Flexible goods shelf warehousing system combined by multiple devices

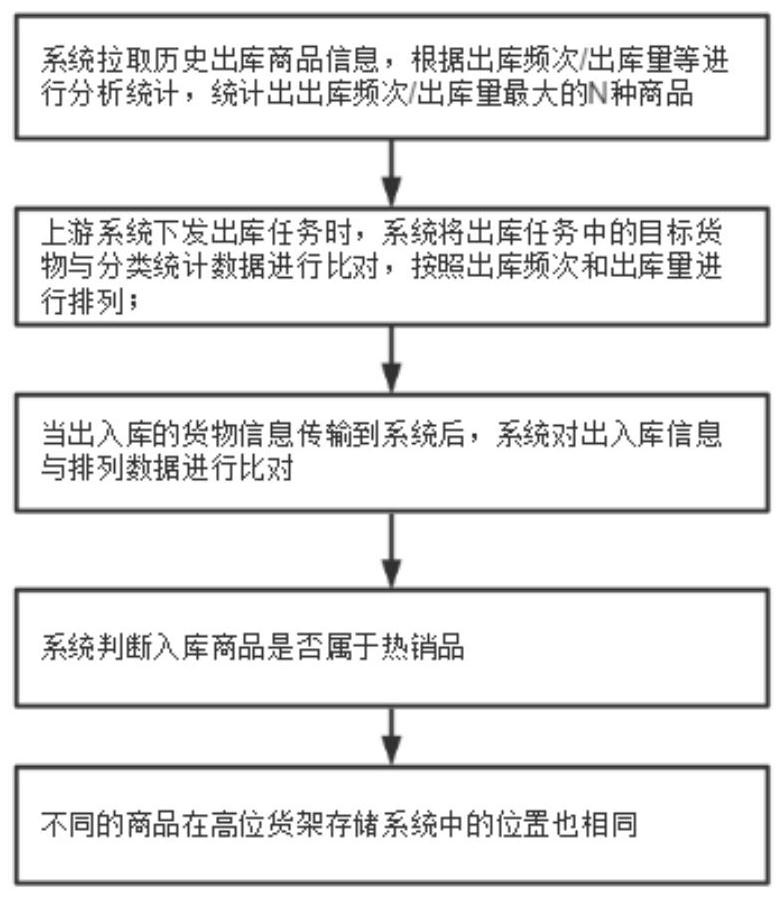

A warehousing system and flexible technology, applied in the field of shelf warehousing systems, can solve problems such as lack of flexibility, insufficient flexibility of on-site automation, and large horizontal displacement, and achieve the effect of improving system flexibility and improving cargo handling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

