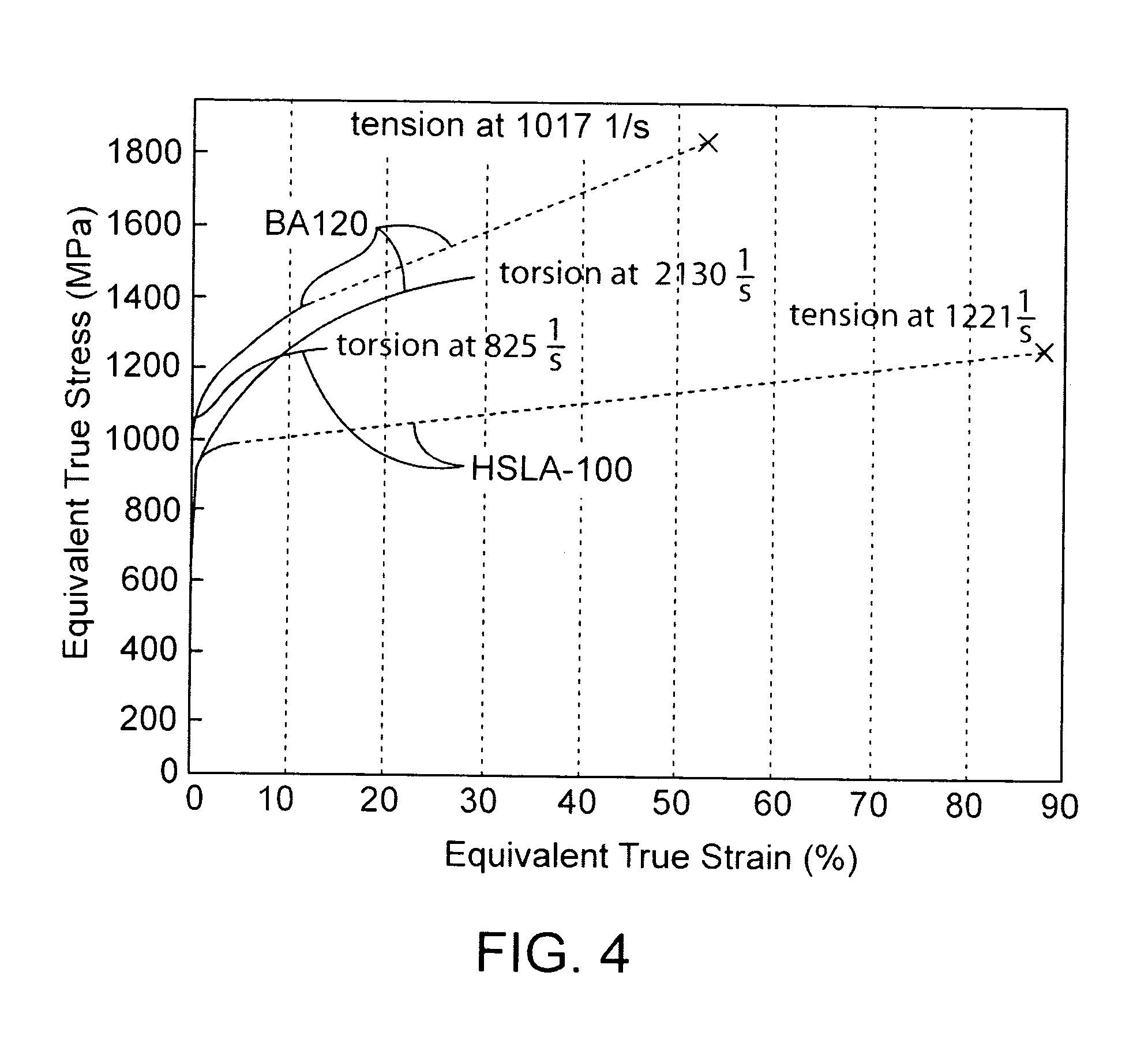

High strength austenitic trip steel

An austenitic TRIP steel consisting essentially of, in weight %, 0.14 to 0.18% Al, 2.8 to 3.2% Ti, 23.5 to 23.8% Ni, 3.8 to 4.2% Cr, 1.1 to 1.3% Mo, 0.29 to 0.31% V, 0.01 to 0.015% B, 0.01 to 0.02% C, and balance Fe and incidental impurities exhibits combined high yield strength and high strain hardening leading to improved stretch ductility under both tension and shear dynamic loading conditions.

Owner:NORTHWESTERN UNIV

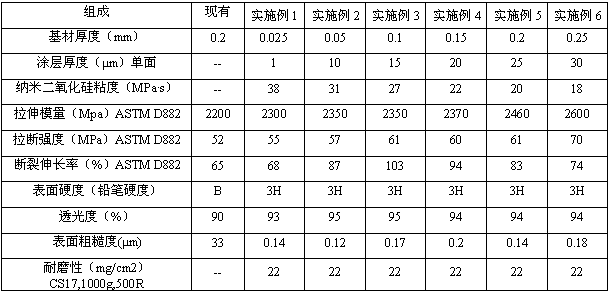

High-strength wear-resistant high-transmission polycarbonate film

InactiveCN103214687ADoes not affect light transmissionHigh strengthSynthetic resin layered productsCoatingsWear resistantUltraviolet

The invention relates to the field of polycarbonate resin, in particular relates to a high-strength wear-resistant high-transmission polycarbonate film. The high-strength wear-resistant high-transmission polycarbonate film comprises a base material made from polycarbonate, wherein the base material is a sheet or a film with the thickness of 0.025-25mm, a layer of nano silicon dioxide dried and cured by ultraviolet rays is sprayed on at least one of an upper surface and a lower surface of the sheet or film, the average spraying thickness of the single surface is 1-100mum, the viscosity of the nano silicon dioxide is 18-38MPa.s, the split particles with particle size distribution of 0.1-0.5mum are more than 99%, and the specific surface area is 25-100m<2> / g. According to invention, the high-strength wear-resistant high-transmission polycarbonate film is sprayed on the surface of the polycarbonate, and one layer of nano silicon dioxide is dried and cured by ultraviolet rays, so that on the premise that the transmission of the film is not influenced, the strength and tensile ductility of the film can be improved, the wear resistance and finishing can be enhanced, the applications of the film are wide. Thus, the high-strength wear-resistant high-transmission polycarbonate film is a novel environment-friendly multifunctional film.

