Heat treatment technology for improving high-temperature tensile ductility of Ni-Fe-Cr based deformation high-temperature alloy

A technology for deforming superalloys and tensile plasticity, applied in the field of heat treatment, can solve the problems of low tensile plasticity, high alloy yield and fracture strength, and achieve the effect of improving tensile plasticity and grain boundary strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

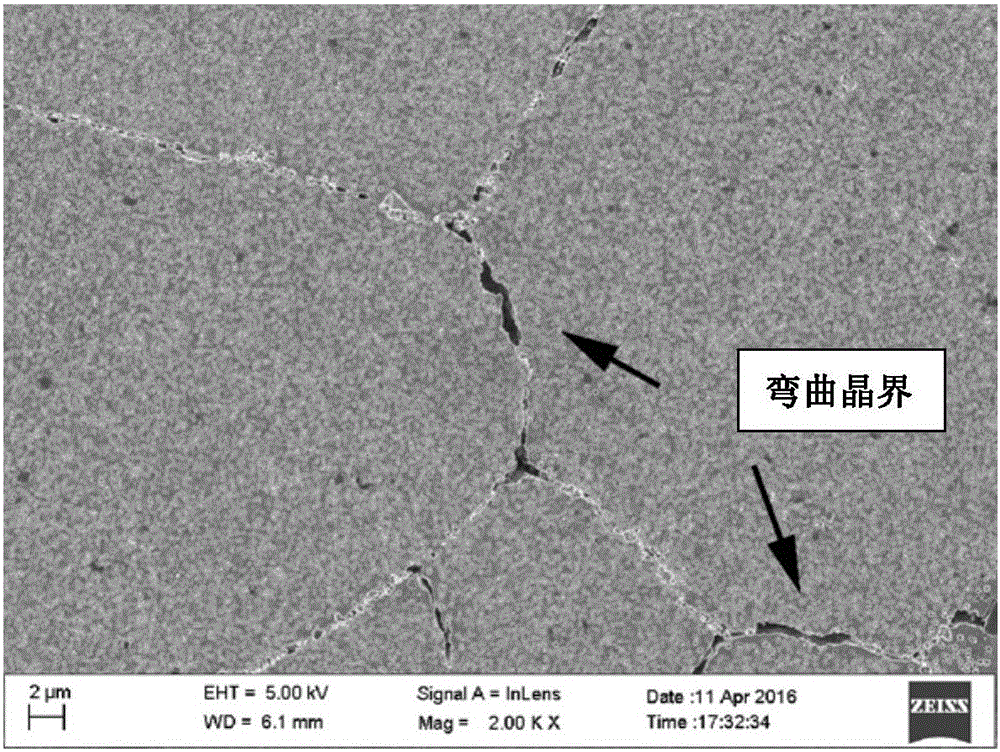

[0026] see figure 1 , taking a nickel-iron-chromium-based superalloy within the composition range in the summary of the invention, the precipitation temperature of the γ' phase is 971°C. The deformed nickel-iron-chromium-based superalloy sample was subjected to high-temperature solution treatment, the solution temperature was 1150°C, and the holding time was 1 hour; then it was slowly cooled to 900°C at a rate of 4°C / min, held for 2 hours, and then air-cooled to Room temperature; low temperature aging treatment at 650°C, heat preservation for 16 hours and air cooling to room temperature; then medium temperature aging at 780°C, heat preservation for 8 hours and air cooling to room temperature. The tensile plasticity of the alloy at 750 °C is shown in Table 1.

Embodiment 2

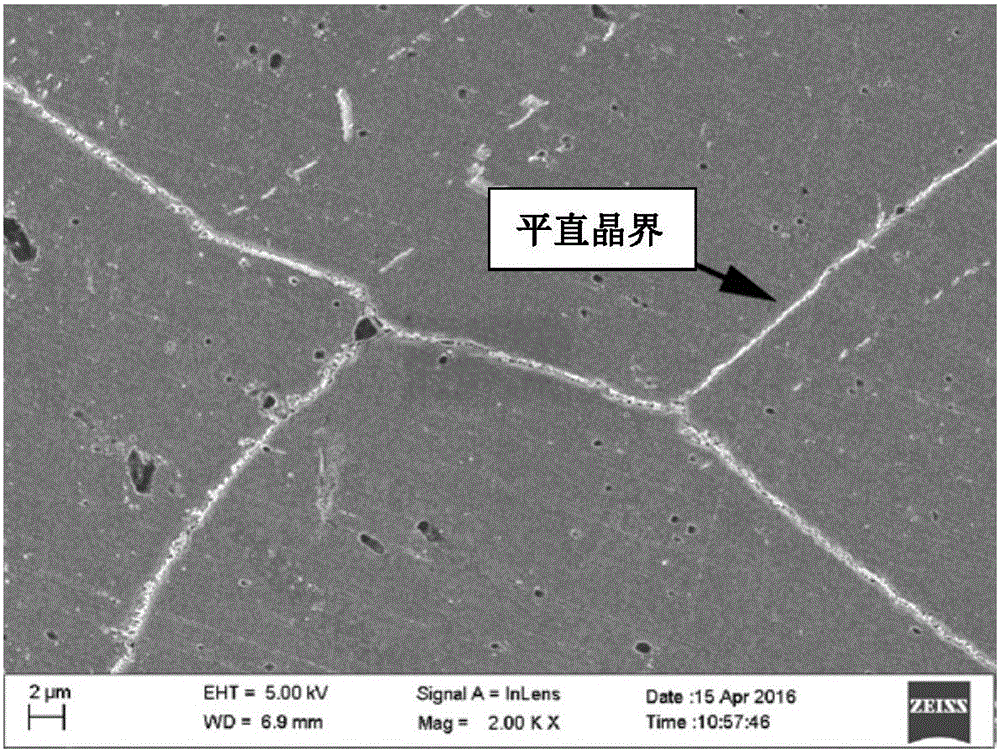

[0028] Taking a nickel-iron-chromium-based superalloy within the composition range in the summary of the invention, the precipitation temperature of the γ' phase is 971°C. The deformed nickel-iron-chromium-based superalloy sample was subjected to high-temperature solution treatment, the solution temperature was 1150°C, and the holding time was 1 hour; then it was slowly cooled to 900°C at a rate of 4°C / min, held for 2 hours, and then air-cooled to Room temperature; followed by aging, the aging temperature is 780°C, the holding time is 8 hours, and then air-cooled to room temperature. The tensile plasticity of the alloy at 750 °C is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com