Patents

Literature

221 results about "Plastic joining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic joining is the method of joining semi-finished products of plastic materials together or to other materials as a fabrication process or damage repart.

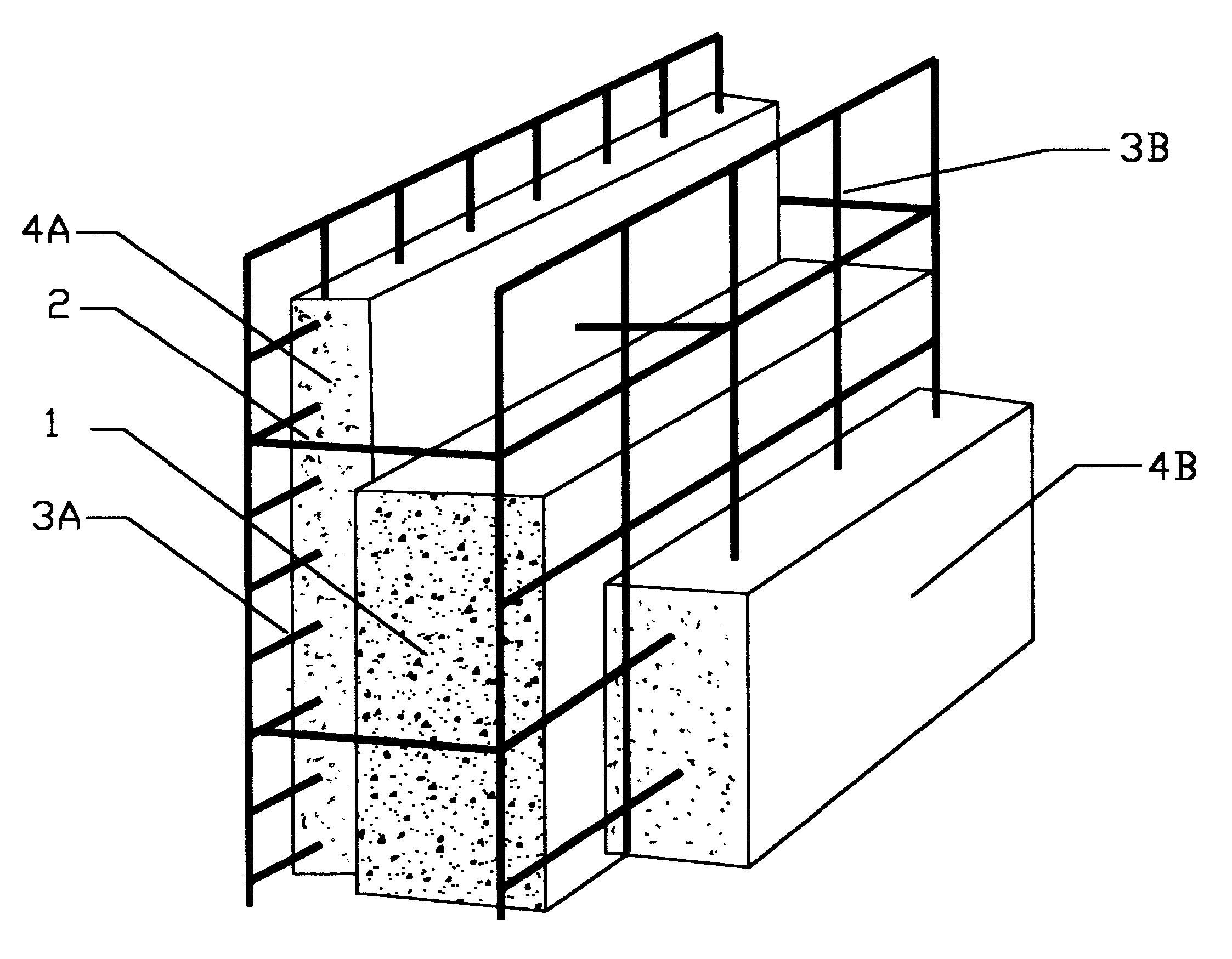

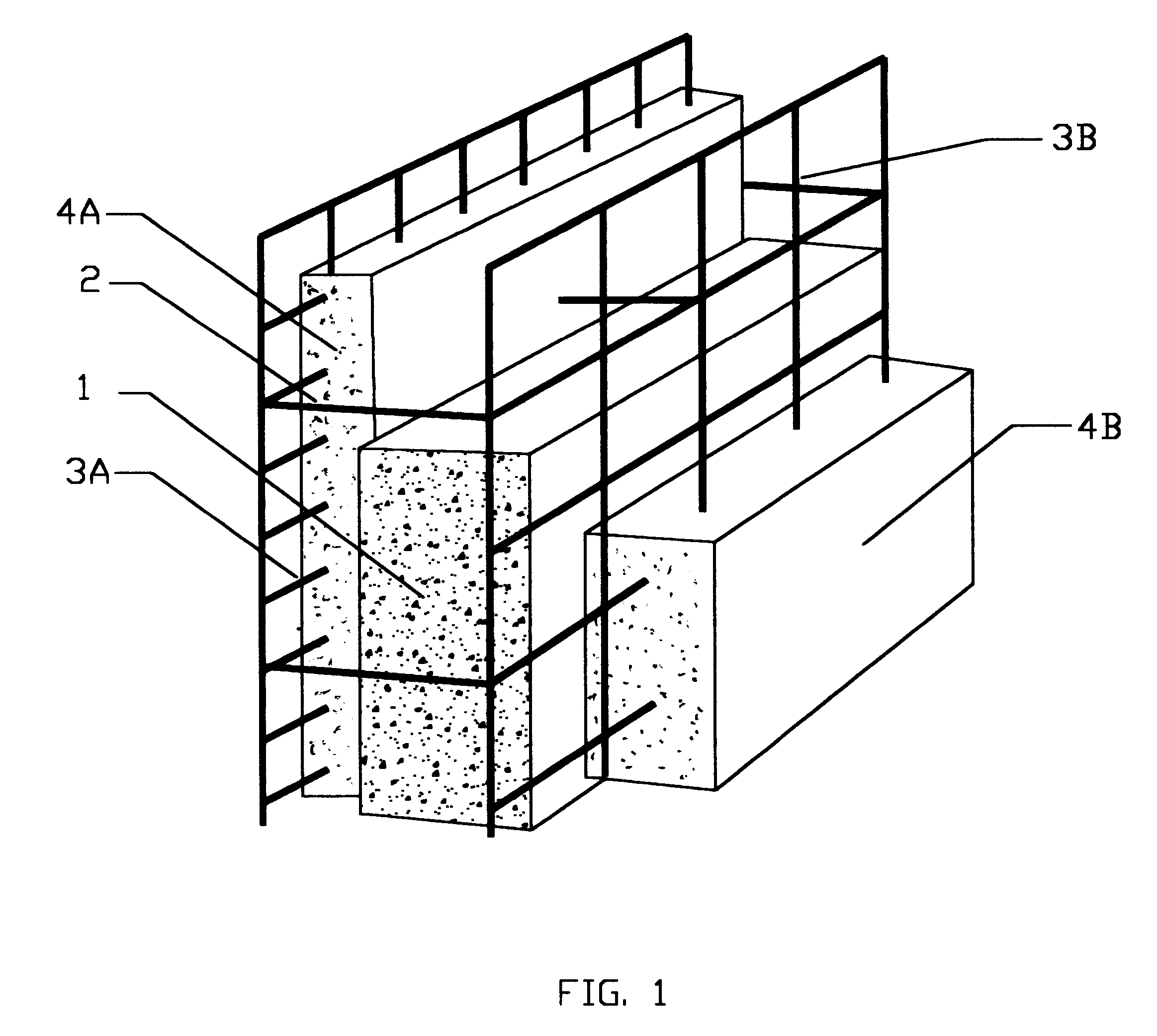

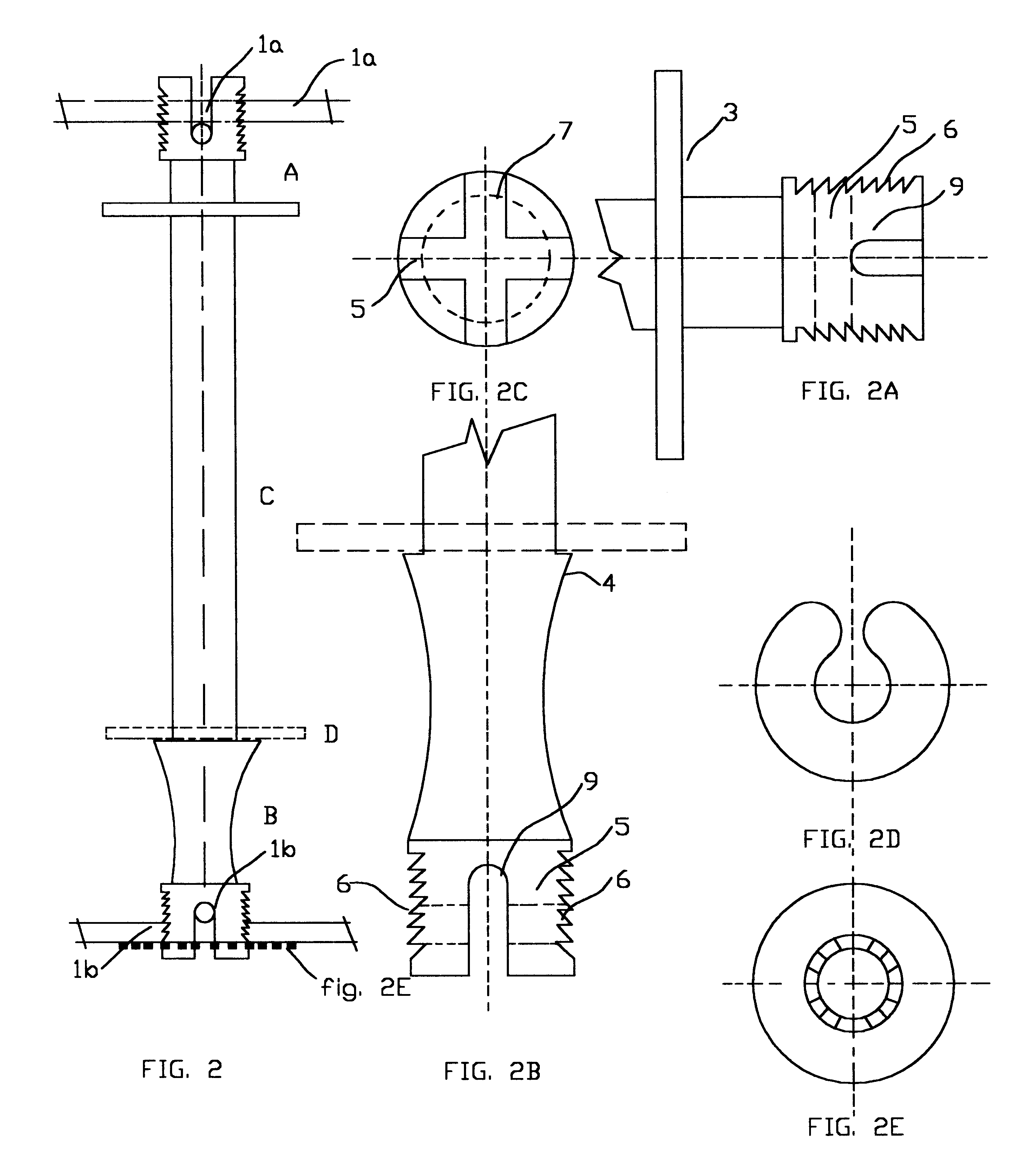

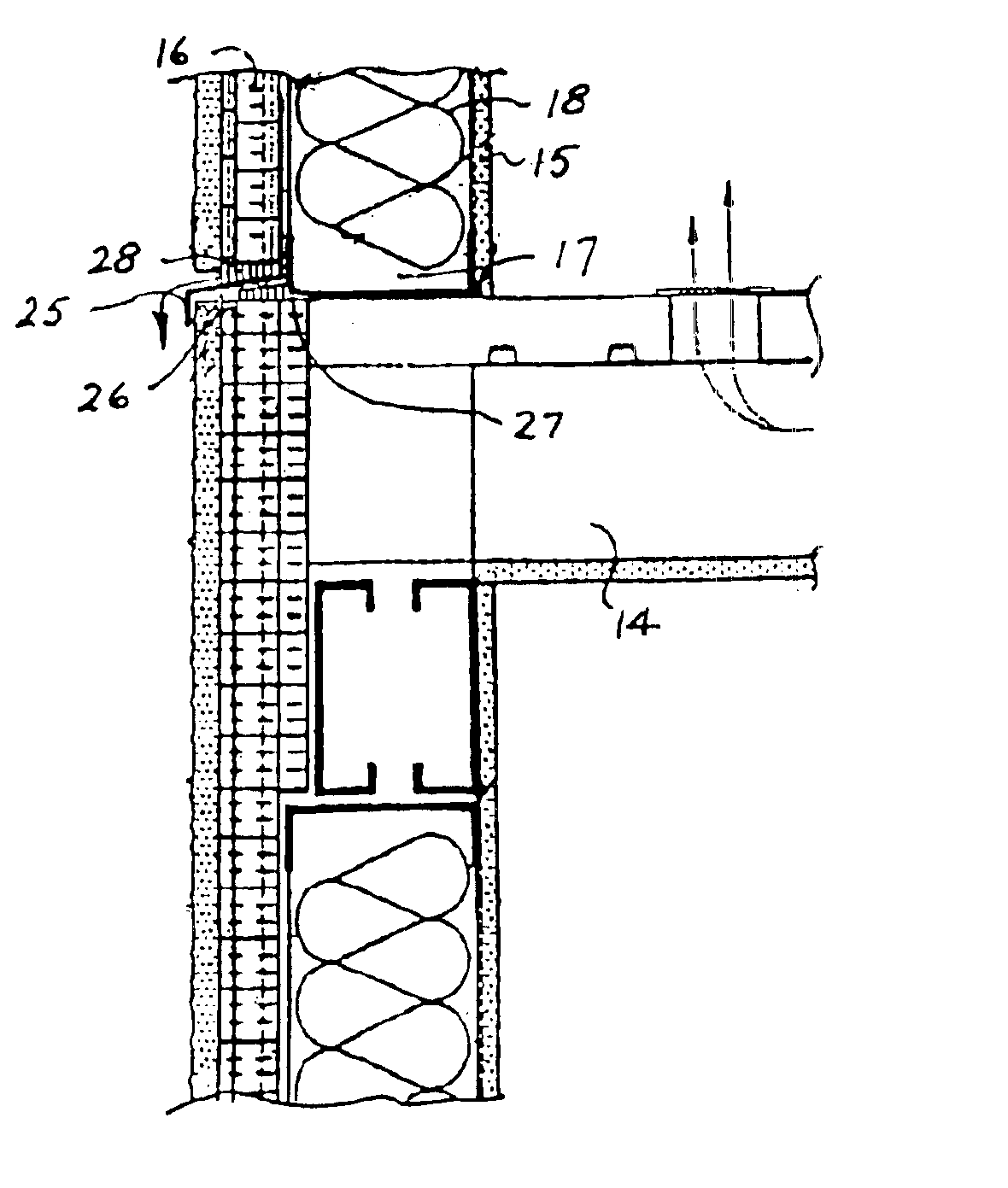

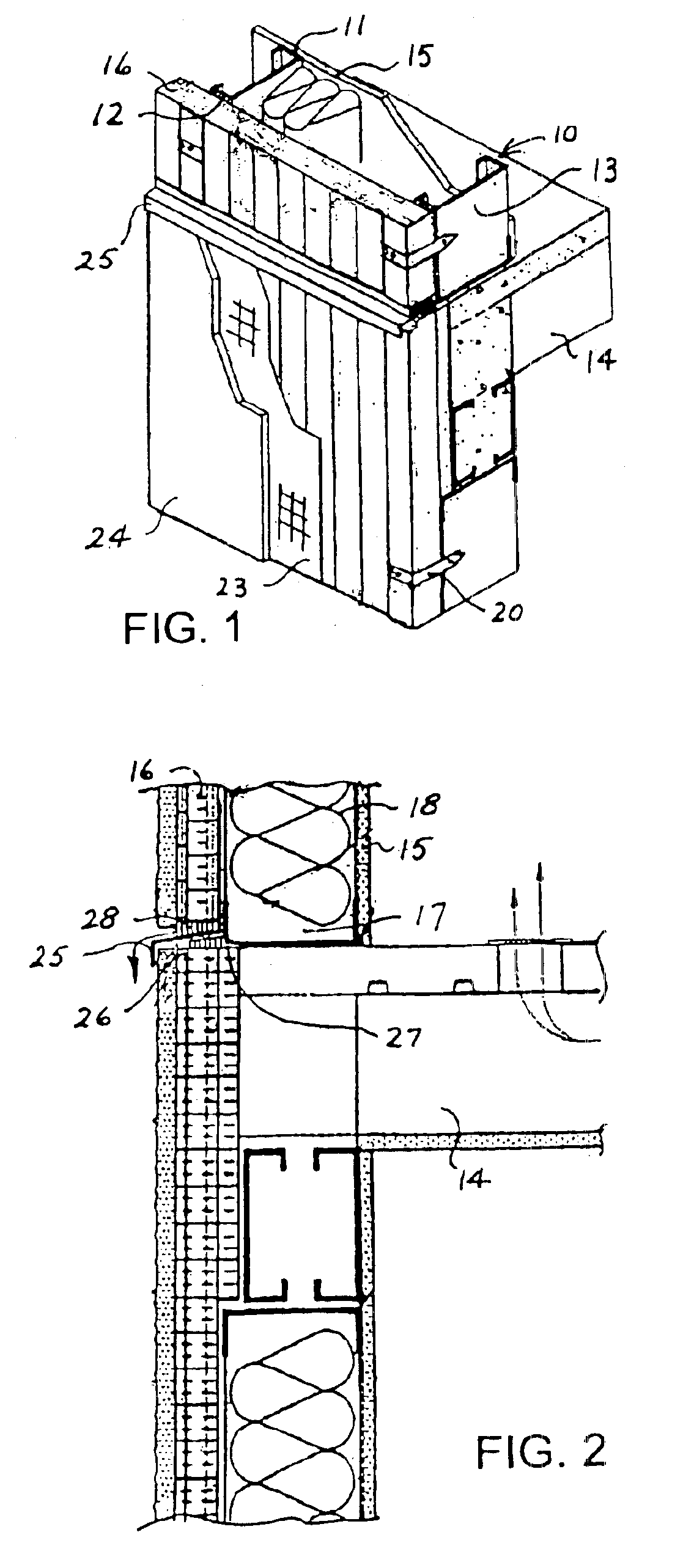

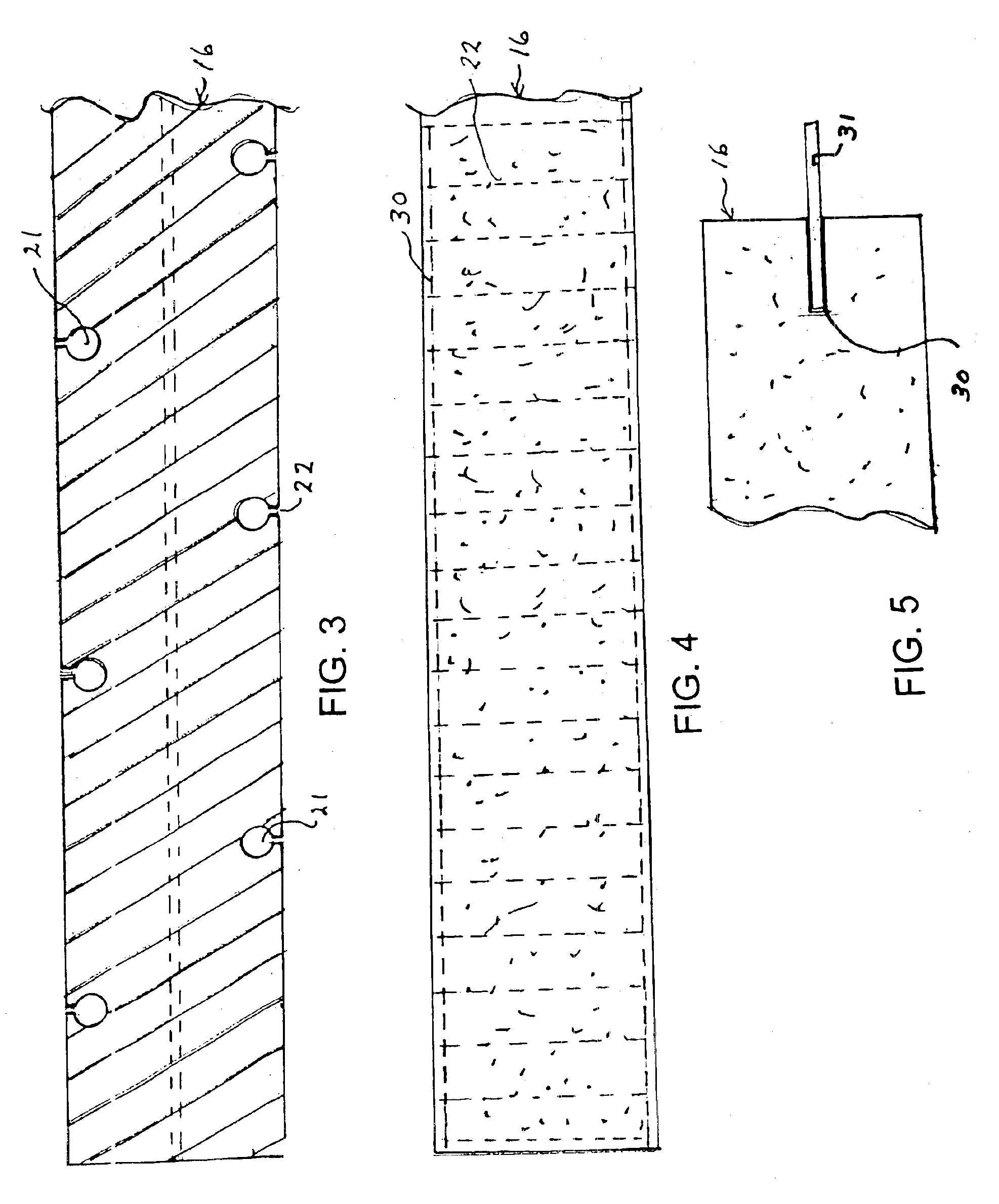

Method for concrete building system using composite panels with highly insulative plastic connector

InactiveUS6202375B1Easy to assembleEasy to transportBuilding roofsConstruction materialFiberShotcrete

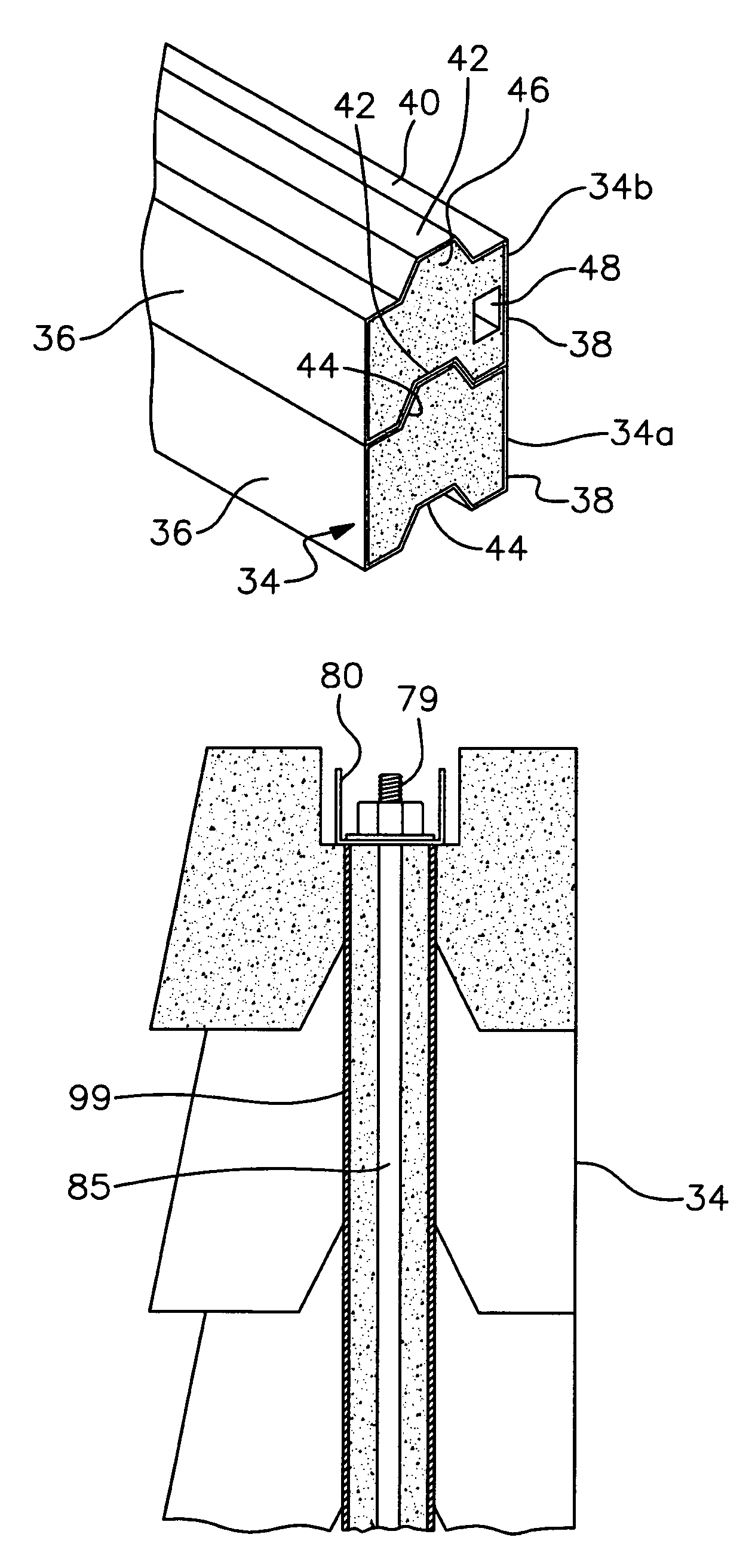

The present invention comprises a concrete building system with a method for fabricating composite panels using an improved design plastic connector and assembling them at the construction site to a structure which will be shotcreted on both sides to a concrete building which is highly insulated, is fire and termite proof, hurricane, earthquake and flood resistant and fulfills the requirement for flexible design. The Composite Panels are composed of two concrete layers, enclosing an insulative foam core. The skins are reinforced with wire mesh as structurally required and are connected through the foam core by structural highly insulative plastic connectors using the snap connection on both ends of the connectors so they form a tri-dimentional system and hold the wire mesh in place for the onsite shotcrete application, which includes an application of fiber for shrinkage and cracking. This replaces the welded wire fabric use for secondly reinforcing and let the wire mesh reinforcing only related to the structural strength of the composite panel. The plastic connector guarantees that no thermal bridging occurs like in other systems also the inside layer of the shotcrete panel.

Owner:FCN FOUND FOR THE CONSERVATION OF NATURE

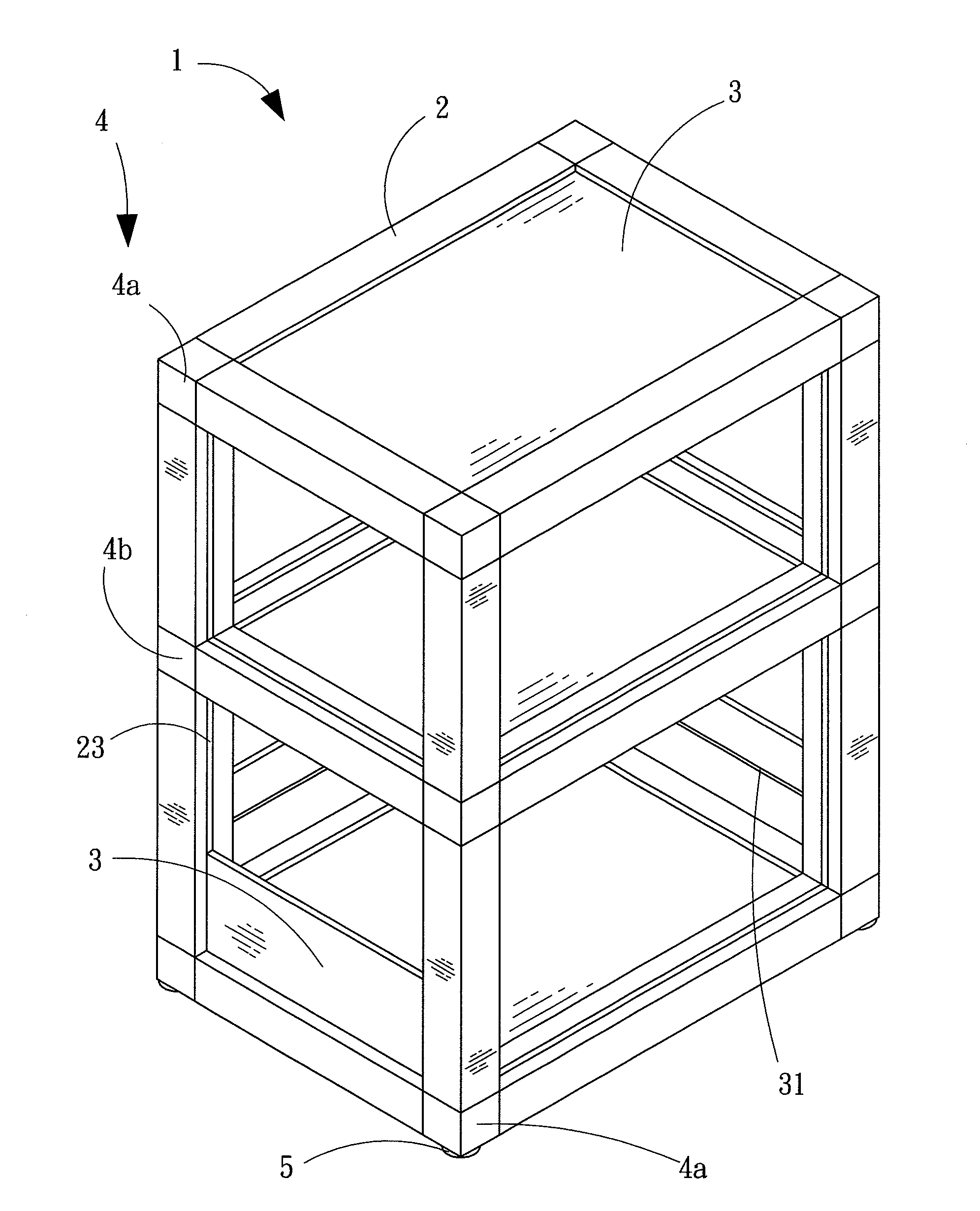

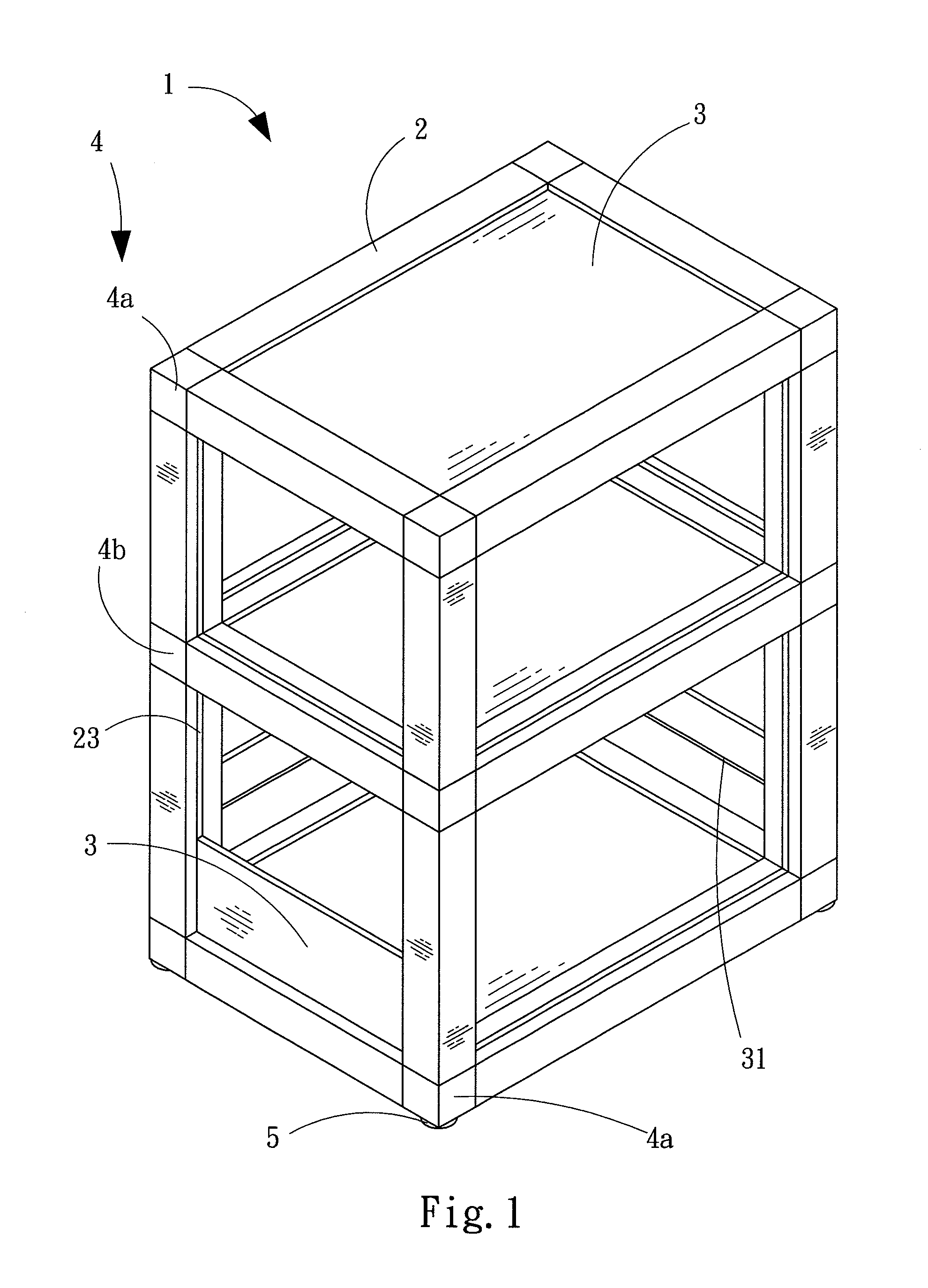

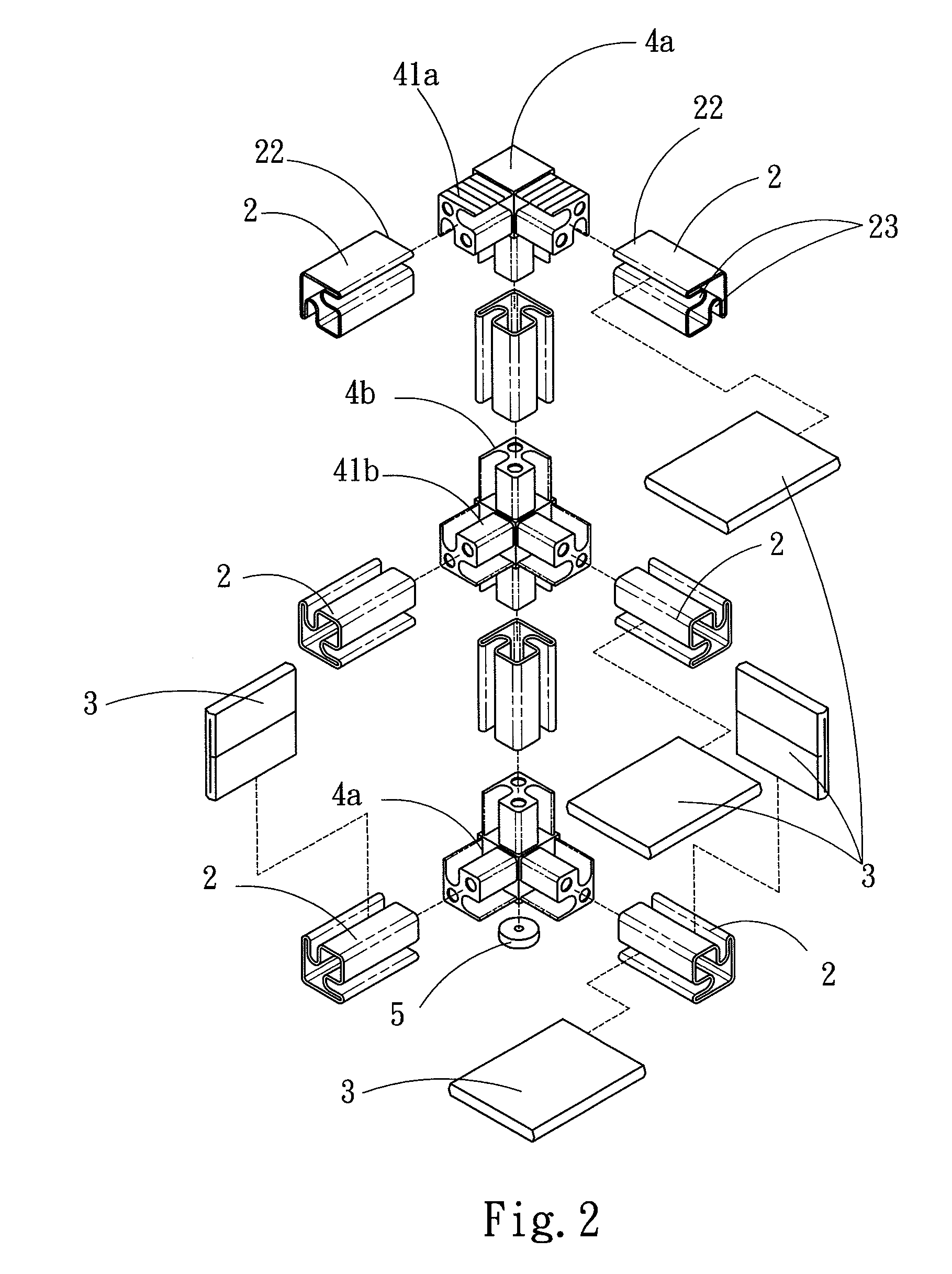

Environmental protection shelving combination

InactiveUS20110017691A1Easy constructionEasy to processFurniture partsFolding cabinetsEnvironmental resistanceMetal framework

The environmental protection shelving combination of the present invention includes sleeves and panels made of corner protection paper for support and plastic connector sets used for coupling the sleeves. Therefore, in accordance with different requirements, the assembly thereof can be altered as desired. Furthermore, since the corner protection paper is formed by pressing Kraft paper and the sand tube paper into a supporting structure, it can provide bearing and pressure capability, so that can replace the conventional wood, plastic or metal framework. Accordingly, not only the costs of material, conveying and assembly can be reduced, the pollution to the environment also can be minimized.