Owner:上海冠旗电子新材料股份有限公司

Multi-layer micro-wire structure

ActiveUS20150313008A1Improve conductivityImprove robustnessCircuit optical detailsTransparent dielectricsMetallurgyTensile ductility

A multi-layer micro-wire structure resistant to cracking including a substrate having a surface, one or more micro-channels formed in the substrate, an electrically conductive first material composition forming a first layer located in each micro-channel, and an electrically conductive second material composition having a greater tensile ductility than the first material composition forming a second layer located in each micro-channel, the first material composition and the second material composition in electrical contact to form an electrically conductive multi-layer micro-wire in each micro-channel, whereby the multi-layer micro-wire is resistant to cracking

Owner:EASTMAN KODAK CO

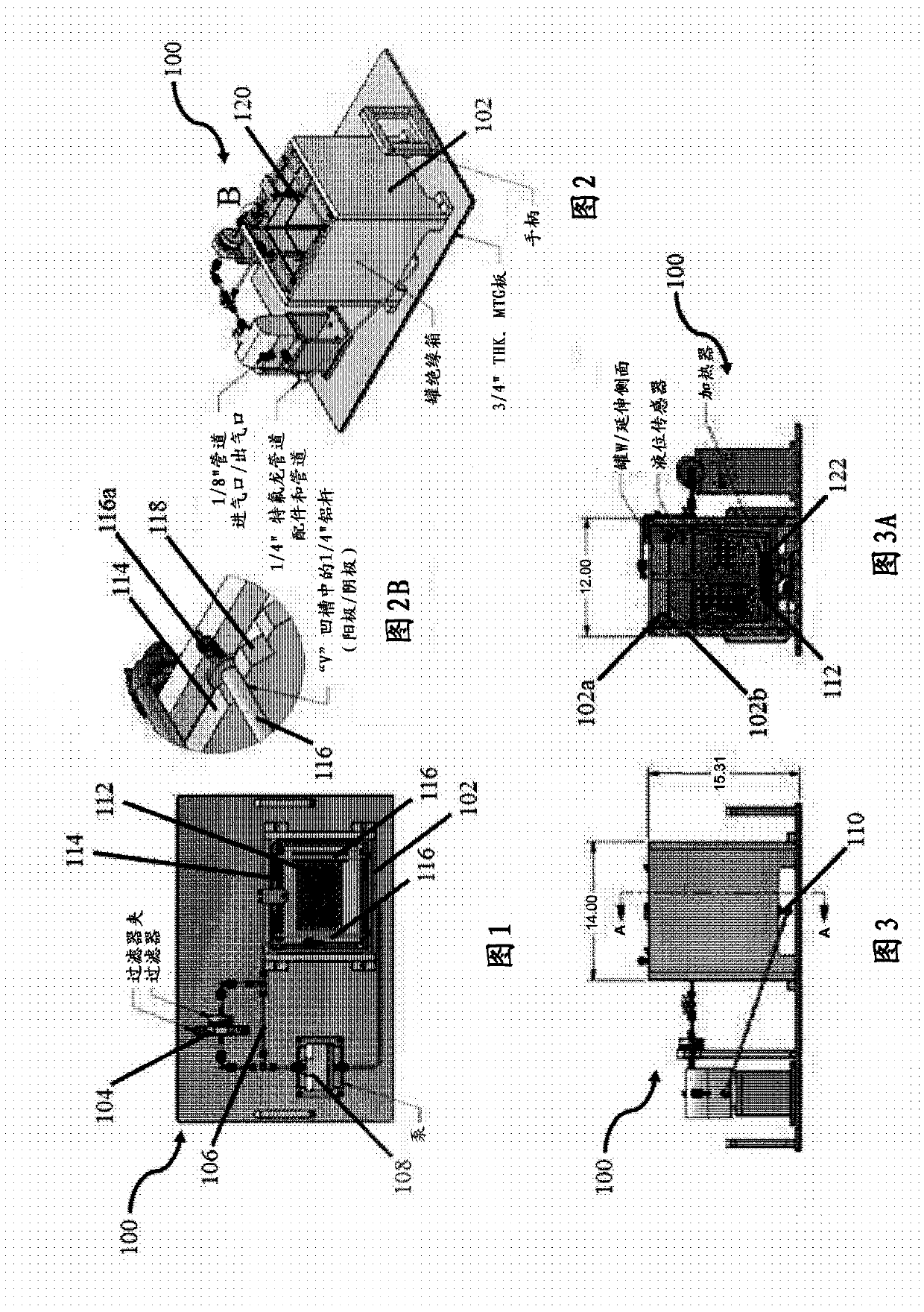

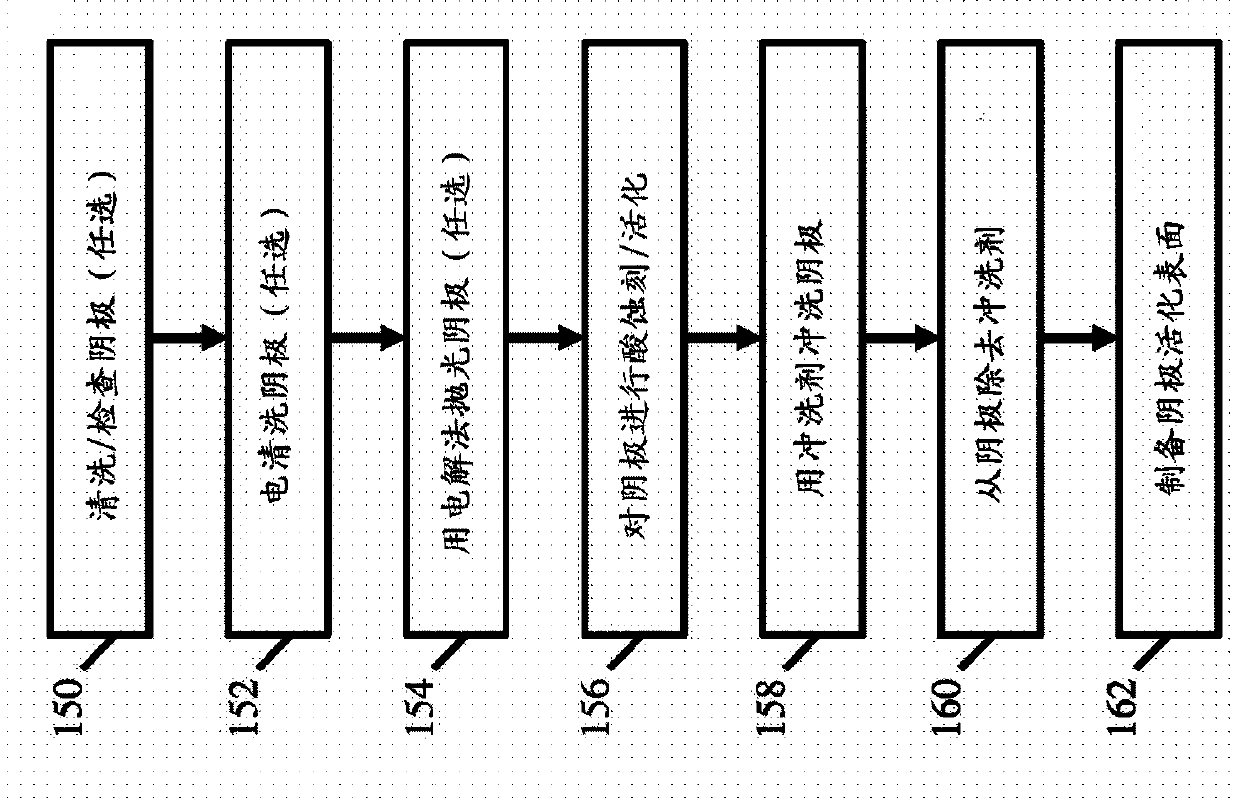

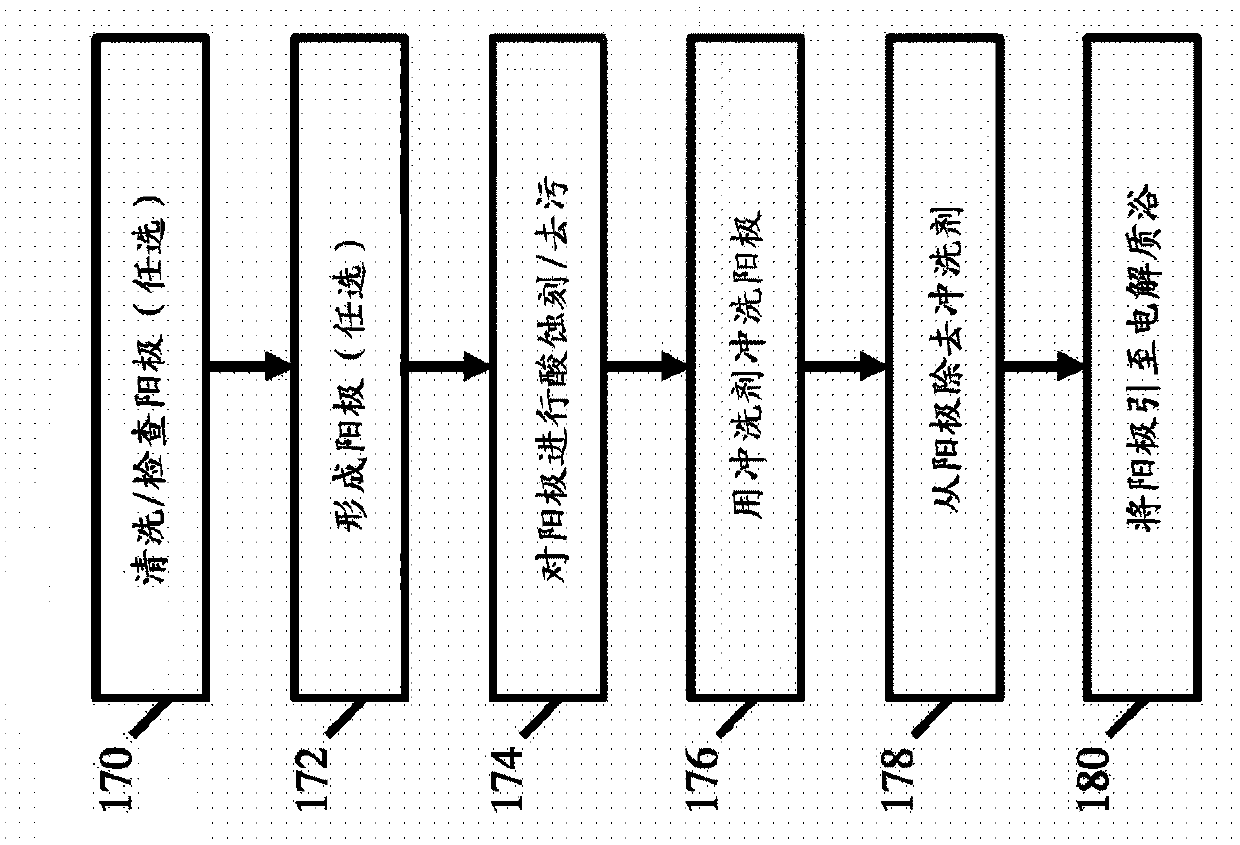

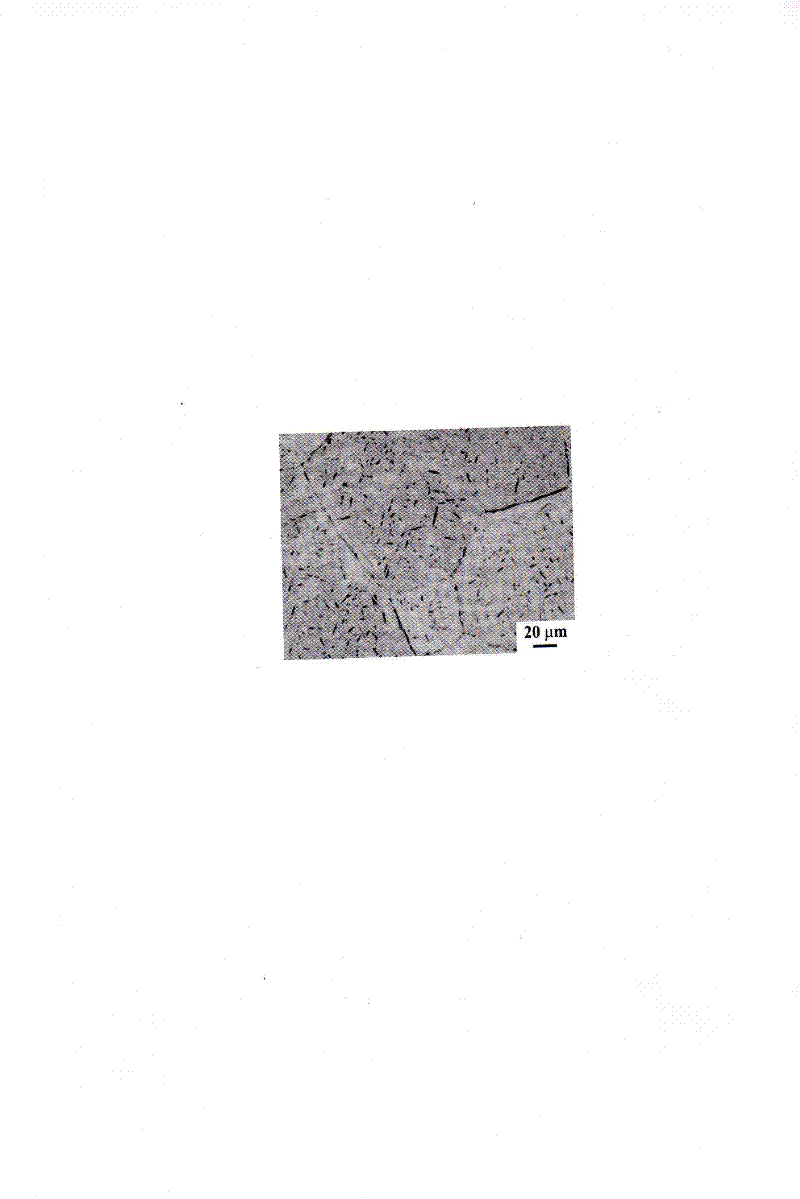

Electrodeposition in ionic liquid electrolytes

