Long cantilever upper pier structure and method for medium and long span steel beam incremental launching construction

A technology of jacking construction and long cantilever, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of lack of jacking method and upper pier, difficult unloading, transportation, high temporary pier cost, etc., to achieve good economy performance and operability, easy access to equipment, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

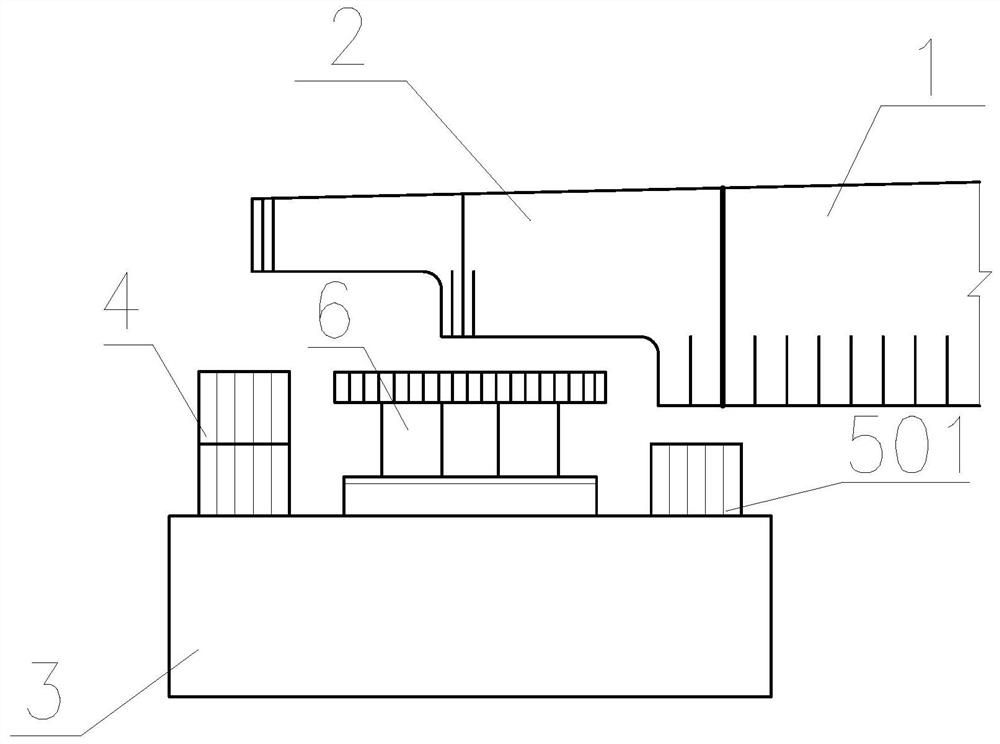

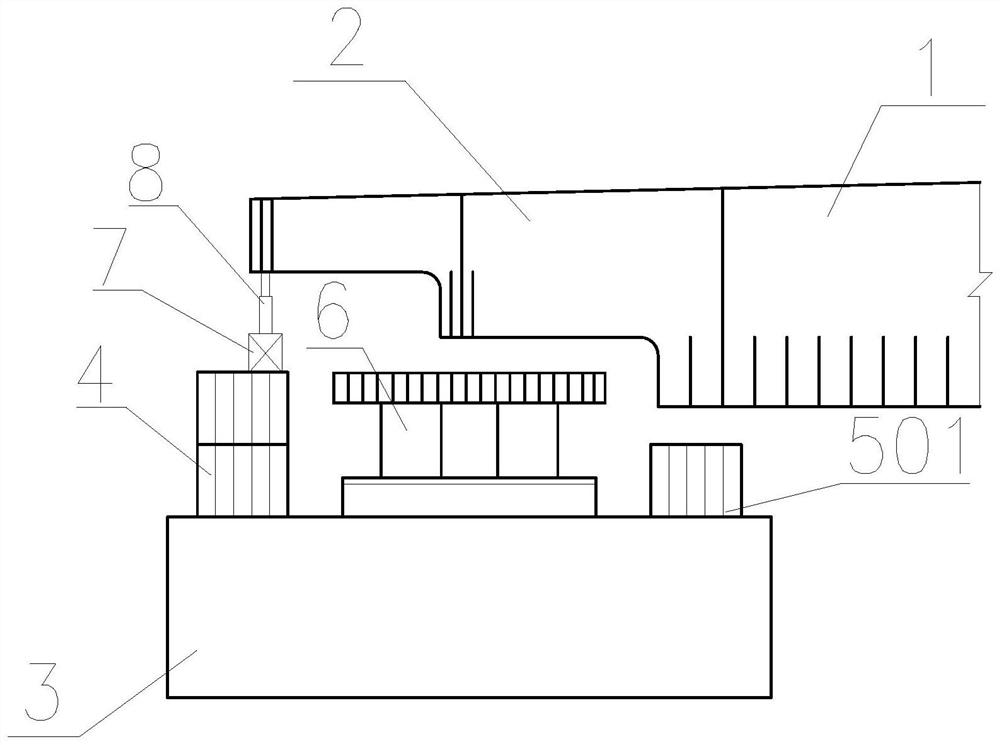

[0034] see Figure 1-6 As shown, in this embodiment, the span of the steel beam 1 is 70m, and the length of the nose bridge 2 is 4m. Its implementation process includes the following steps:

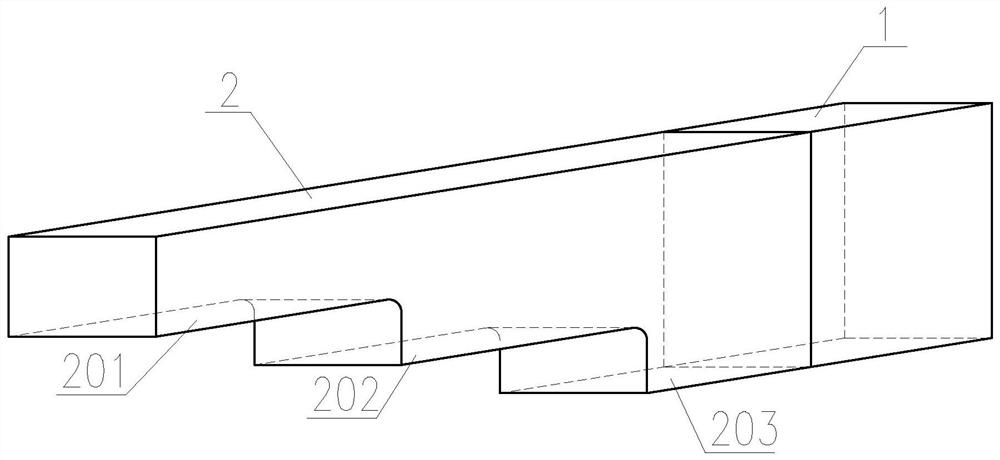

[0035] S1 as figure 1 As shown, a nose bridge 2 is used as an auxiliary structure for the upper pier of the steel beam, and then the setting of the long steel guide beam is banned. In this embodiment, the root section of the nose bridge 2 is the same as that of the steel beam 1, and the height of the nose bridge gradually changes in a trapezoidal shape from the root , three steps are set, the third step 203 of the nose bridge is flush with the bottom of the steel beam, and the roots of the nose bridge 2 and the web of the steel beam 1 are connected by bolt welding to form an integral structure.

[0036] S2 as figure 2As shown, the steel beam 1 with the nose bridge 2 is pushed forward to the front end of the distribution beam 3 on the top of the next pier by using the conventional push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com