Owner:WU CHUAN CHING

Friction stir welding fastener

ActiveUS9555580B1Joining is strengthenedReduce the amount requiredLaminationLamination apparatusMulti materialEngineering

A heat assisted friction stir welding system and fastener for use therewith allows the joining a variety of dissimilar materials, including joining composites and plastics to metal, in which the fastener becomes part of the bond. The fastener can be constructed from multiple materials, allowing for the joining of dissimilar metals. Heating the materials to be joined reduces the clamping force and torque required by the friction stir weld process. The result is a bond that is stronger with less energy input.

Owner:TEMPER IP

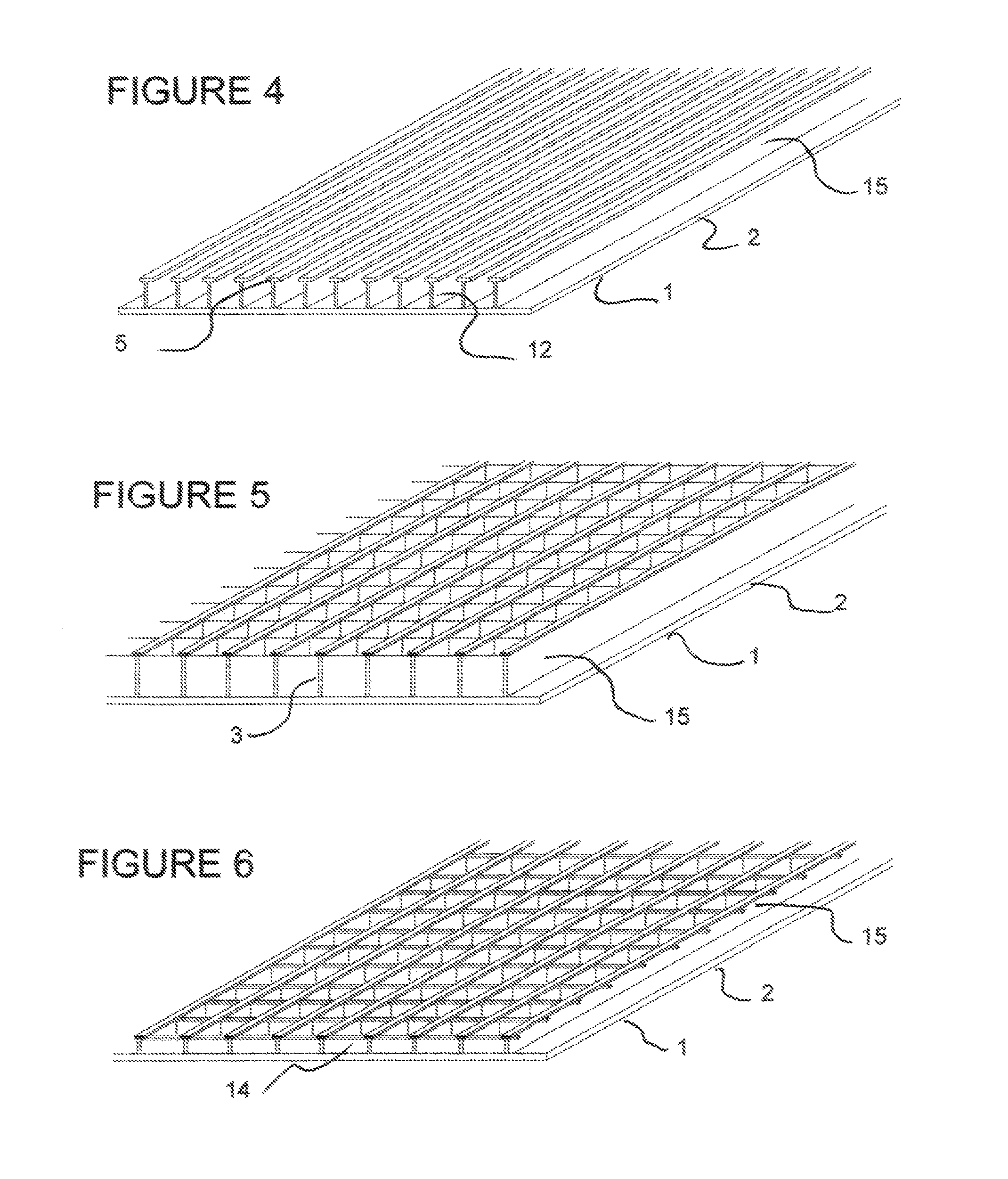

Exterior building cladding having rigid foam layer with drain channels

InactiveUS6886301B2Reduce conductivityStructural failureCeilingsConstruction materialInsulation layerSteel frame

A novel building construction is described for exterior building walls. The construction comprises an interior frame formed of a plurality of laterally spaced studs or beams, a layer of rigid insulation adjacent to the exterior side of this steel frame, exterior building cladding adjacent the exterior side of the rigid insulation and a plurality of low conductivity connectors, e.g. insulating plastic connectors or thin metal strips having an insulating plastic foam coating, extending through the layer of rigid insulation and connecting together the exterior cladding and the interior steel studs or beams. Vertical channels are formed adjacent both the inside and outside faces of the insulation layer to remove moisture. This provides the required structural strength with a minimum of thermal conductivity from the warm side to the cold side of the building envelope, while providing exterior drain channels and interior moisture removing channels.

Owner:SCHILGER HERBERT K

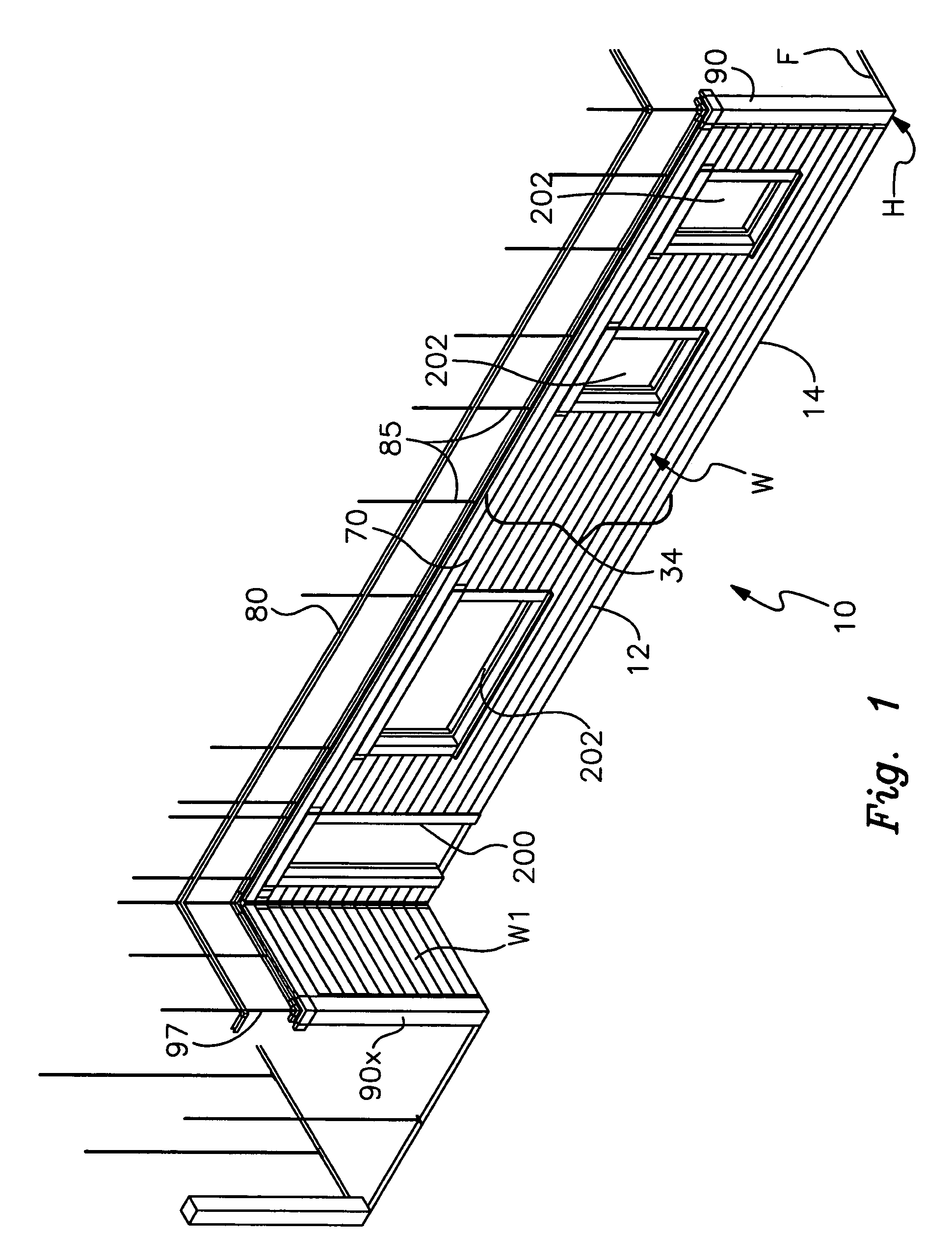

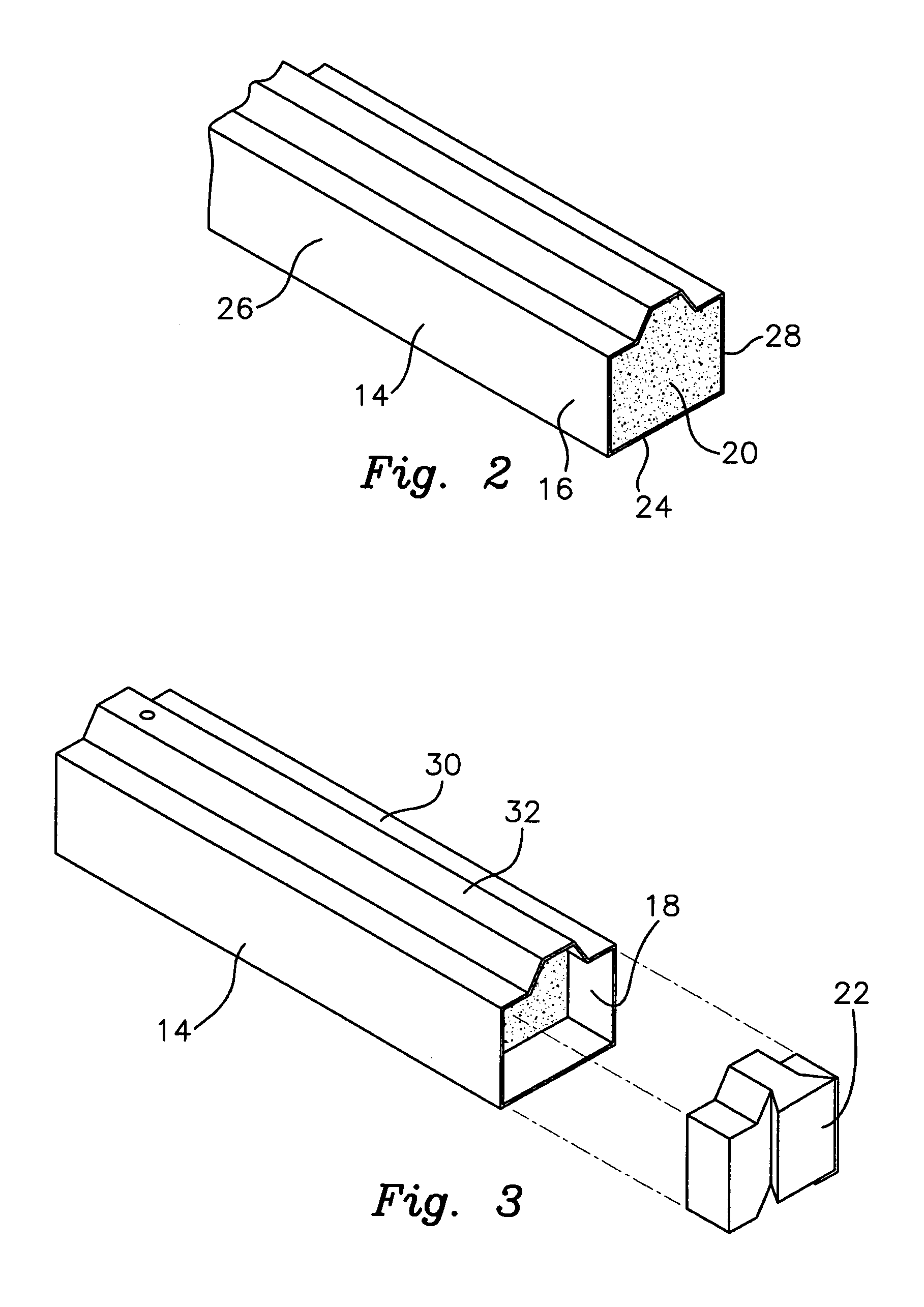

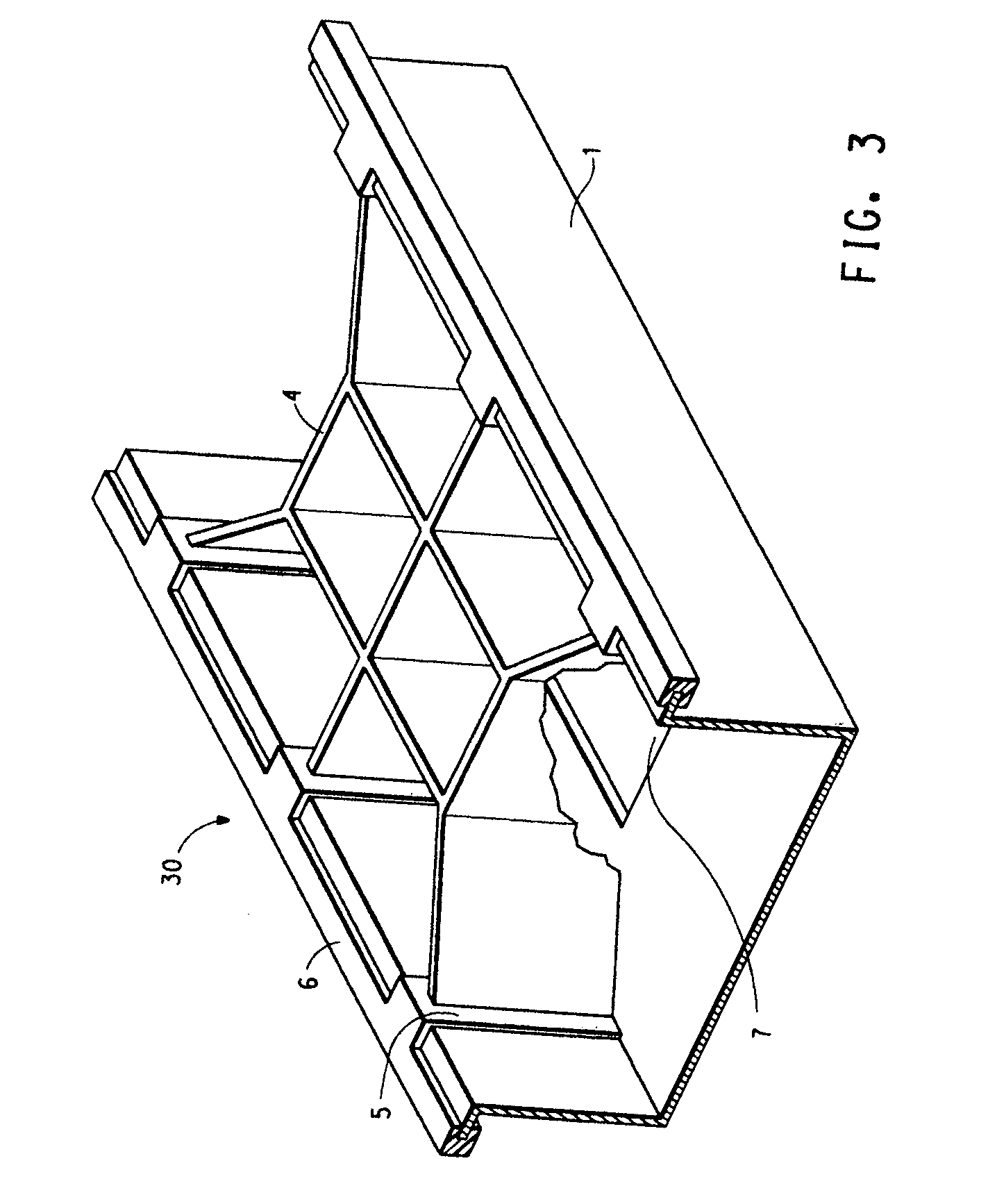

Modular building system

InactiveUS6931803B1Constructed quickly and inexpensivelyLess laborBuilding roofsWallsArchitectural engineeringTongue and groove

A modular building system includes a plurality of extruded plastic beams that are stacked and interlocked using a tongue and groove interengagement. Plastic connecting components are provided for interlocking the horizontal beams to a vertical column.

Owner:DAVIS GARY +1

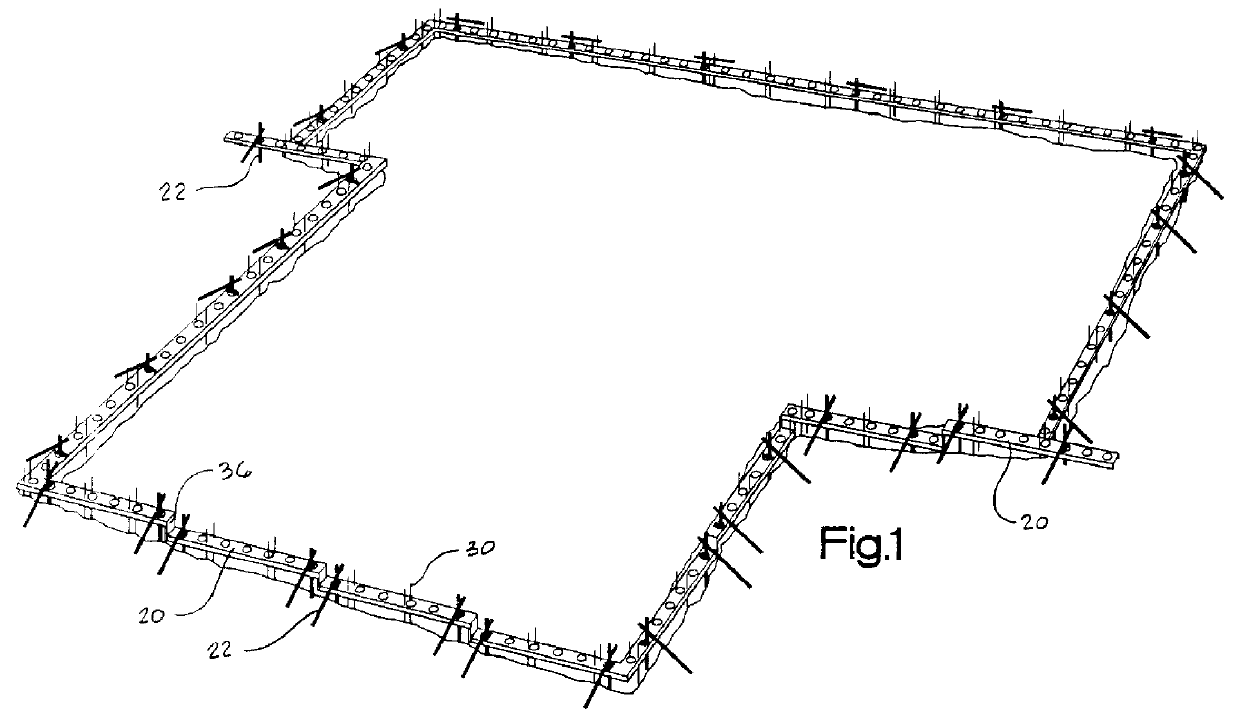

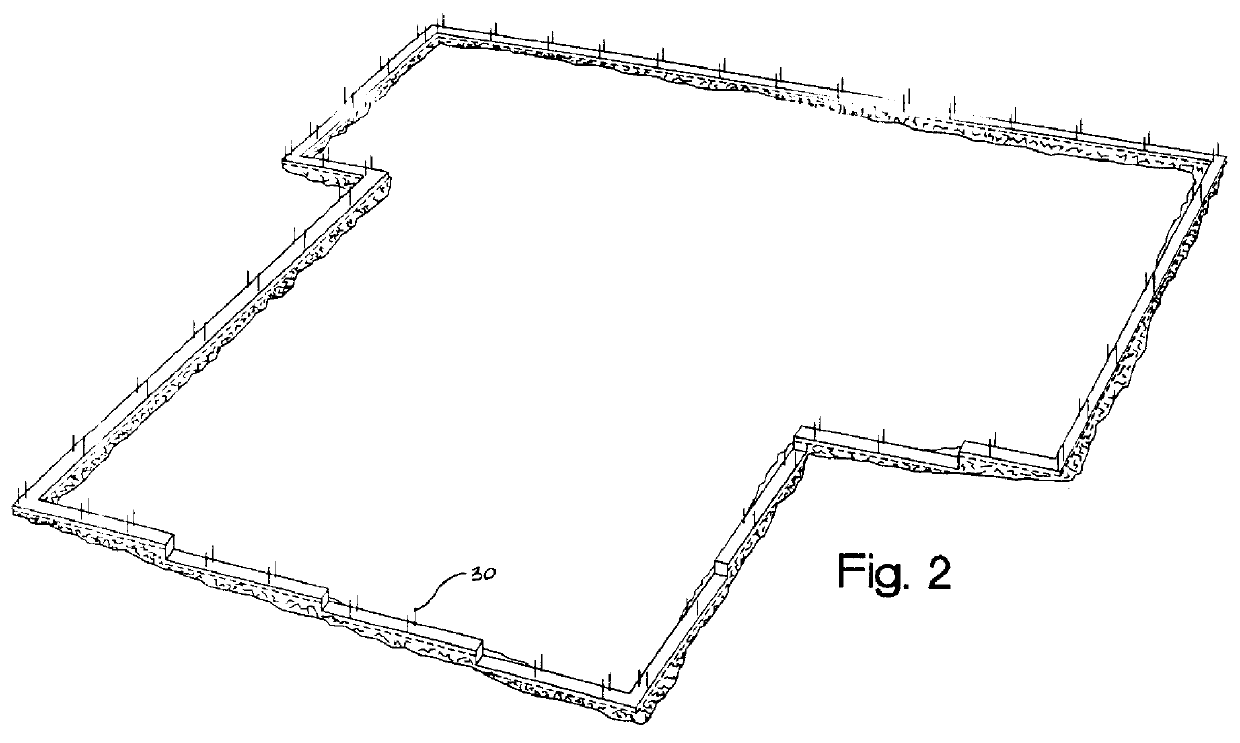

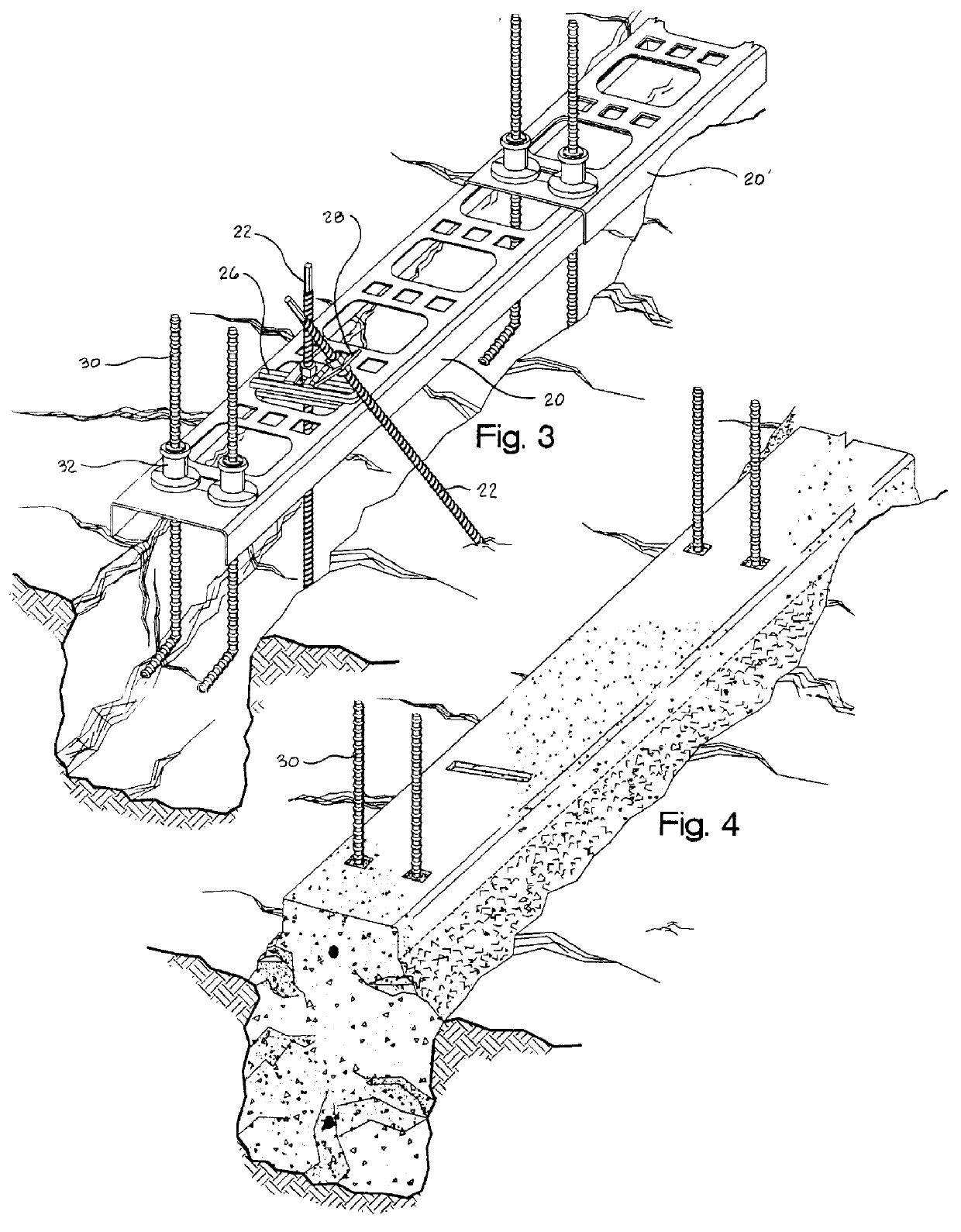

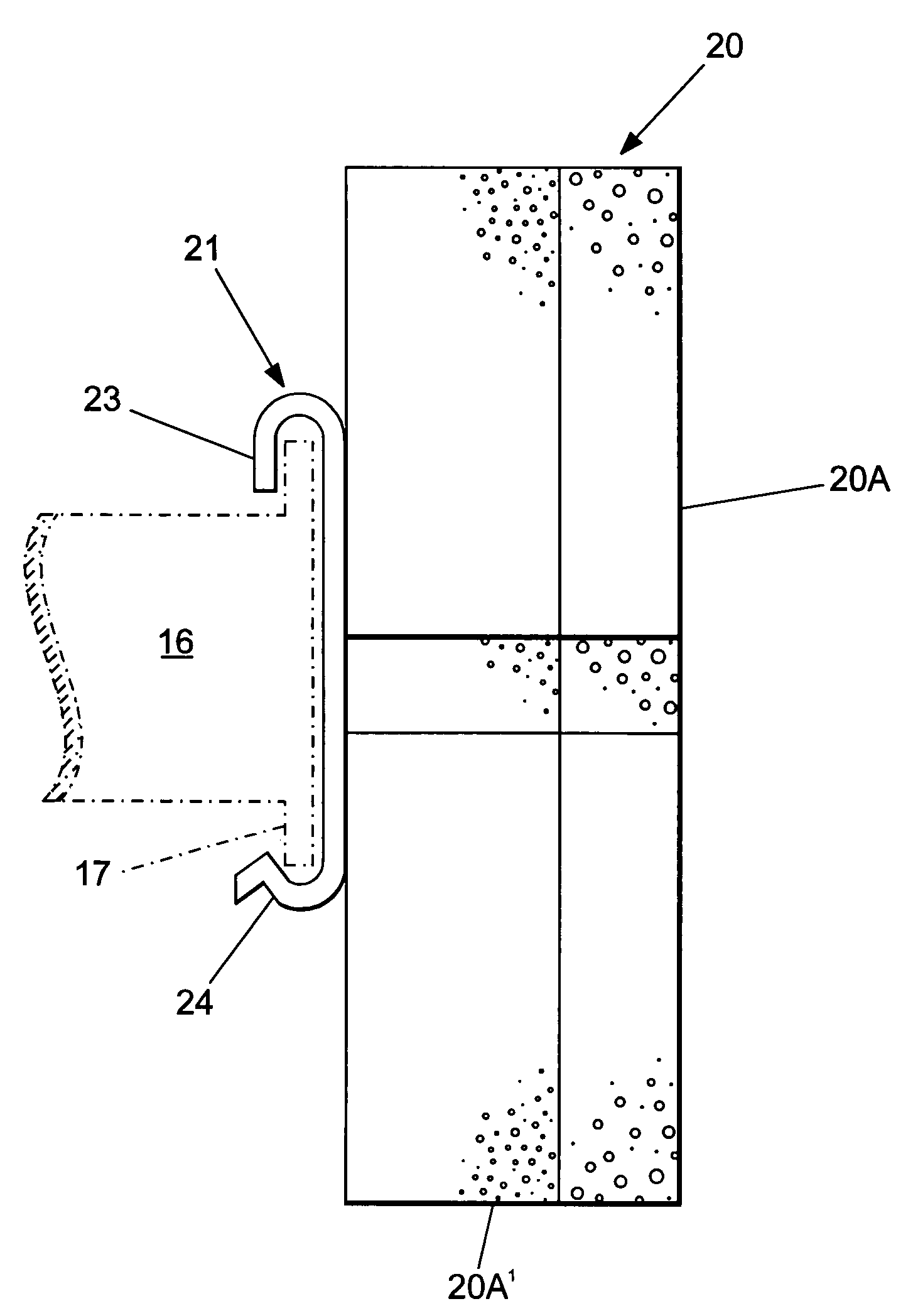

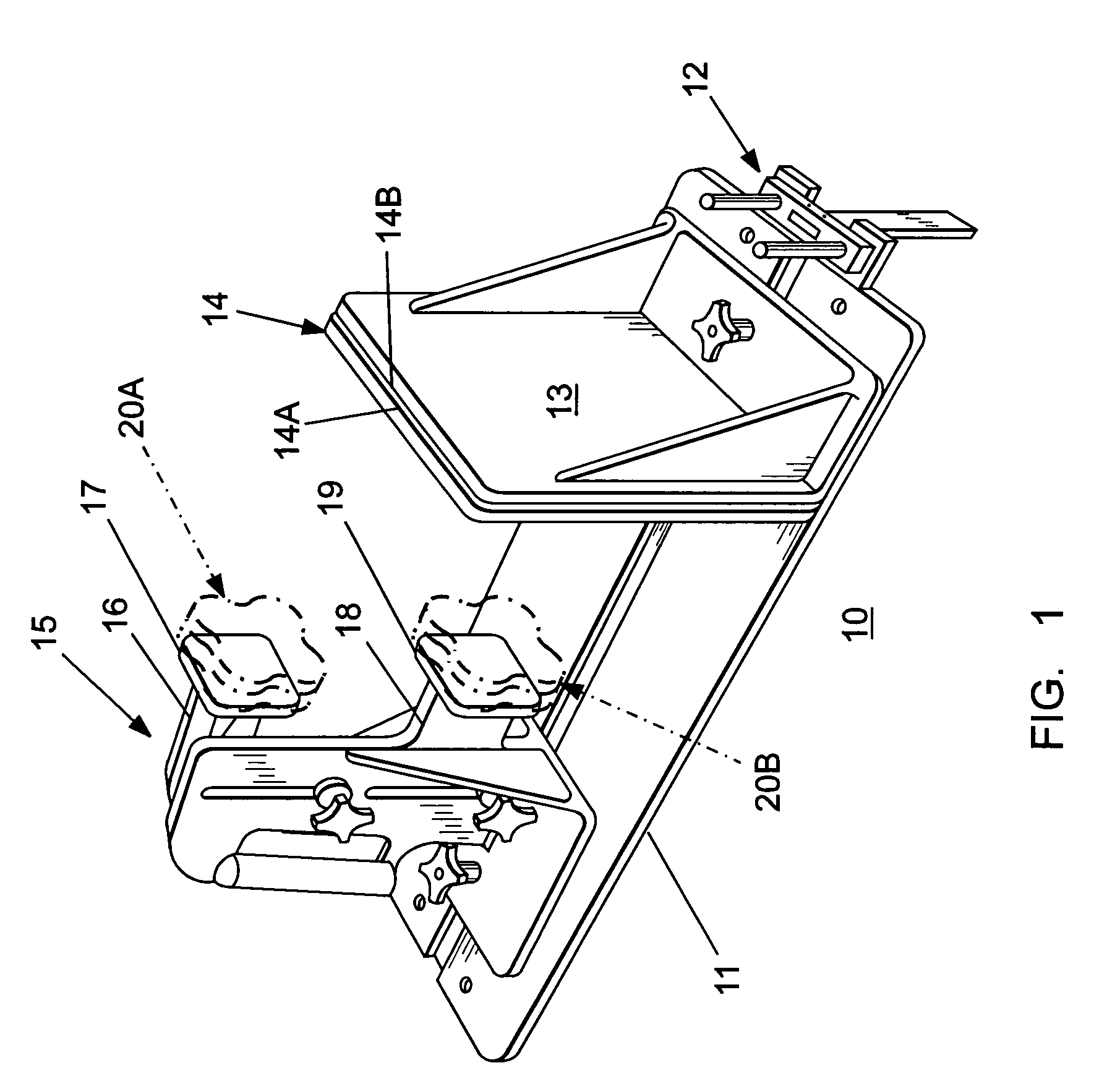

Foundation footing construction method, particularly as serve to efficiently precisely emplace wall anchors

Owner:BUTLER MICHAEL G

Dual compression pad for surgical positioner units

ActiveUS7426930B1Contact flexibleGreat patient comfortOperating chairsOperating tablesSingle pairPatient comfort

A dual compression foam pad arrangement for use with surgical postioner devices is formed from a single pair of cloverleaf-shaped foam pieces. The foam piece in contact with the patient is more porous than the foam piece in contact with the positioner support plate for greater patient comfort. A solid plastic connector clip connects the pad arrangement with the surgical postioner support in press-fit relation.