Embodiments of the current disclosure are related to electrodeposition. Electrodeposited stable nano structured aluminum manganese alloys exhibit an exceptional combination of high hardness and tensile ductility. In addition to the combination of high hardness and tensile ductility, the alloys are approximately the same density as other aluminum alloys. This combination of high strength, ductility, and light weight make it an ideal structural material for applications such as armor, aircraft, sporting equipment, and other applications where a light weight high strength ductile material would be of benefit.

Owner:思力柯集团

A kind of preparation method of zirconium-niobium alloy with α/β double state structure

The invention relates to a method for preparing a zirconium-niobium alloy with an alpha / beta dual-state organization, which mainly comprises the following steps of: firstly obtaining an alpha single-phase martensite or basket-shaped organization from the zirconium-niobium alloy and then rolling the alloy to deform at the temperature of 20-600 DEG C, wherein the deformation amount is 30%-60% and the alloy is air-cooled to room temperature after the alloy is deformed; and coating a layer of static high-temperature anti-oxidizing paint on the deformed alloy, putting the alloy in a furnace for annealing treatment after the paint is dried and the furnace temperature reaches 800-900 DEG C, taking out the alloy after heat-preserving for 0.5-2 hours and air-cooling the alloy to room temperature. The final heat-treatment process in the invention can be used for final heat treatment of the cold-deformed zirconium-niobium alloy and is also suitable for the final heat treatment of the hot-deformed zirconium-niobium alloy. The invention has the advantages that: the strength and the impact toughness of the zirconium-niobium alloy with the dual-state organization are respectively increased by about 2 times and 0.6 times of that of a zirconium-niobium alloy with the basket-shaped organization and an equiaxial organization, the strength is increased by about 100 MPa, and meanwhile, the excellent tensile ductility is remained.

