Device for producing microbubble water by using ultrasonic vibrator, cell culture medium containing microbubble water, cell culturing method using same, high efficiency mixed fuel using microbubbles, and method for manufacturing same

A mixed fuel and micro-bubble technology, applied in cell culture medium, biochemical equipment and methods, shaking/oscillating/vibrating mixer, etc., can solve the problems of water and oil separation, mixed oil instability, etc., to achieve uniform size, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Preparation of nano-bubble water

[0101] In order to produce the cell culture fluid according to Example 1, nanobubble water was prepared.

[0102] 1) Preparation of hydrogen nanobubble water

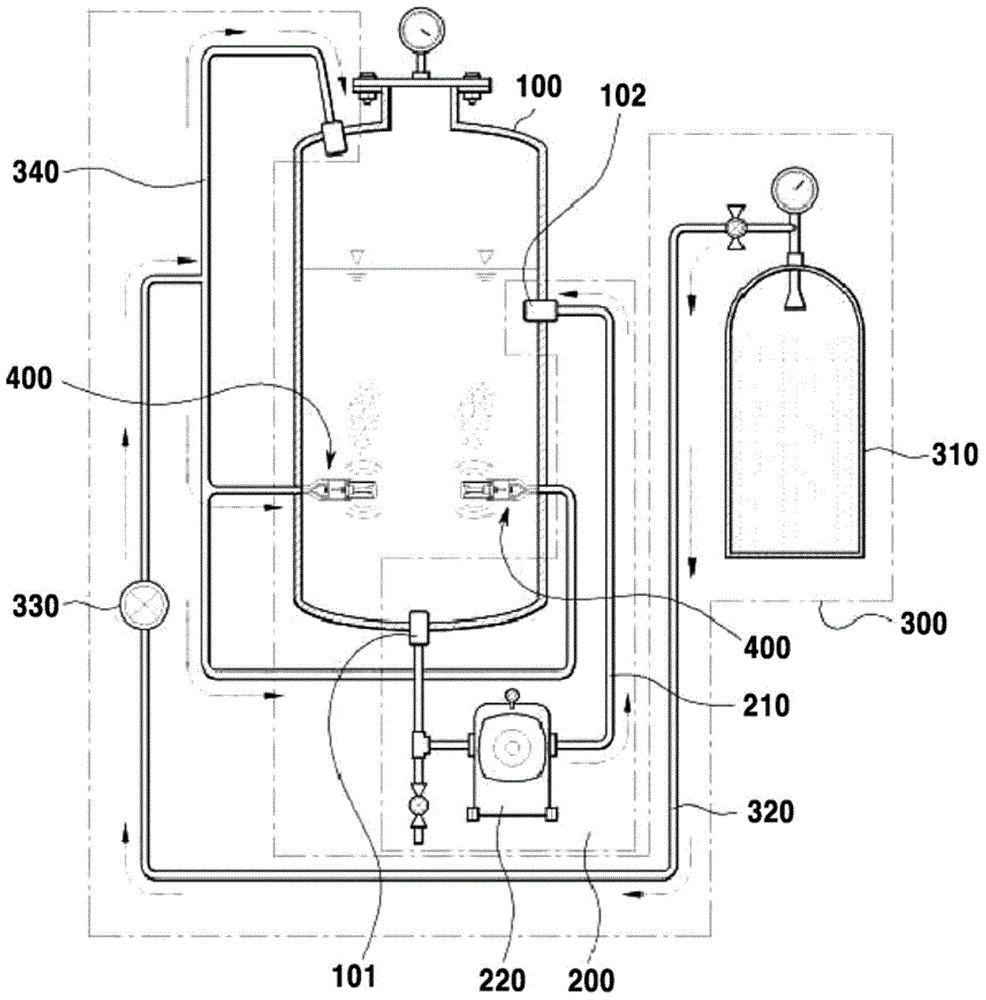

[0103] use as figure 1 The shown apparatus for producing microbubble water using an ultrasonic vibrator and using a microporous filter for injecting gas without applying ultrasonic waves allows hydrogen nanobubble water to be produced by a pressure dissolution method.

[0104] The prepared hydrogen nanobubble water was examined by nanoparticle tracking analysis (NTA, LM10-HSBFT14, UK) method. According to its result, such as Figure 4A and Figure 4B As shown, the hydrogen nanobubbles contained in the hydrogen nanobubble water have an average diameter of about 87 nm, and a concentration of about 2.12×10 17 per about 1 ml.

[0105] 2) Preparation of oxygen nanobubble water

[0106] use as figure 1 The shown apparatus for producing microbubble water using an ultrasonic vib...

Embodiment 2

[0108] cell culture

[0109] In the cell culture method according to Example 2, the four cell lines were divided into the corresponding media and then incubated at 37 °C in 5% CO 2 Cultured in a confluent manner in an incubator. In this case, lung cancer cell A549 (purchased from ATCC) contained 10% FetalClone III (Lonza) and 1% penicillin-streptomycin (MP) in DMEM (Cellgro); CXCR2) containing 10% FetalClone III (Lonza), 1% penicillin-streptomycin (MP), and 600 μg / ml G418 (Cellgro) in DMEM (Cellgro); osteoblast MC3T3 (purchased from ATCC) contained 10% fetal bovine serum (FBS, Lonza) and 1% penicillin-streptomycin (MP) in MEMα modified (HyClone); and fibroblast NIH3T3 (purchased from ATCC) and kidney cells HEK293 (purchased from ATCC) containing 10 % Fetal Bovine Serum (FBS, Lonza) and 1% Penicillin-Streptomycin (MP) in DMEM (Cellgro).

Embodiment 3

[0110] Cell growth and survival analysis

[0111] 1. Cell Growth Analysis

[0112] Cells were detached and subcultured by using trypsin-EDTA (Ix, GibcoBRL). To check cell viability, cells were approximately 4 x 10 4 24-well culture plates and 96-well culture plates were seeded at a cell density of 24 cells / ml, and optical image cell counts were performed. In this case Image-J (Wayne Rasband) was used for cell counts. One day after the cells were inoculated, the cell culture medium was replaced with medium containing 5 volume %, 10 volume %, and 20 volume % of nanobubble water, and the cells were cultured for different periods of time. In this case, nanobubble water was sterilized under UV light and then mixed into the medium. Meanwhile, cells including culture medium were only used as negative controls.

[0113] As a result, as shown in Figure 6, Figure 8 , Figure 10 , Figure 12 ,as well as Figure 14 As shown, it was confirmed that lung cancer cell A549, lung can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com