Patents

Literature

67results about How to "Avoid breakage etc." patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

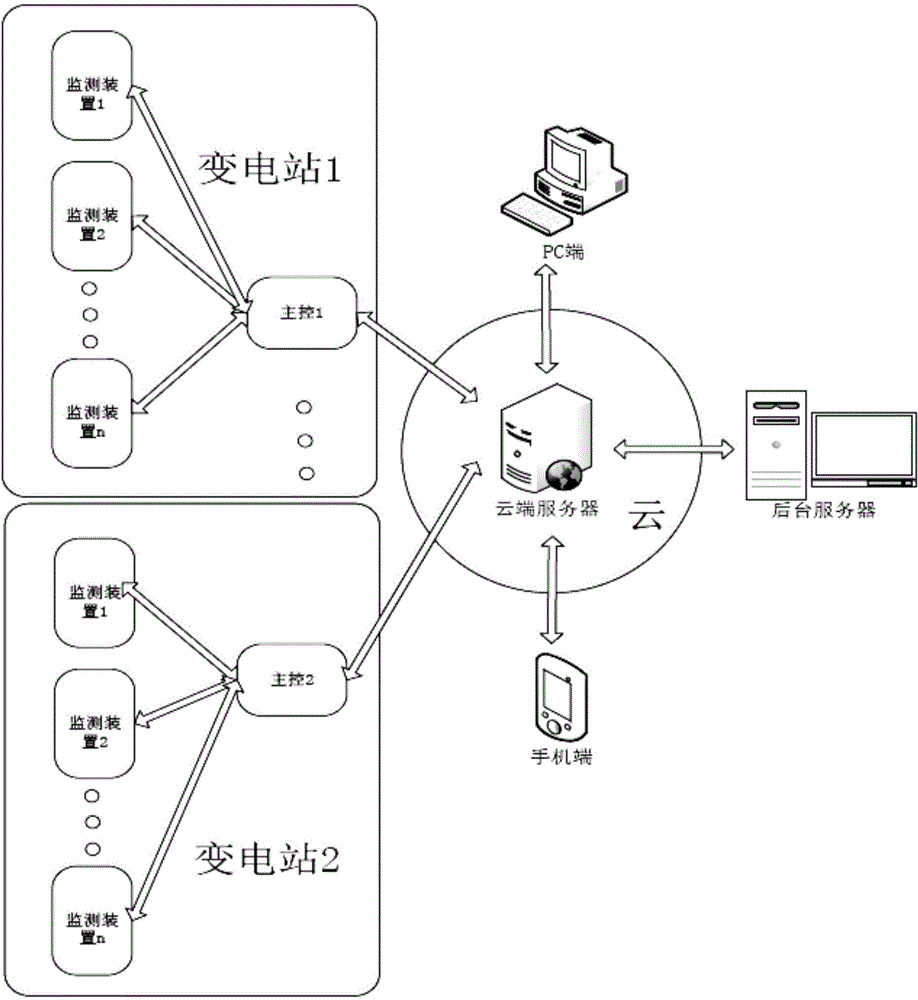

