Power lead recovery device

A recovery device and power wire technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of affecting work efficiency, increasing the number of times of transportation, and large volume of the take-up reel, so as to improve the work efficiency. Efficiency, reduced work intensity, convenient and fast transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be further described in detail below through specific embodiments.

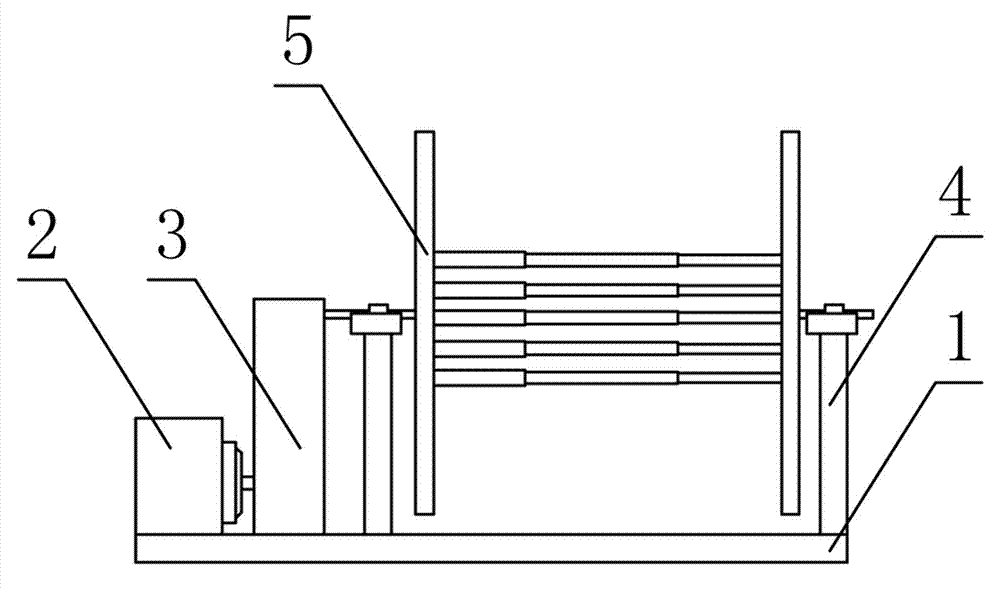

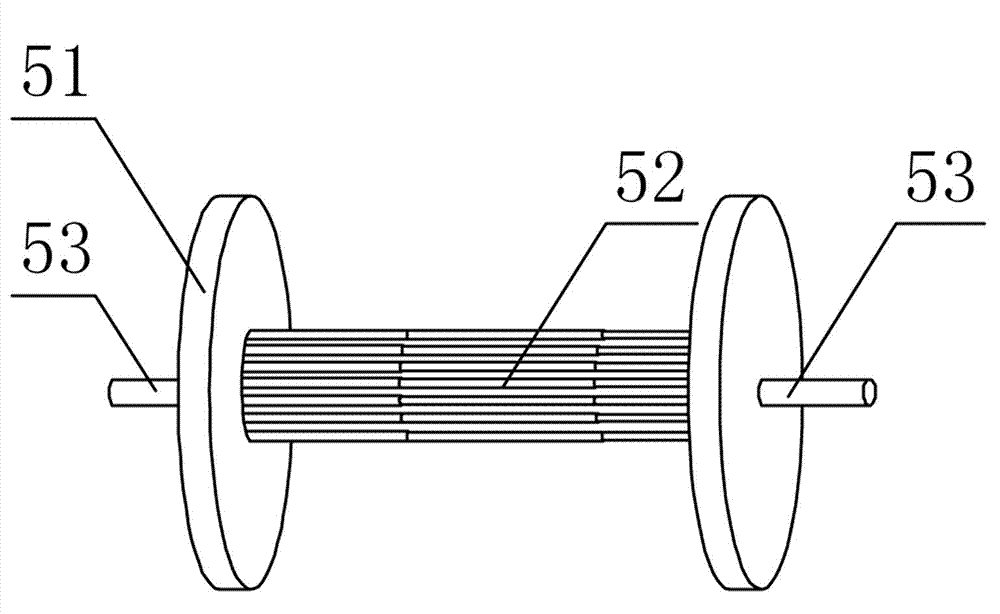

[0012] like figure 1 and figure 2 As shown, a power wire recovery device includes a base 1, a motor 2, a reducer 3, a bracket 4, and a take-up reel 5, wherein the take-up reel 5 includes two circular end plates at both ends of the take-up reel 51. A plurality of round rods 52 and rotating shafts 53 constituting the take-up reel body, the rotating shaft 53 is installed in the middle of the two circular end plates 51, and the round rods 52 are telescopic stainless steel round rods, The two ends of the round rods 52 are respectively arranged on the two circular end plates 51, and the interval between the adjacent round rods 52 is the same; The bracket 4 is arranged on the base 1, one end of the base 1 is fixed with the motor 2, the motor 2 is connected to the rotating shaft 53 of the take-up reel 5 through the reducer 3, and Drive the take-up reel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com