Owner:INNOVATIVE MEDICAL PRODS

Plastic living hinge with metal support

InactiveUS20070283529A1High strengthEnhanced living hinge structureWing accessoriesPinless hingesAdhesiveEngineering

A living hinge structure has two plastic side sections and a plastic connecting section, wherein the plastic side sections are integrated with metal supports so as to enhance the strength of the living hinge structure. The metal supports can be metal inserts bonded to the plastic side sections in an over-molding process. Each of the metal supports can be located on the outside surface or the inside surface of the plastic section. When the metal sections are located on the outside surfaces, they can be used to restrict the opening angle of the hinge. The metal supports can also be a part of a device that uses the hinge for mechanically coupling two device parts. As such, the living hinge is directly integrated into the device without the need for post-assembling by using screws, adhesive, welding or heat stacking.

Owner:NOKIA CORP

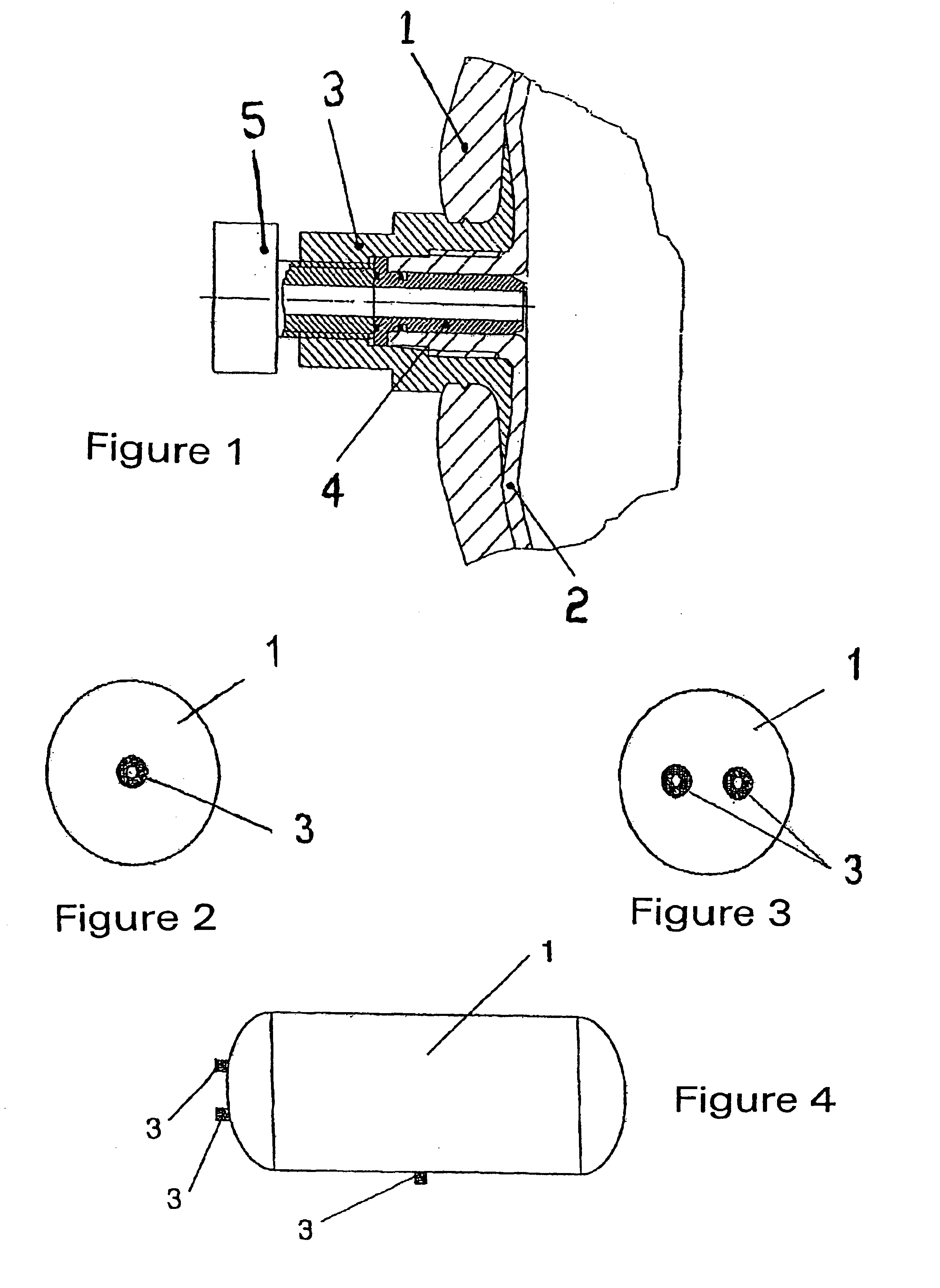

Pressurized container for storing pressurized liquid and/or gaseous media, consisting of a plastic core container which is reinforced with fibre-reinforced plastics and a method for producing the same

InactiveUS7032767B2Reduce weightImprove corrosion resistanceVessel mounting detailsVessel wallsFiberEngineering

Owner:FUNCK RALPH

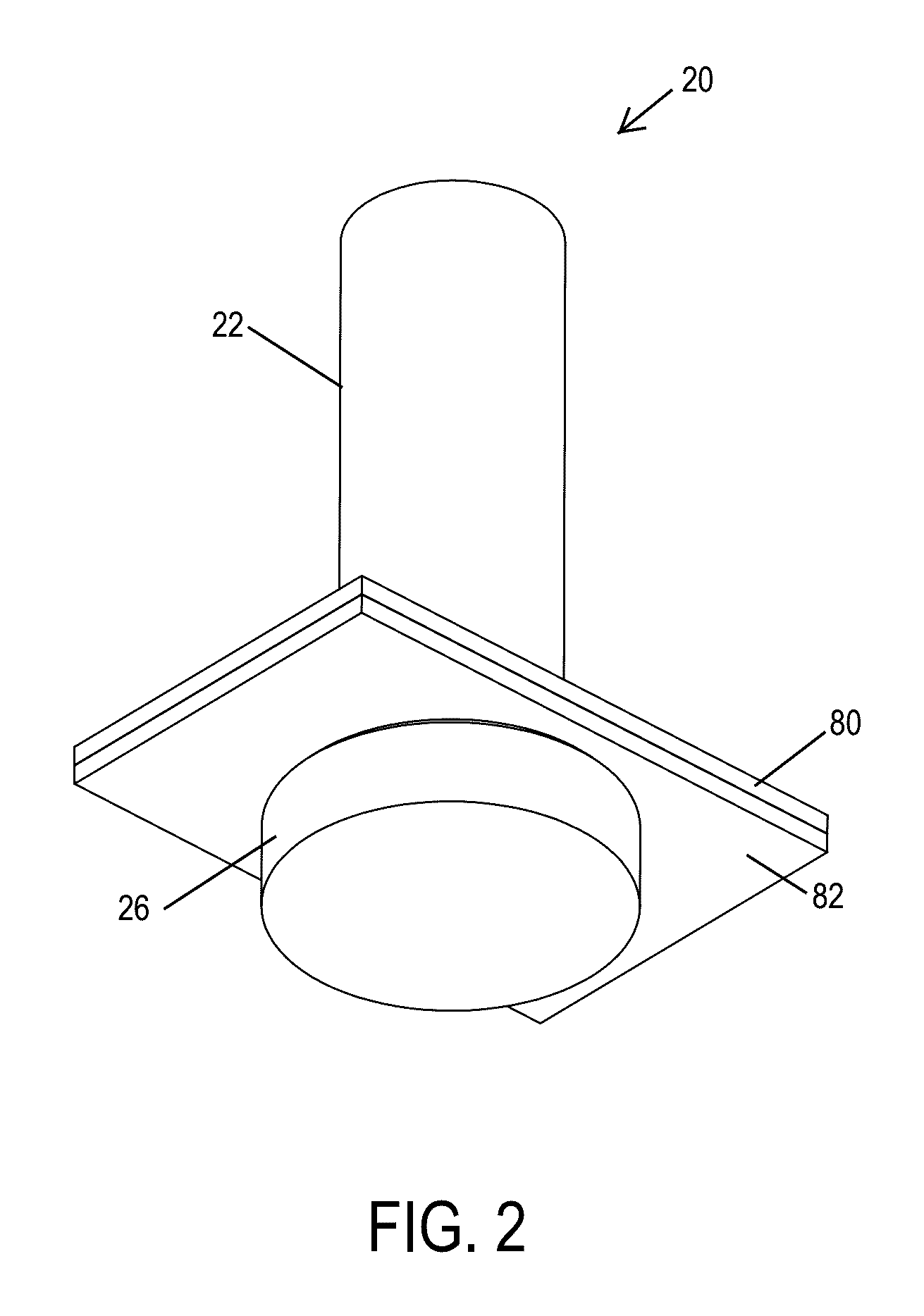

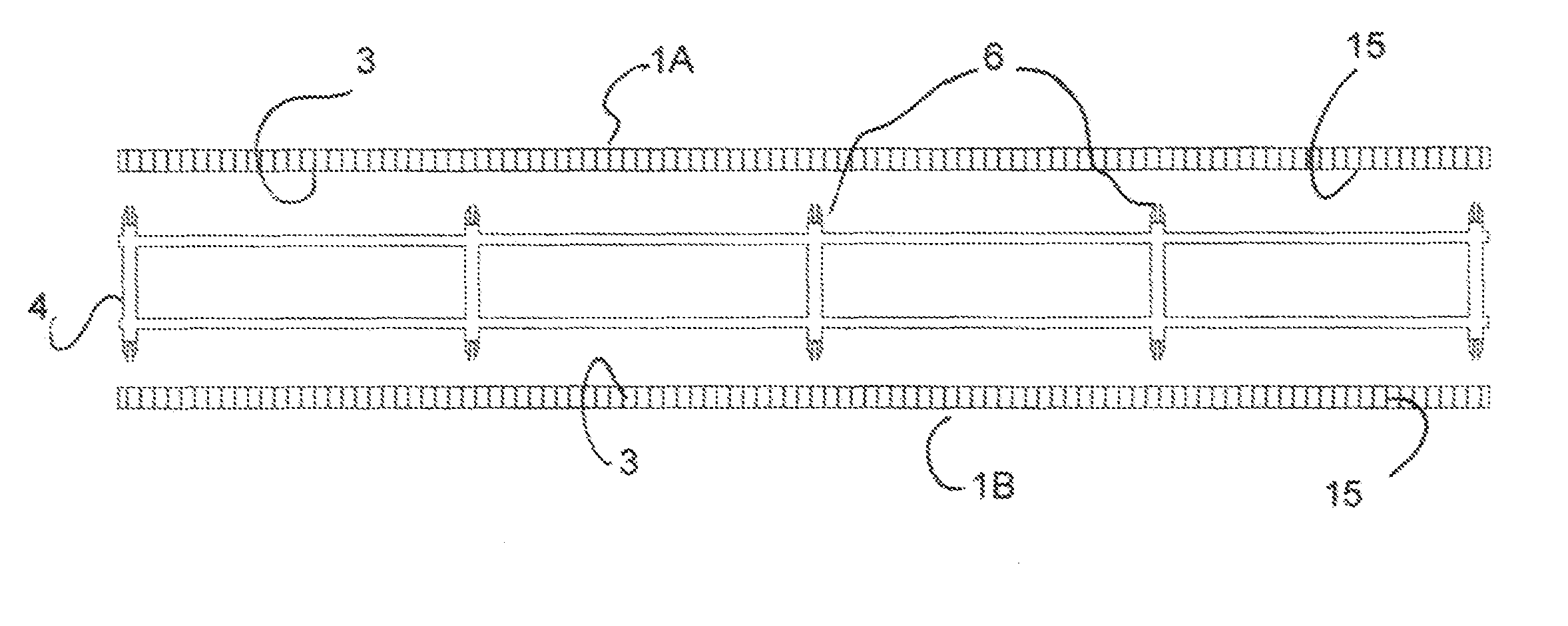

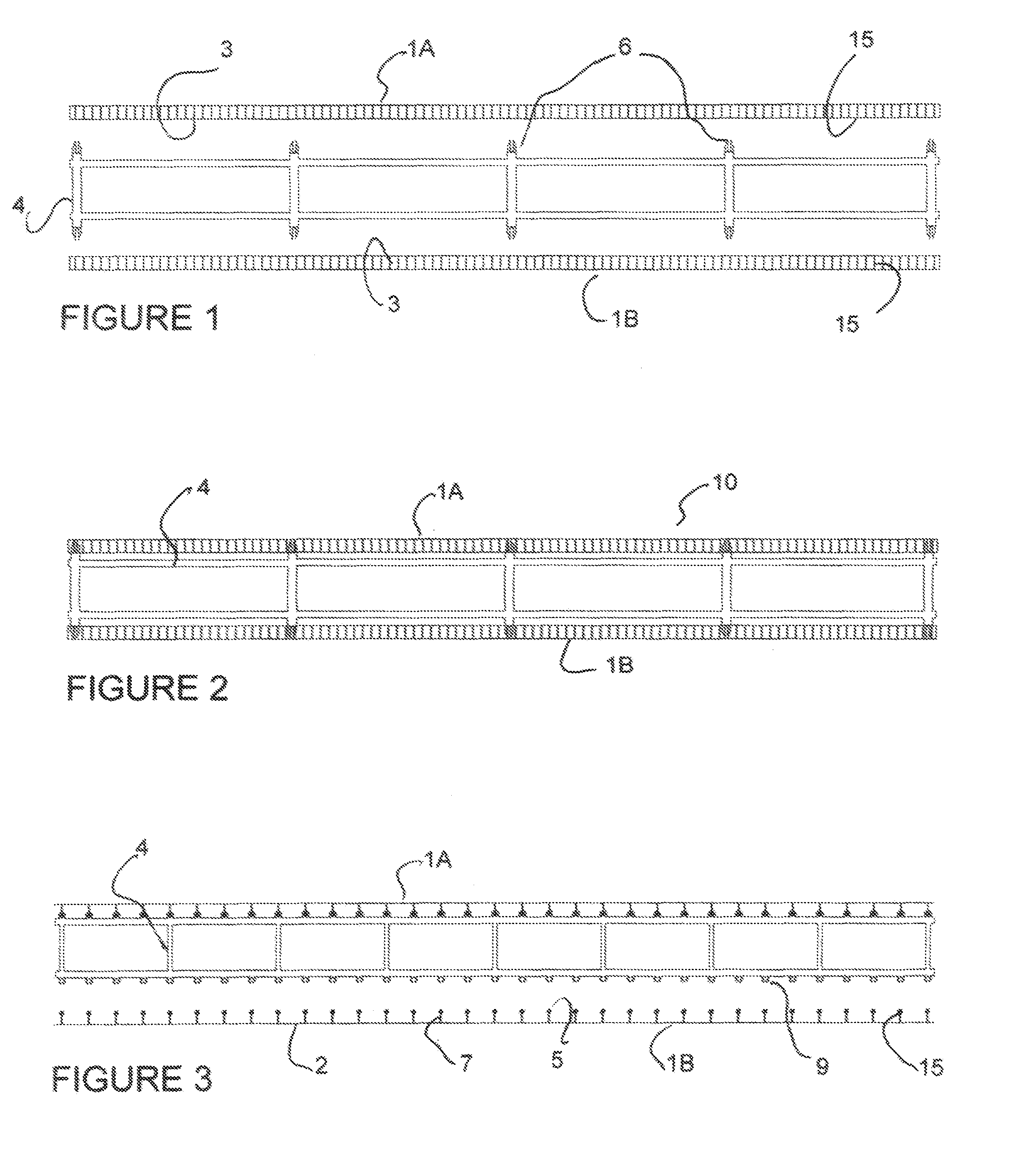

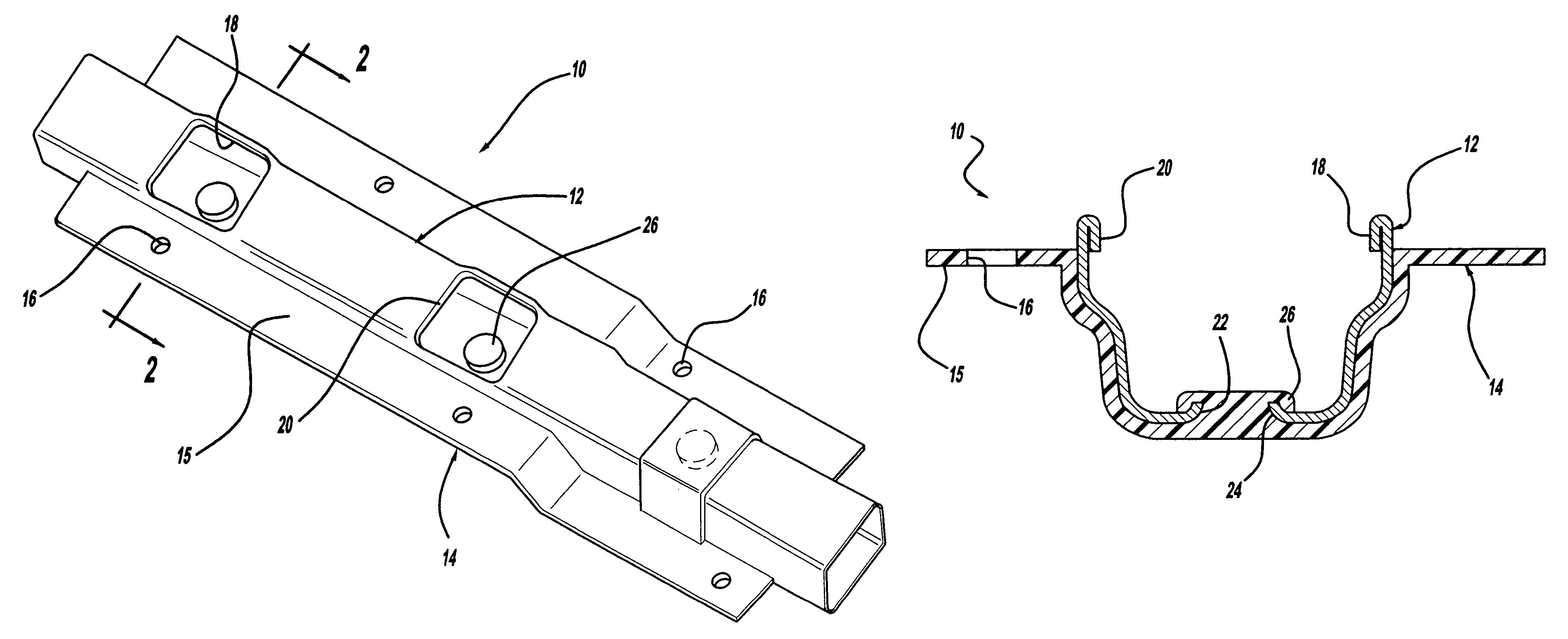

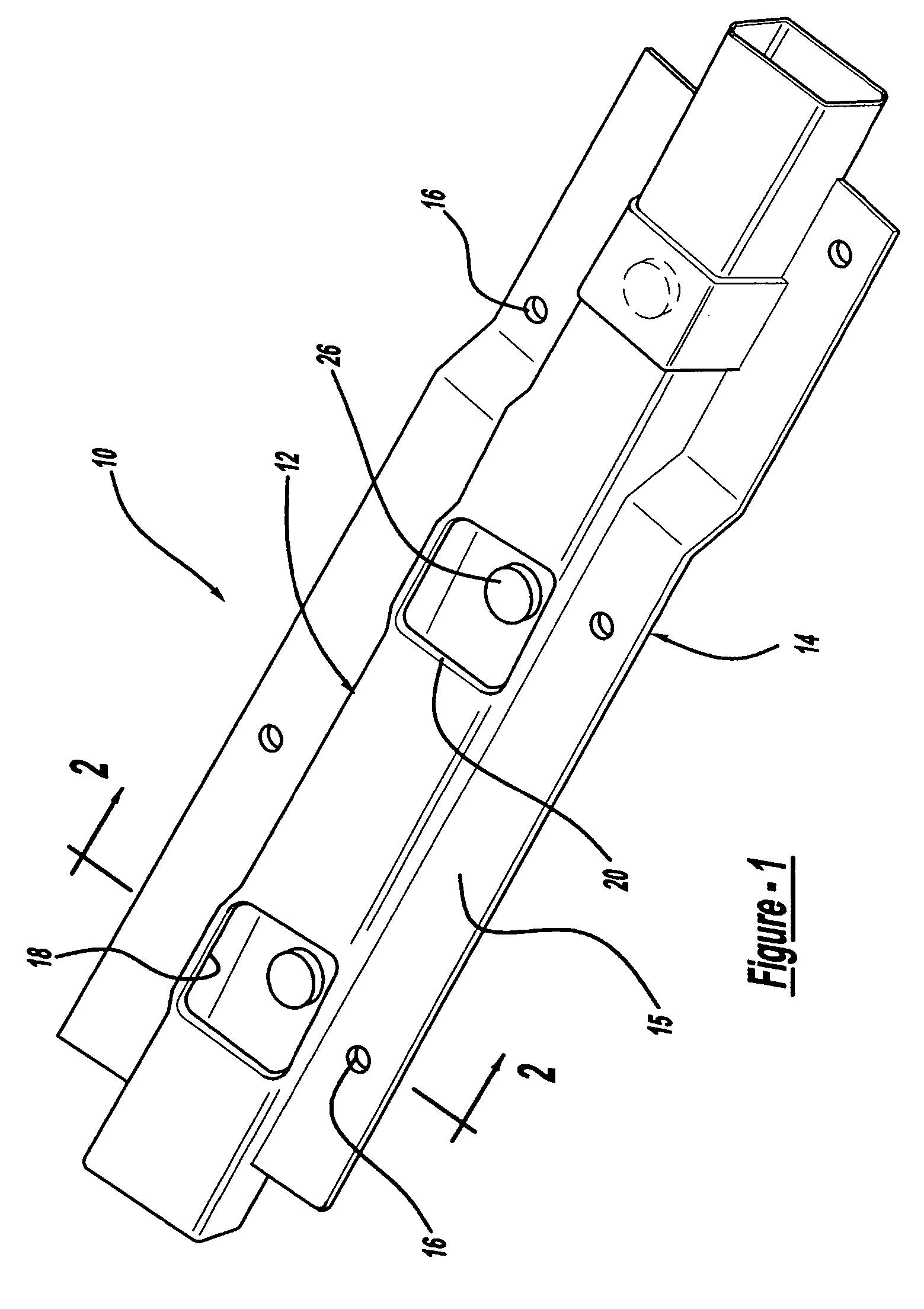

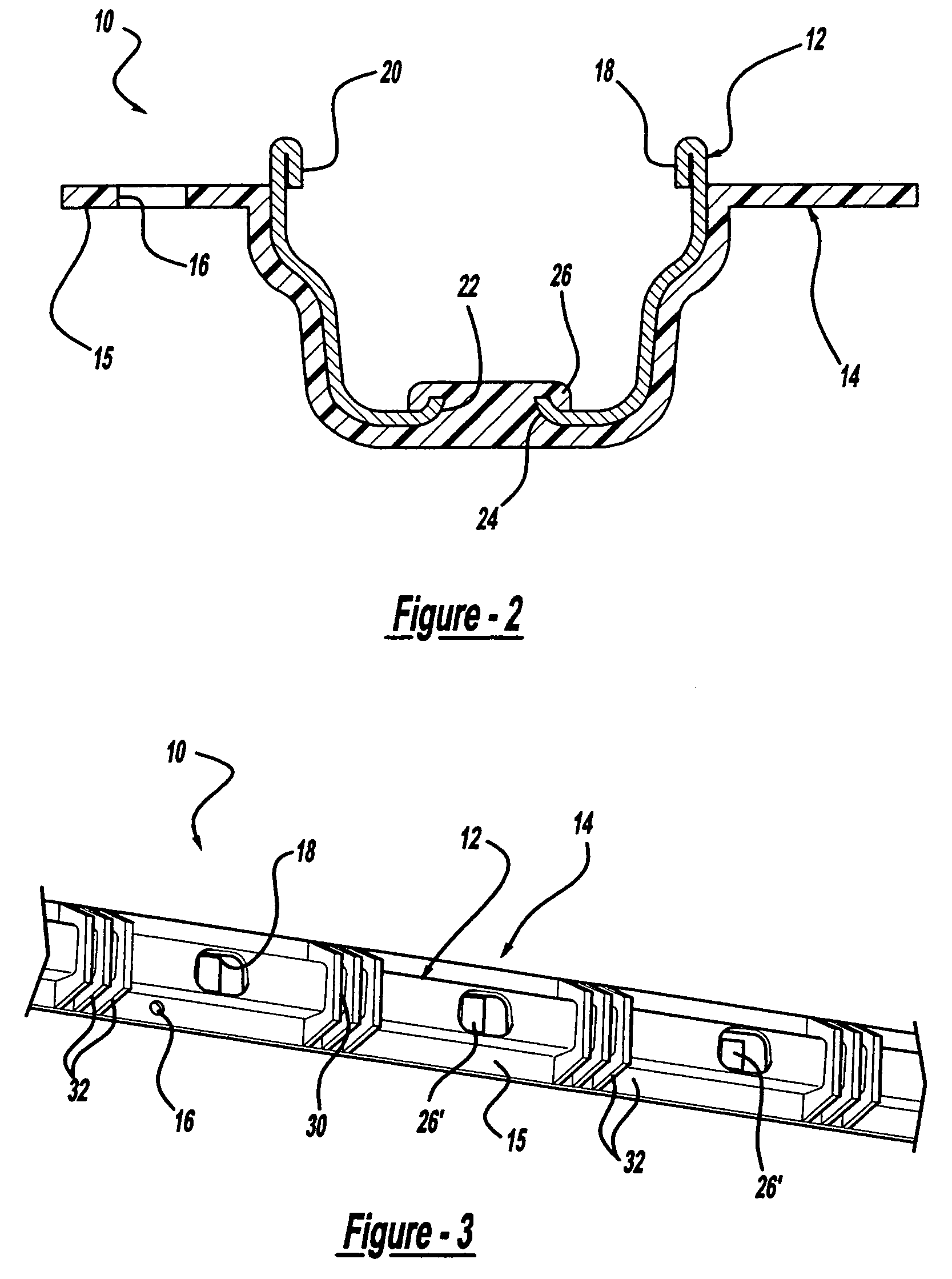

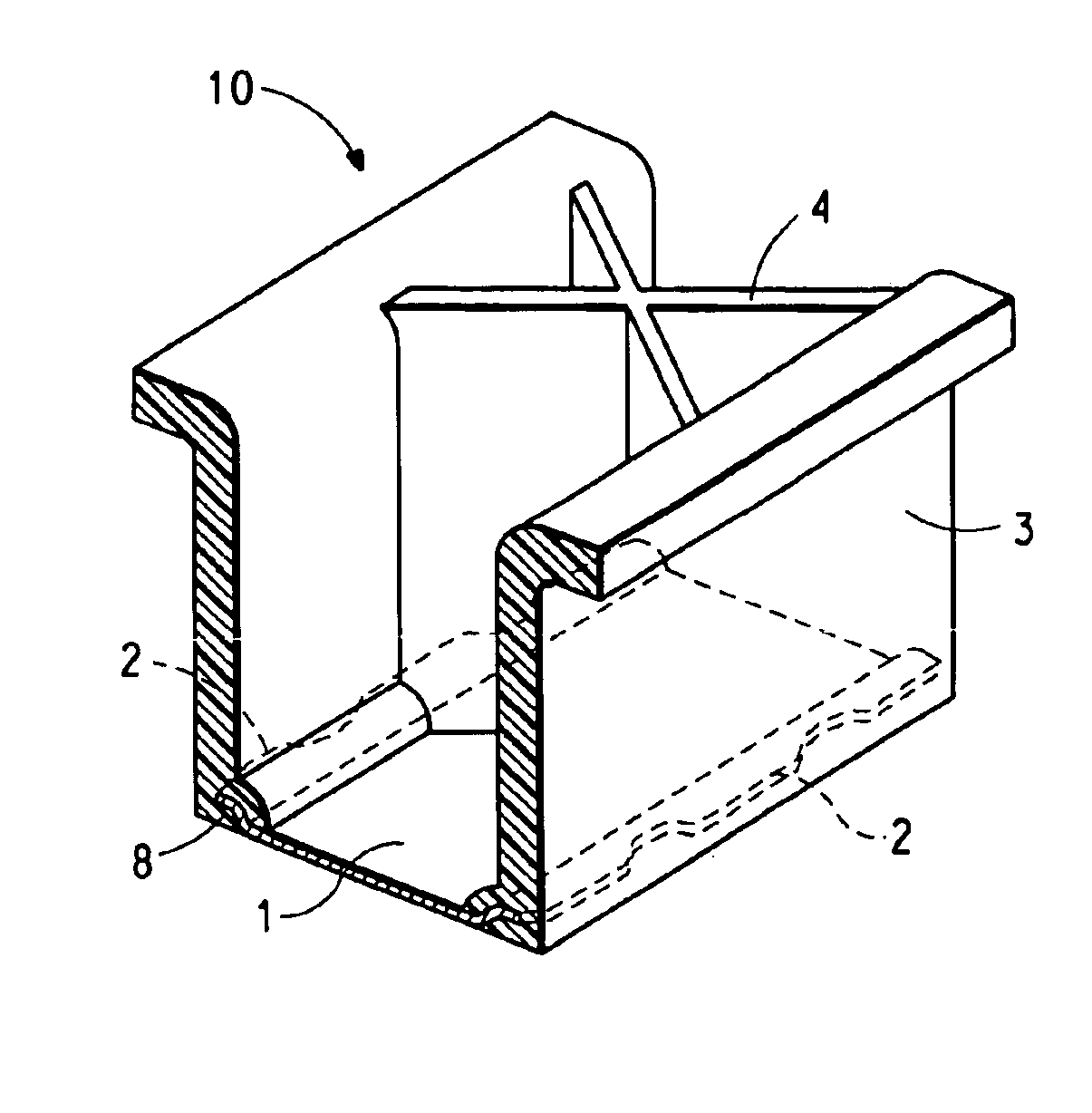

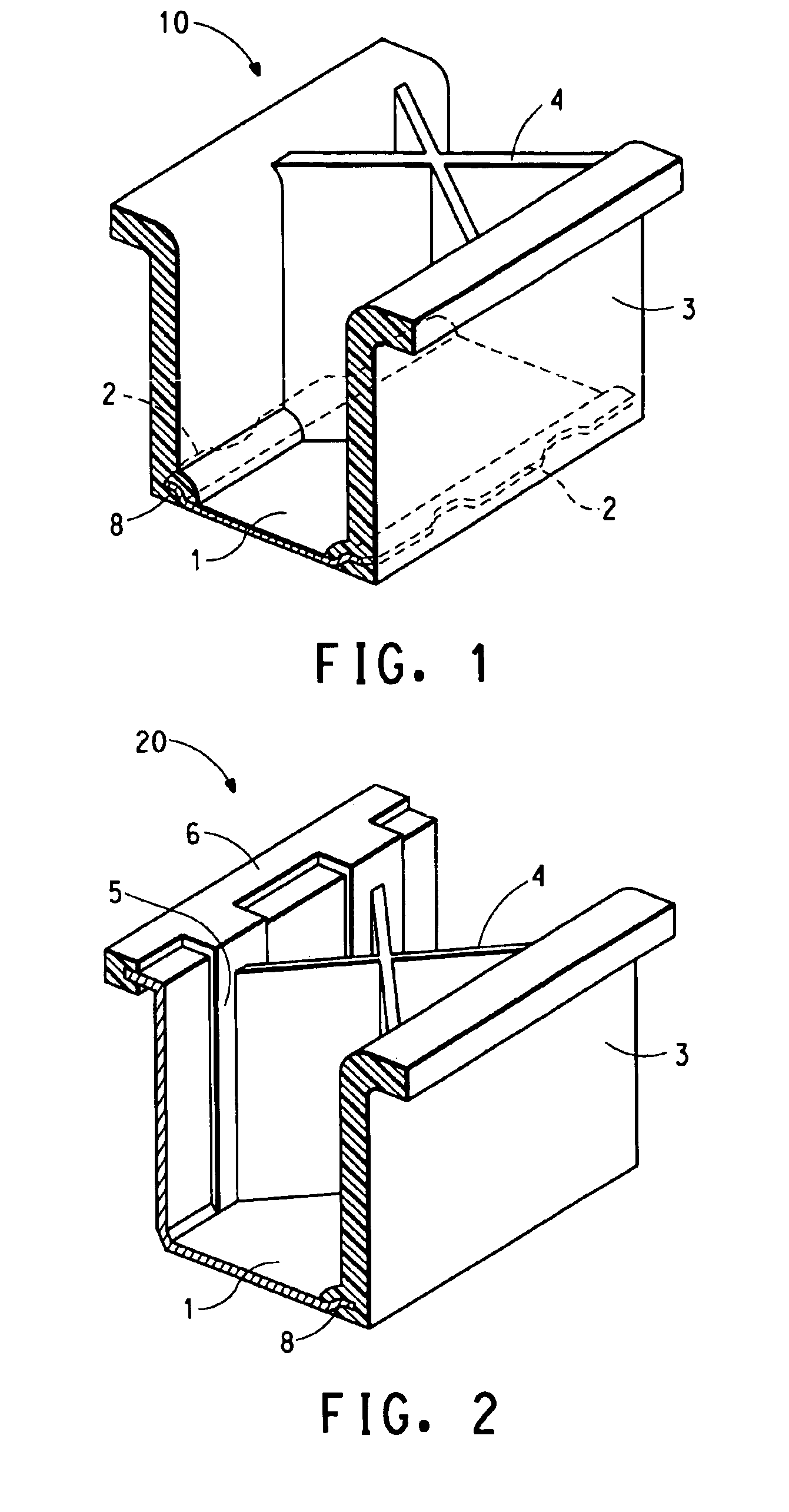

Plastic Stay-In-Place Concrete Forming System

InactiveUS20130312350A1Reduce hydrostatic pressureReduce pressureStrutsWallsEngineeringElectrical and Electronics engineering

A plastic stay-in-place concrete forming system used for one or more sides of a multi-sided form and is based upon a form panel comprised of a thin plastic sheet reinforced on its interior side and capable of bonding to the concrete cast inside the form to create a solid composite structure. In one configuration the form panels are connected to internal bracing that connects to a second form side. The internal bracing is comprised of plastic connecting frames, lateral supports or individual connectors that may further reinforce the form panels or may be used solely for connecting purposes. The second side form may be any type of form including the form panel or a stud supporting foam board. The form panel may also be shaped to form two or more sides of an internally braced, multi-sided form. It may also be externally braced on one or more sides of a form.

