Plastic chain conveyor with magnet connecting pins

A technology of chain conveying and connecting pins, applied in the directions of conveyors, transportation and packaging, can solve the problems of high cost, time and effort of magnet equipment and plate magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

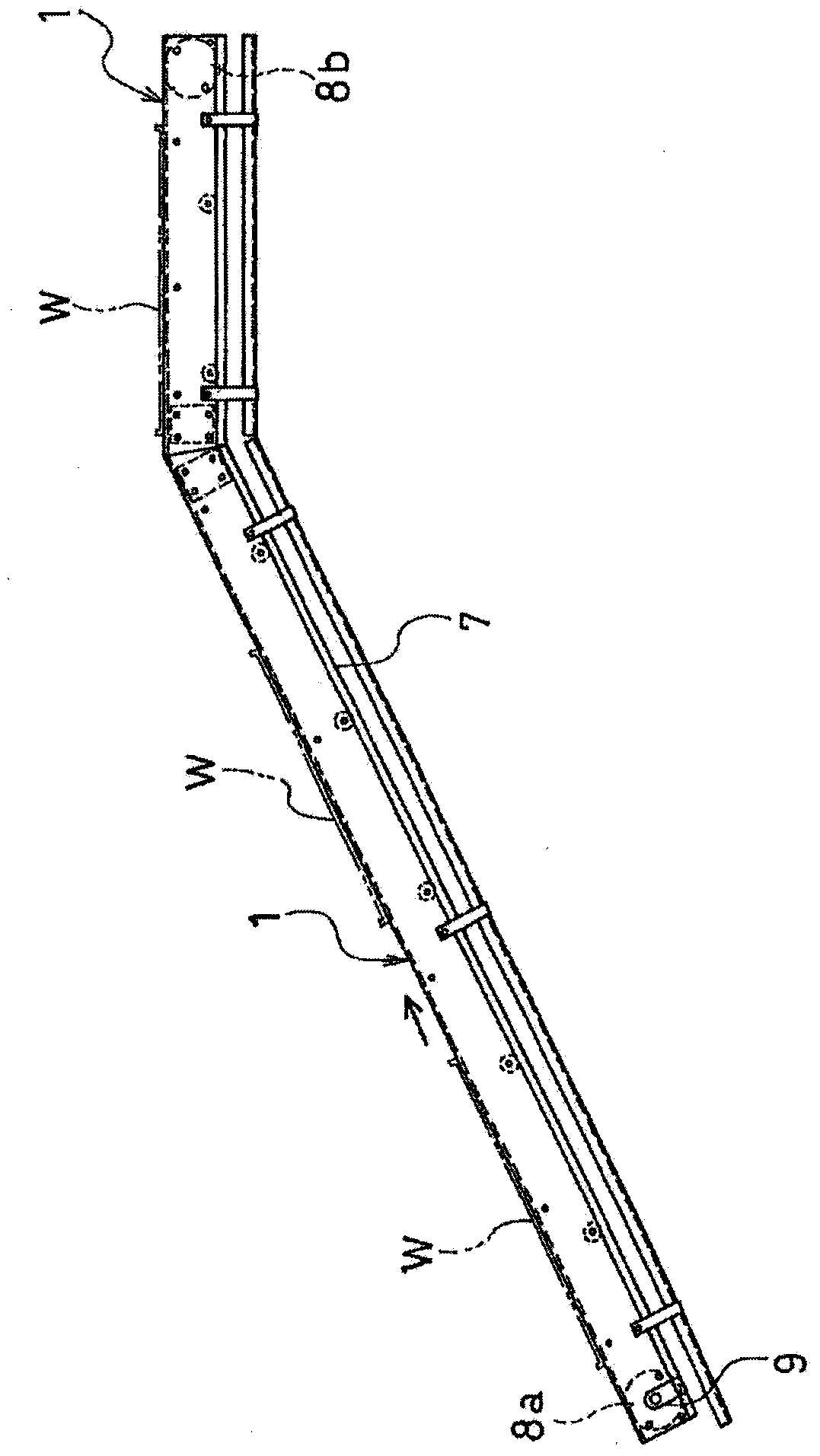

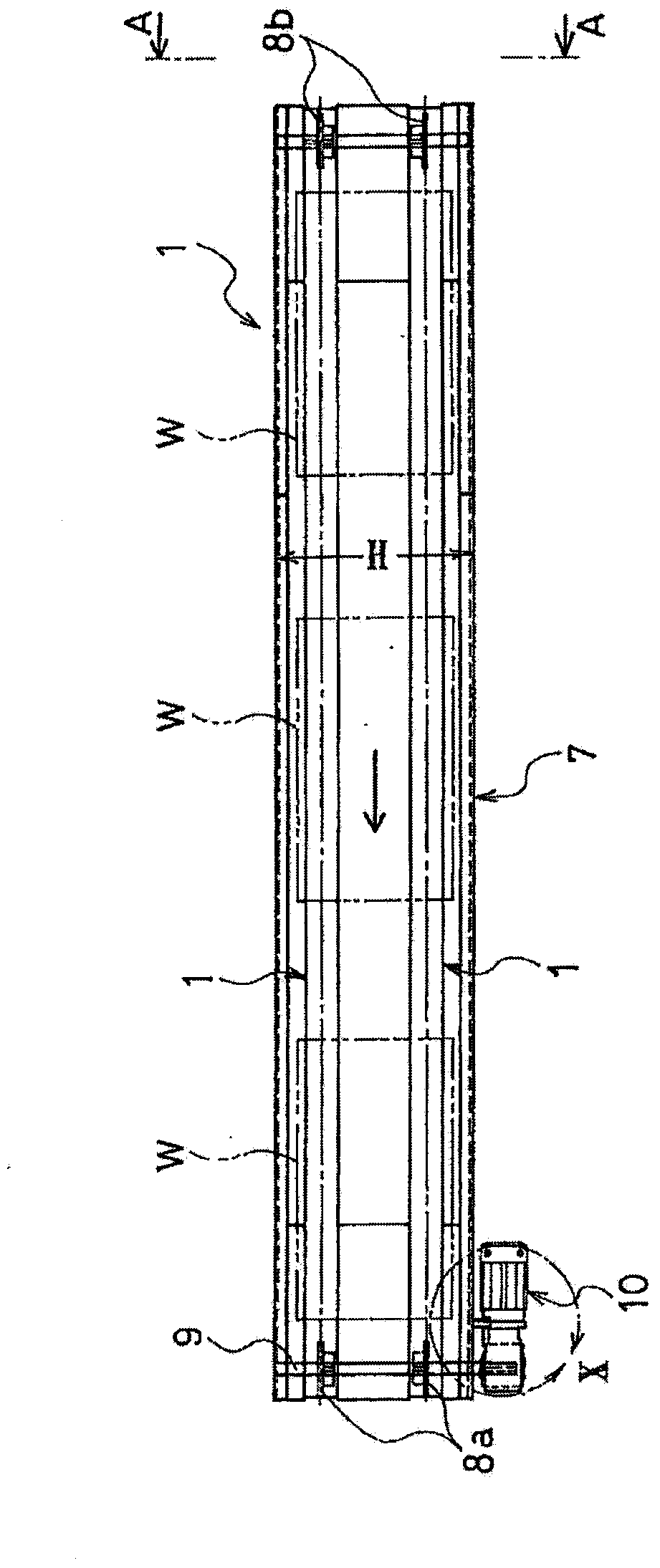

[0026] A scheme embodying the plastics chain conveyor of feature of the present invention is as Figure 1-9 shown. The plastic chain conveyor 1 is mounted on a steep slope (for example with an inclination angle of 30°-60°), but the invention is not limited to steep slopes: it is also possible to mount the conveyor in a horizontal position.

