Novel precast drainable tube pile and preparing construction method thereof

A technology of drainage pipe piles and prefabricated pipe piles, which is applied in the fields of geotechnical engineering and prestressed concrete pipe piles, which can solve problems such as unsatisfactory foundation effects, achieve good foundation treatment effects, slow down soil extrusion effects, and high construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

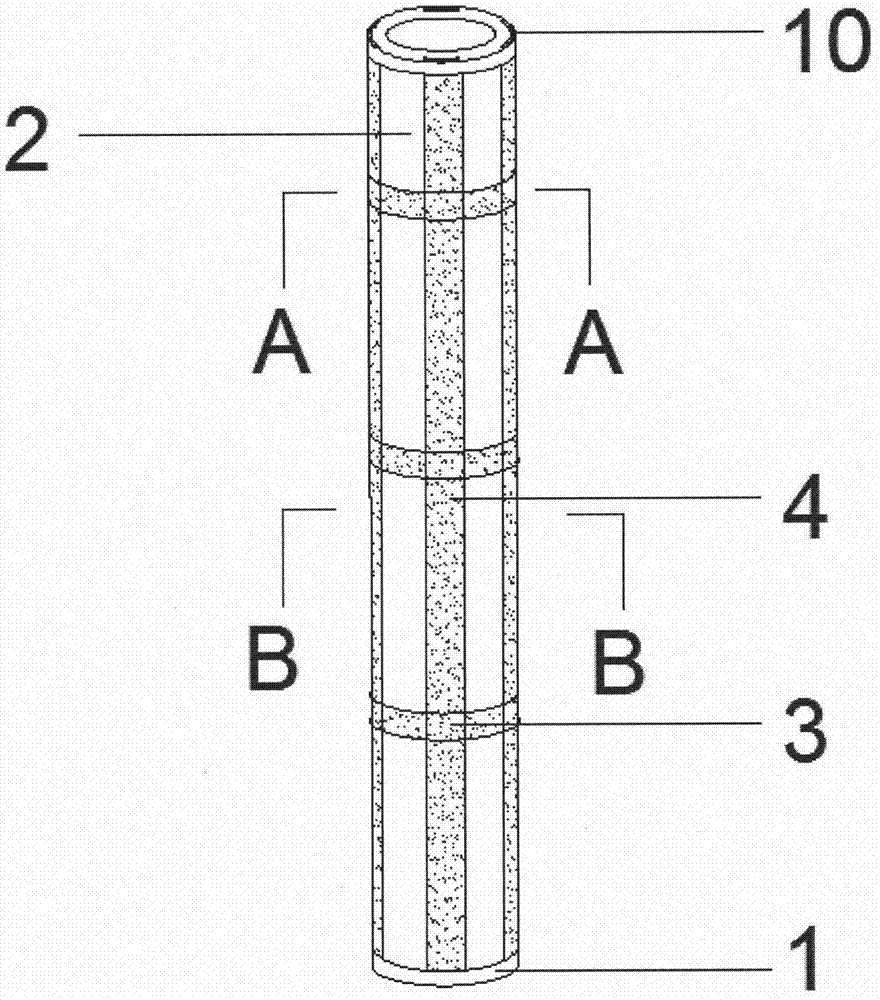

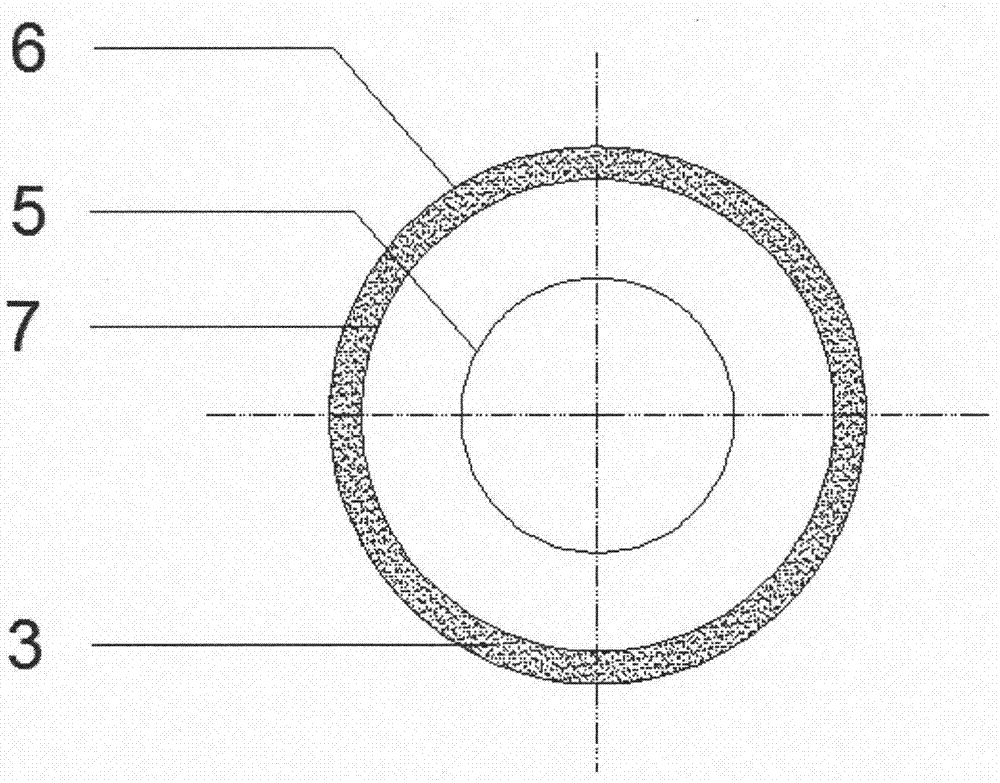

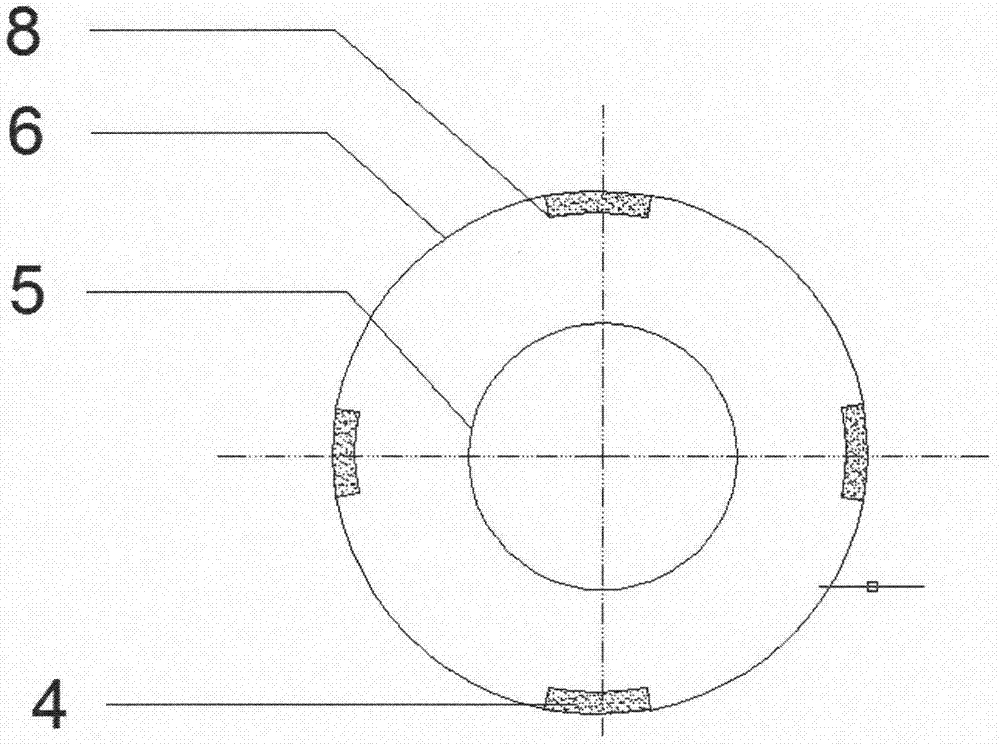

[0023] see Figure 1-6 A new type of prefabricated drainage pipe pile shown includes: a prefabricated pipe pile body, longitudinal and transverse reserved grooves on the surface of the pile, a permeable concrete layer, and corresponding pipe pile end plates. The outer wall of the prefabricated drainage pipe pile body is reserved with horizontal and vertical grooves, the groove width is 50-150mm, the groove depth is 10-20mm, the longitudinal grooves are arranged symmetrically at equal intervals, and the number is an even number. The groove is as long as the pile body, the transverse groove is circular and surrounds the outer wall of the pile body, and the groove is filled with permeable concrete. The permeable concrete filled in the groove is made by mixing 80% of aggregates with a particle size of 1.25-2.5mm and 20% of aggregates with a particle size of 2.5-5mm. The water-cement ratio is 0.3 and an appropriate amount of Early strength agent and water reducer. Correspondingly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com