Owner:KREIZINGER KENNETH ROBERT

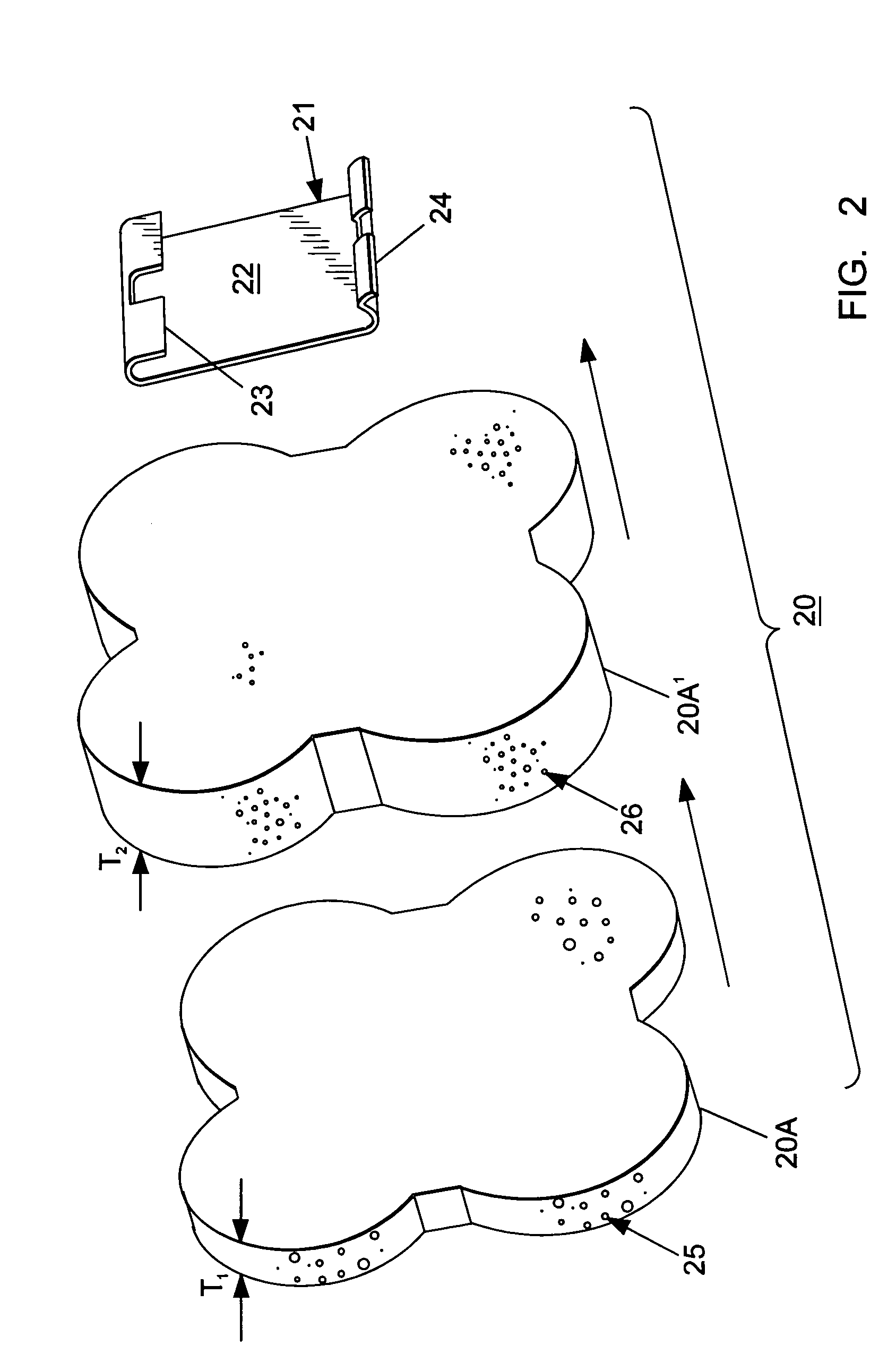

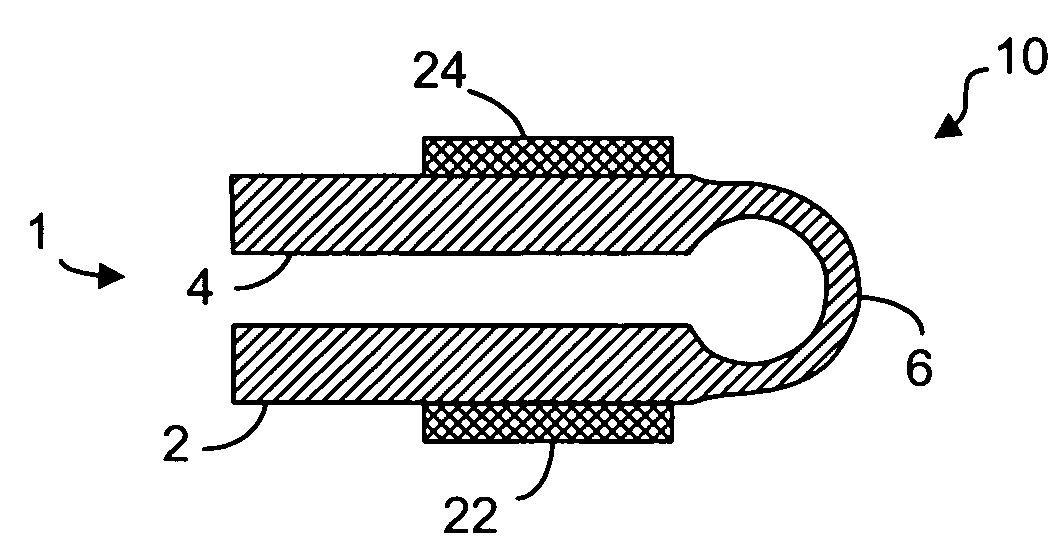

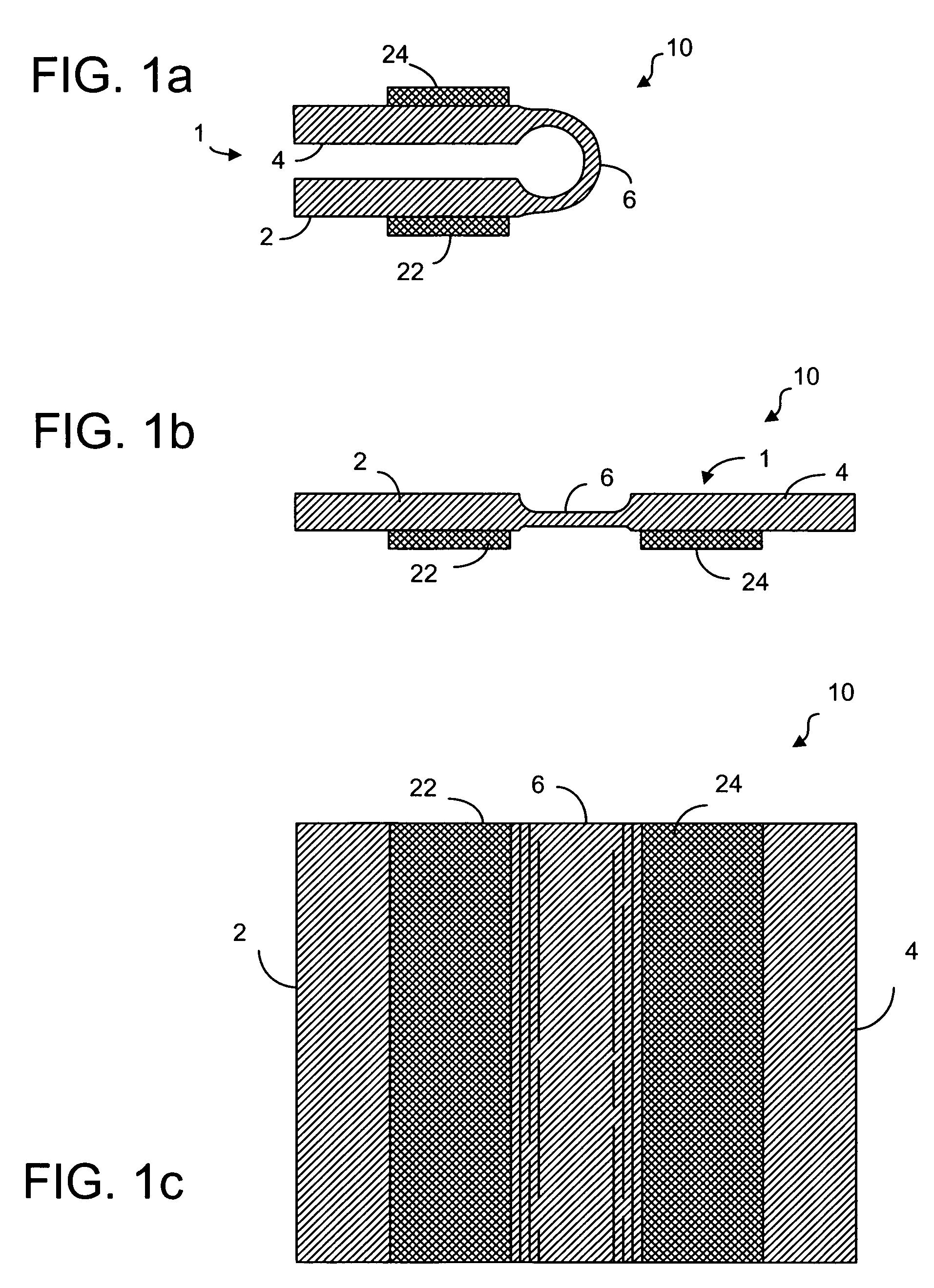

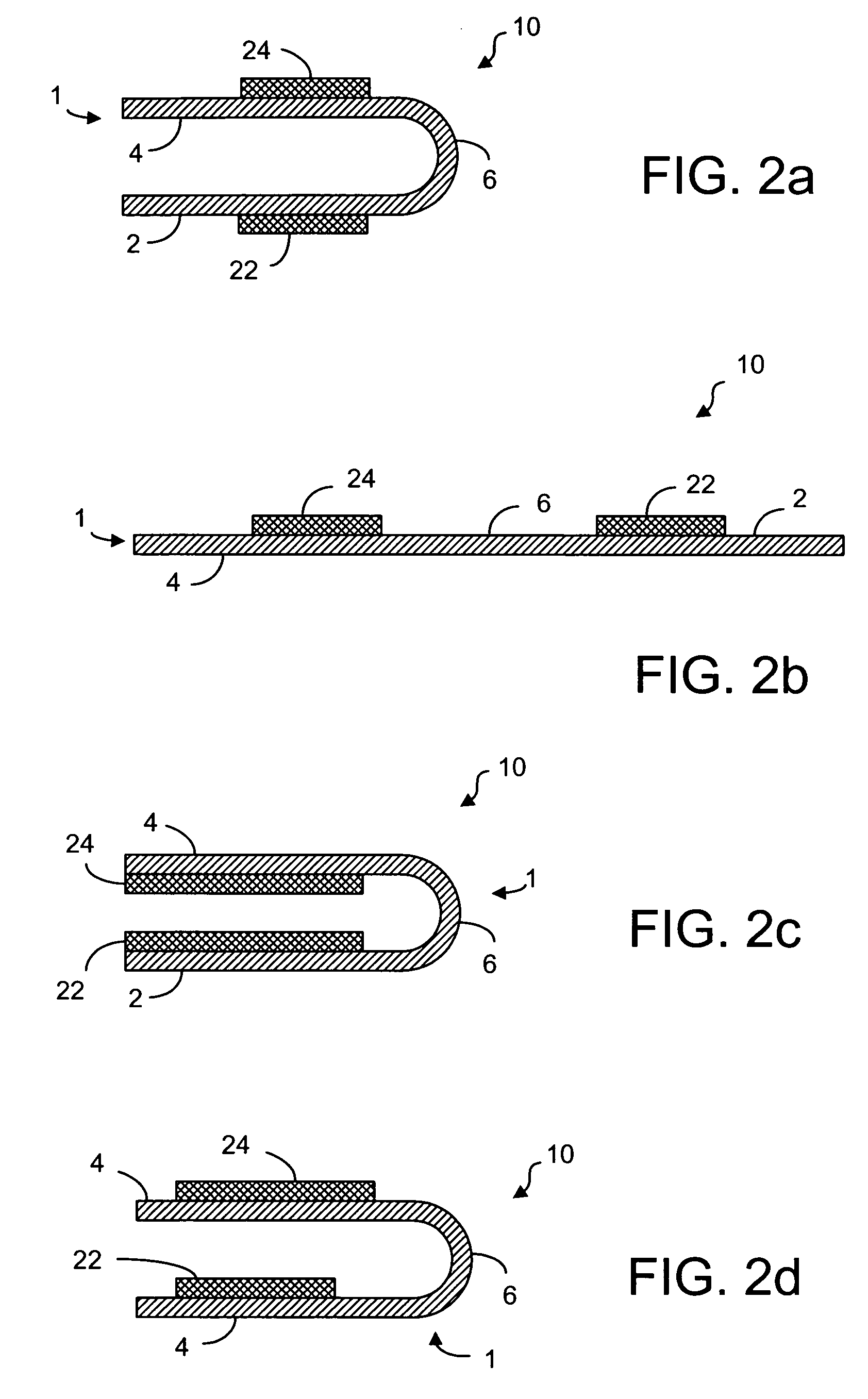

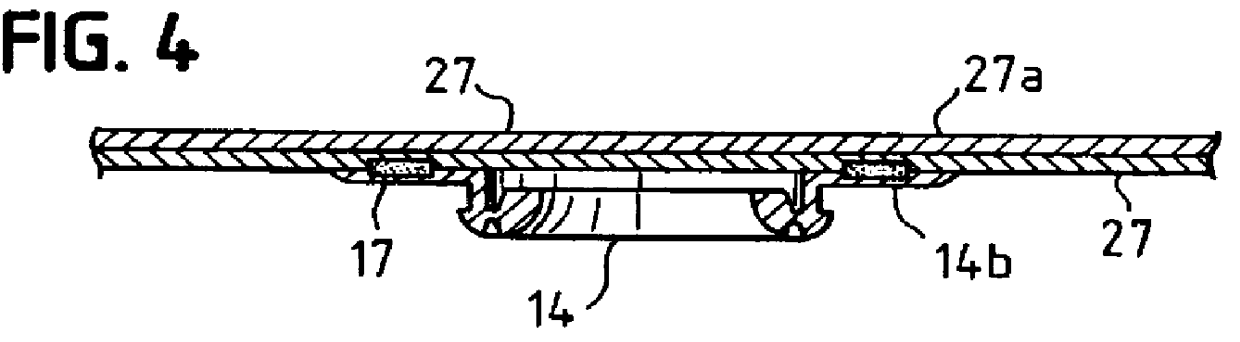

In-line method of manufacture of ostomy appliance faceplate

A low-profile faceplate assembly for a two-piece ostomy appliance, and a method for manufacturing it, are disclosed. The faceplate includes a wafer of an adhesive skin barrier material and a flexible plastic coupling ring (for detachably coupling the faceplate to an ostomy pouch having a mating ring), and is distinguished by the mounting flange of the coupling ring being embedded within the faceplate. The faceplate is made by a convergence of in-line processes taking place simultaneously with an injection / compression molding operation for the skin barrier wafer as disclosed in U.S. Pat. No. 5,716,475, thereby eliminating or greatly reducing the assembly labor for the various process steps plus the handling, storing and transferring steps commonly associated with the manufacture of ostomy faceplate assemblies.

Owner:HOLLISTER INCORPORAED

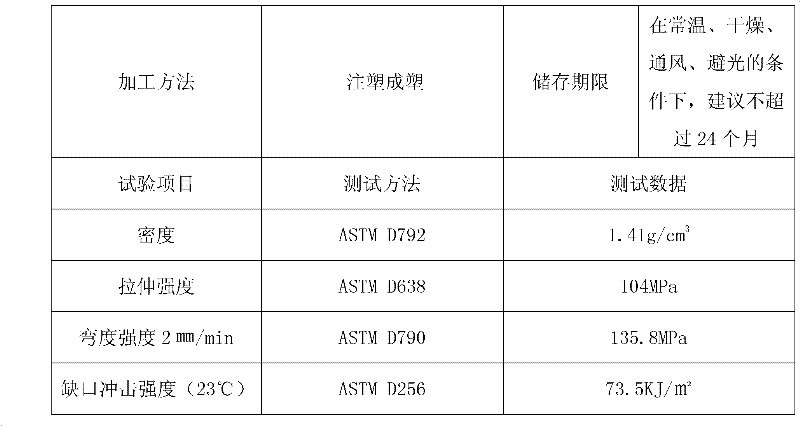

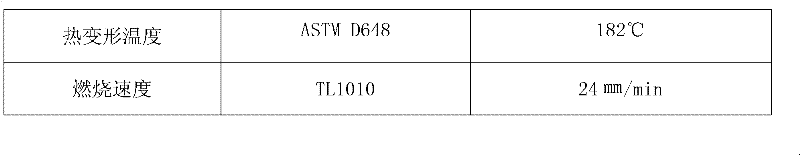

Multi-component plastic connector and manufacturing method thereof

InactiveCN102408706AImprove product qualityIncrease productivityCoatingsInjection pressureHigh probability

The invention discloses a multi-component plastic connector and a manufacturing method thereof. Mainly, dried and proportioned raw materials are added into an injection molding machine which has been heated; and injection pressure, speed, time and volume of different sections of the injection molding machine are set, meanwhile, final holding pressure and holding speed are set to achieve the best injection molding process so as to obtain a final qualified product. In the invention, the physical performance defects of high probability of pulling, breakage, poor toughness, low strength and the like during molding of a multi-component plastic connector of injection molding are solved; meanwhile, the injection molding process is stable, the resultant product has stable quality, the production efficiency is increased, and the production cost is reduced.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

Stamped and molded igniter body for airbag inflators

InactiveUS20090114109A1Reduce and eliminate gas leakEliminate needBlasting cartridgesPedestrian/occupant safety arrangementAirbagElectrical and Electronics engineering

An igniter body for an airbag inflator comprising a stamped metal body portion having a generally annular flange and a central opening. A generally cylindrical plastic connector portion is disposed within the annular flange and is connected to the body portion. The connector portion may be integrally molded within the body portion. The central opening in the body portion is constructed to receive an initiator therein, and the connector portion is constructed to receive a power module therein for connection to an initiator disposed in the central opening and surrounded by a sleeve that is secured to the body portion to retain the initiator thereon.

Owner:ARC AUTOMOTIVE

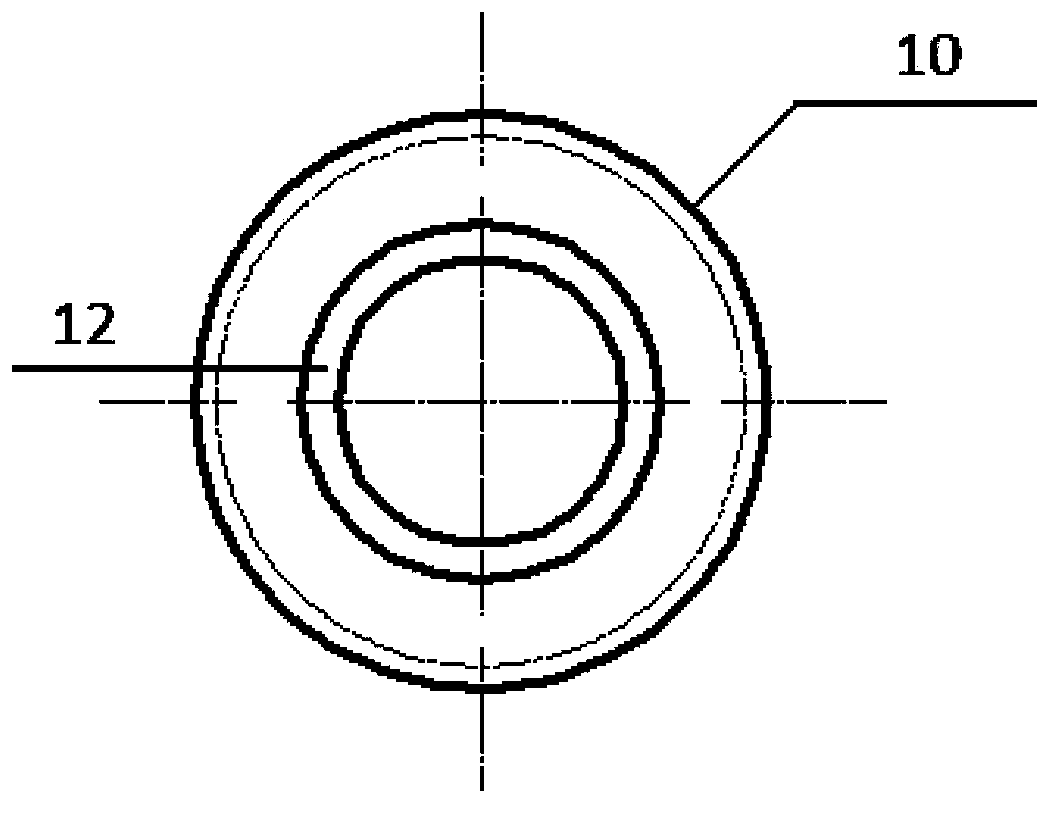

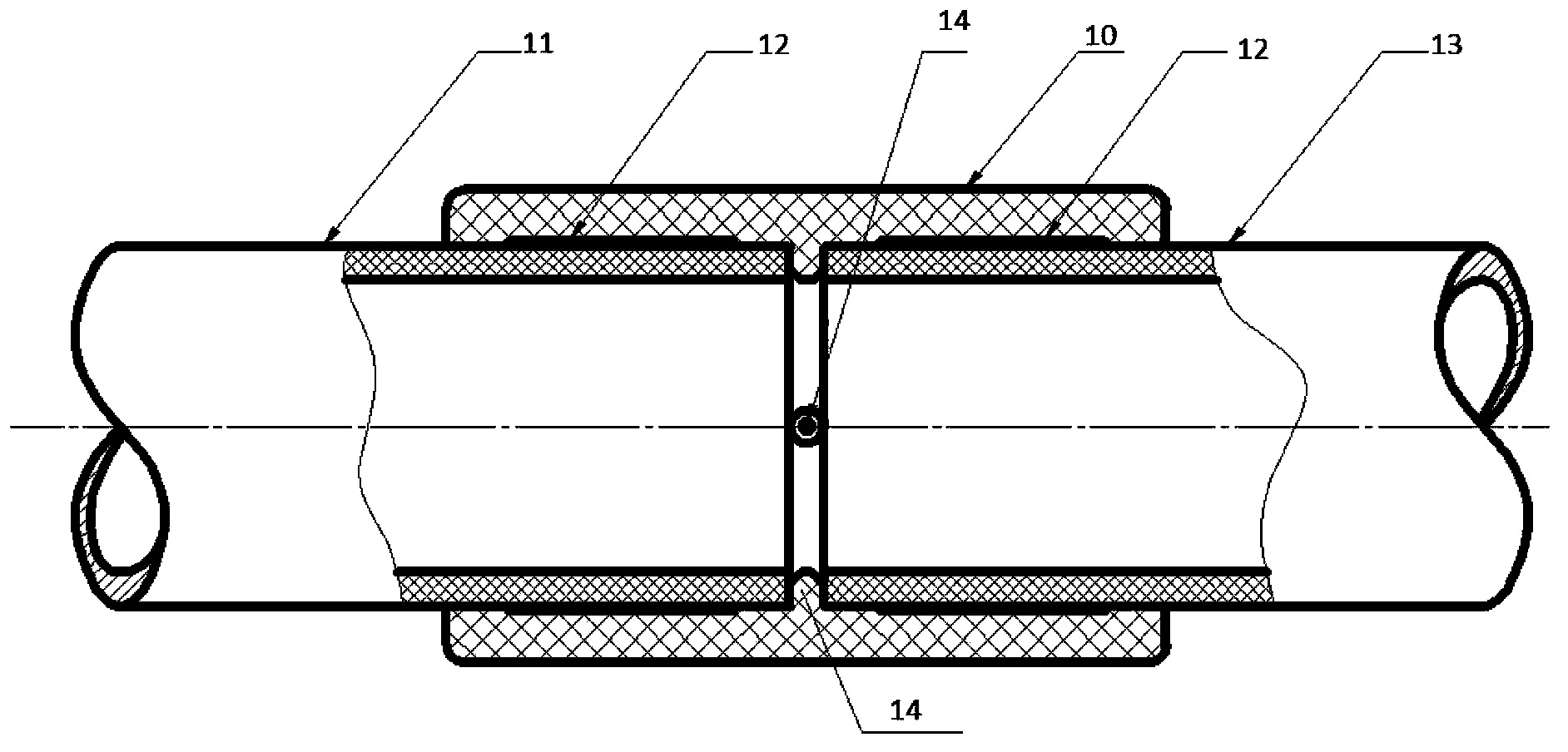

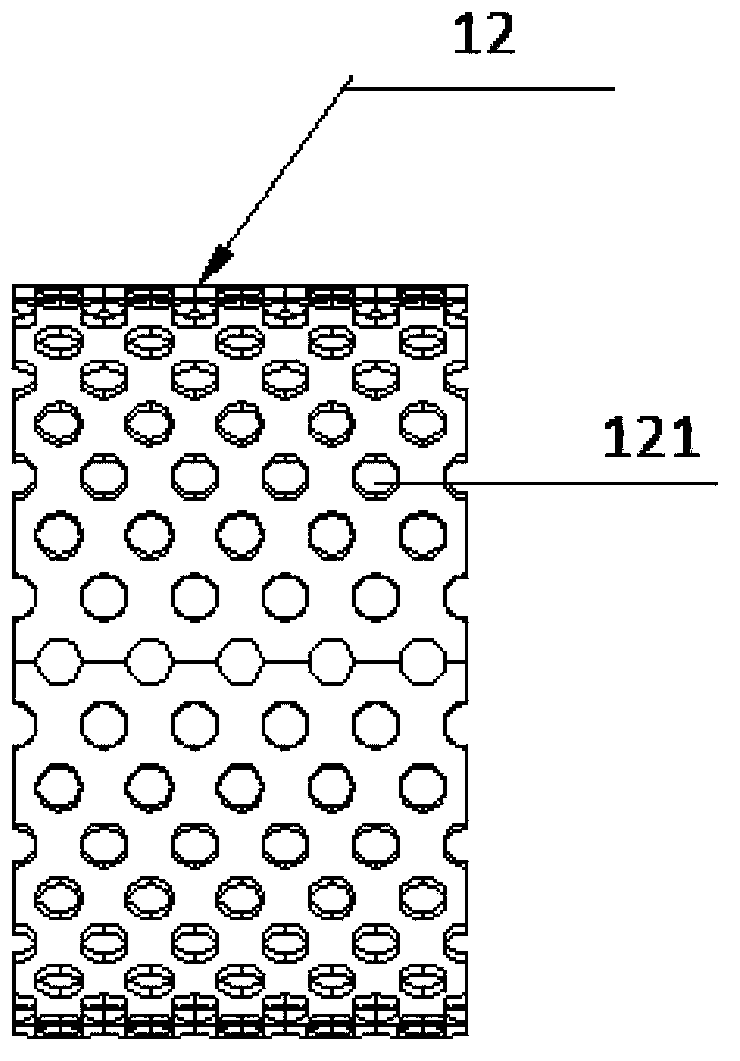

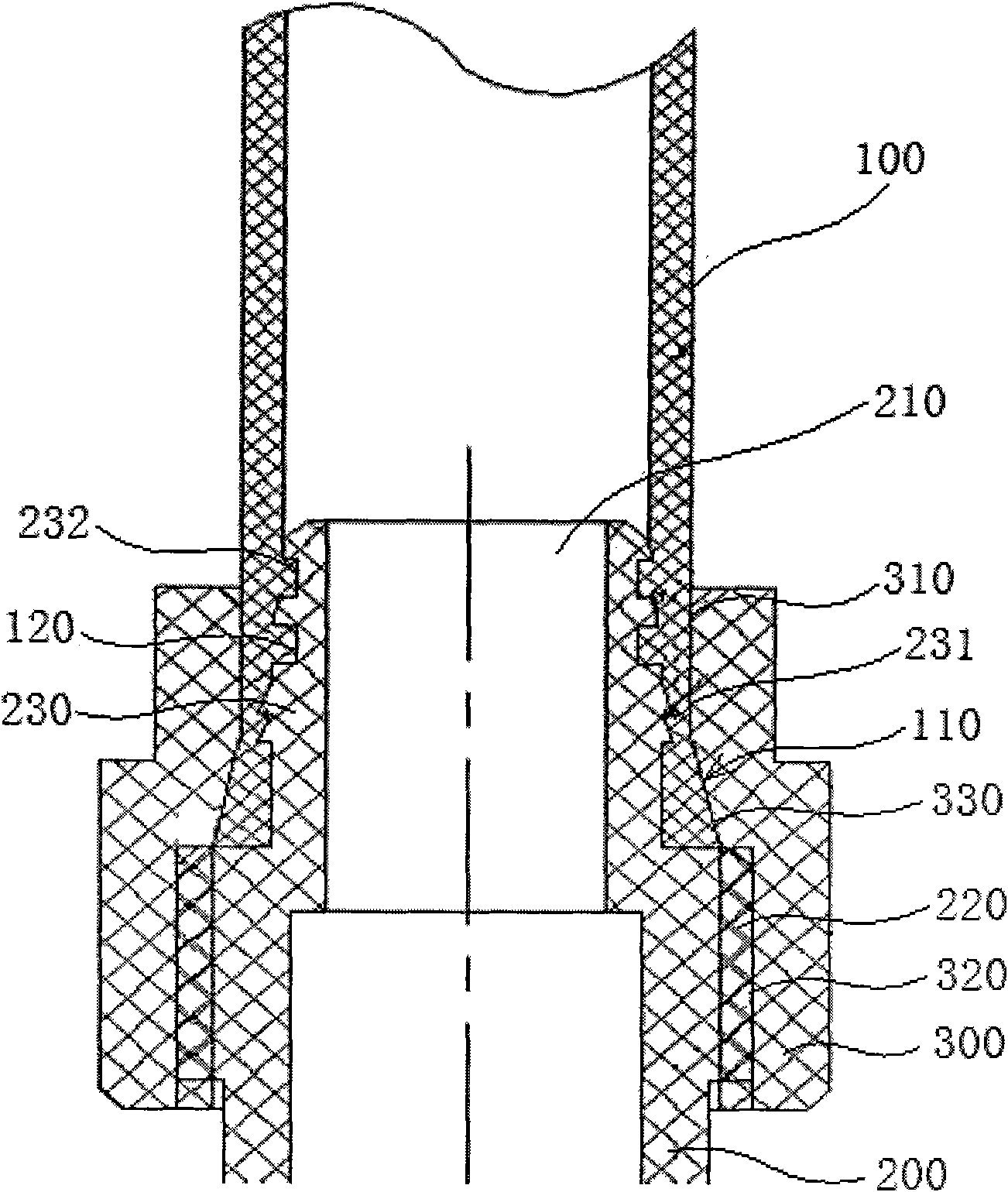

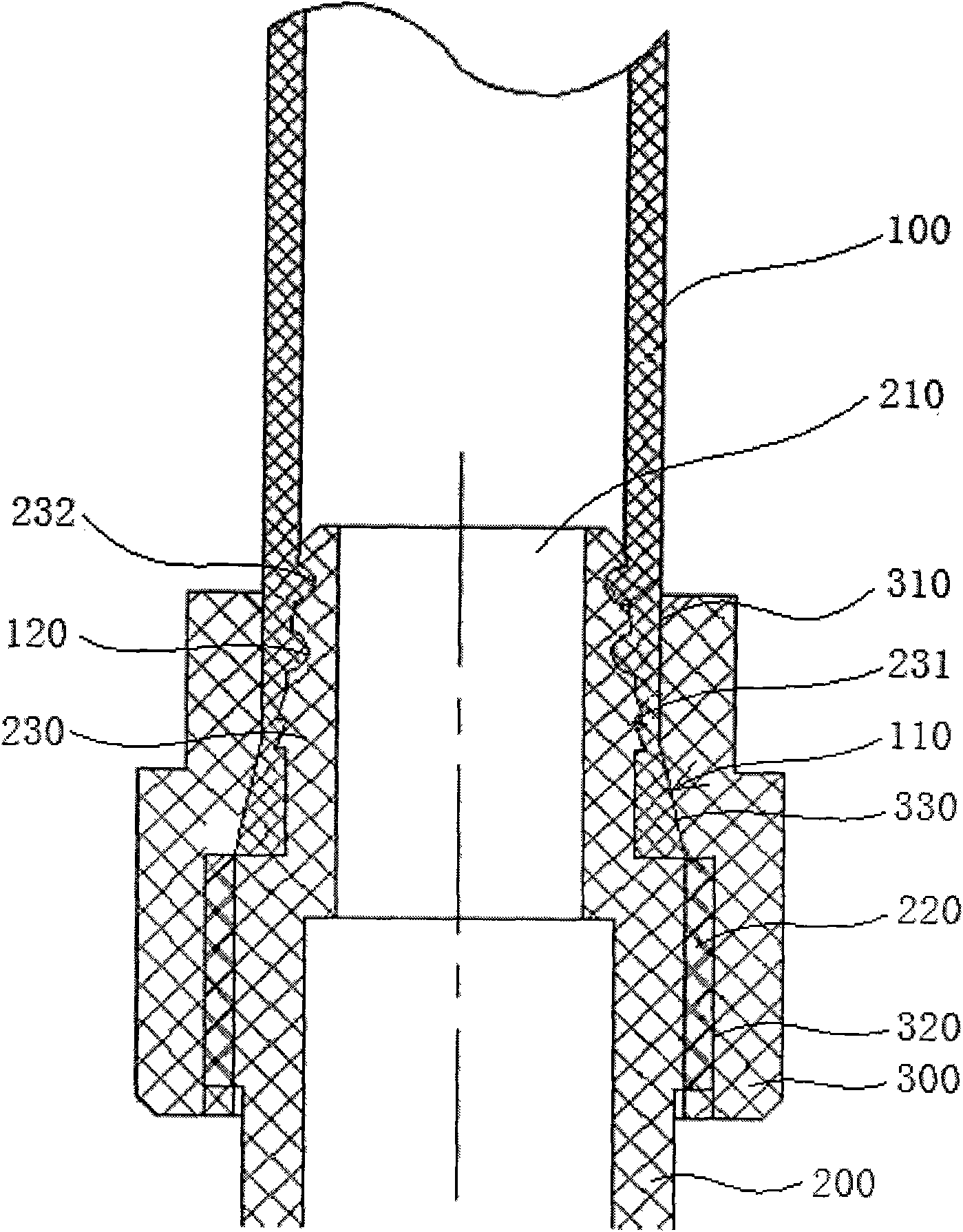

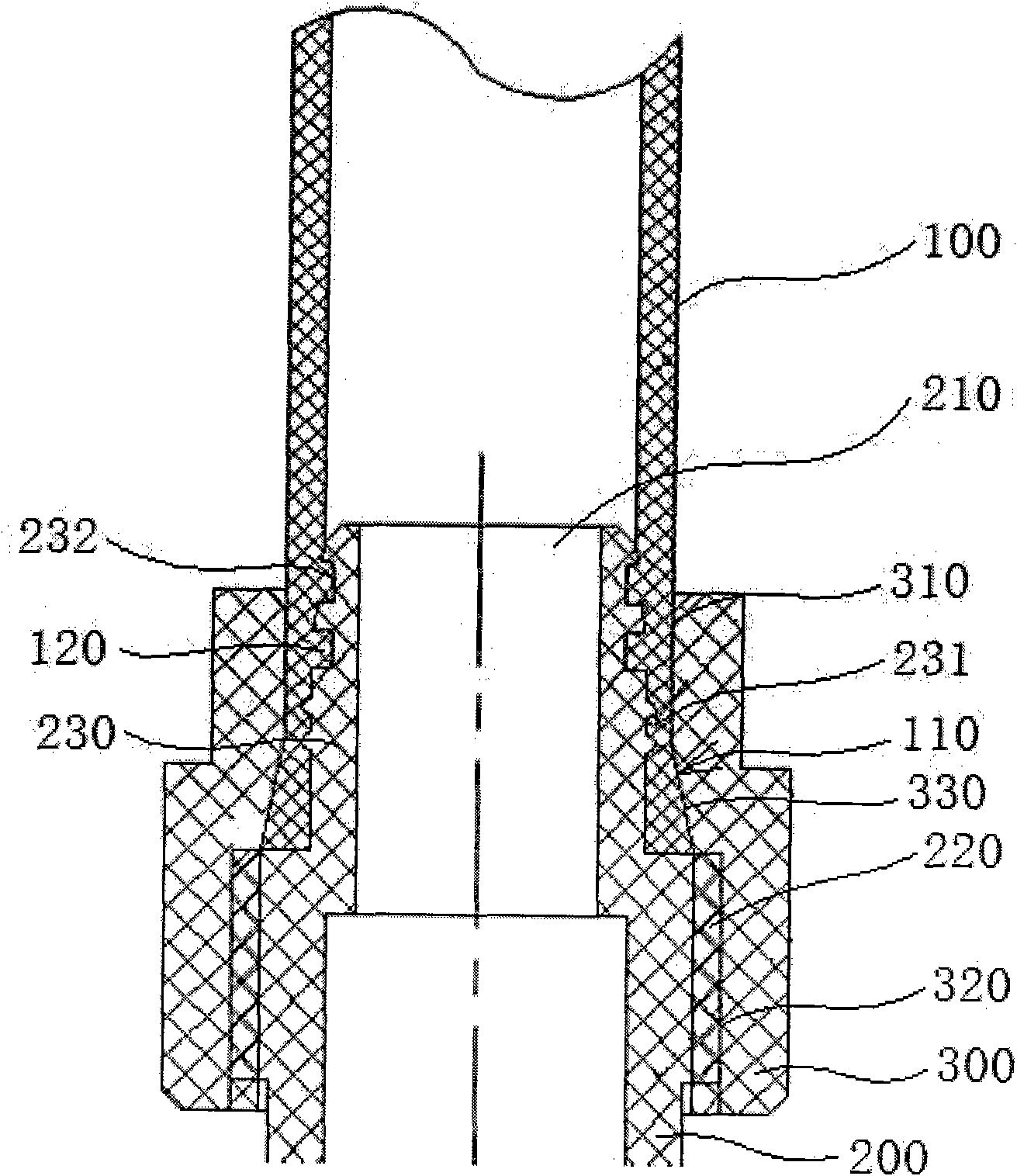

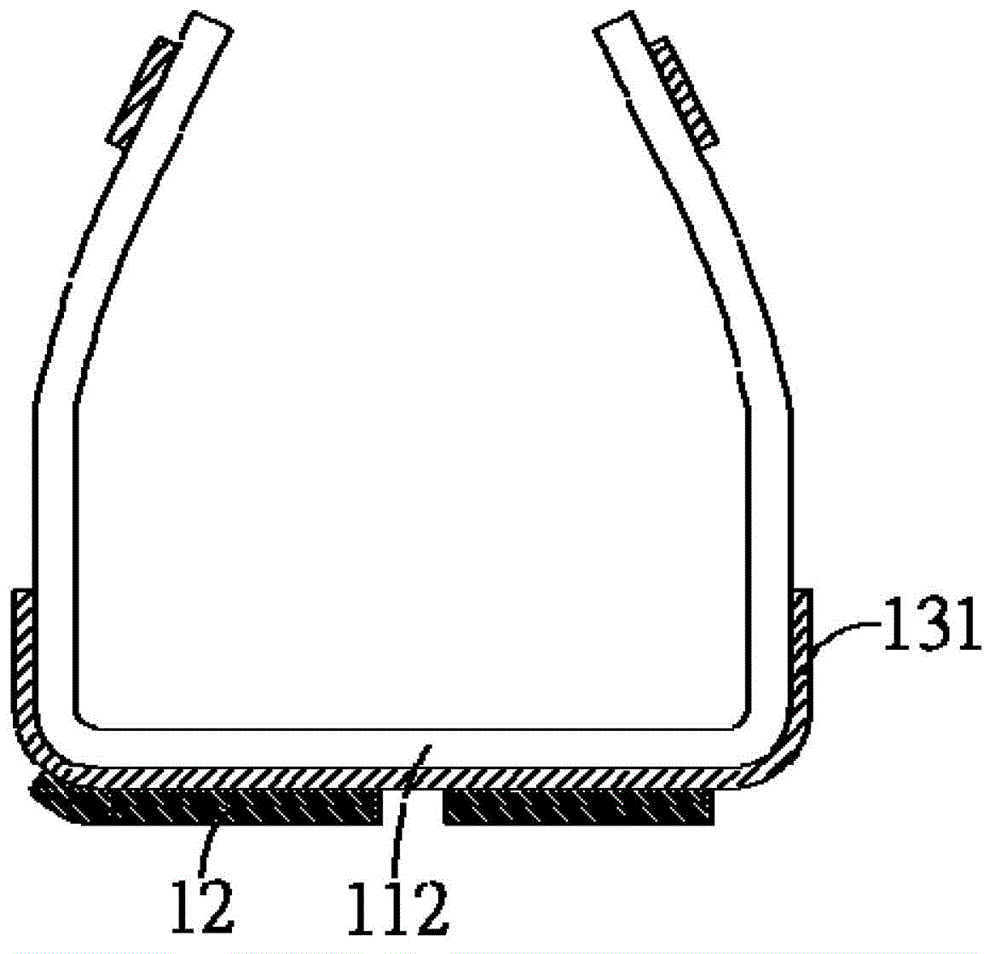

Electromagnetic heating welding method for thermoplastic pipes

InactiveCN103383044AImprove connection efficiencyReduce labor costsPipe connection arrangementsThermoplasticEngineering

The invention relates to a heating welding method for thermoplastic pipes. The method comprises the steps of Step 1, forming a metal mesh layer (12) on the inner wall of a plastic connecting piece (10); Step 2, performing inserting connection on the two thermoplastic pipes and the plastic connecting piece, and performing centering and positioning through positioning pins (14) in the plastic connecting piece; Step 3, sleeving an electromagnetic induction heating coil on the plastic connecting piece (10), and performing energization for heating; Step 4, performing heating till the two thermoplastic pipes and the plastic connecting piece are welded fully, and then performing deenergization; Step 5, performing cooling shaping. According to the method, the thermoplastic pipes or steel-plastic composites pipes are connected through the plastic connecting piece in advance and then fixed through electromagnetic heating hot melting, so that the traditional mode of heating before inserting connection is changed, the connection efficiency is improved, and meanwhile, the labor cost is reduced.