Owner:YANSHAN UNIV

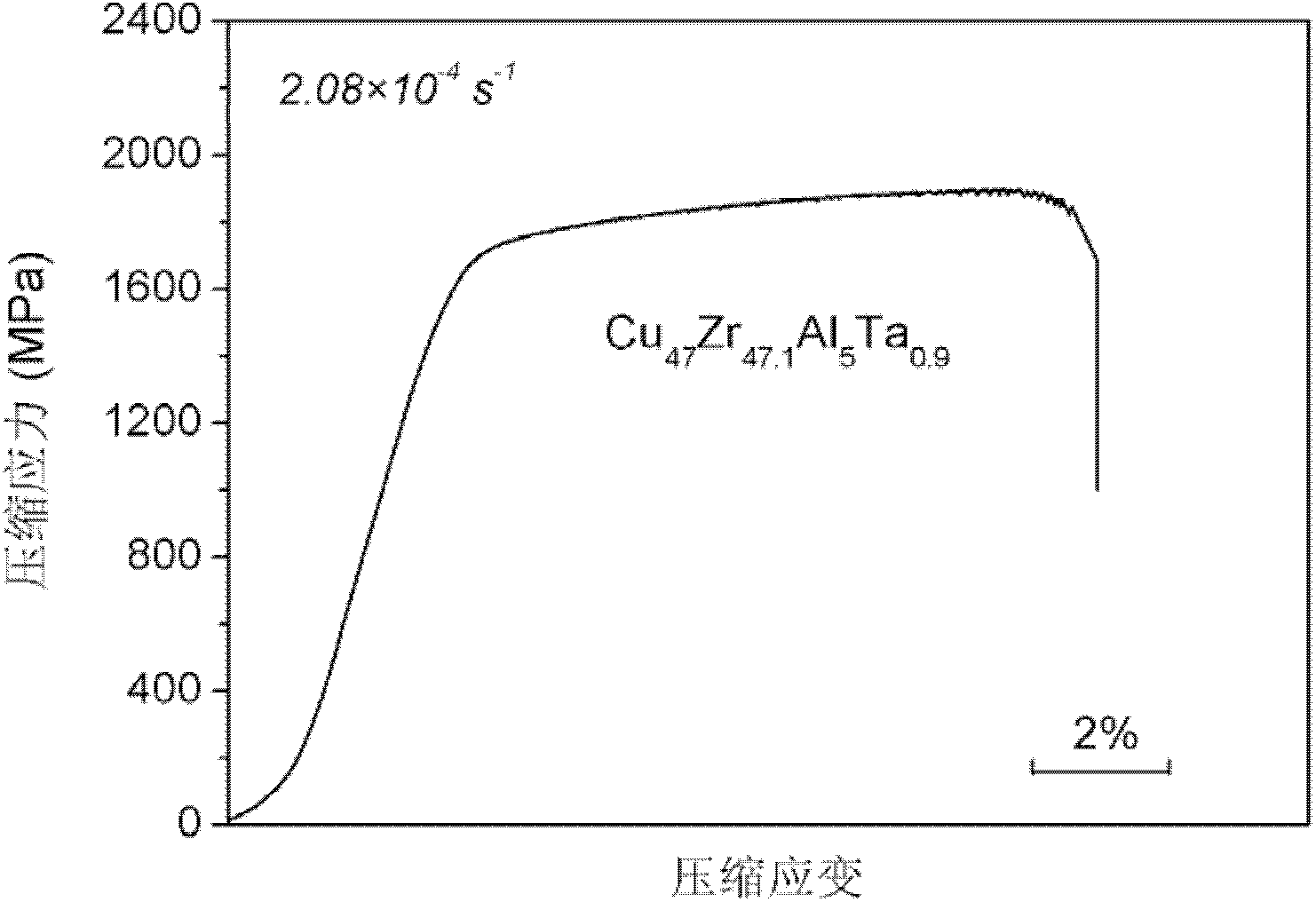

Cuazrbalcmd amorphous alloy composite material with ductile crystal phase and homogenization method of its crystal phase

