Prestressed concrete filled steel tube tensile tie beam for preventing displacement of cushion caps and construction method

A technology of steel pipe concrete and construction methods, applied in the direction of basic structure engineering, construction, etc., can solve problems such as the displacement of the horizontal component force of the superstructure and the adverse effects of supporting inclined column building structures, so as to improve the compressive capacity, avoid adverse effects, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

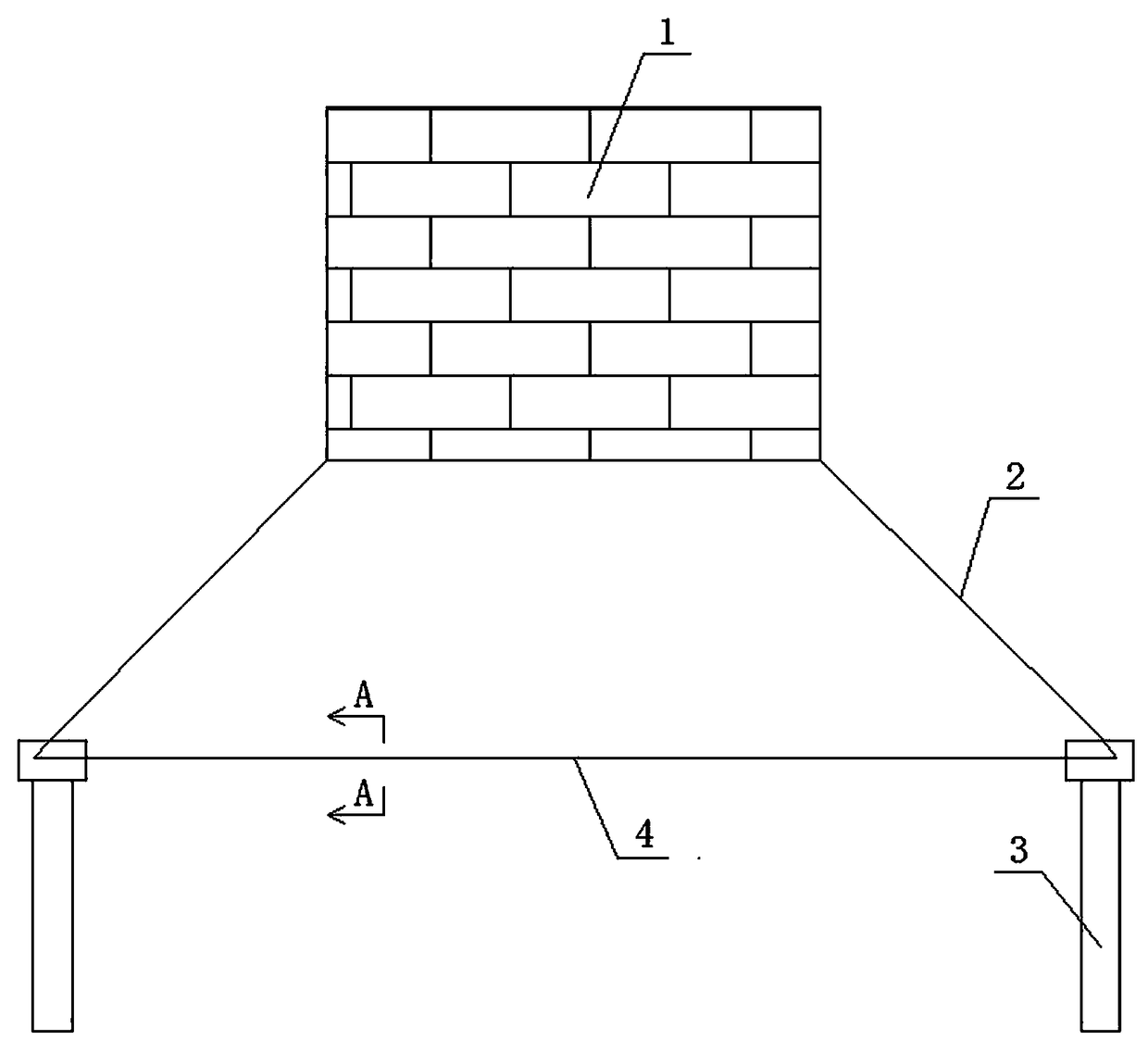

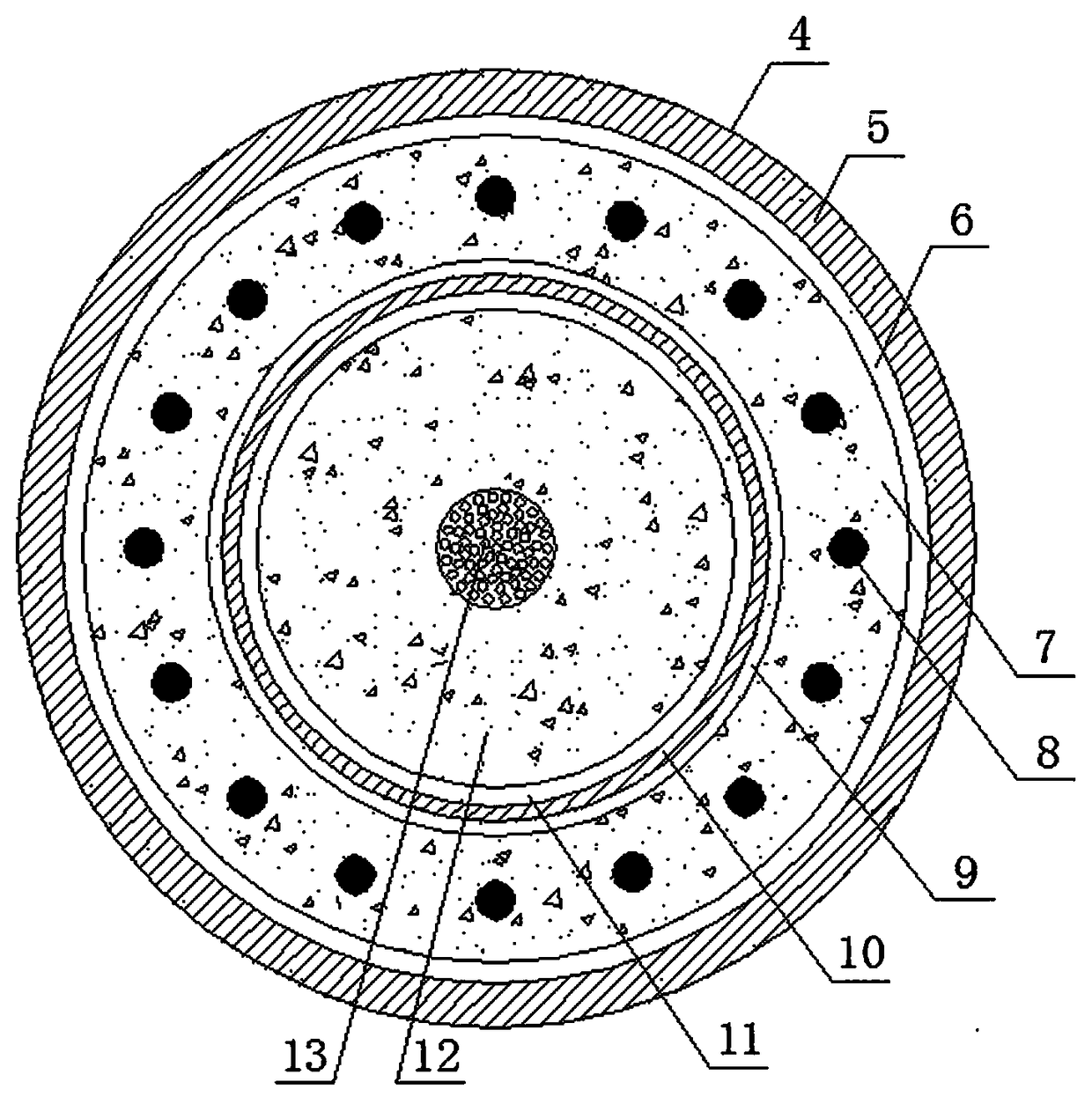

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 2 As shown, a prestressed concrete-filled steel tube tensile tie beam for preventing displacement of caps includes an outer steel tube 5, an inner steel tube 10 is coaxially arranged in the outer steel tube 5, and a prestressed steel beam is coaxially arranged in the inner steel tube 10 13. On the inner wall of the inner steel pipe 10, a first geotextile layer 11 is connected by structural glue, and a concrete protective layer 12 is poured between the first geotextile layer 11 and the prestressed steel bundle 13, and on the outer wall of the inner steel pipe 10 The second geotextile layer 9 is connected by structural glue, and the third geotextile layer 6 is connected by structural glue on the inner wall of the outer steel pipe 5. The compressive concrete layer 7 of the retractive force after the prestressed steel beam 13 is stretched.

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com