Owner:TIANJIN JUNXING PIPE GRP CO LTD

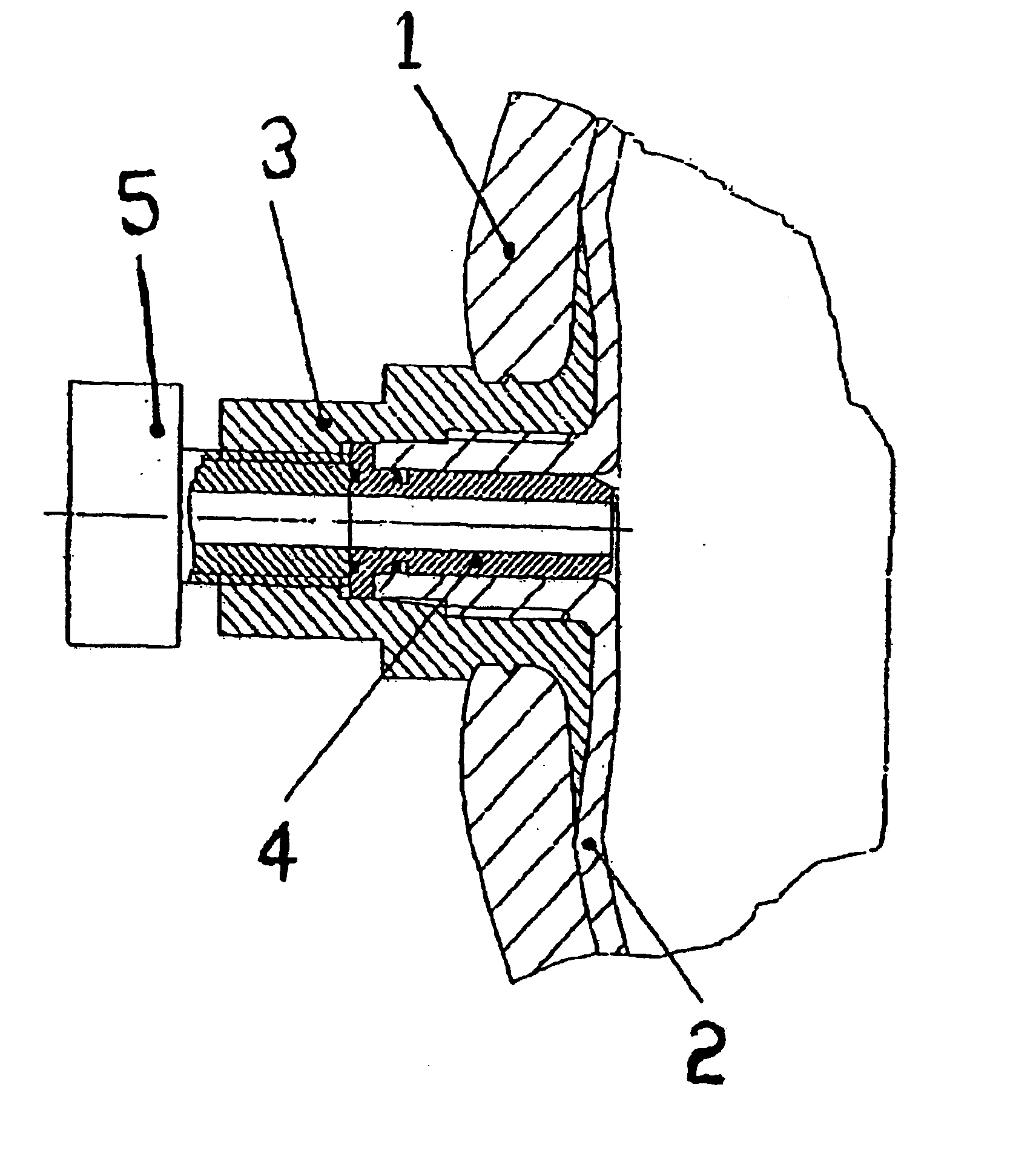

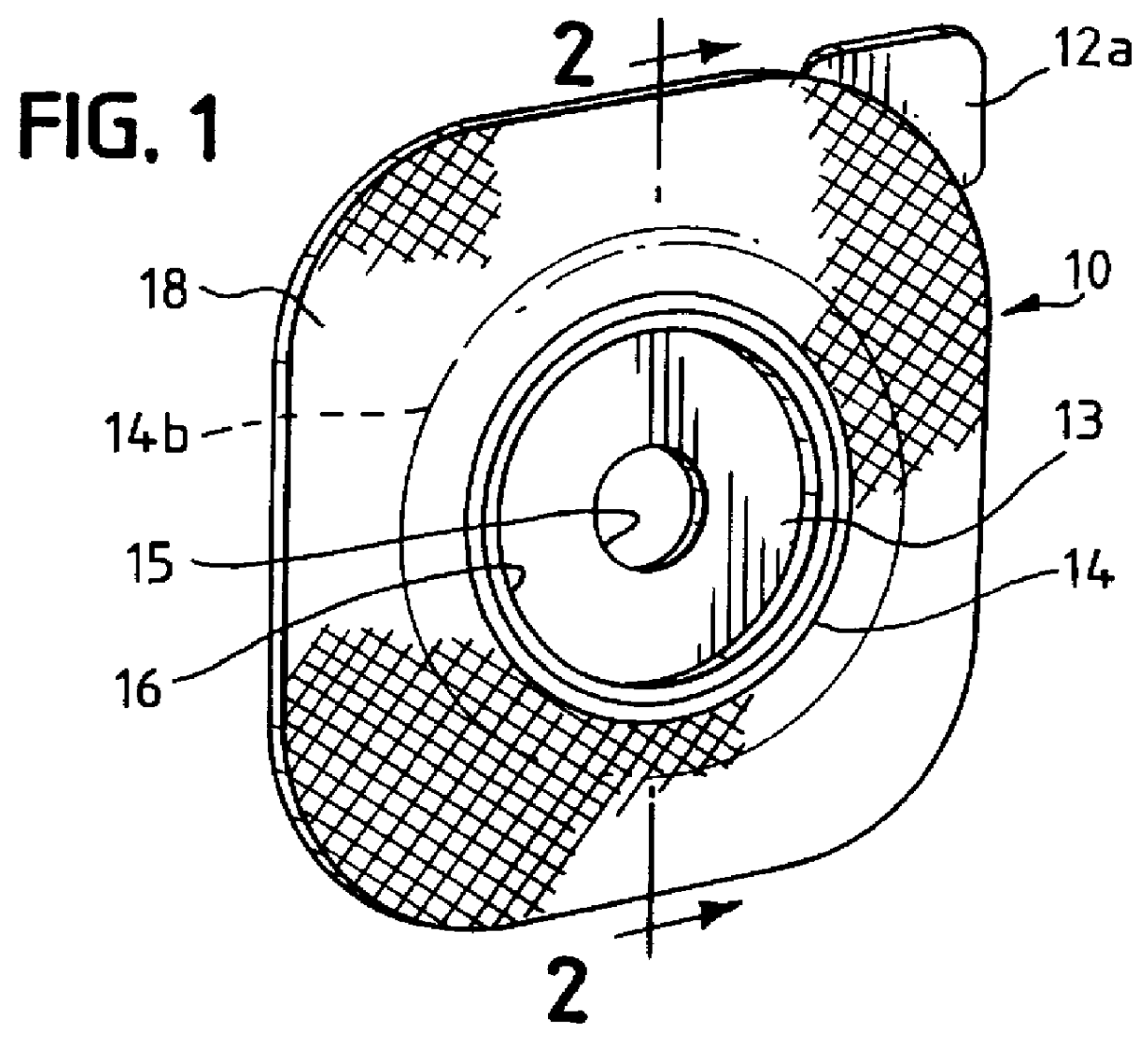

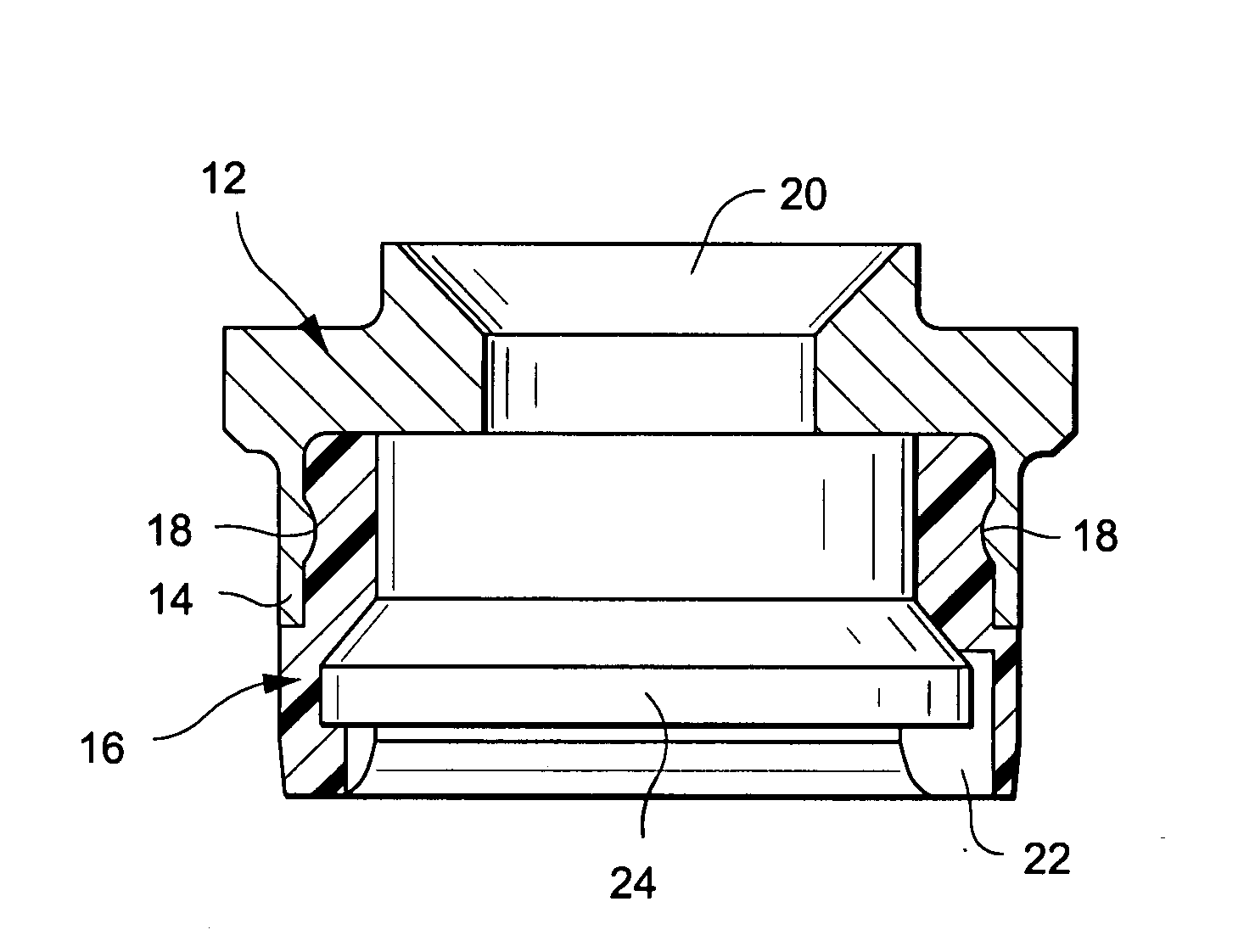

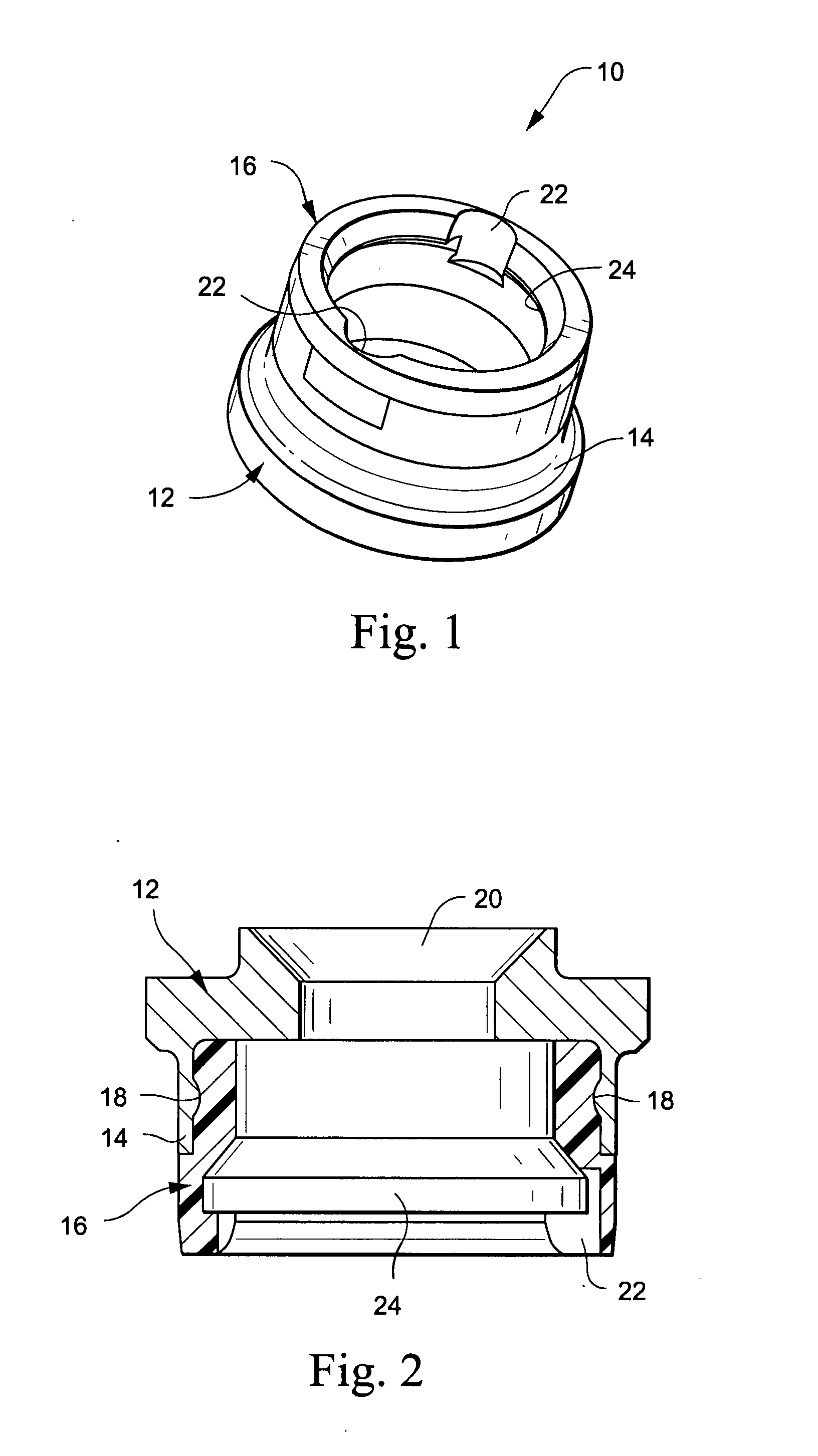

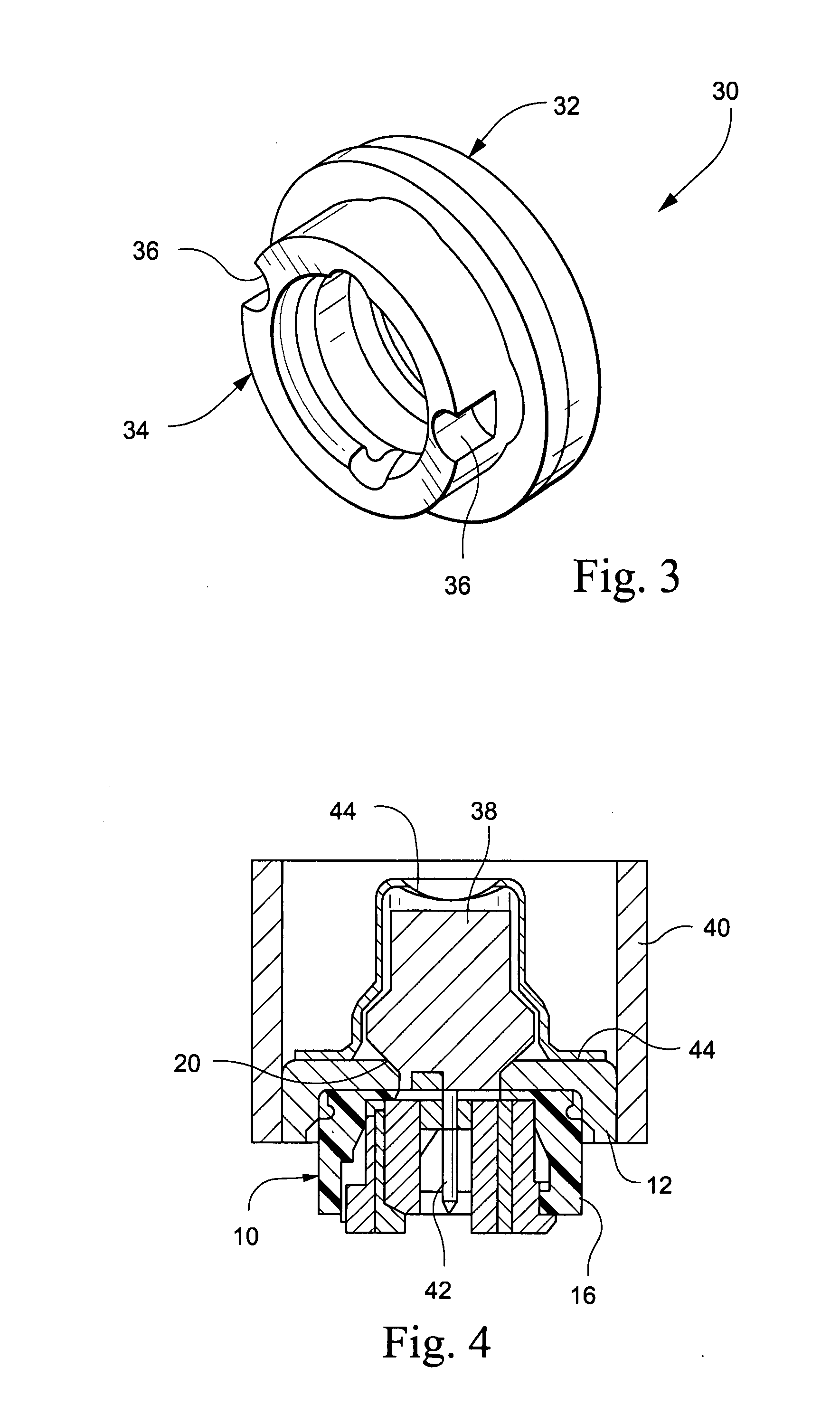

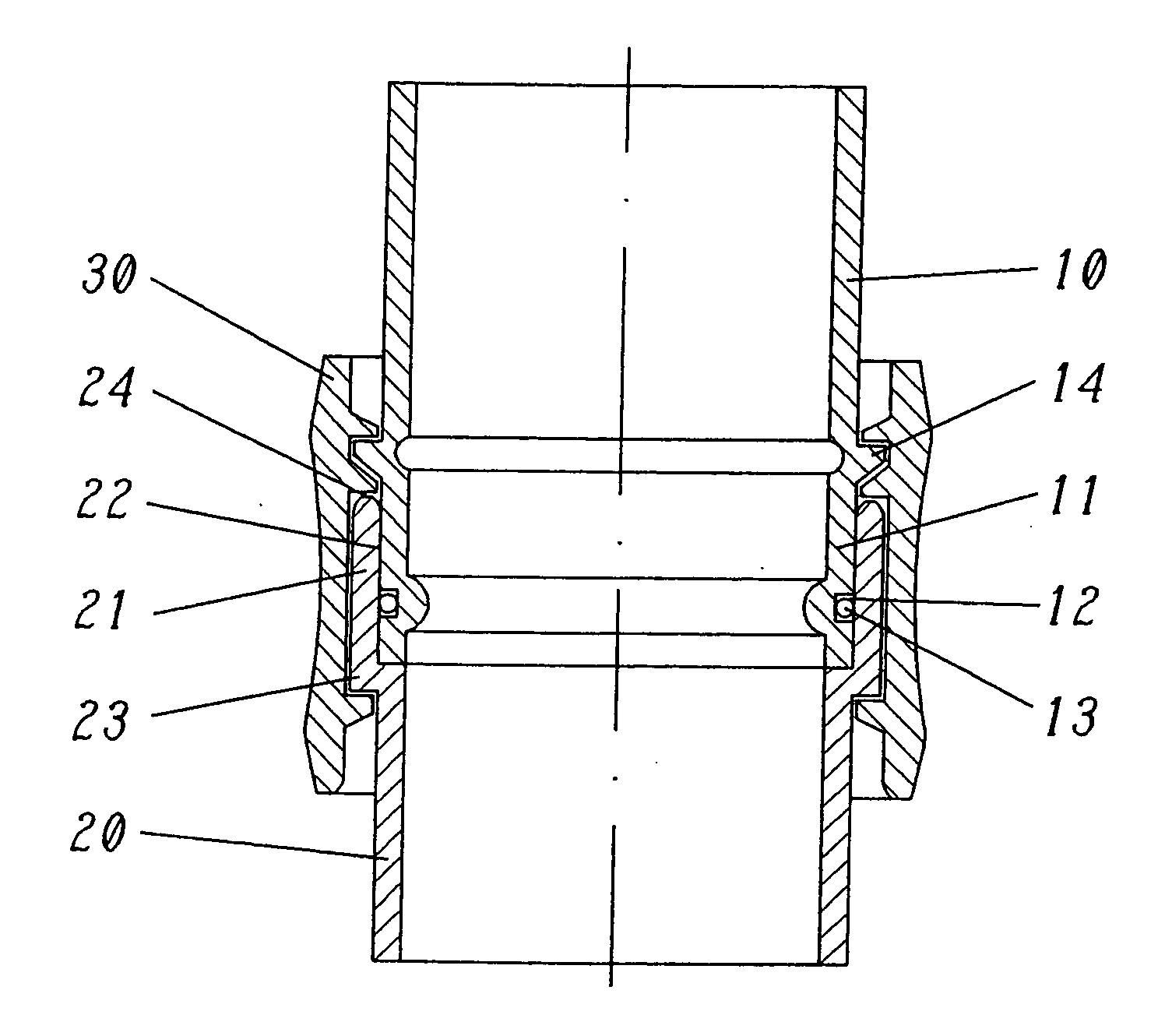

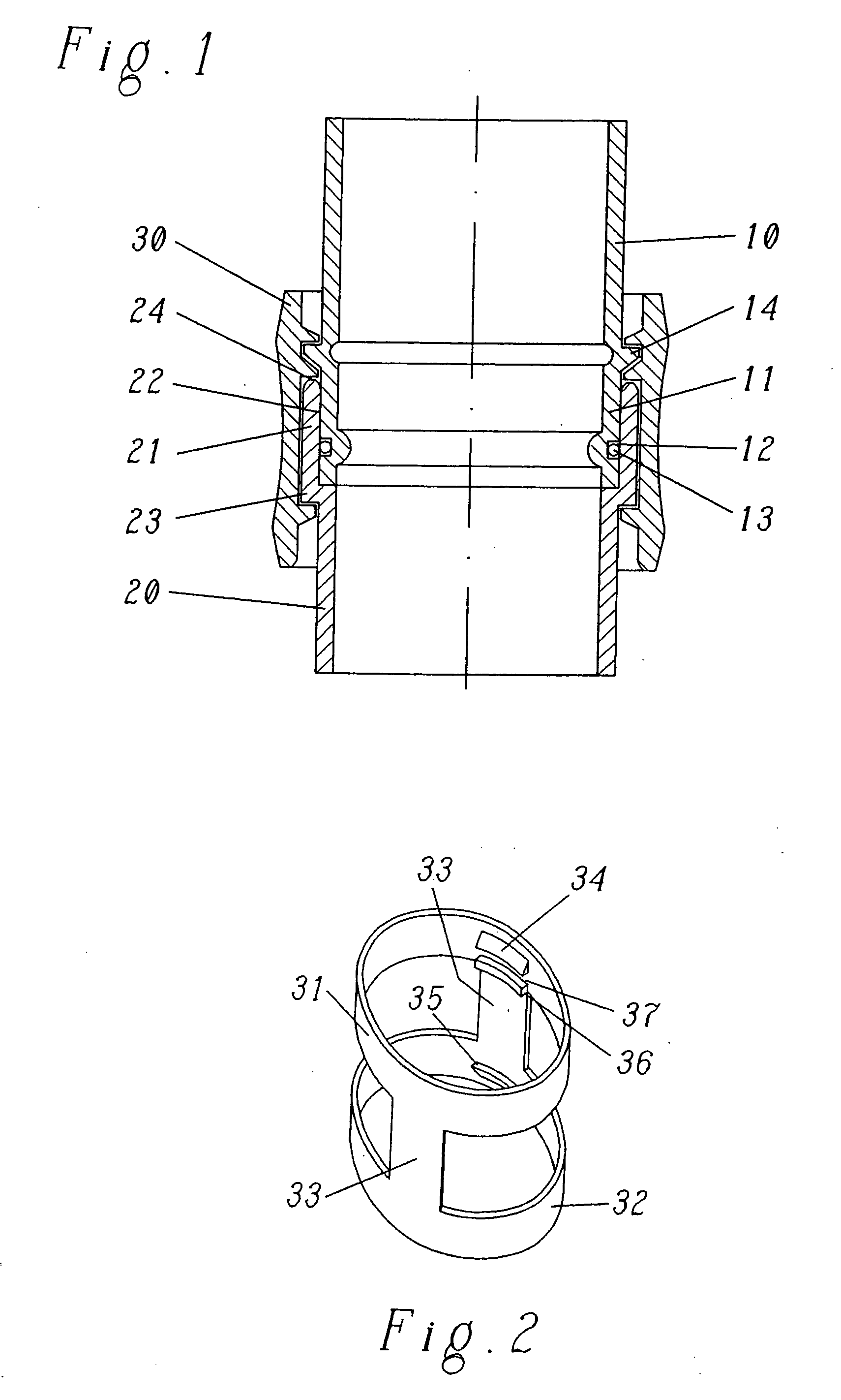

Snap connection for connecting two tube ends

InactiveUS20040070205A1Sleeve/socket jointsFluid pressure sealed jointsPlastic injection moldingStructural engineering

The snap connection for sealed and releasable connection of a first tube end (10) with a second tube end (20), with spring arms (33), with a first outer stop projection (14) on the first tube end (10), with a first elastically deformable ring (31) connected with the spring arms (33), and with two first inner stop cams (34) on the first ring (31) cooperating with the first outer stop projection (14), is characterized according to the present invention by a second outer stop projection (23) on the second tube end (20), a second elastically deformable ring (32) connected with the spring arms (33) with distance from the first ring (31), and by two, second inner stop cams (35) on the second ring (32) cooperating with the second outer stop projection (23). Both rings with their stop cams, connected to one another via the spring arms, form a double-connection element (30) separable by and on both tube ends (10, 20), which can be made from a plastic injection molding part. The first tube end (10), for example, can be made by extrusion blow-molding and directly assembled with the second tube end (20), which can be a metal or plastic connecting piece, whereby the connection is fixed in a sealed position after the snapping of the double-connection element (30).

Owner:EMS CHEM AG

Flexible conduit, particularly for sanitary purposes

InactiveUS6971414B2Reduction in flow areaImprove sealingDomestic plumbingPipe elementsCouplingMetal hose

A flexible conduit includes a metal hose provided with a helical groove having a plurality of turns; a plastic jacket surrounding the metal hose and conforming to the helical groove thereof; a plastic inner hose received in the metal hose and having a projecting length portion extending beyond an end of the metal hose. The conduit further includes a plastic coupling part which surrounds the metal hose. The coupling part includes a cylindrical collar surrounding the projecting length portion and having a material-to-material bond therewith; and an overlapping portion adjoining the cylindrical collar and extending away therefrom. The overlapping portion surrounds the jacket and extends into the helical groove. The overlapping portion and the plastic jacket have a material-to-material bond with one another.