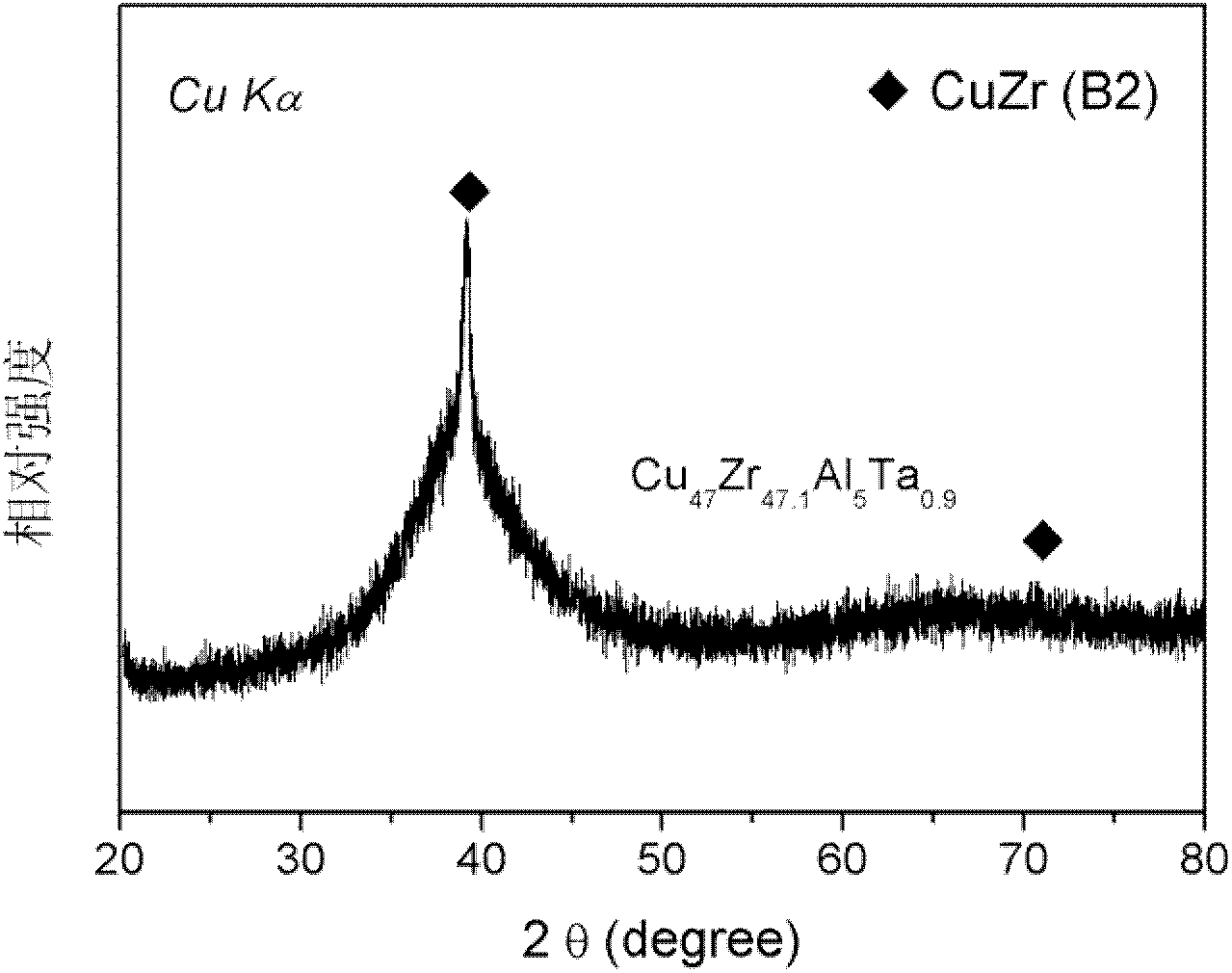

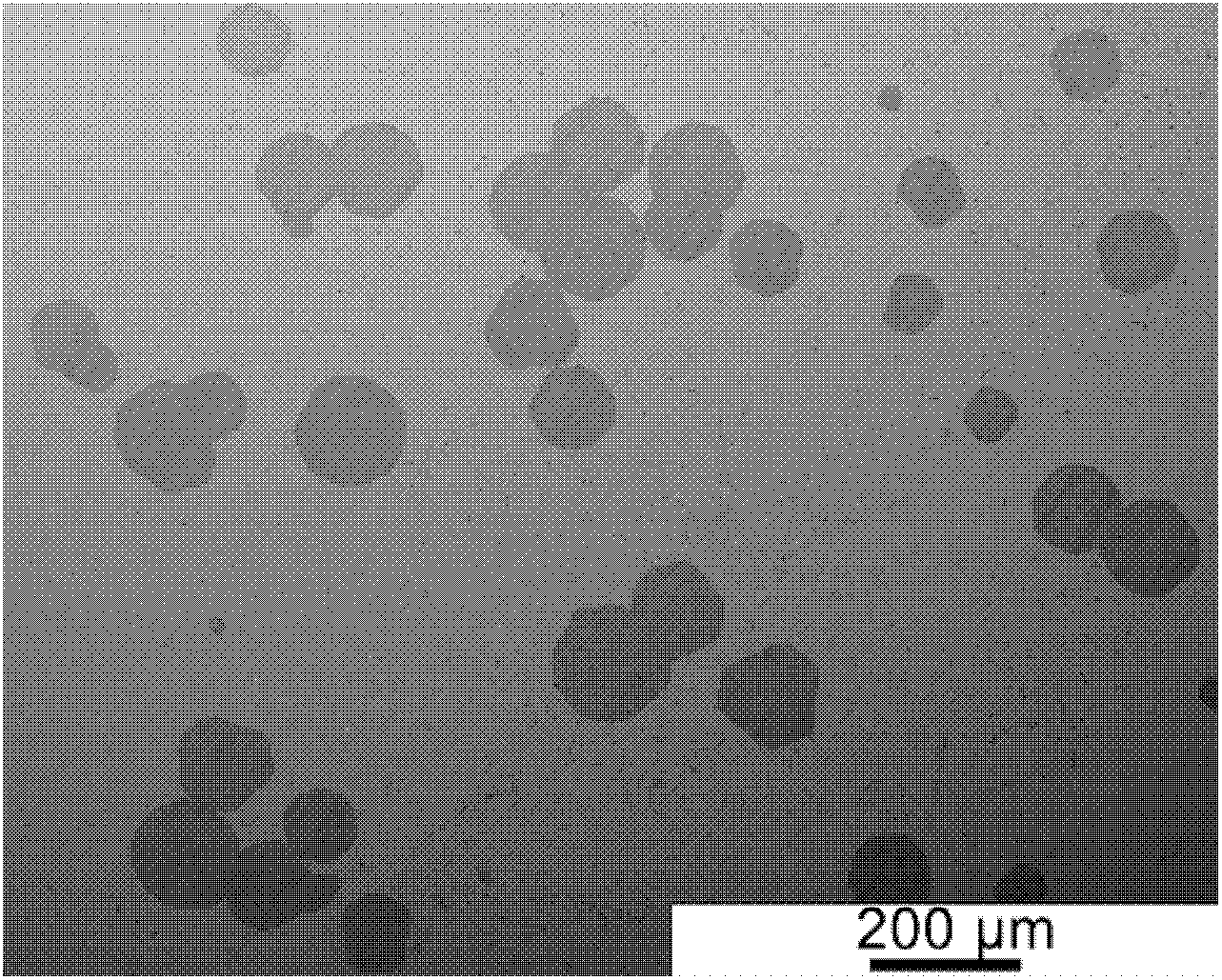

InactiveCN102286707AGood mechanical propertiesUniform particle sizeElectric arc furnaceAlloy composite