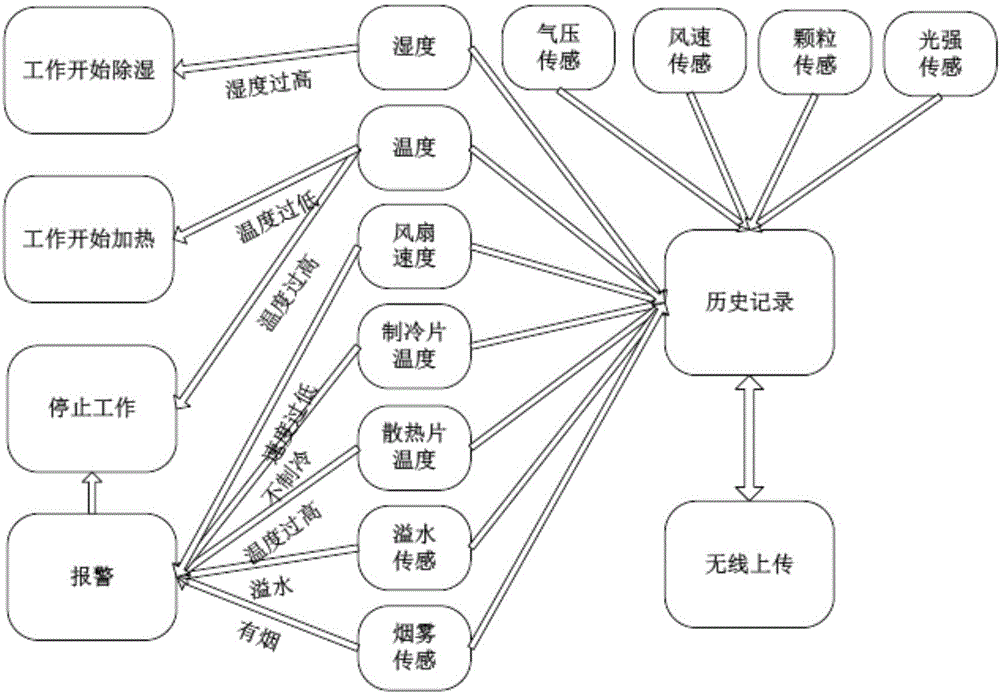

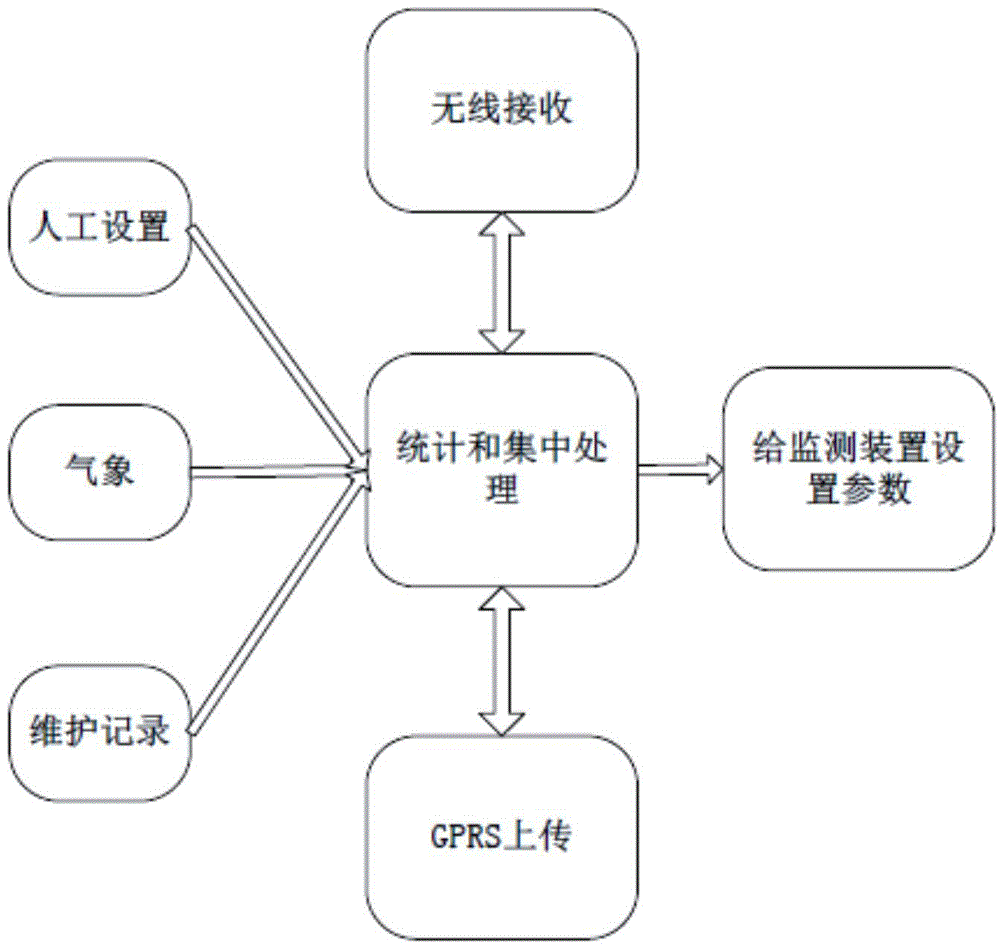

Intelligent electrical equipment environment monitoring system based on cloud computing and big data analysis