Owner:VOHRAN PATENTVERW

Method of attaching plastic to a metal section and part made thereby

Owner:SABIC INNOVATIVE PLASTICS IP BV +3

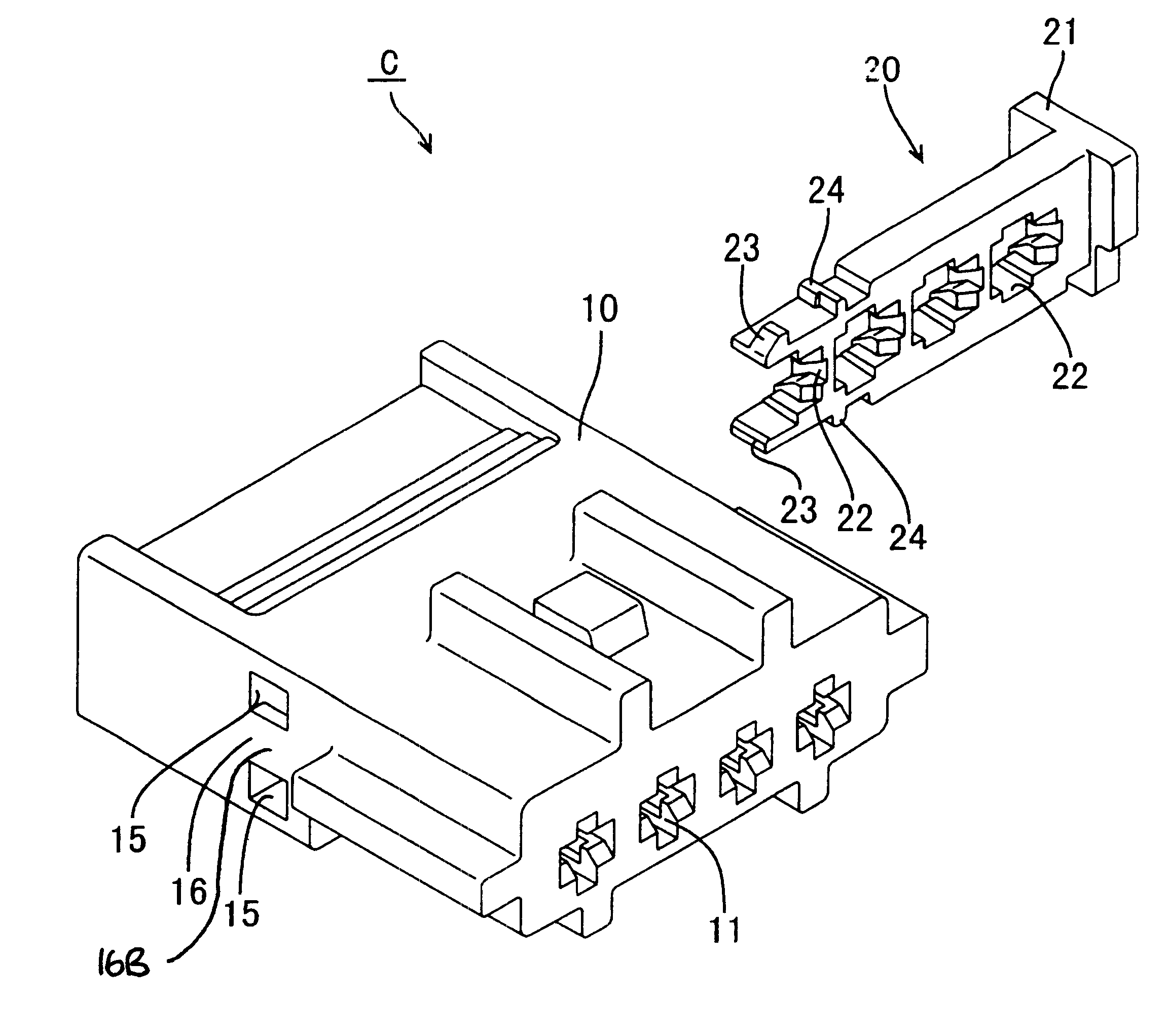

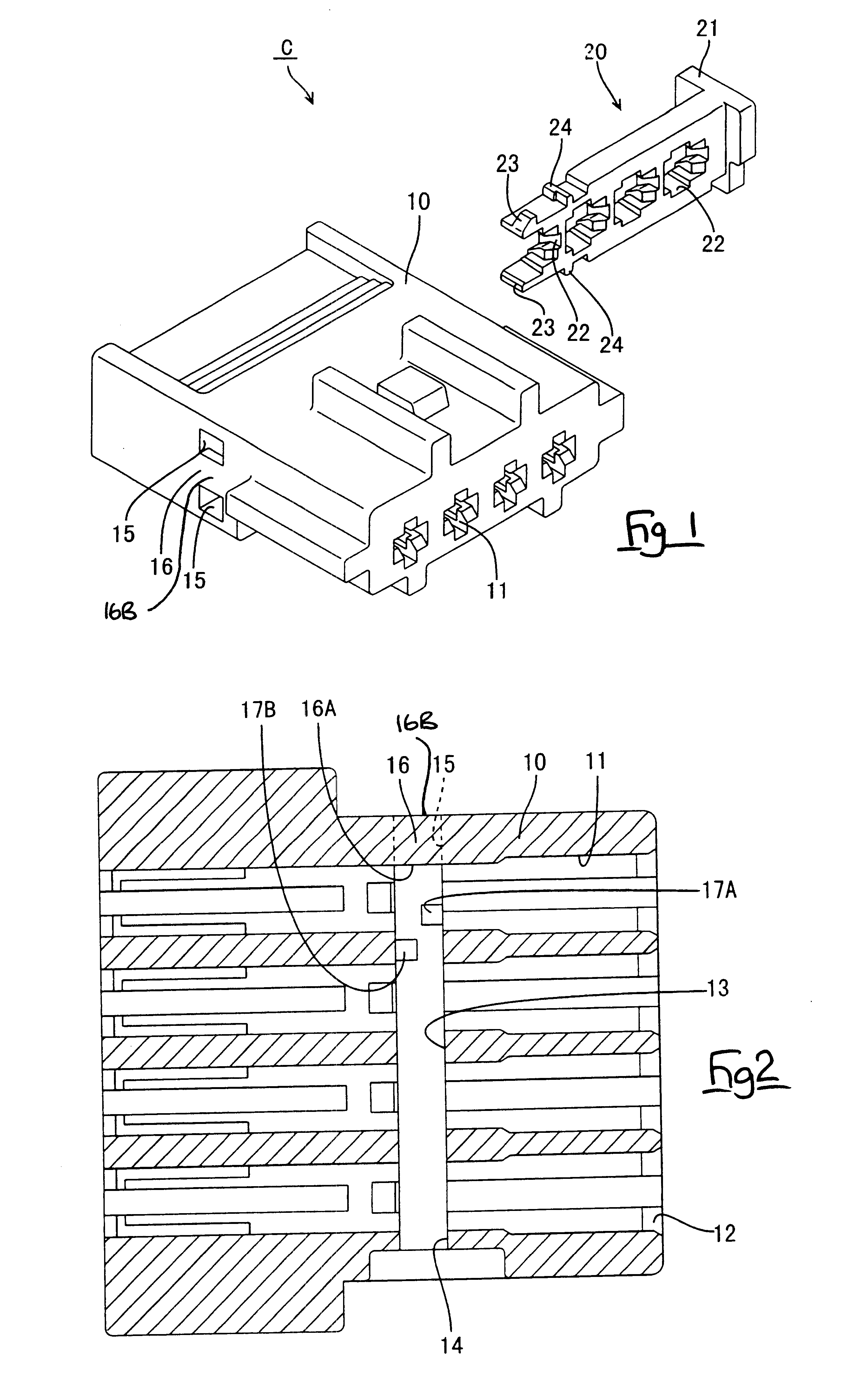

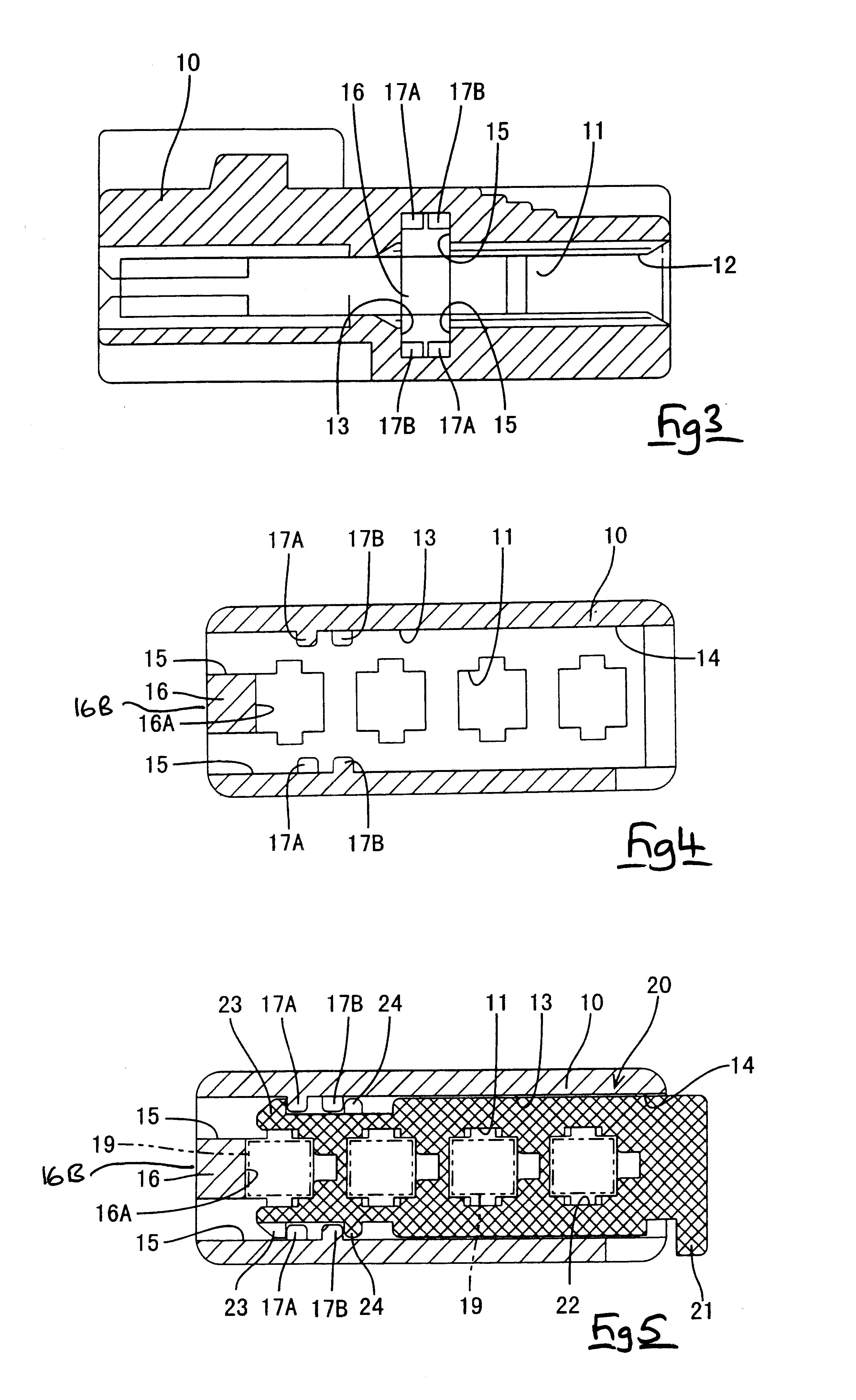

Connector and mould

InactiveUS6435919B1Contact member assembly/disassemblySecuring/insulating coupling contact membersEngineeringMould removal

The invention provides a moulded plastic connector in which the mould is not weakened, and in which terminal fittings are not exposed. Portions of a side of a retainer attachment hole 13, which are opposite an insertion hole 14 for a retainer 20, are open to form mould removing holes 15, the remaining portion being covered by a wall 16. This wall 16 reduces the degree to which terminal fittings 19 are exposed from the interior of a housing 10. When a connector C is to be moulded, anterior ends of a first mould 30 (which is removed from the housing 10 via the insertion hole 14) and a second mould 40 (which is removed via the mould removing holes 15) fit together within the retainer attachment hole 13 in a doubled-over manner in a direction which intersects with the direction of mould removal. Consequently, the strength of the moulds 30 and 40 is not decreased.

Owner:SUMITOMO WIRING SYST LTD

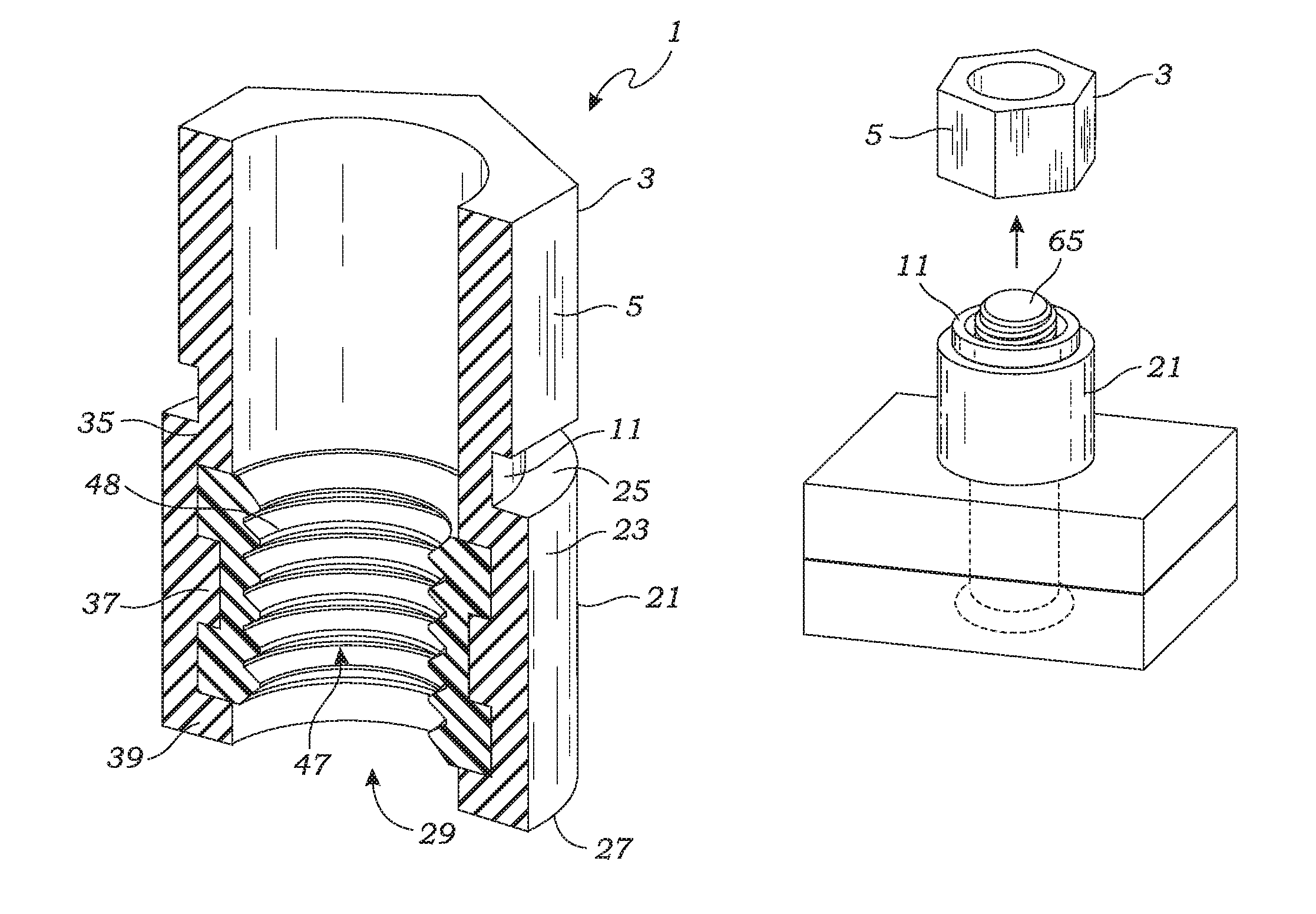

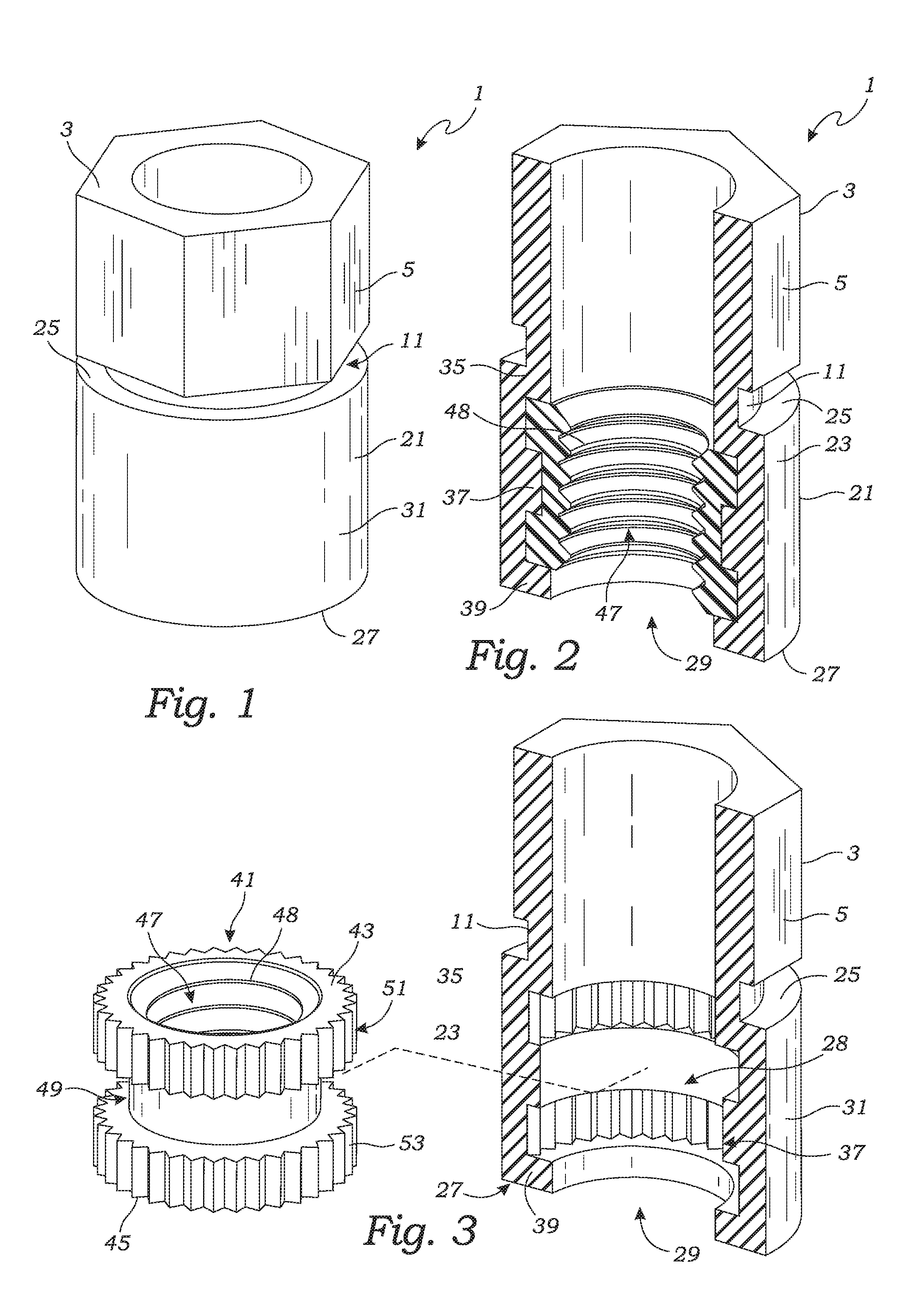

Expanding and extruding connection method for mechanical connection of plastic pipes

InactiveCN102032413ALifetime SynchronizationFirmly connectedJoints with sealing surfacesPipe connection arrangementsEngineeringTensile ductility

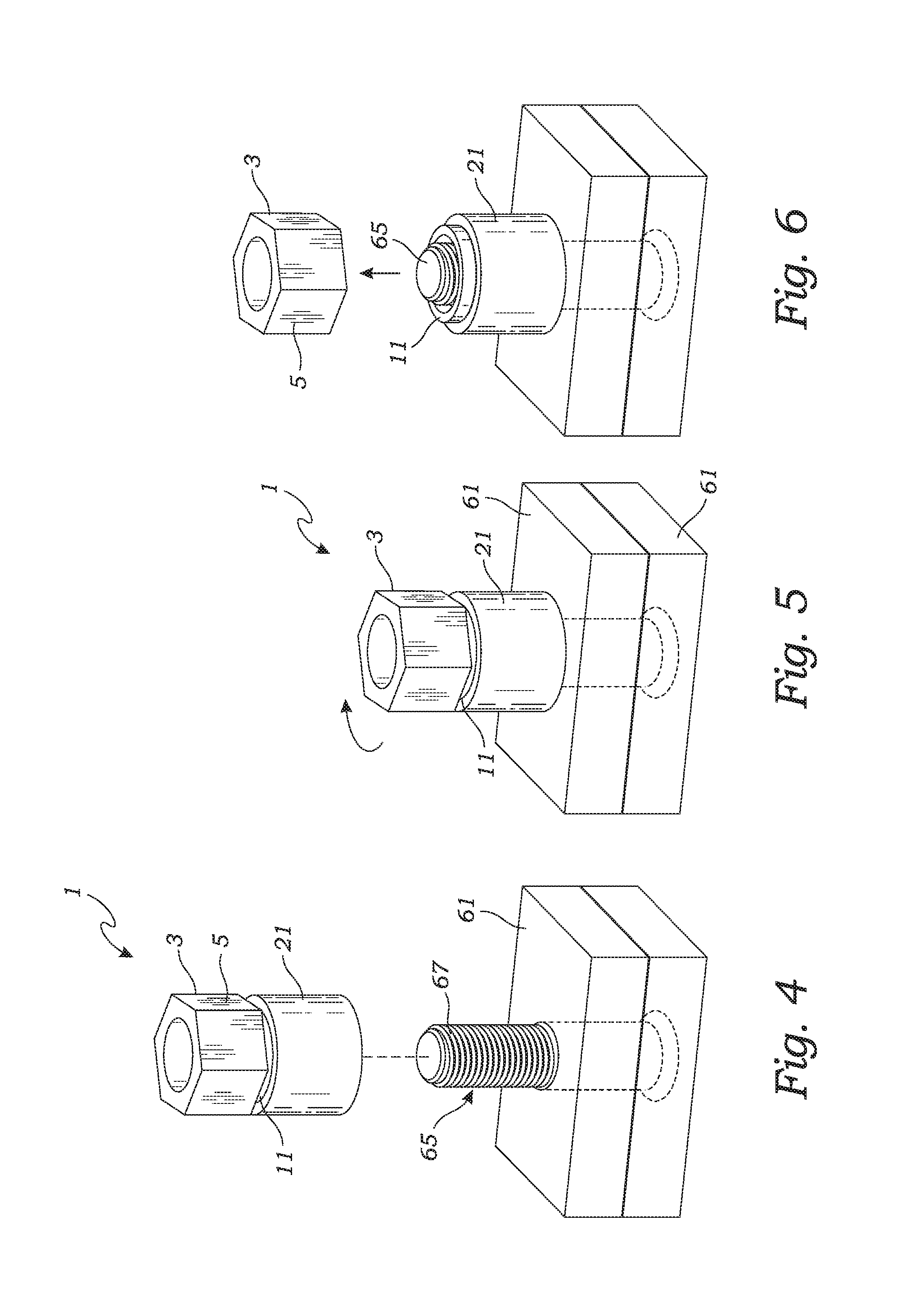

The invention relates to an expanding and extruding connection method for mechanical connection of plastic pipes, specifically comprising the following steps of: (1) expanding the inner diameter of each plastic pipe connection part by 10-25 percent by using a pipe expander and utilizing the stretching ductility of the plastic pipes; and (2) connecting the plastic pipes by adopting a plastic expanding and extruding connector comprising a plastic connector and a plastic nut, sleeving the plastic nut on the plastic pipe, inserting an insertion part of the plastic connector to a connection part of the plastic pipes, fastening the plastic nut on an outer thread of the plastic connector, enabling ribbed edges to clamp the inner wall of the connection part of the plastic pipes, and storing an extruded deformation part of the plastic pipeline into a concave ring. The expanding and extruding connection method of the invention is convenient, concise and reliable to connect various plastic pipelines.

Owner:上海三山信邦科技有限公司

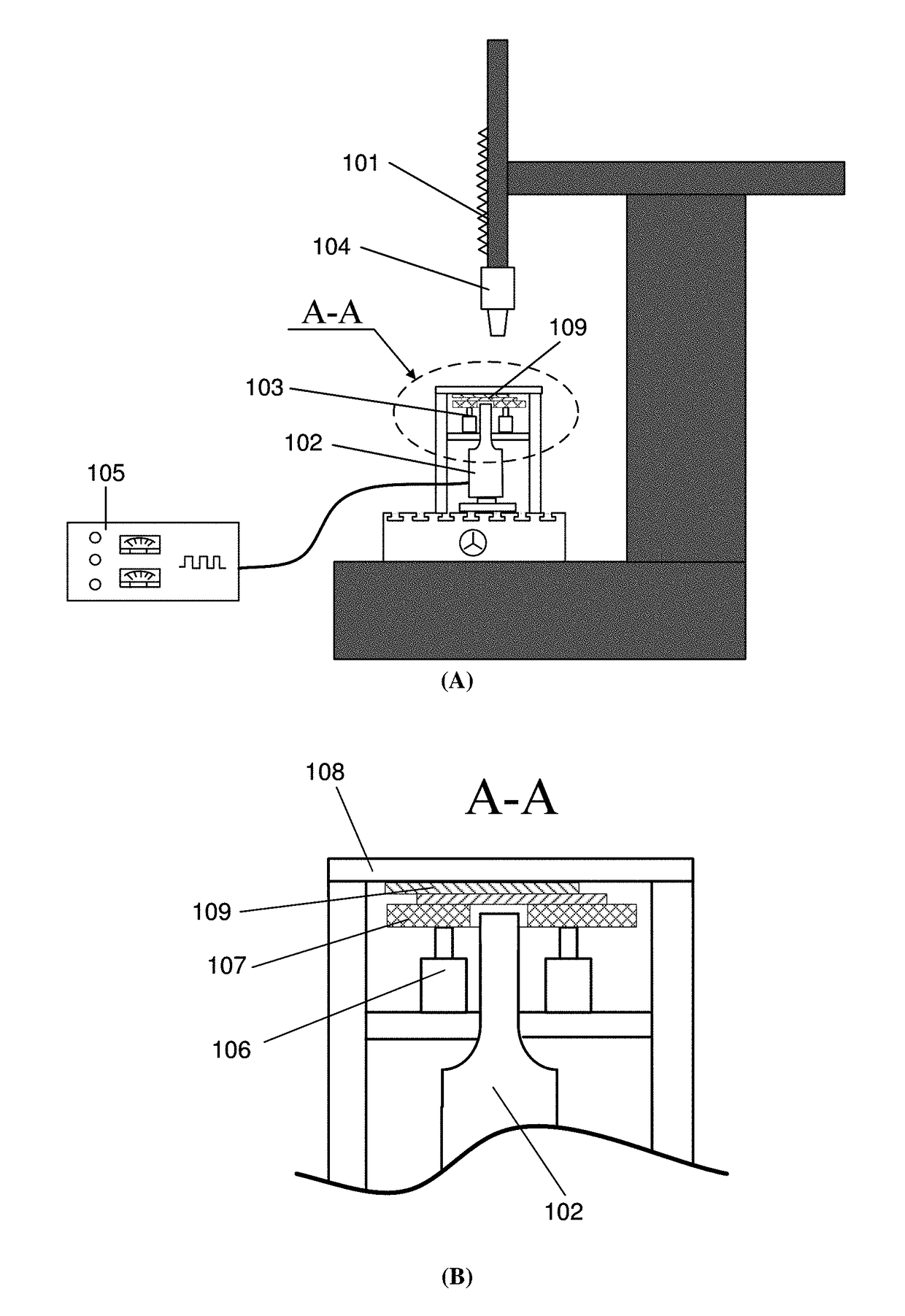

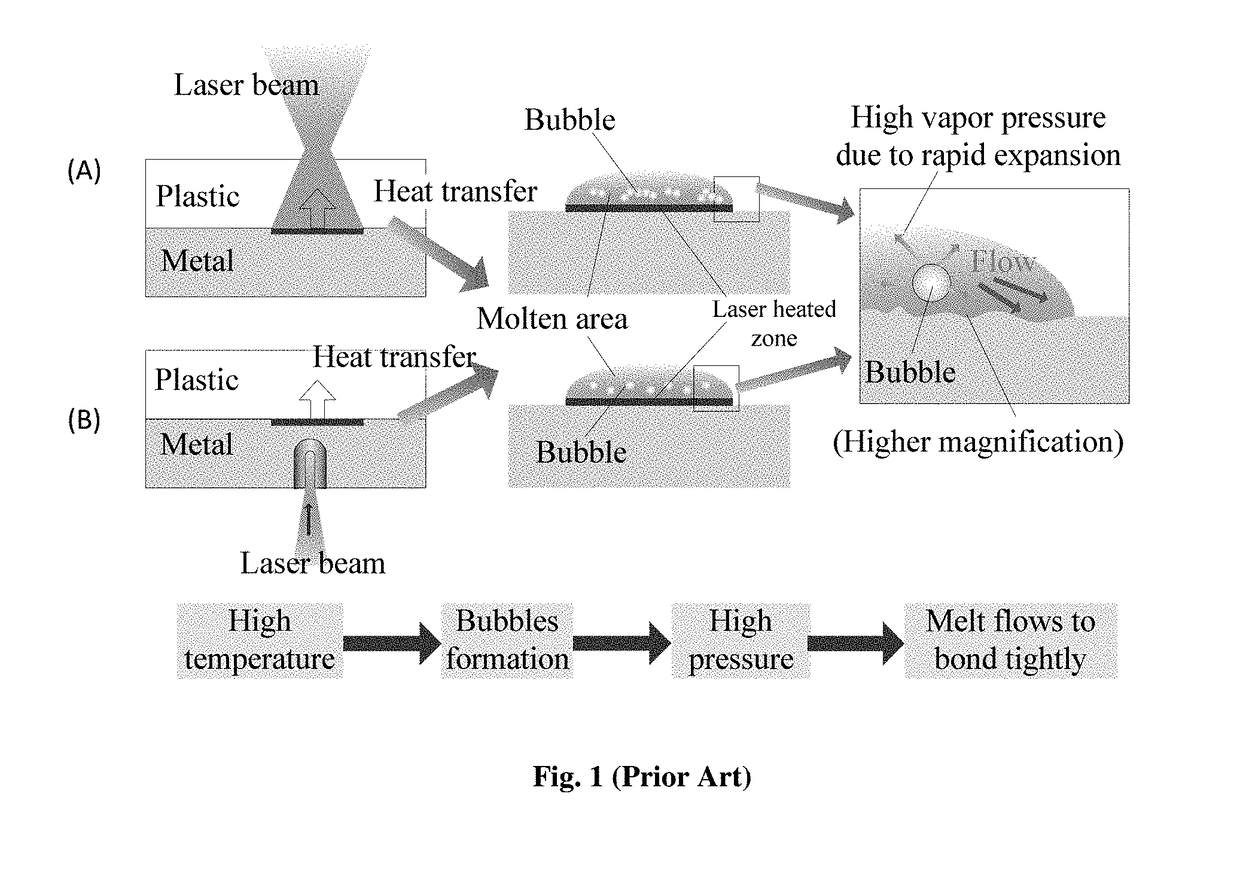

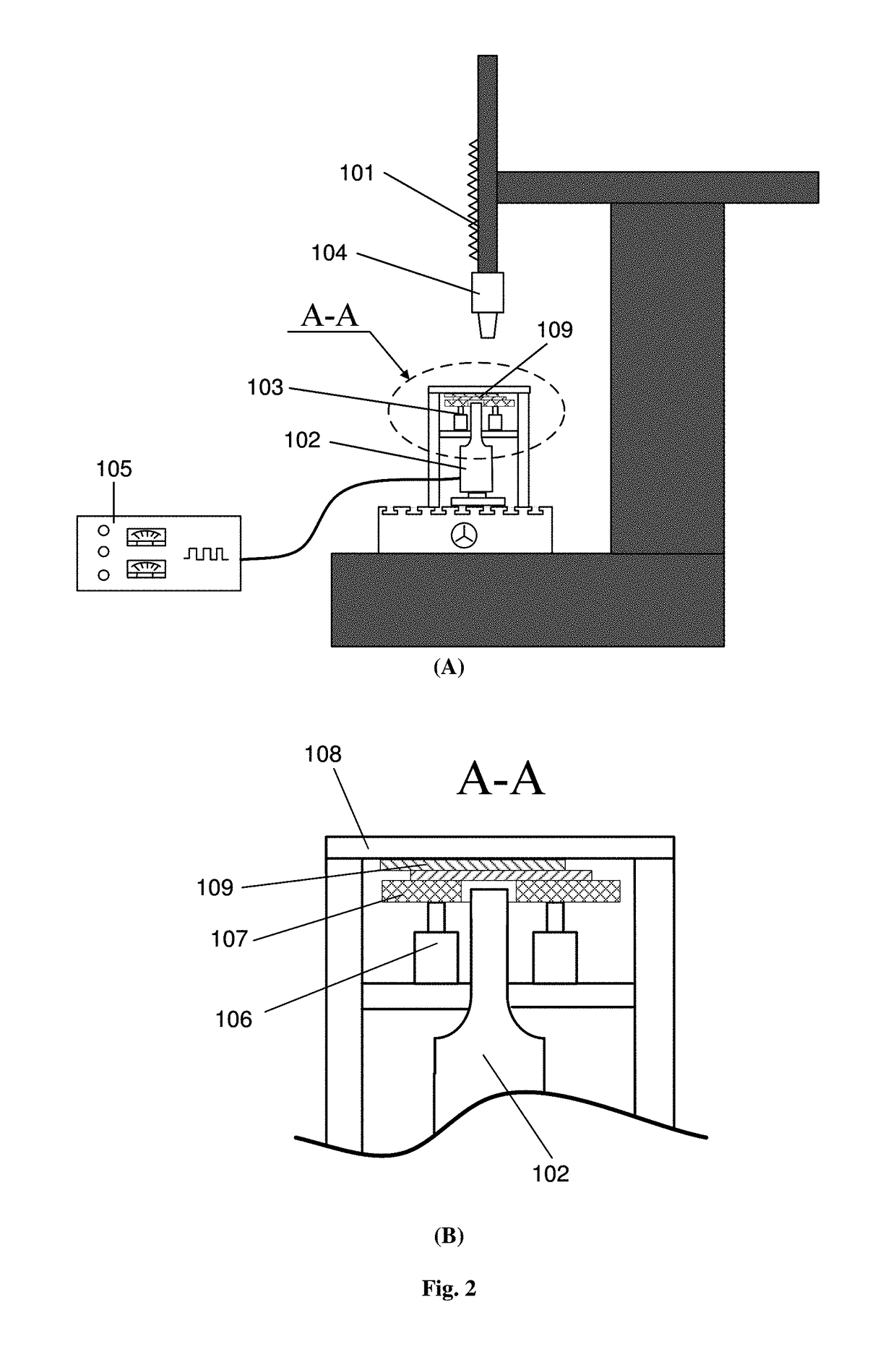

Method Of Laser Joining Of Dissimilar Materials With Ultrasonic Aid

ActiveUS20170320167A1Amount of bubbles can be reduced or even be eliminatedProblem can be addressedWelding/soldering/cutting articlesLaser beam welding apparatusPolyethylene terephthalateUltrasonic assisted

A new ultrasonic aided laser joining method (UAL) for bonding dissimilar materials has been developed. The method is capable of eliminating the laser-induced bubbles at the bonding faces and to improve the joint strength over that of the conventional laser-assisted metal and plastic joining method (LAMP). Some experiments on joining titanium to polyethylene terephthalate have been conducted to show the superiority of UAL over LAMP. The results showed that the joint strength, measured in terms of failure load, was significantly increased when ultrasonic vibration was employed during laser joining. For the LAMP joined specimens, fracture normally occurred at the metal-plastic interface, whereas for the UAL joined specimens, fracture normally occurred in the parent plastic part. The improvement in joint strength is mainly due to the elimination of pores in the resolidified plastic. In addition, ultrasound vibration promotes chemical bonding between the plastic and metal parts, and this is supported by the XPS results.

Owner:THE HONG KONG POLYTECHNIC UNIV +1

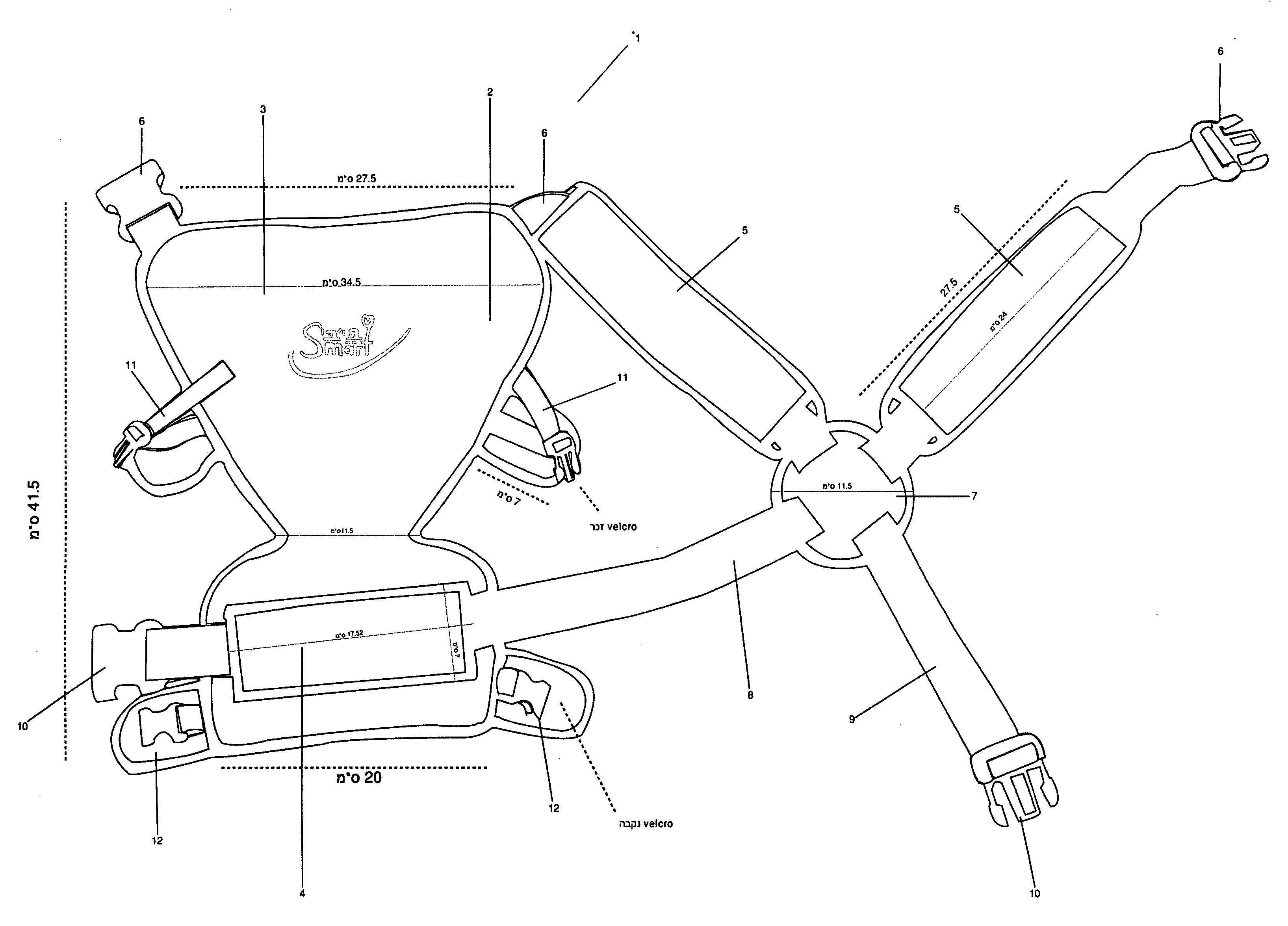

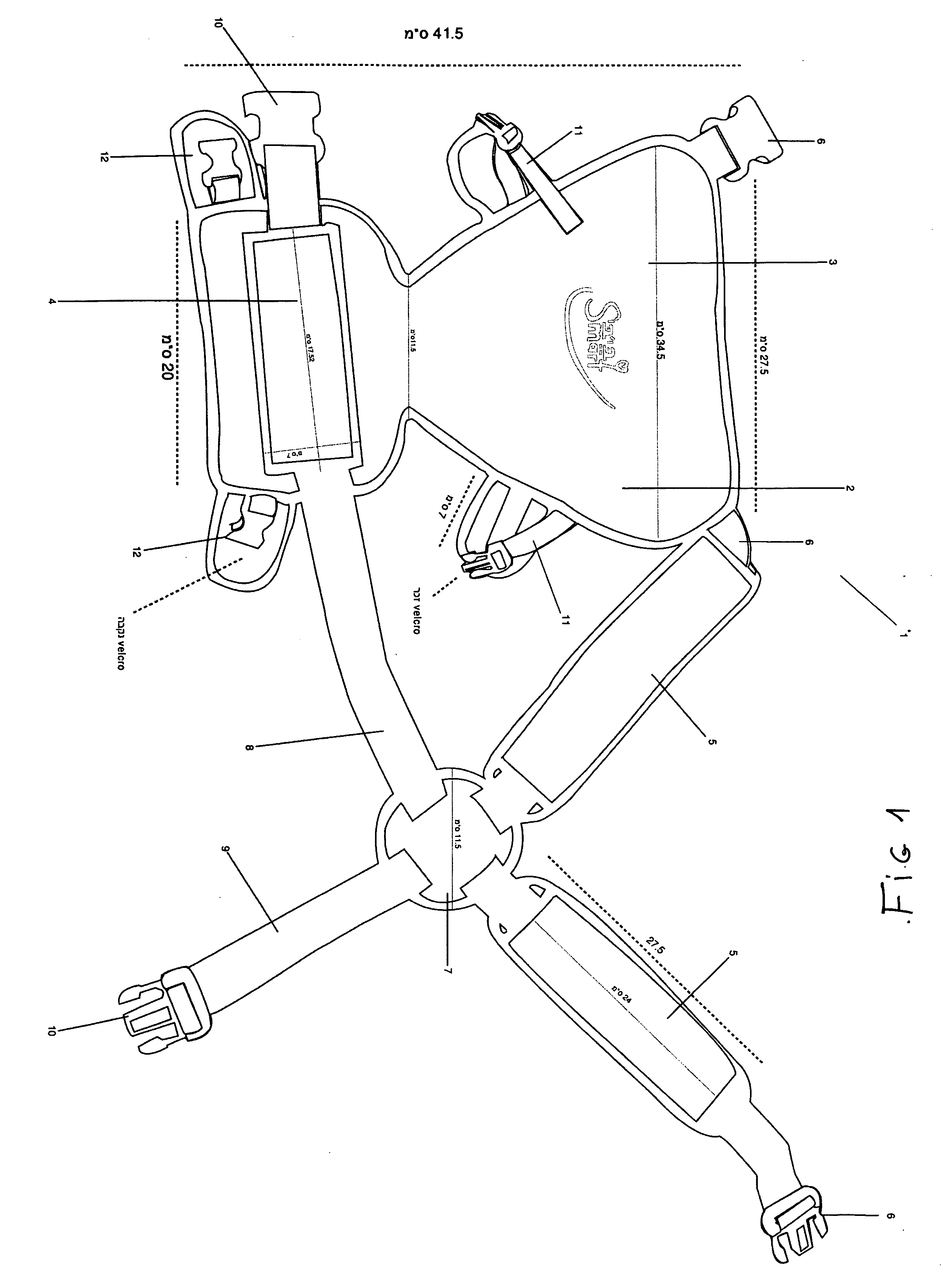

Baby carrier for use on land, at the pool and at the sea

A baby carrier that is made of water resistant materials and its design suits the materials the carrier is made of and the purpose it is intended to fulfill. The carrier comprises a sheet that envelops the baby's body, a harness and belts that attach the sheet to the adult's body, and standard plastic connectors. The connectors are made of plastic, whereas the carrier's sheet, harnesses and belts are made of a water resistant material such as the material used in the manufacture of scuba diving or surfing suits, namely neoprene.