The invention discloses a CuaZrbAlcMd amorphous alloy composite material with a ductile crystal phase and a homogenization method for the crystal phase thereof. In CuaZrbAlcMd, a, b, c and d are the molar percentages, 44 <= a <= 50, 44 <= b <= 50, 3 <= c <= 7, 0.05 <= d <= 1.50, and a + b + c + d = 100; and M is one or the combination of more than two of the metals, namely Ta, W, Mo, Nb, Hf and Re. In the invention, the target component alloy is firstly smelted in an arc furnace under the protection of inert atmosphere, then various sizes and shapes of bulk amorphous alloy are prepared by spray casting, suction casting or water quenching and other rapid solidification methods, and the performance analysis is finally carried out on the obtained alloy. The composite material prepared by themethod disclosed by the invention has a structure that ductile crystal phase particles are uniformly distributed on an amorphous alloy matrix, and the crystal phase particles can carry out martensitic phase transformation in a force-deformation process, so that the composite material has significant tensile ductility and work hardening characteristics and other excellent mechanical properties.

Owner:BEIHANG UNIV

Thermoplastic flame-retardant elastomer used for glass fiber reinforcement of cable

InactiveCN103849132AEasy to use and installExtended service lifePlastic/resin/waxes insulatorsInsulated cablesElastomerAlkane

The invention discloses a thermoplastic flame-retardant elastomer used for glass fiber reinforcement of a cable. The thermoplastic flame-retardant elastomer comprises the following raw materials by weight: 100 parts of a matrix resin, 20 to 40 parts of a fire retardant, 30 to 40 parts of a glass fiber, 10 to 30 parts of a plasticizer, 5 to 20 parts of a compatilizer, 1 to 2 parts of a lubricant and 1 to 2 parts of an anti-oxidant, wherein the matrix resin is one selected from or a mixture of phenyl ether and polyurethane, the fire retardant is one selected from or a mixture of ammonium polyphosphate and triphenyl phosphate, the plasticizer is one selected from or a mixture of saturated straight-chain alkane oil and cycloalkane oil, the compatilizer is oligosiloxane, the lubricant is one selected from or a mixture of siloxane and erucamide, and the anti-oxidant is one selected from or a mixture of a hindered phenol anti-oxidant, a phosphite anti-oxidant and a thioester anti-oxidant. The elastomer disclosed in the invention has good thermoplastic, strong tensile ductility, great strength and a good flame retardation effect.

Owner:宁波日月电线电缆制造有限公司

A 1300mpa grade ultra-high strength structural titanium alloy

A 1300MPa-level ultra-high-strength structural titanium alloy relates to a near-β titanium alloy, which has the potential to be used in load-bearing structural parts of aircraft. It is characterized in that the weight percent composition of the alloy is Al: 4%-5.5%, Zr: 2%-4%, Mo: 4%-6%, V: 3%-5%, Cr: 2%-3%, and the rest The amount is Ti and unavoidable impurities. Finished alloy forgings are treated by 770~860℃ / 1-2h air cooling +540-620℃ / 4-8h air cooling or 810-830℃ / 2-3h cooling to 750-770℃ / 2-4h air cooling +540-570℃ / 4-8h air cooling treatment use. Alloy finished forgings have high tensile plasticity and fracture toughness while maintaining high strength after strengthening heat treatment.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

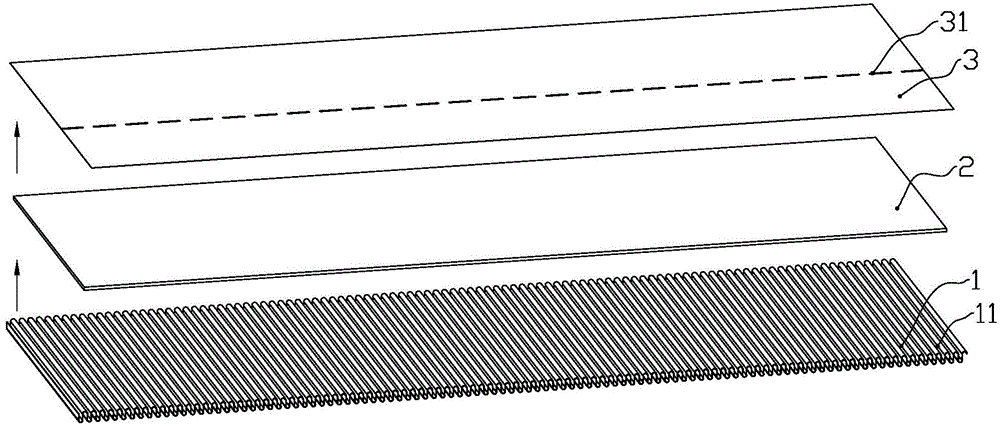

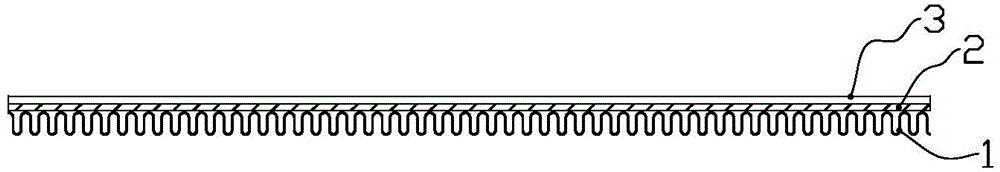

Composite flexible flashing band and preparation method thereof

InactiveCN104647812AImprove anti-agingImprove adhesionSynthetic resin layered productsFrame fasteningAdhesiveEngineering

The invention discloses a composite flexible flashing band and a preparation method thereof and provides a waterproof auxiliary building material of a novel structure. The composite flexible flashing band consists of a membrane material substrate, a butyl rubber adhesive layer with an adhesive effect and a substrate from bottom to top, wherein the membrane material substrate refers to a fold shape which is formed by adopting a one-way extrusion mode, of which the number of the folds in every 10cm is not less than 80 and of which the stretch rate is not lower than 50 percent; and the thickness of the butyl rubber adhesive layer is 0.2-0.3mm. The invention also discloses a method for preparing the flashing band. The flashing band has the characteristics of excellent aging resistance, lasting adhesiveness, excellent tensile ductility, convenience in construction and capacity of effectively preventing water seepage and leakage.