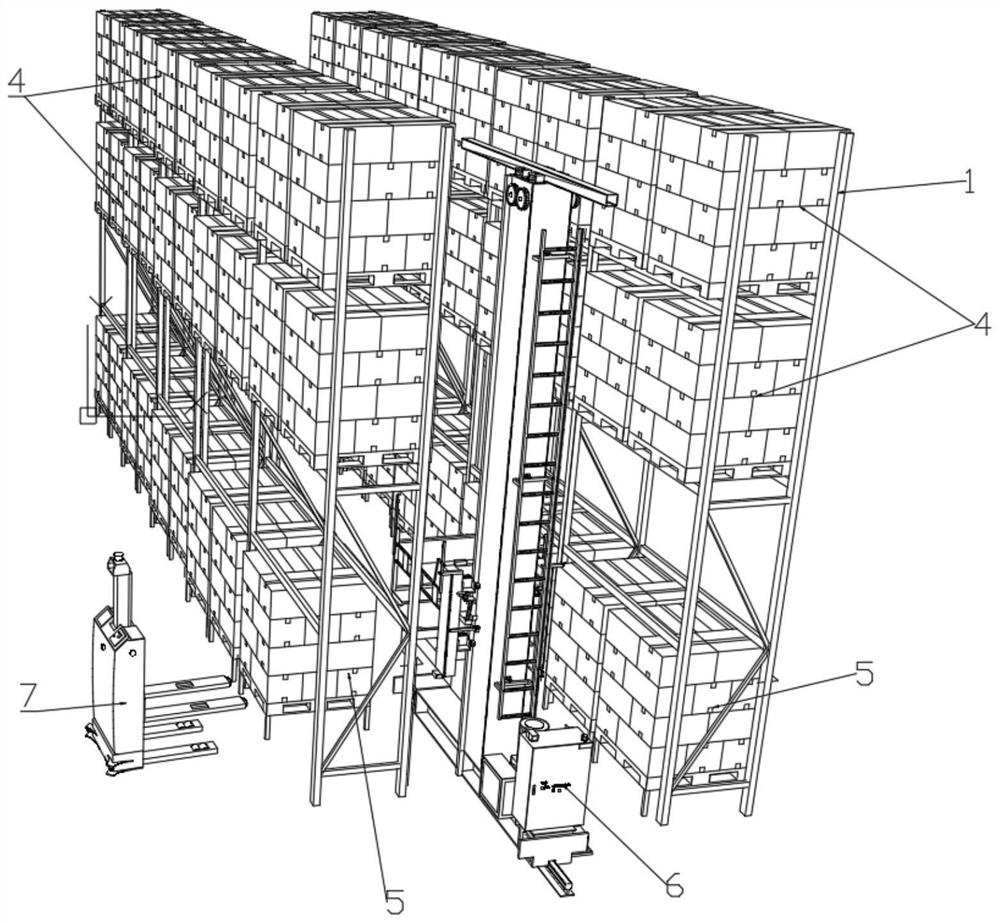

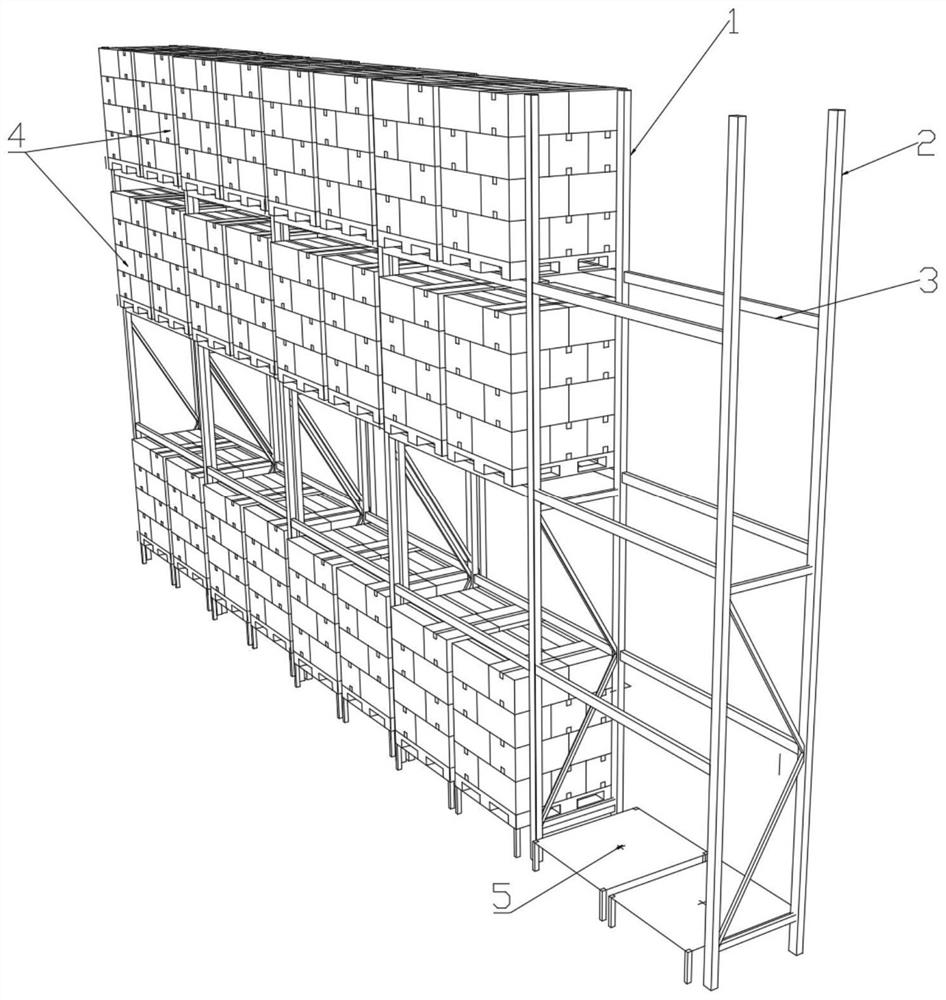

[0034] like Figure 1-Figure 5 shown:

[0035] A flexible shelf storage system with a combination of various equipment, including a high-level shelf 1 and an operation system, the bottom one or more layers of the high-level shelf 1 is a connection position 5, the top of the connection position 5 is a storage position 4, and the high-level shelf 1 One side is provided with a stacker 6 for transporting goods between the storage position 4 and the connecting position 5, and the other side of the high-level rack 1 is provided with a single storage position truck 7 for moving goods on the ground.

[0036] like figure 1 and figure 2 As shown, the high-level shelf 1 includes a plurality of vertically arranged uprights 2, and a plurality of horizontally arranged placement rods 3 are installed between the uprights 2, and the placement bars 3 are provided with pallets for placing goods.

[0037] It is also possible to set a walking layer fixed on the high-level shelf 1 at the positi...

Embodiment 2

[0063] Example 2, as Image 6 As shown, in this embodiment, a multi-storage location truck 8 is selected to replace the single-storage location truck 7, and the multi-storage location truck 8 is suitable for small and medium-sized goods of different types of storage units. The warehousing can carry a plurality of goods, other than that, this embodiment is the same as the other technical solutions of the first embodiment.

Embodiment 3

[0064] Example 3, as Figure 7 As shown, in this embodiment, the lifting robot 9 is selected to replace the single-storage truck 7. The jacking robot 9 is smaller in volume than the single-storage truck 7, and is more flexible, which further avoids being blocked by other transport robots on the transport route.

[0065] In this embodiment, the jacking robot 9 can not only move on the reserved channel, but also can pass through the line of the stacker 6 to realize random movement in the plane.

[0066] In this embodiment, the goods stored on the high-level rack 1 can be any standardized appliance, only a stacker or a forklift or other mobile equipment with a lifting function, a single-storage truck, a multi-storage truck or It is sufficient that the jacking robot or other handling equipment can perform its functions normally.

[0067] The stacker of the invention only needs to transport the commodities from the upper layer to the lower layer, which reduces the horizontal displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com