Expanding and extruding connection method for mechanical connection of plastic pipes

A plastic pipe, extrusion connection technology, applied in the direction of pipe connection layout, mechanical equipment, sealing surface connection, etc., can solve the problems of difficult to repair, short service life, unreliable mechanical connection method, etc., to achieve convenient connection, sealing reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

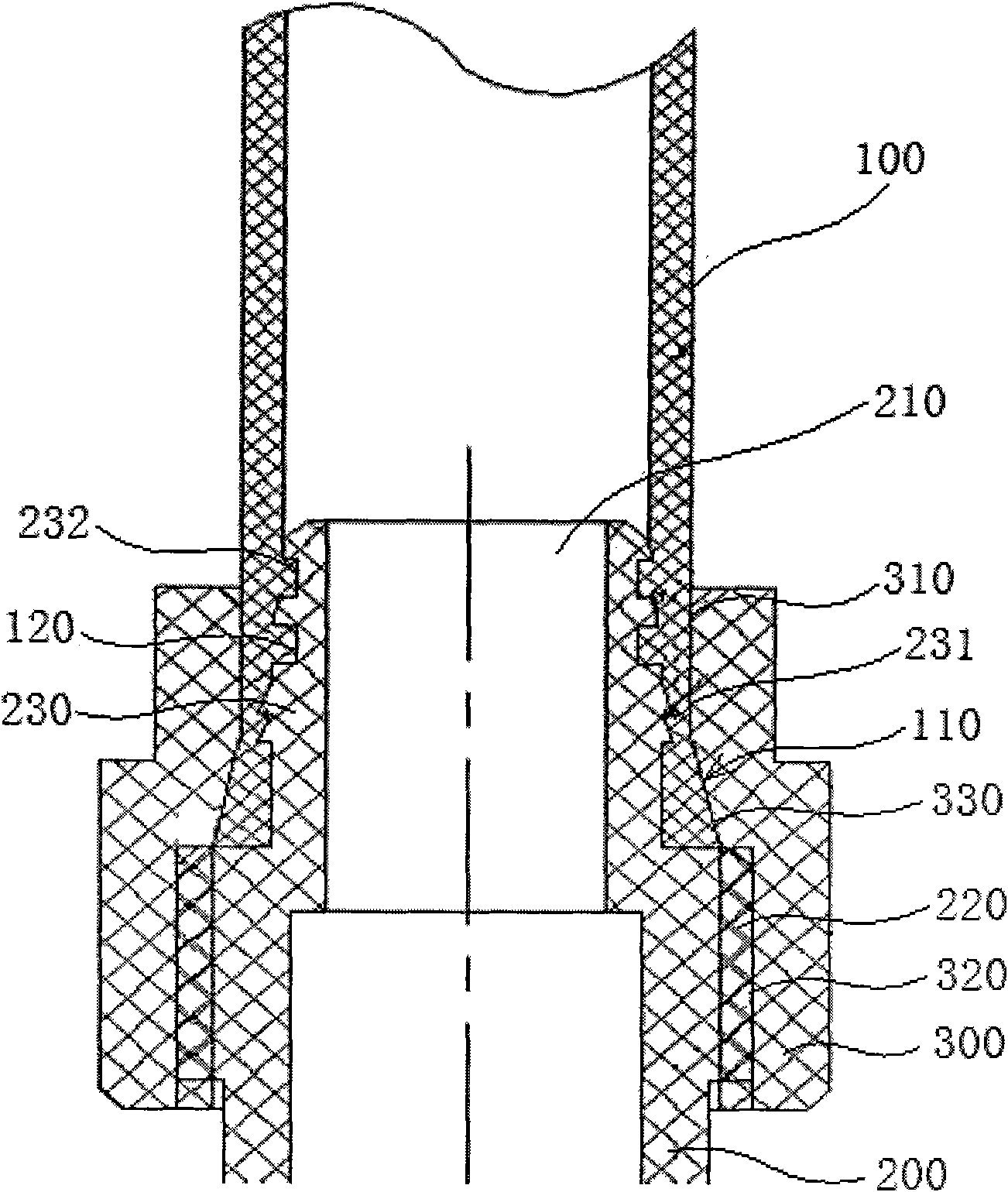

[0031] see figure 1 , an extended extrusion connection method for mechanically connecting plastic pipes, specifically comprising the following steps:

[0032] 1. Use a pipe expander to expand the inner diameter of the connection part 110 of the plastic pipe 100 to 10%-25% by utilizing the tensile ductility of the plastic pipe 100;

[0033] 2. Connect the plastic pipe 100 with a plastic expansion extrusion connector. The plastic expansion extrusion connector includes a plastic connector 200 and a plastic nut 300. The axial center of the plastic connector 200 is provided with a central through hole 210. In the plastic connector 200 A section of external thread 220 is provided on the outer ring surface of the external thread 220, and the outer diameter of the external thread 220 is larger than the outer diameter of the plastic pipe 100; the outer thread 220 is provided with an insertion part 230 inserted into the plastic pipe 100 along the axial direction. For dn10 plastic pipe ...

Embodiment 2

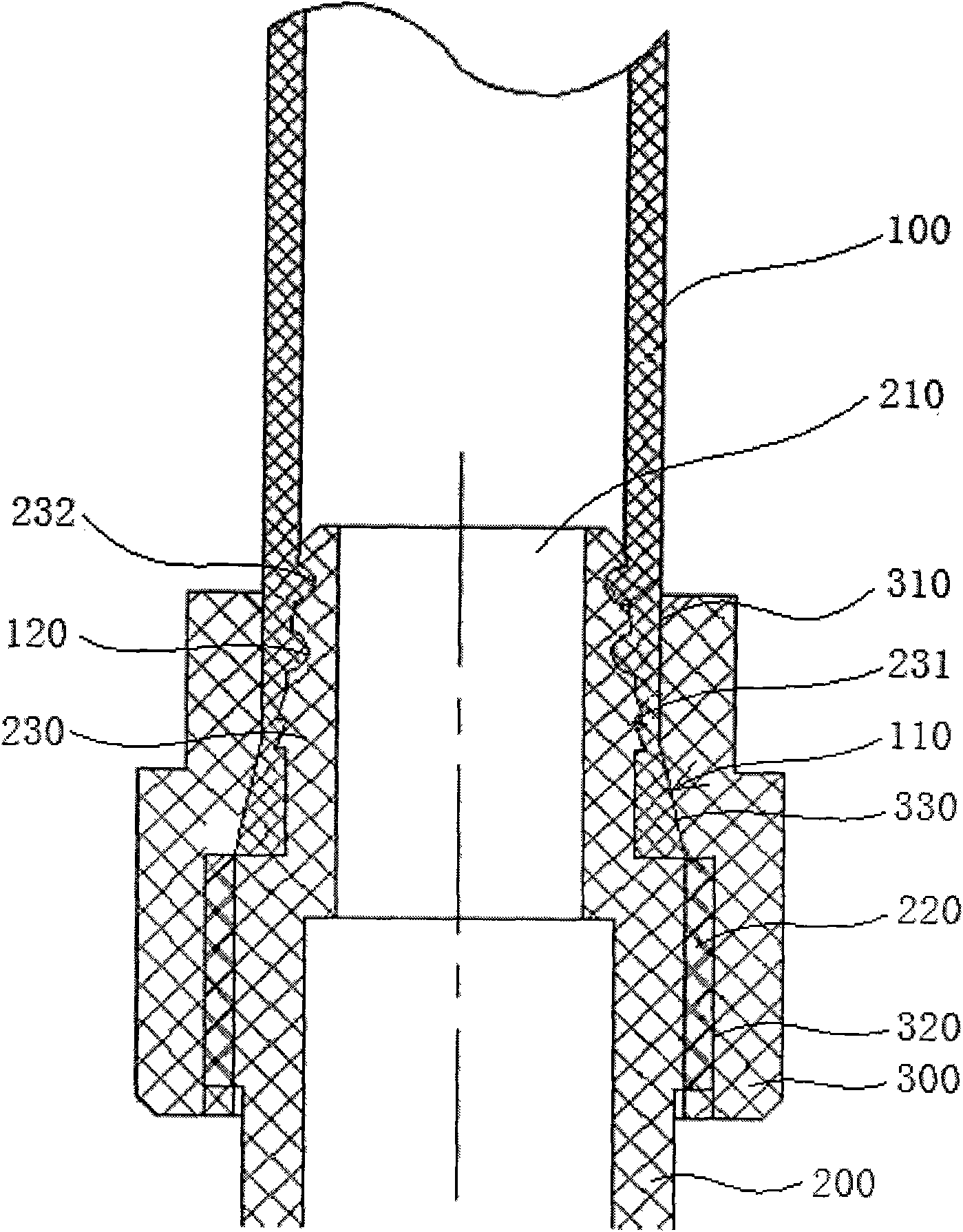

[0036] see figure 2 , This embodiment is the same as Embodiment 1, wherein the convex rib 231 is a sawtooth ring, and the concave ring 232 is a circular groove.