Owner:山东富友泰跃建筑科技有限公司

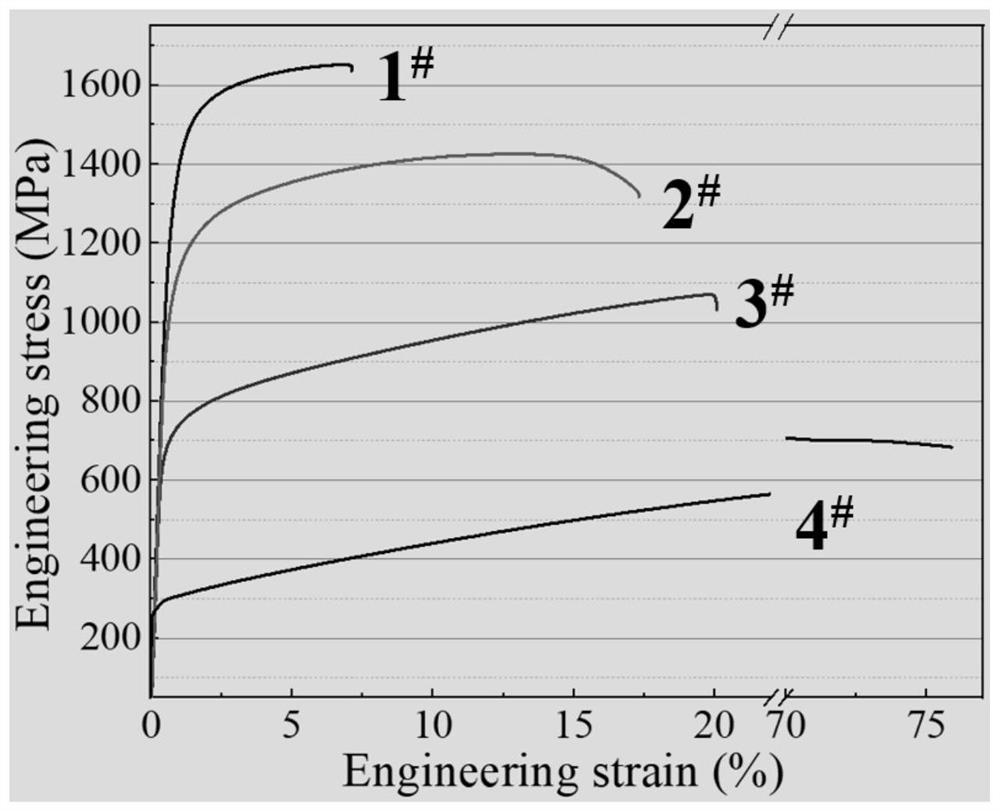

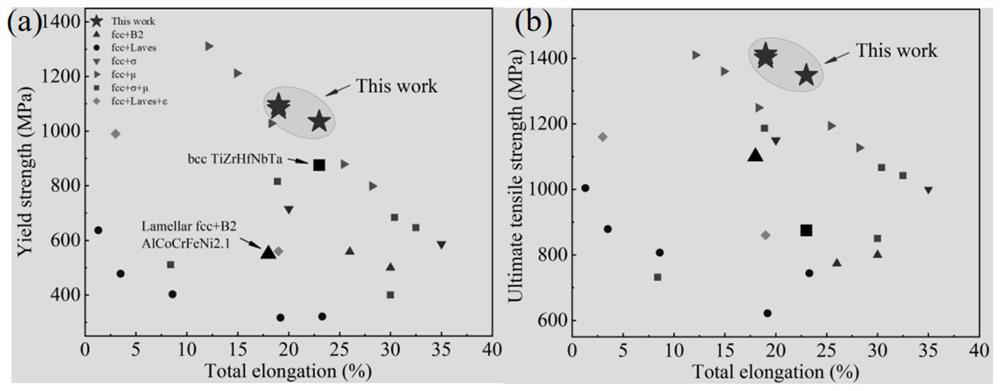

High-strength and large-plasticity multi-stage heterostructure medium-entropy alloy and preparation method thereof

ActiveCN113737078AHigh strengthHigh yield strengthTemperature control deviceMetal rolling arrangementsBack stressHeterojunction

The invention provides a high-strength and large-plasticity multi-stage heterostructure medium-entropy alloy and a preparation method thereof. Multiple strengthening mechanisms are introduced at the same time through component, process and structural design, so that the yield strength of the alloy is improved to 3-4 times. And each strengthening mechanism has obvious contribution, wherein the contribution of solid solution strengthening, dislocation strengthening, grain boundary strengthening and back stress strengthening to the strength is 274 MPa, 175 MPa, 189 MPa and 366 MPa respectively. However, the alloy still keeps an fcc matrix, so that the alloy still possesses good toughness while the strength of the alloy is improved. The high-strength and large-plasticity multi-stage heterostructure medium-entropy alloy has the advantages that the room-temperature mechanical property is excellent, the yield strength of the NiCoCr medium-entropy alloy is improved by 3.6 times to about 1100 MPa, the tensile strength is improved by 2 times to about 1400 MPa, and meanwhile, the alloy possesses 20% of tensile ductility. The NiCoCr medium-entropy alloy with the double-phase multistage heterostructure is excellent in comprehensive mechanical property, the process is simple and feasible, and the alloy has great engineering application prospects.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com