Owner:COHEN RAZ TAMMY +1

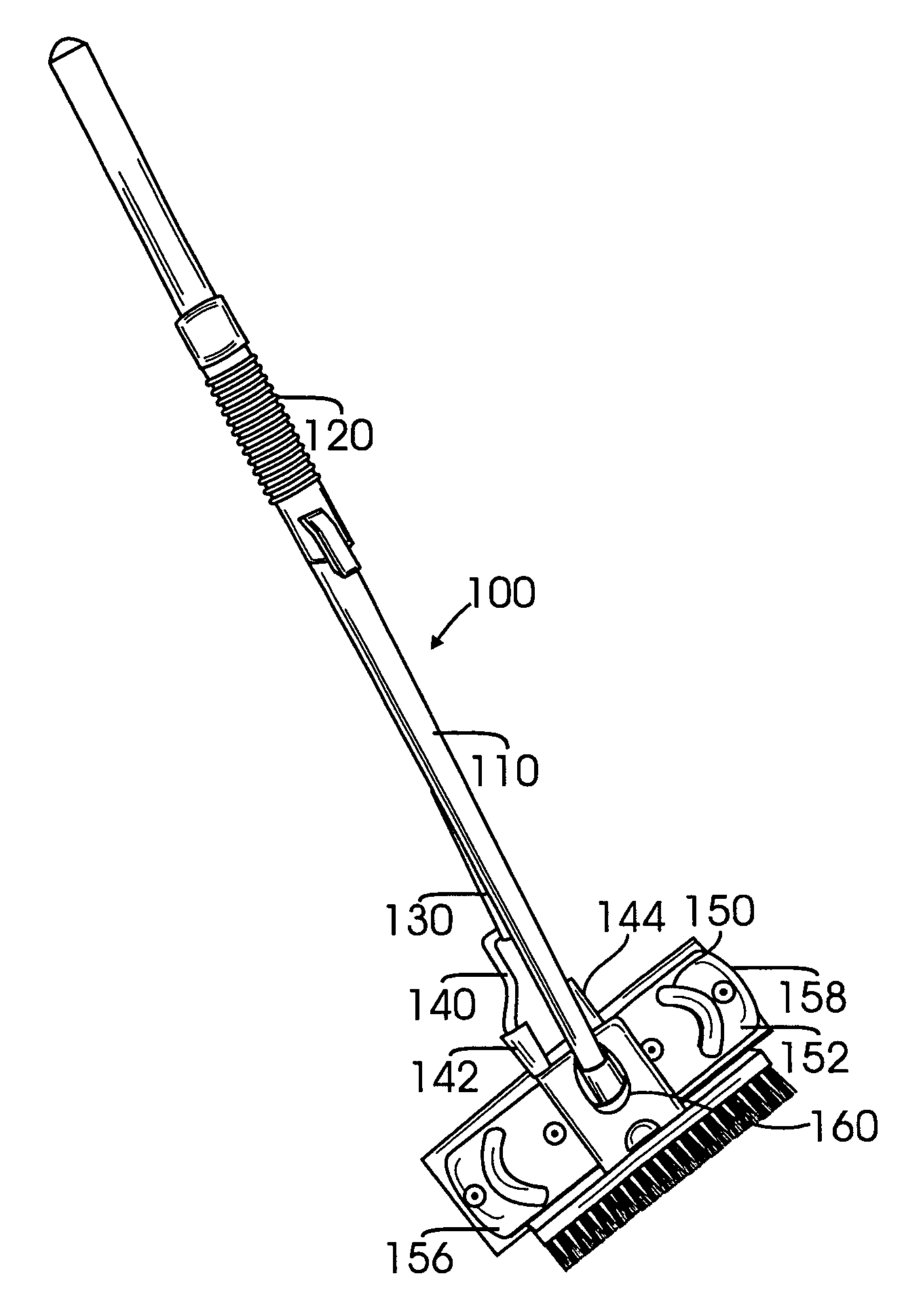

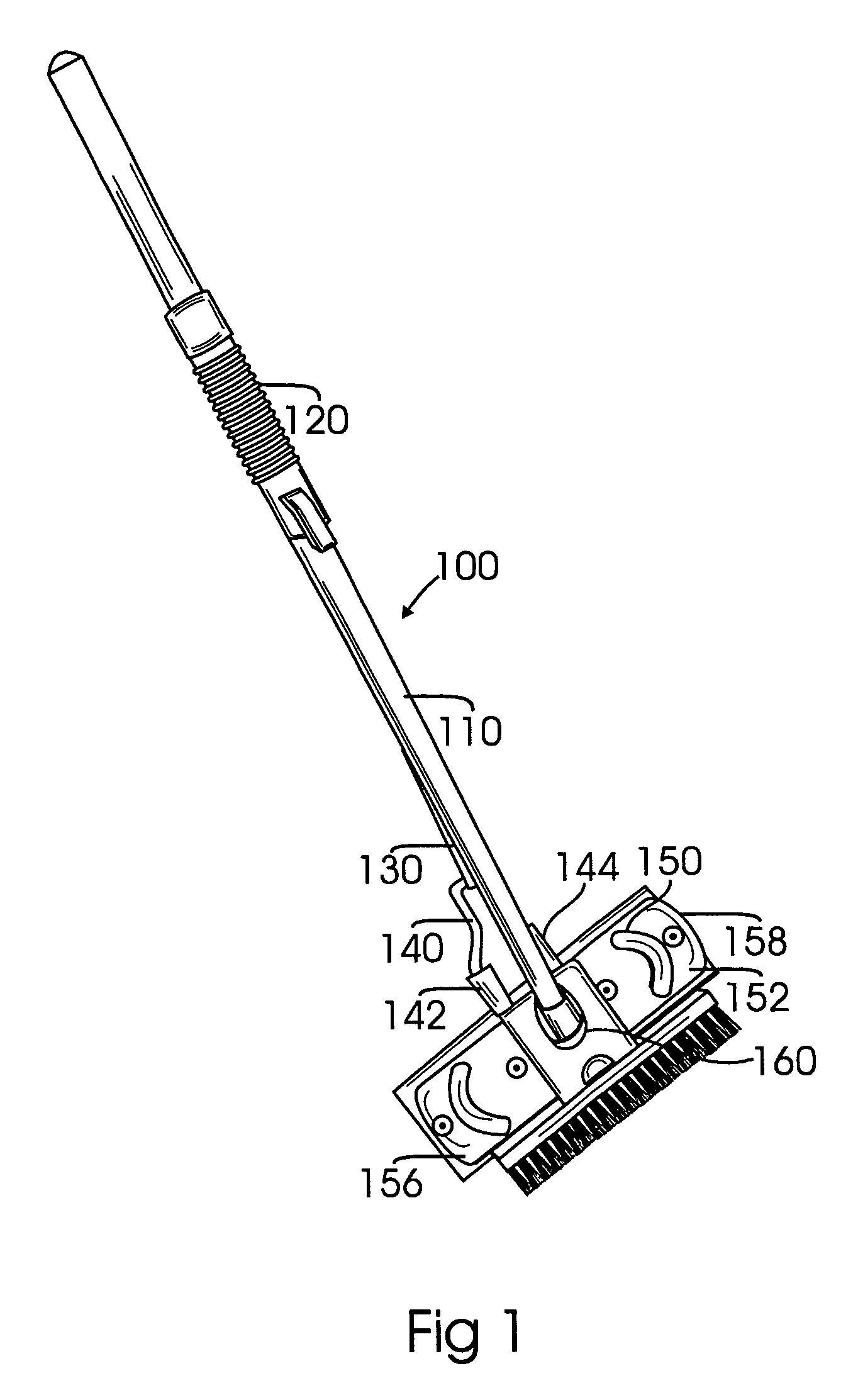

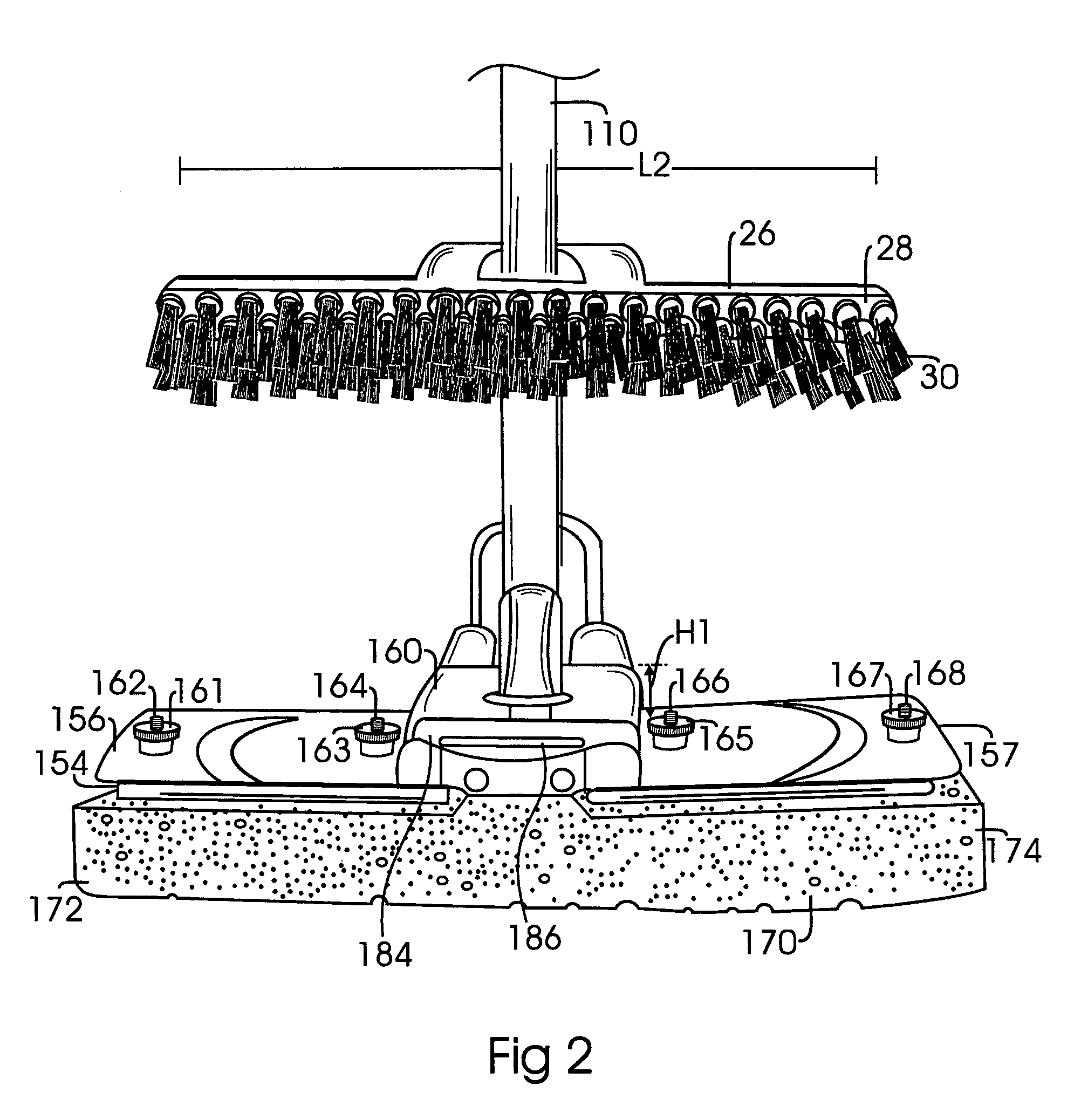

Attachment mechanism to a metal mop head to securely retain a cleaning implement attachment on a butterfly mop

The present invention is a cleaning implement such as a scrubber brush attachment which permanently holds the scrubber brush attachment in place on a metal butterfly sponge mop head and will not fall off during the vigorous scrubbing action because it is locked in place by means of a novel attaching mechanism. The present invention is comprised of a molded plastic attaching mechanism which has a body having a generally flat plate which at one end is molded to a brush head which receives the scrubbing bristles of the brush. The fixed metal housing of the metal butterfly mop head is modified so that the front and rear of the fixed metal housing of the mop head have mating openings which receive corresponding teeth formed into the plastic attaching mechanism.

Owner:WORLDWIDE INTERGRATED RESOURCES

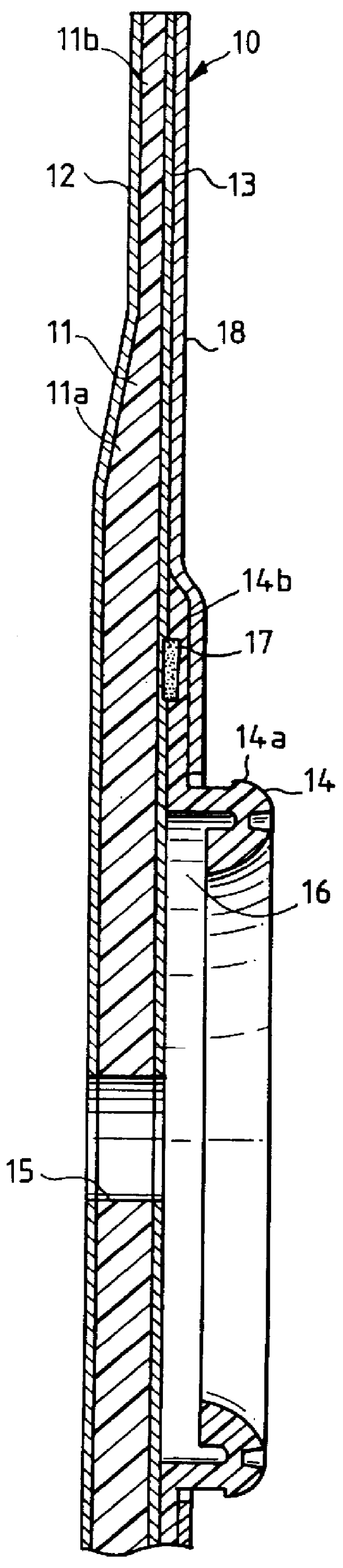

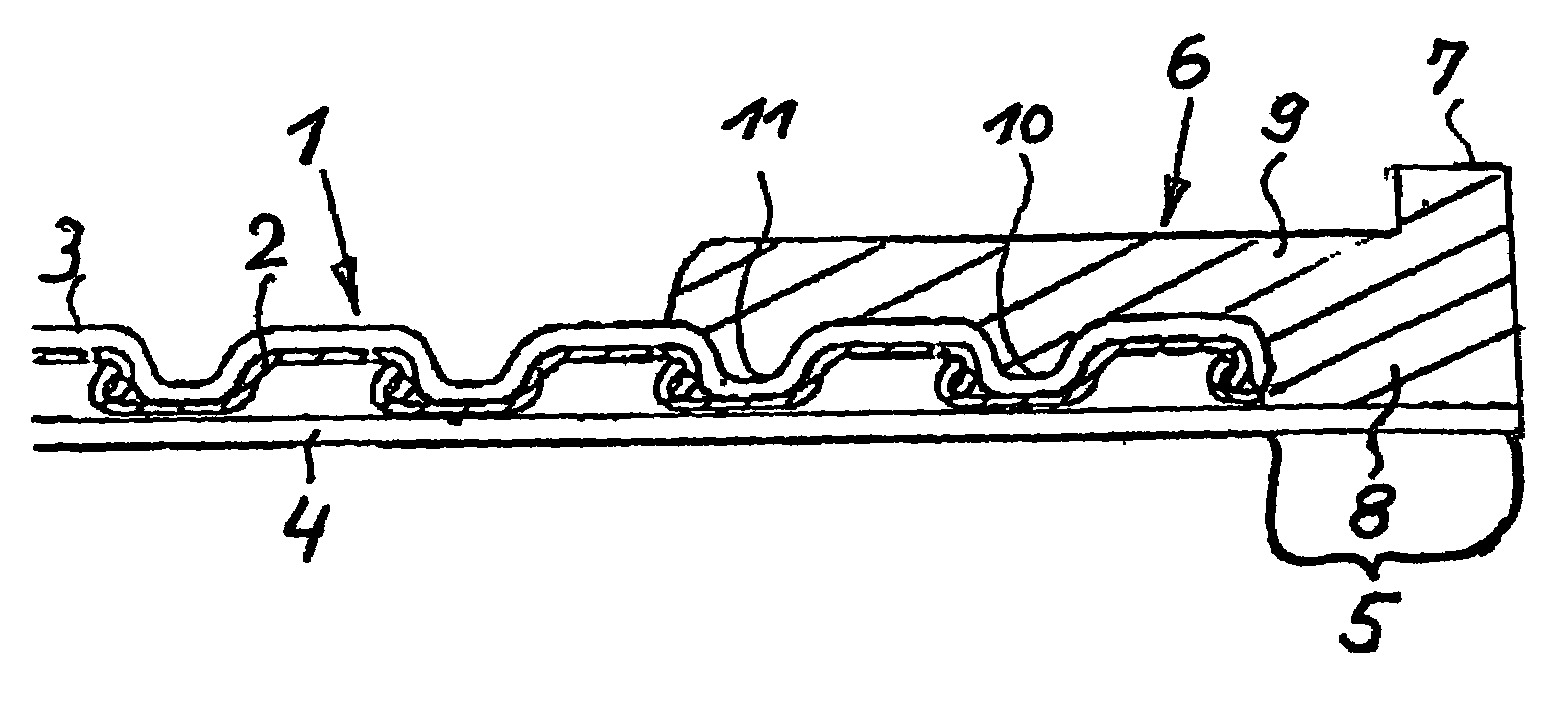

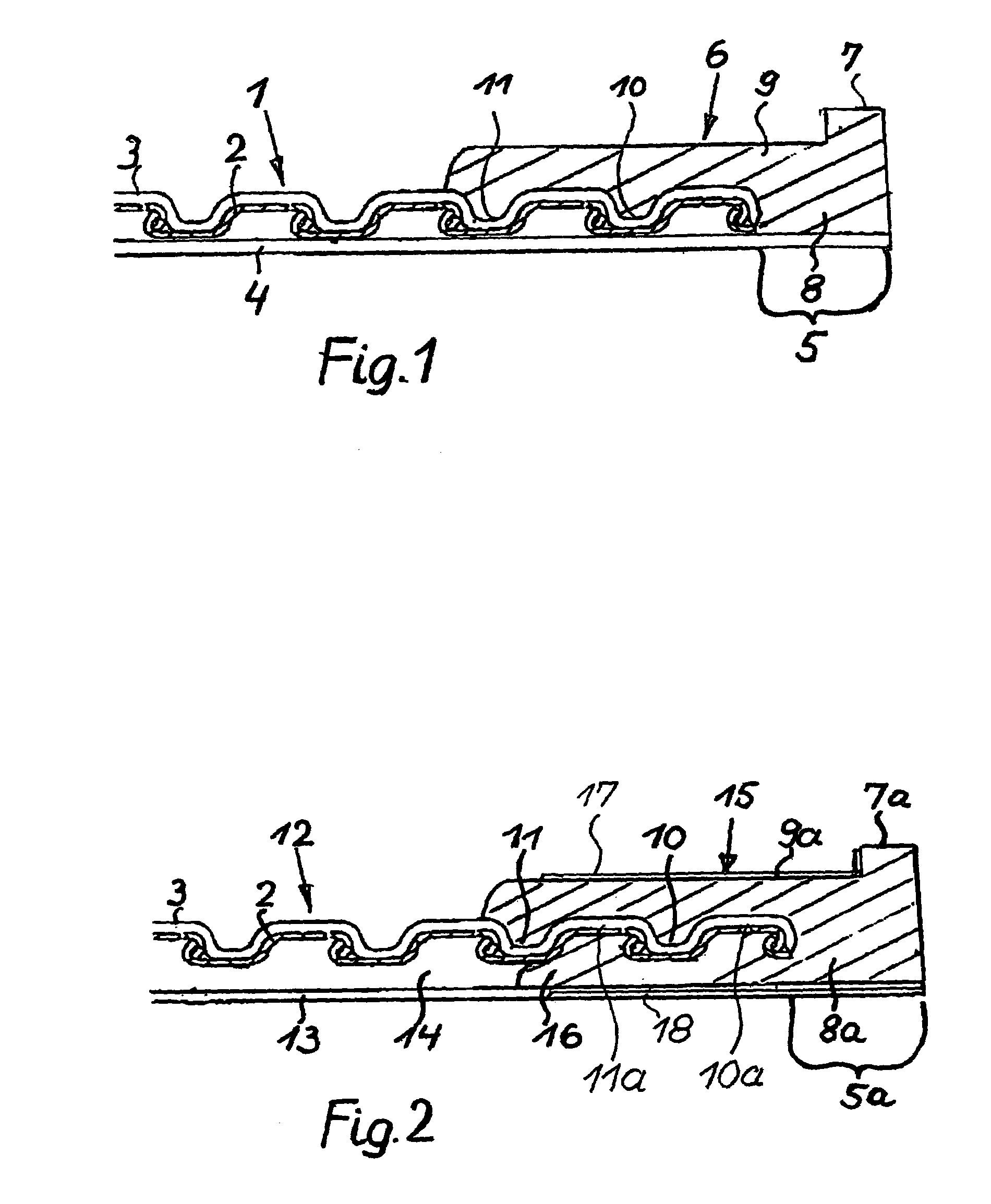

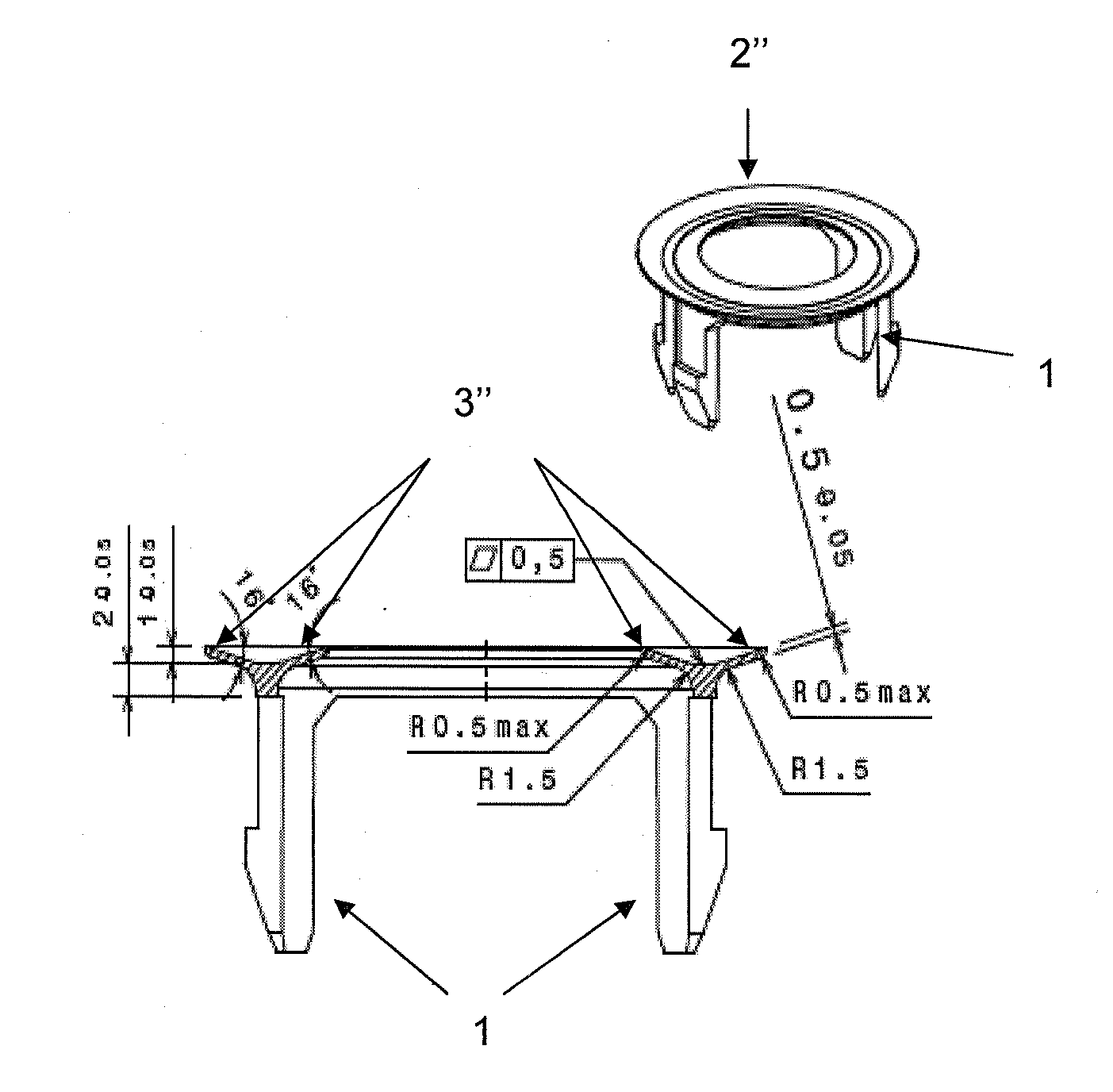

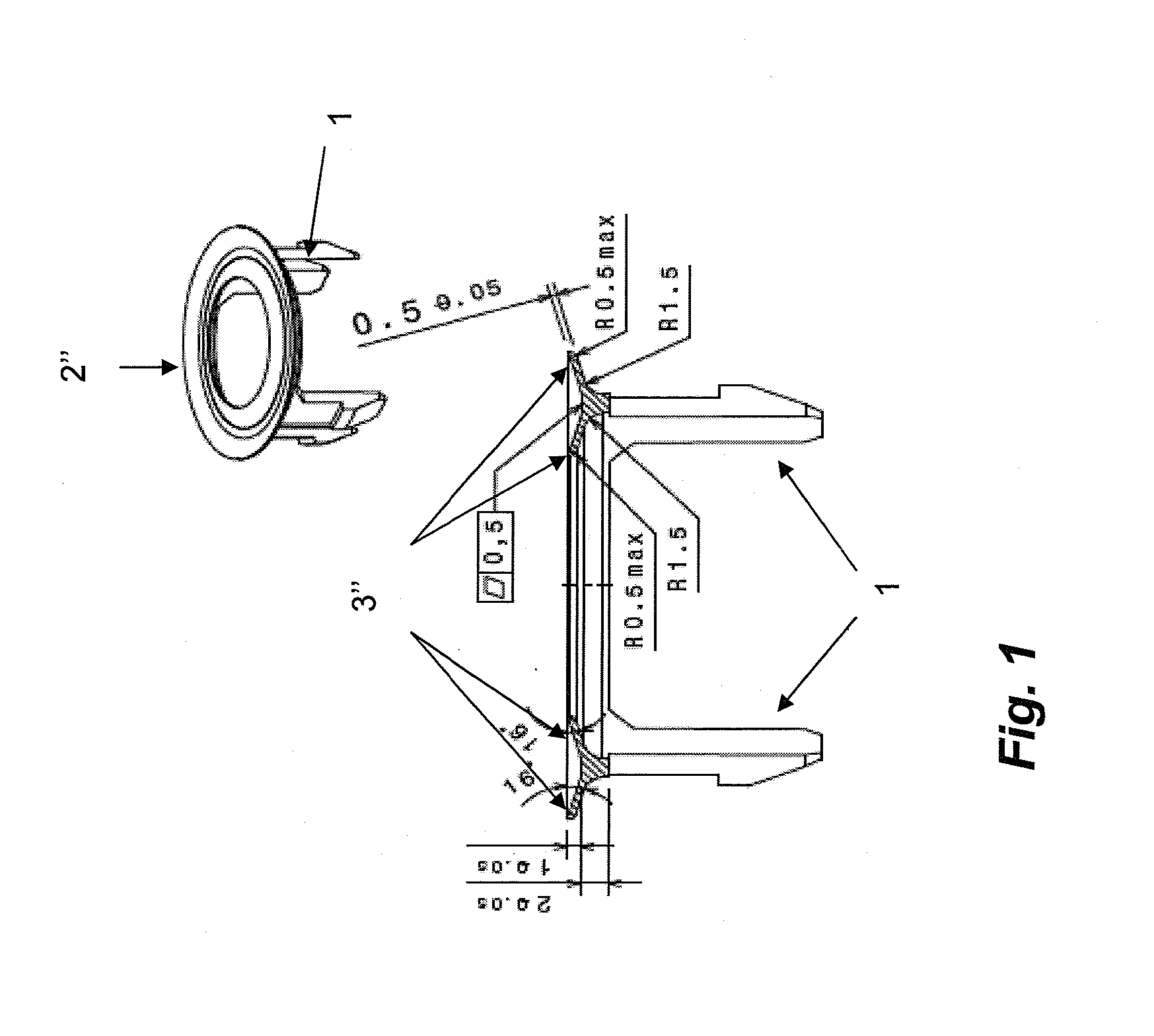

Process for fastening an accessory to a plastic hollow body during the molding thereof and a connection piece

ActiveUS20110131771A1Improve welding qualitySimple designSnap fastenersSlide fastenersCouplingEngineering

Process for fastening an accessory to a hollow body obtained by molding a molten plastic parison and using a plastic connector comprising coupling means for the accessory and a stop surface intended to limit the penetration of the connector into the molten plastic, according to which the stop surface is provided with a curved double lip (or one-piece part having two concentric curved edges, i.e., two protuberances located preferably at its periphery, which are concentric and are in relief relative to the remainder of the part) and the connector is welded to the inner wall of the parison using this double lip.

Owner:PLASTIC OMNIUM ADVANCED INNOVATION & RES SA

Hybrid composite-metal breakaway nut fastener

ActiveUS20160305464A1Avoid corrosionPrevents unwanted electrical conductionLoad modified fastenersScrewsEngineeringMetal

A breakaway nut fastener is provided having a hybrid construction of plastic and metal. The breakaway nut fastener includes a head portion and a nut portion connected by a thin walled section. The head portion is made of plastic and has a shape so as to mate to a tool. The nut portion has an exterior shell having a cavity for receiving a nut insert. The nut portion's exterior shell is made of plastic while the nut insert is made of metal. The breakaway nut fastener's thin walled section is also made of plastic joining the breakaway nut fastener's head portion and the nut portion's exterior shell. The thin walled section is made of plastic, and preferably the head portion, nut portion and thin walled section are constructed as one part forming a single component of plastic.