Embodiment 3

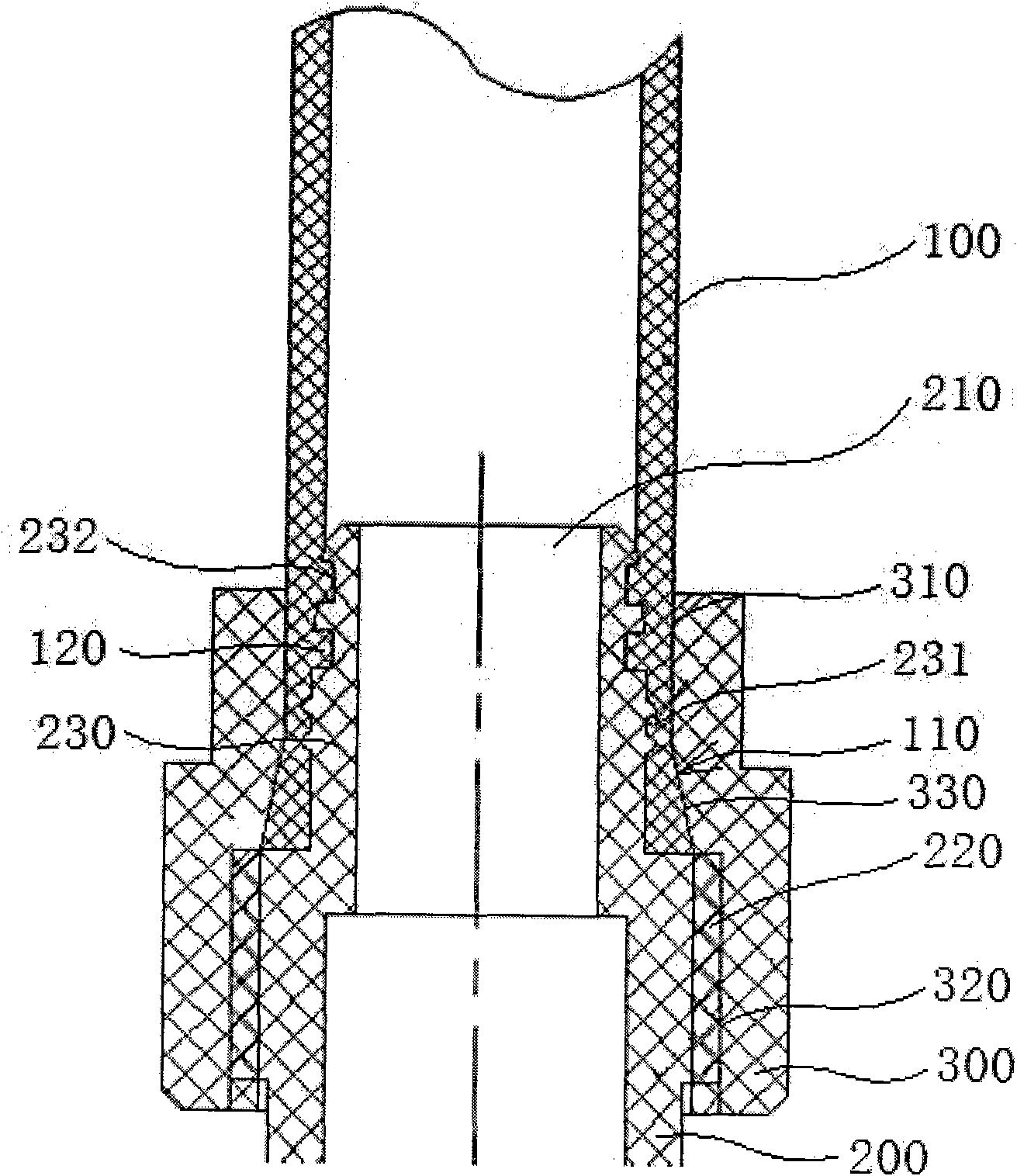

[0038] see image 3 , This embodiment is the same as Embodiment 1, wherein the convex rib 231 is a circular ring, and the concave ring 232 is a rectangular groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com