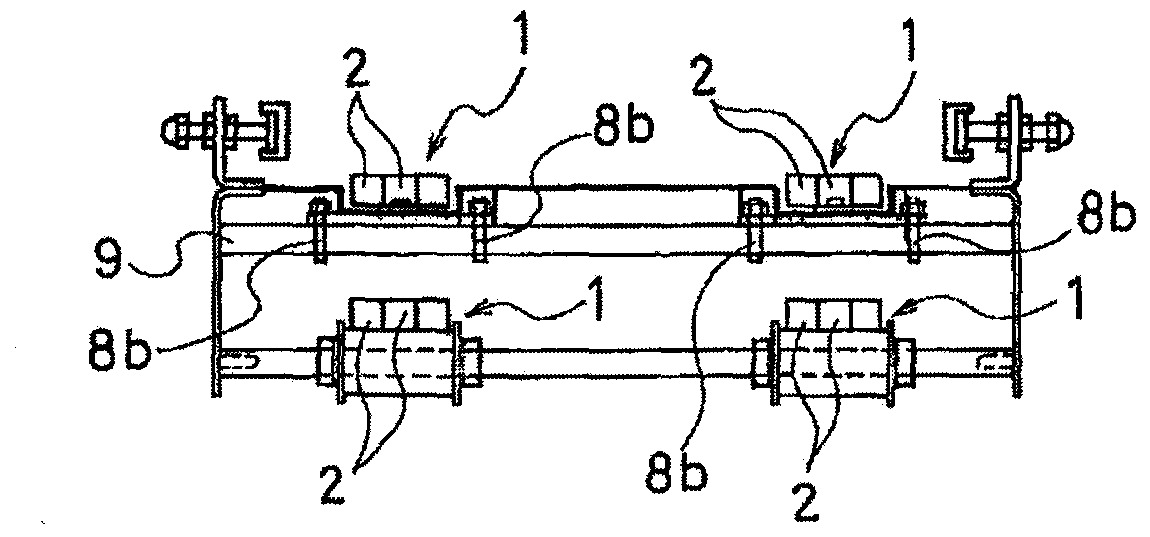

[0027] in such as Figure 5-7 In the shown plastic chain conveyor 1, the front and rear ends 2a, 2b of the plastic chain modules 2 made of plastic material (such as acetal (acetal)) pass through a plurality of plastic connecting pins 3a (such as with round A rod-shaped connecting pin made of nylon with a circular cross-section) and a metal connecting pin 3b (in this example a rod-shaped connecting pin made of a radial bipolar neodymium magnet with a circular cross-section) are rotatably coupled so that Form a predetermined length of endless plastic chain conveyor.

[0028] In the plastic chain module 2 of the plastic chain conveyor 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com