Owner:NMC GROUP

On-site manhole casting system

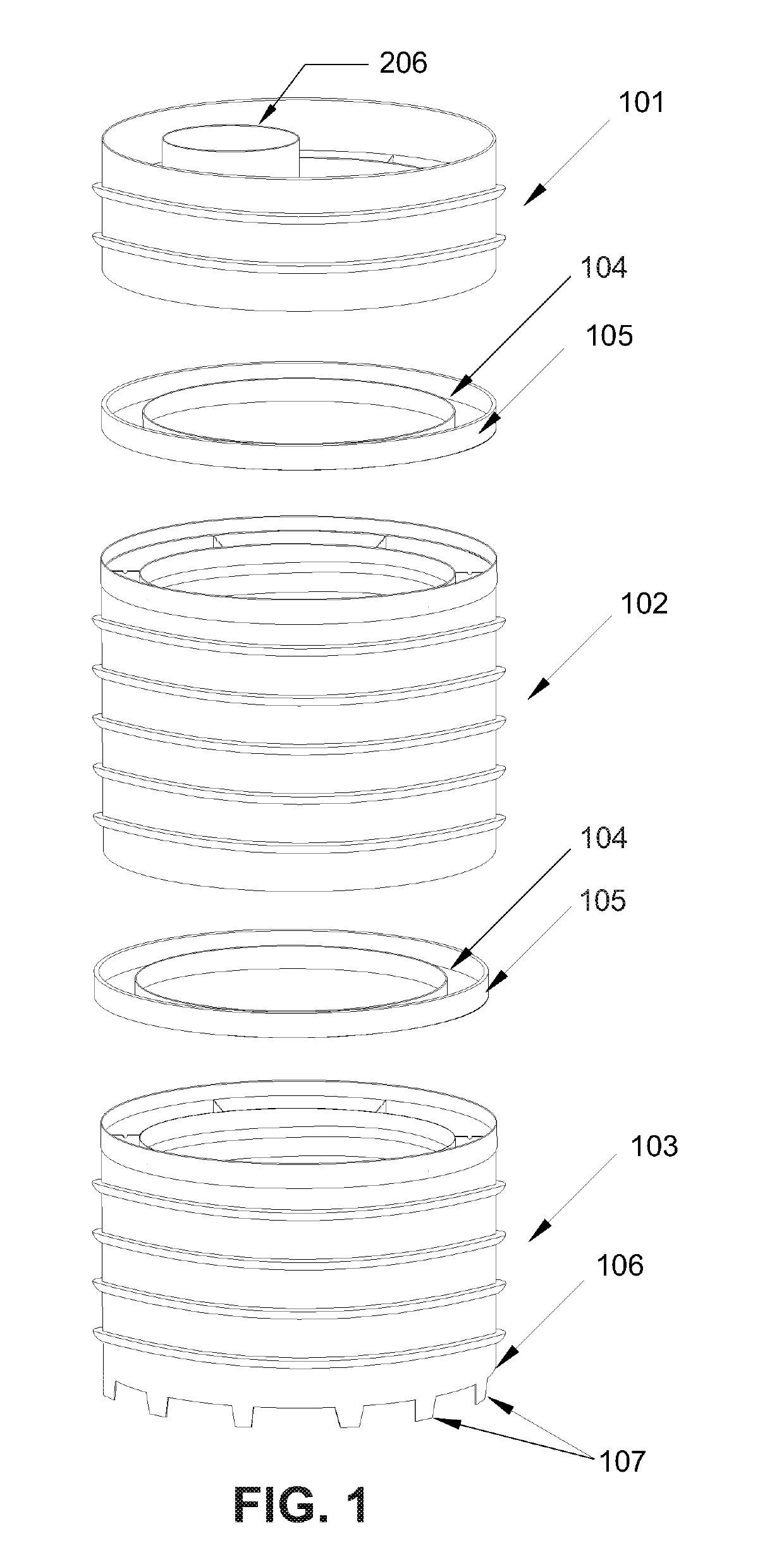

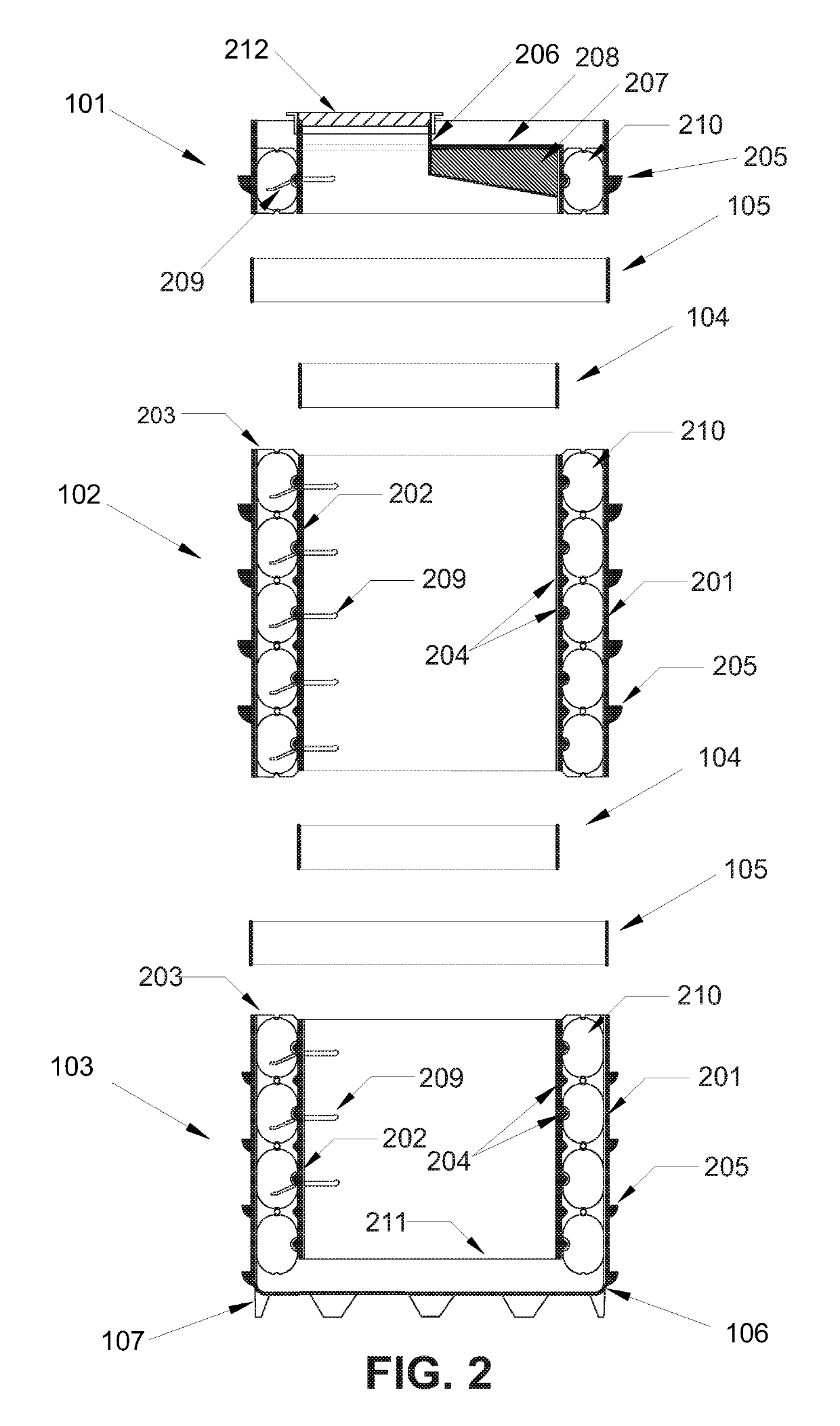

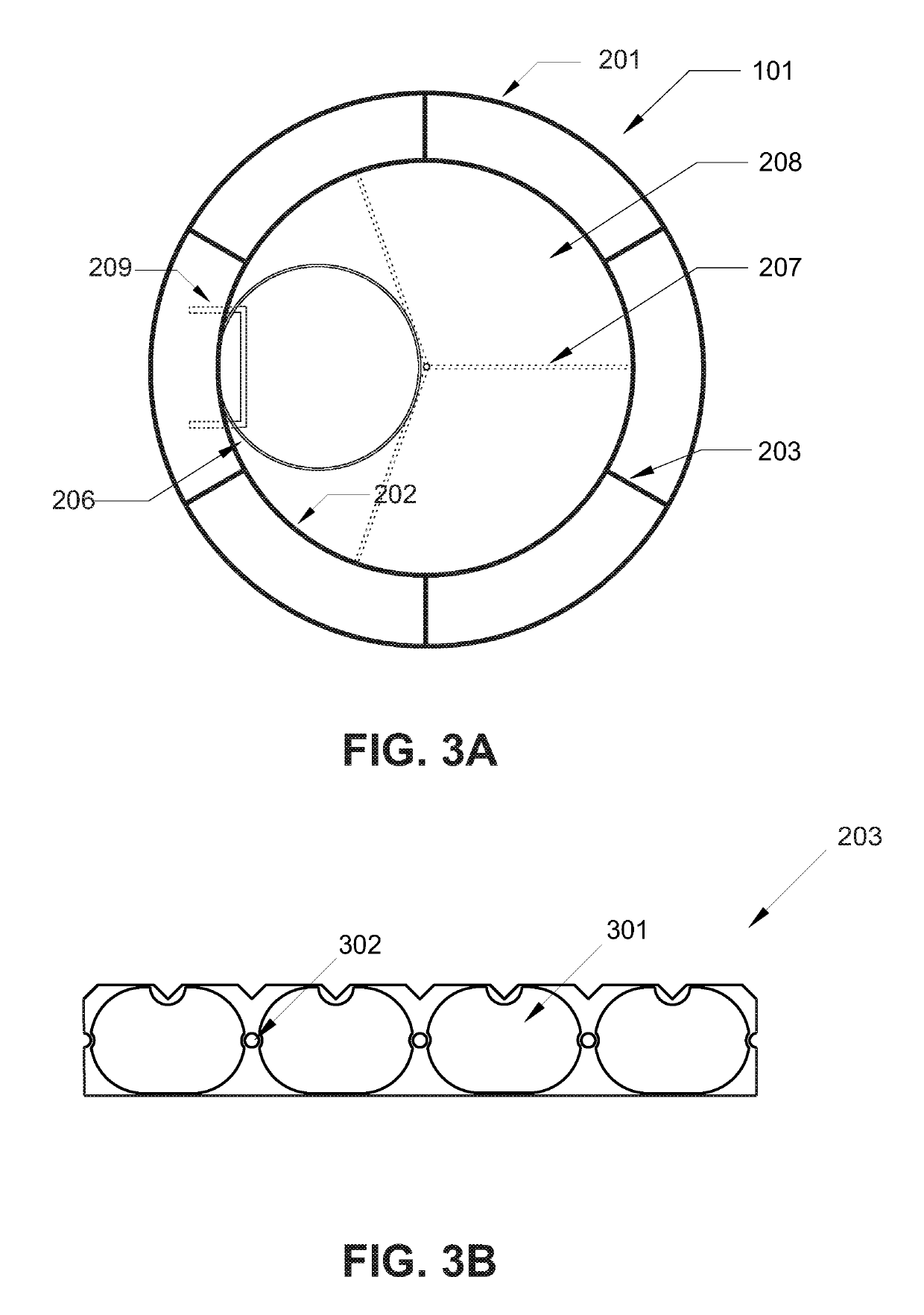

A permanent on-site manhole casting system comprising a top, a main barrel, and a base. Each component consists of a ribbed plastic outer barrel and a ribbed plastic inner barrel with a plurality of plastic tie strips used to connect the said outer and inner barrels. A coupling mechanism consisting of a plastic outer coupling ring and a plastic inner coupling ring is welded to the coupling ends of the top, main barrel and base which connects the top, main barrel and base components. A concrete mixture is poured into the space between the coupled outer and inner barrels where the concrete is then allowed to set and cure and the filled form is then completely buried.

Owner:GILBERT JEFFREY ALLAN

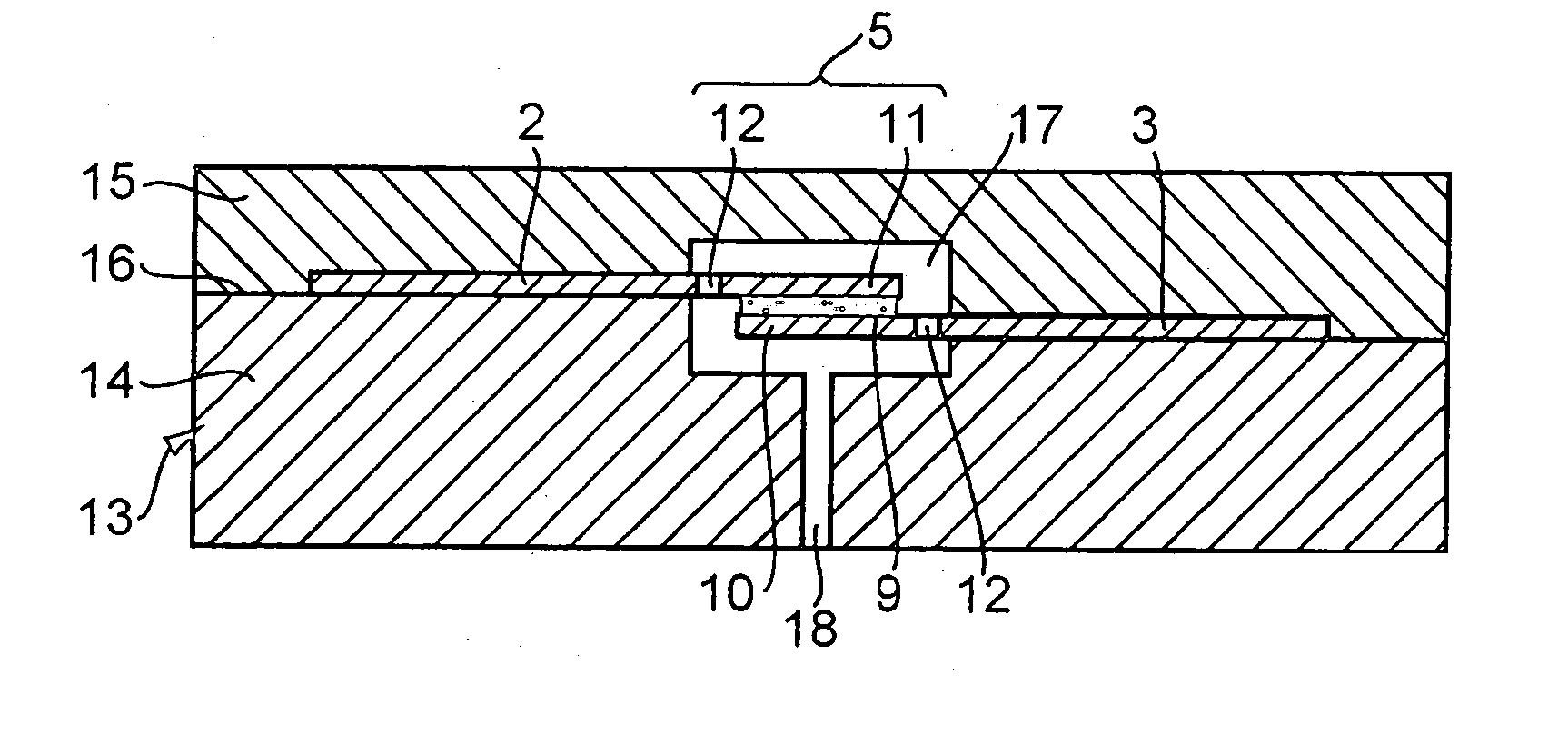

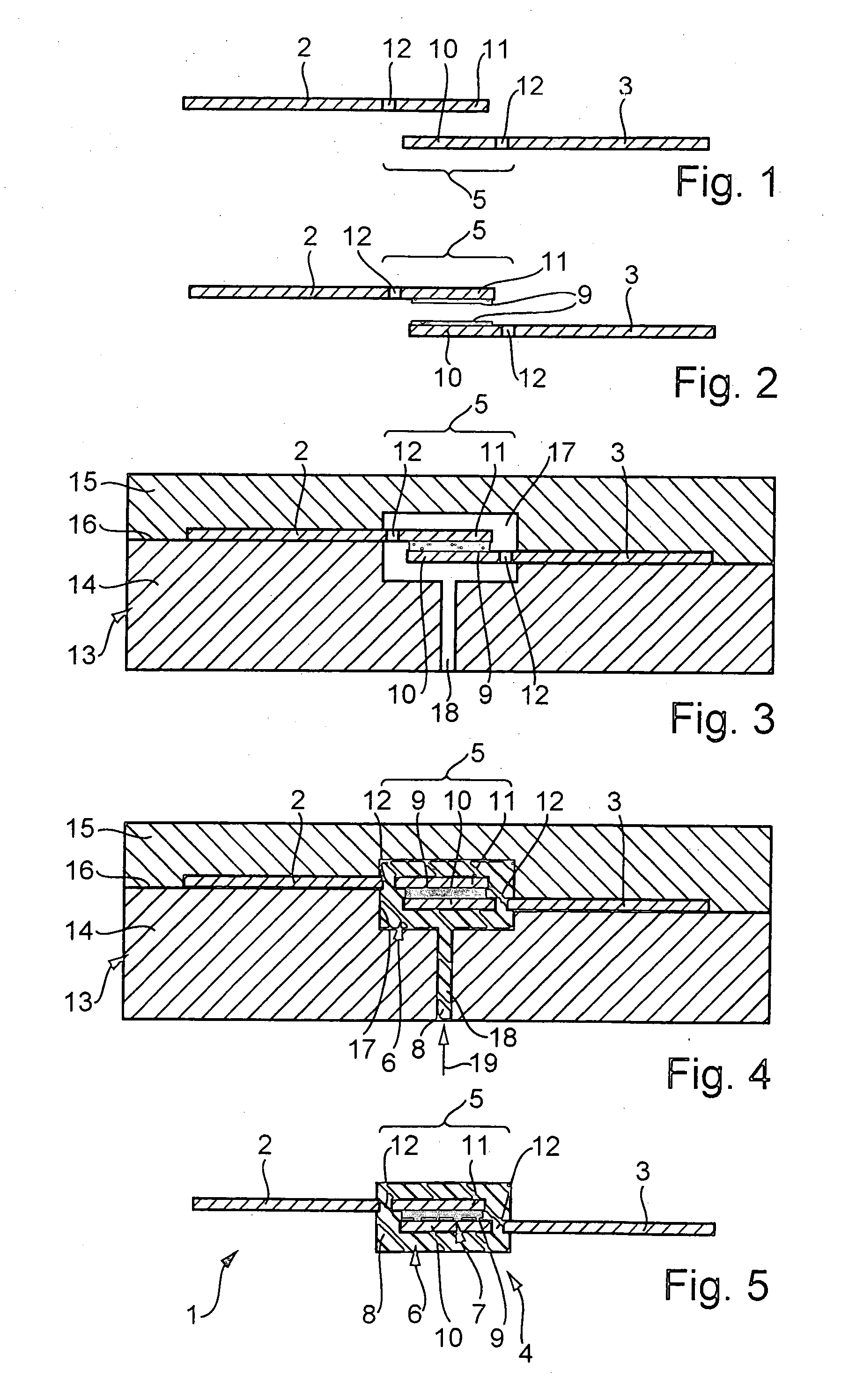

Connection between two parts, and associated connection method

InactiveUS20070182180A1Improve stabilityImprove adhesionItem transportation vehiclesSuperstructure connectionsAdhesiveEngineering

A connection ( 4 ) between two parts ( 2, 3 ), in particular in a motor vehicle. The two parts ( 2, 3 ) are connected to one another in a connection zone ( 5 ) via a plastic connection ( 6 ) consisting of an injection-molded plastic ( 8 ). Additionally, the two parts ( 2, 3 ) are connected to one another in the connection zone ( 5 ) via an adhesive connection ( 7 ) consisting of a cured adhesive ( 9 ).

Owner:DAIMLER AG

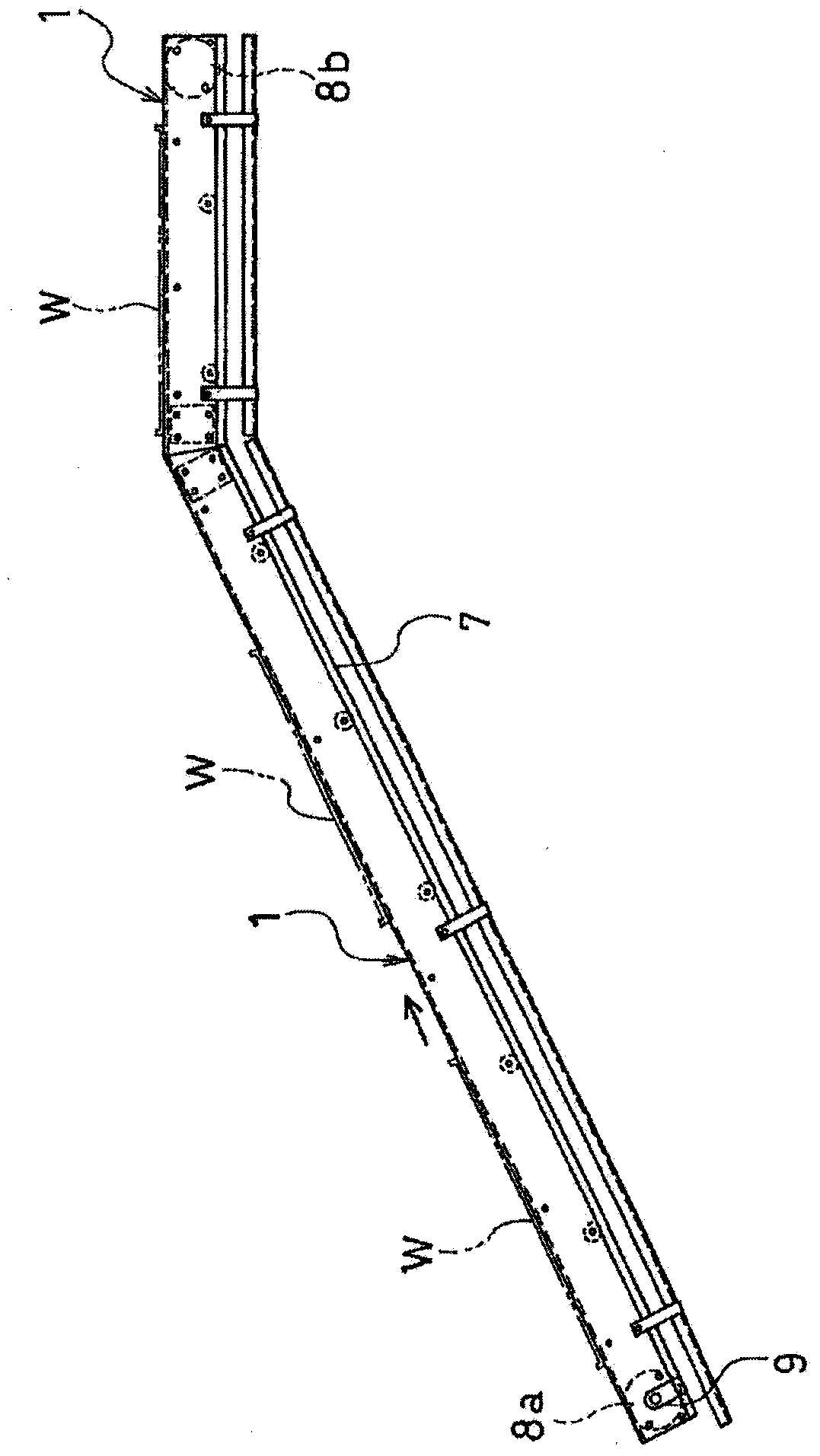

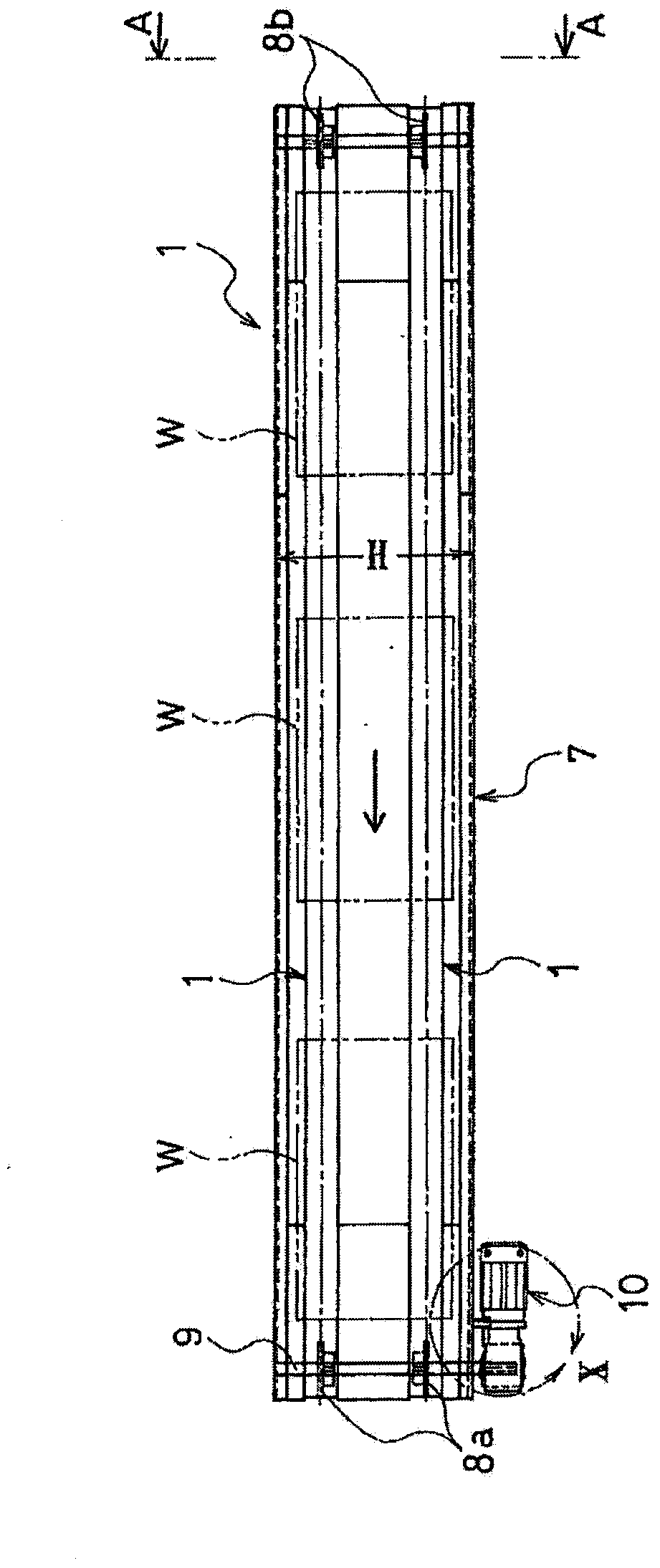

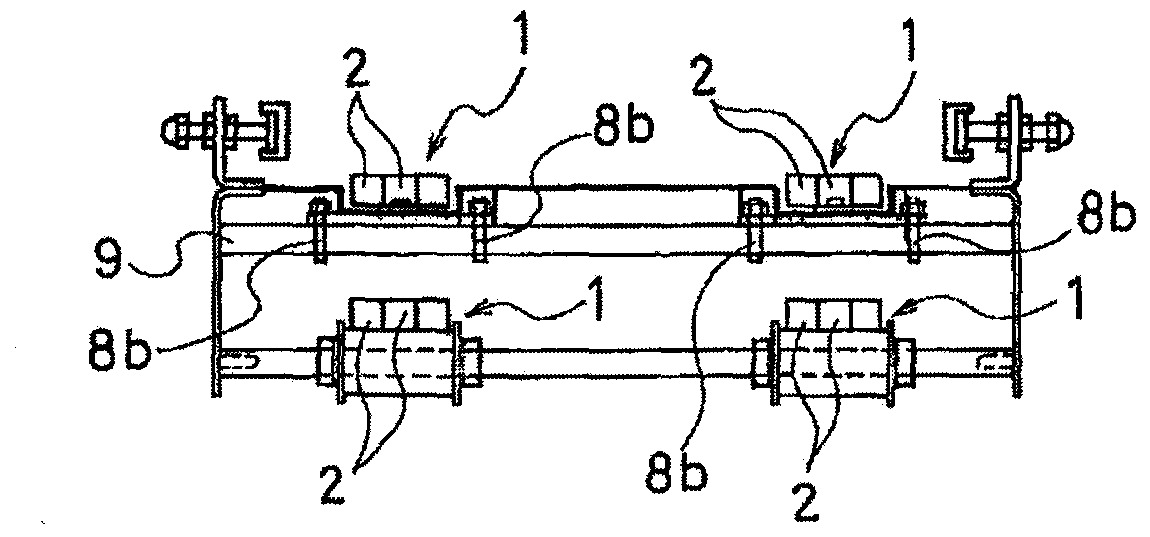

Plastic chain conveyor with magnet connecting pins

ActiveCN103429509AEconomical and safeEconomical and safe carrying capacityConveyorsPlastic materialsChain conveyor

Front and back ends (2a, 2b) of plastic chain modules (2) made of a plastic material are rotatably linked by multiple plastic connecting pins (3a) and metal connecting pins (3b) to form an endless plastic chain conveyor (1). In the plastic chain modules (2) of the plastic chain conveyor (1), carrier surfaces (4a) (top surfaces) of module bodies (4) are smooth. Offset engaging parts (5a, 5b) that can be attached to and detached from each other in the width direction of the plastic chain conveyor (1) are formed on linking end pieces (4X) of the module bodies (4). Circular through-holes (6) receiving the bar-shaped connecting pins (3a, 3b) that rotatably link the offset engaging parts (5a, 5b) of the chain modules (2) are formed at the centers of the sides of the offset engaging parts (5a, 5b).

Owner:LAITRAM LLC

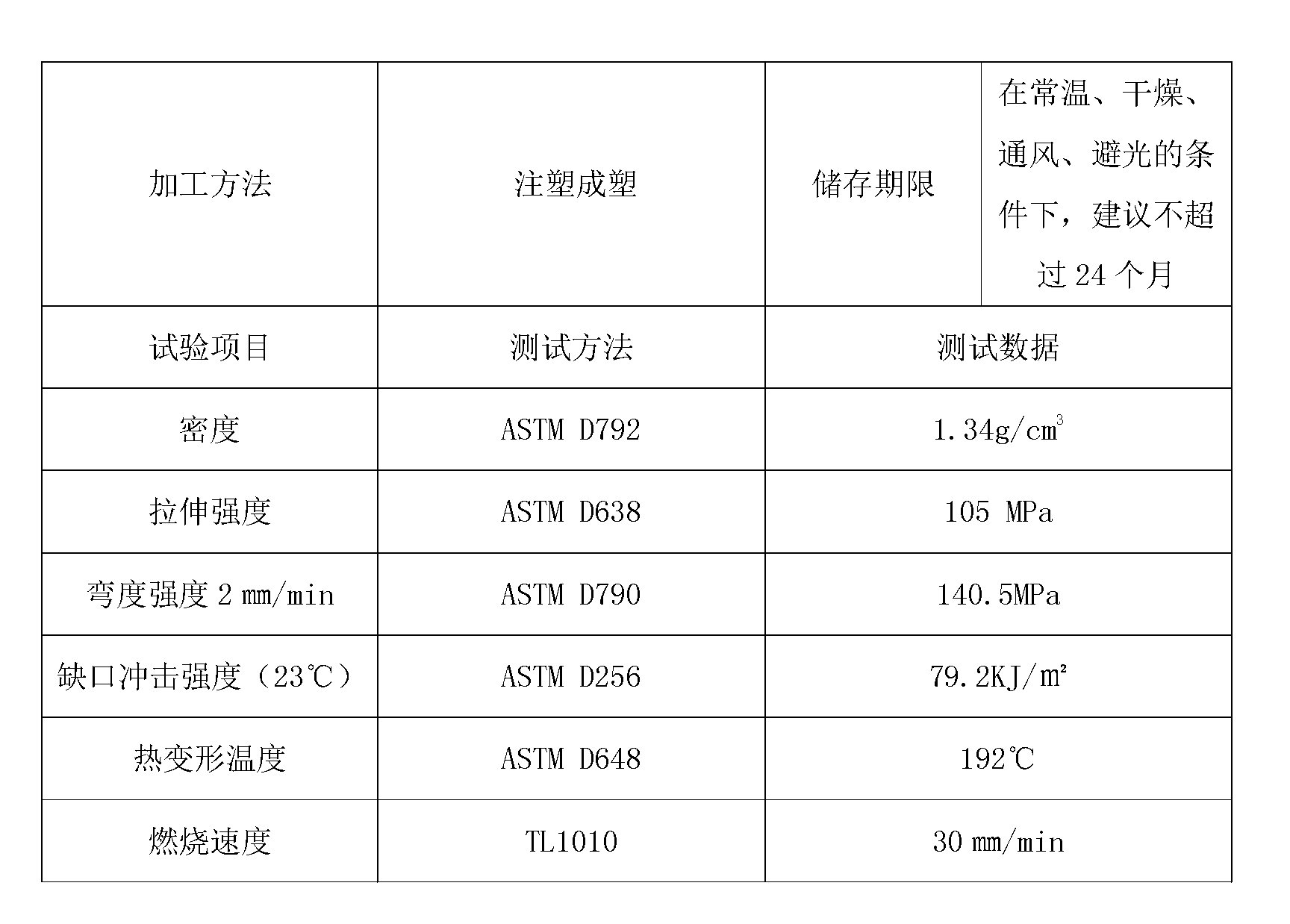

PBT modified nylon PA66 particle material, as well as its preparation method and application in vehicles

The present invention discloses a PBT modified nylon PA66 particle material, which is obtained by mixing a material A of the PBT modified nylon PA66 and a material B of the PBT modified nylon PA66, and then carrying out extrusion granulation. The present invention further discloses applications of the obtained modified nylon PA66 particle material in vehicle parts. The preparation method mainly comprises adding the dried modified material to a heated injection molding machine, setting injection pressures, speeds, injection times and glue injection amounts at different segments of the injection molding machine, and setting a final packing pressure and a packing speed to achieve an optimal injection molding process so as to obtain the final qualified product. After the modified nylon PA66 particle material is used for plastic connection devices of vehicles in the injection molding manner, advantages of high surface finish, good toughness, high strength and the like are provided, demolding is easily performed during injection molding, product quality is stable, a qualification rate is high, production efficiency is improved and production cost is reduced.

Owner:ANHUI KAIDI ELECTRIC

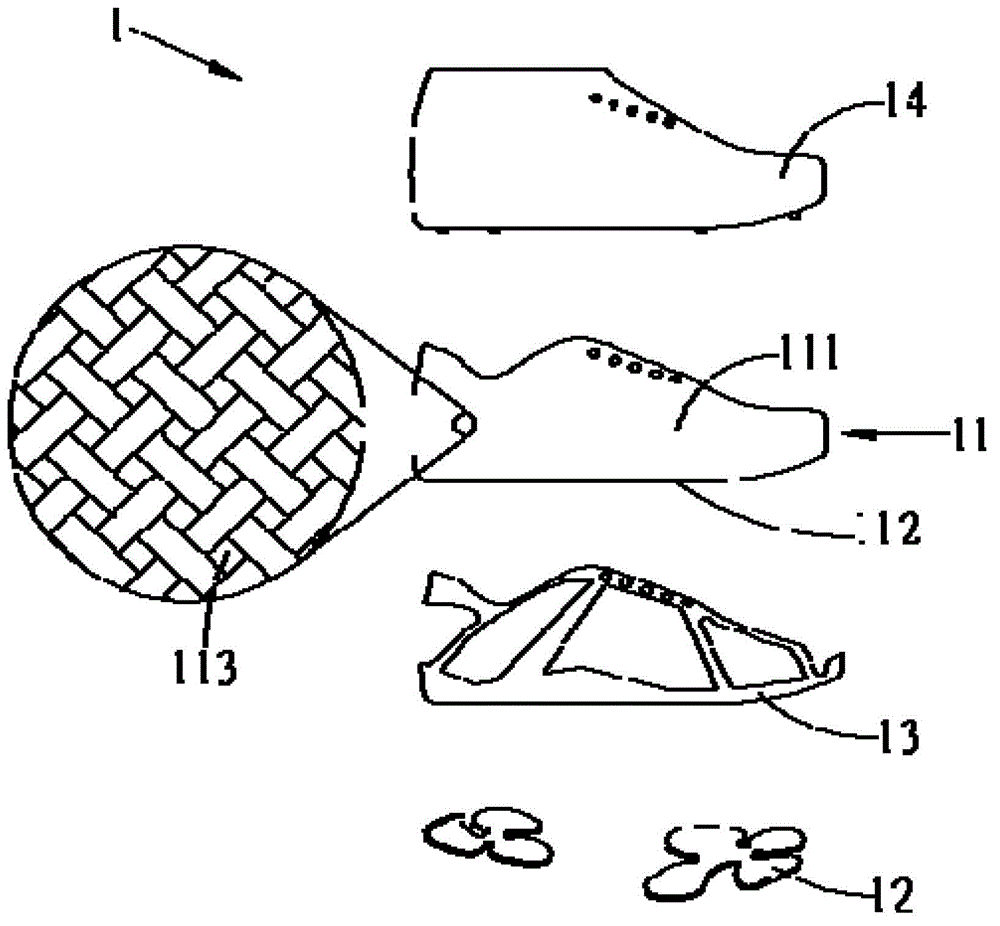

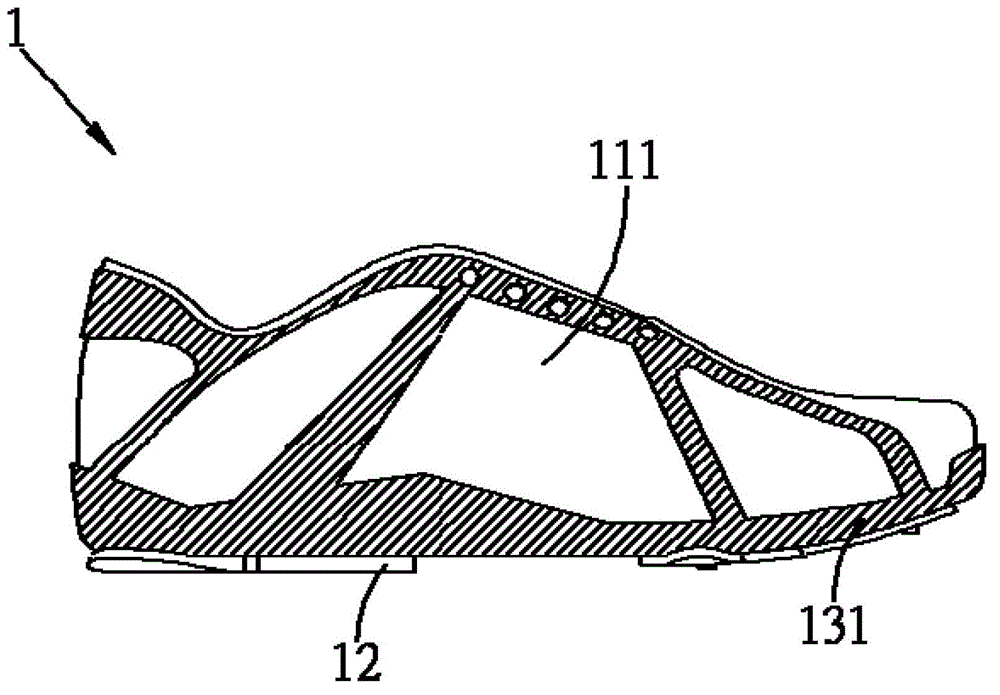

Shoes of automated process production and shoemaking method thereof

InactiveCN103908037ASave materialSave man hoursDomestic footwearUpperPlastic materialsBiomedical engineering

Owner:LONG JOHN TSUNG RIGHT IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com