InactiveCN104950769AImprove scalabilityReduce construction pressureProgramme controlComputer controlReal-time dataMonitoring system

The invention discloses an intelligent electrical equipment environment monitoring system based on cloud computing and big data analysis. The system comprises a cloud server, an intelligent master control device, monitoring devices and communication equipment communicating with the cloud server, wherein the monitoring devices are used for acquiring related data of an electrical equipment environment and transmitting the data to the intelligent master control device; the intelligent master control device is used for controlling the monitoring devices and transmitting the data received from the monitoring devices to the cloud server; the cloud server is used for receiving and storing the related data of the electrical equipment environment; a user accesses the cloud server through a mobile phone or a computer and then controls the master control device and the monitoring devices remotely. The system depends on cloud computing to perform big data analysis on online meteorological information, real-time data and historical data, intelligently monitors the monitoring devices of all nodes, evaluates the monitoring effectiveness, analyzes potential risks effectively and solves problems by which people are puzzled for many years about outdoor electrical equipment microenvironments, online micrometeorology monitoring, real-time intelligent control and the like.

Owner:JIANGSU LIDE INTELLIGENT MONITORING TECH CO LTD

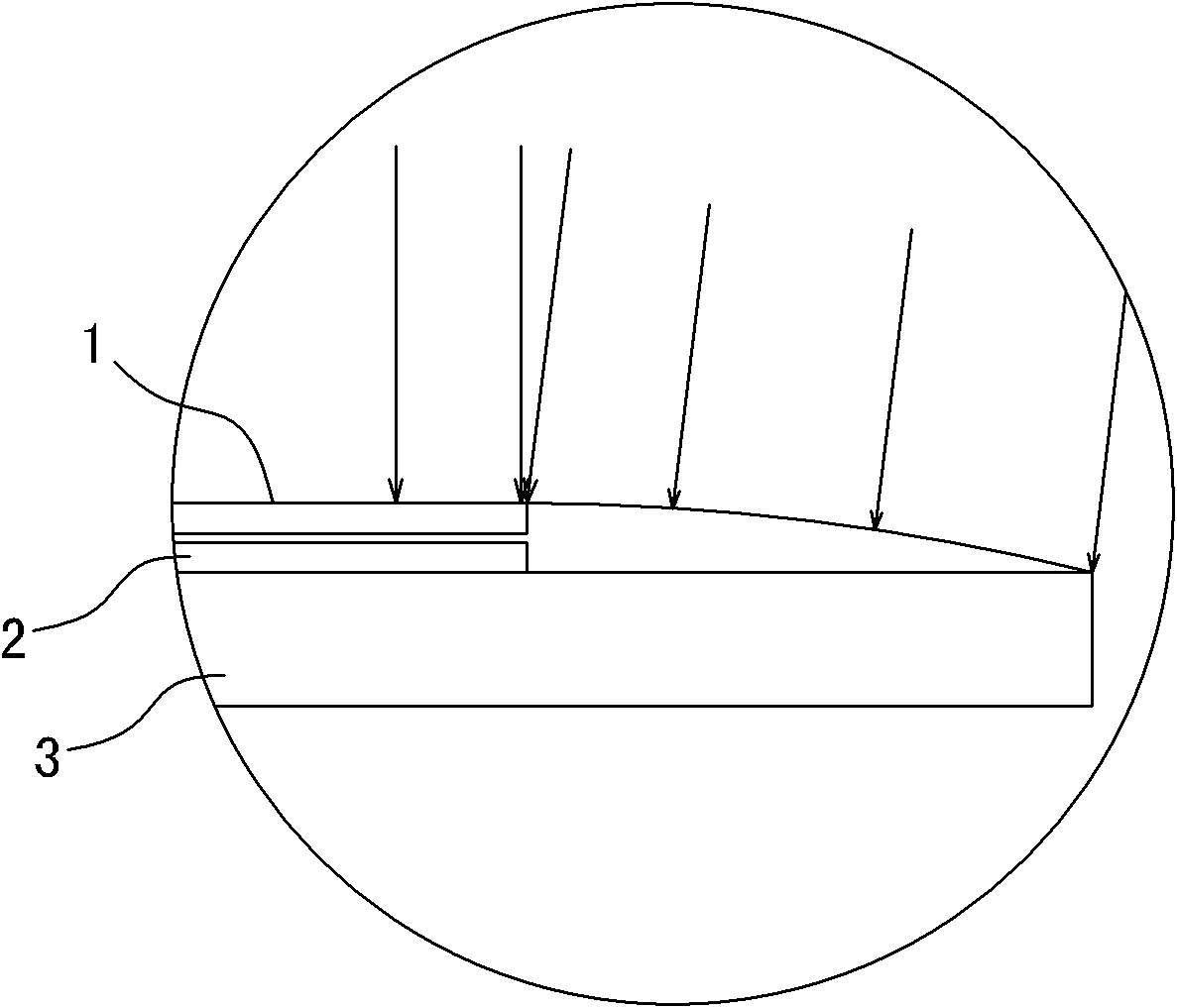

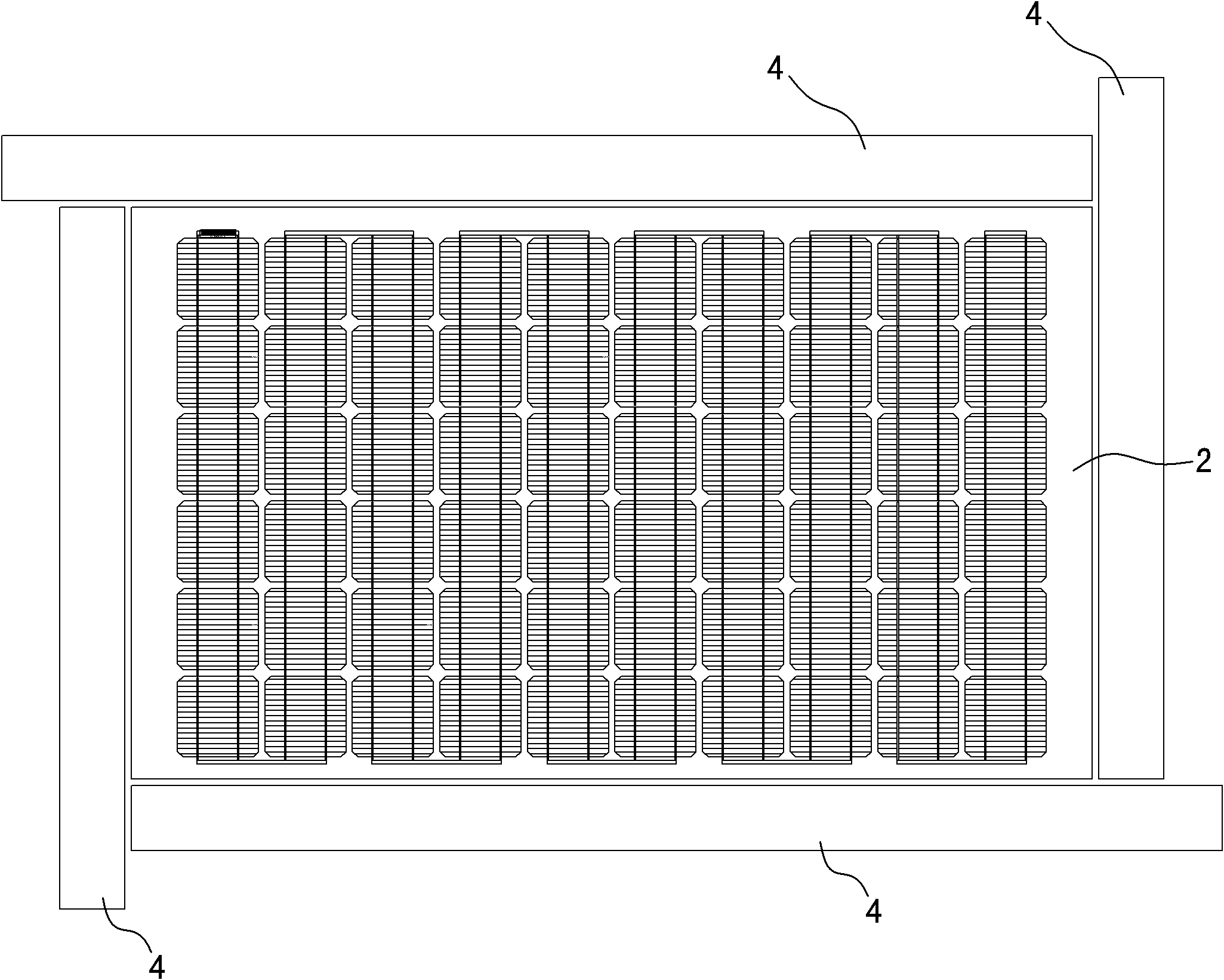

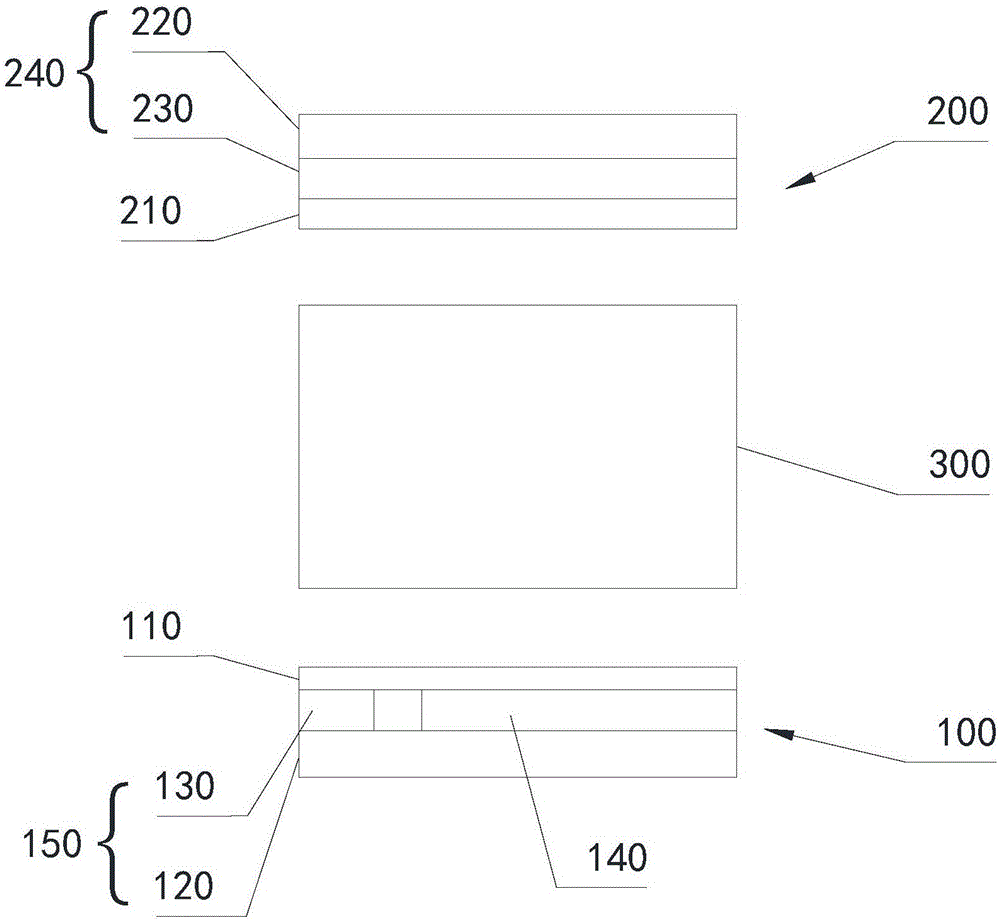

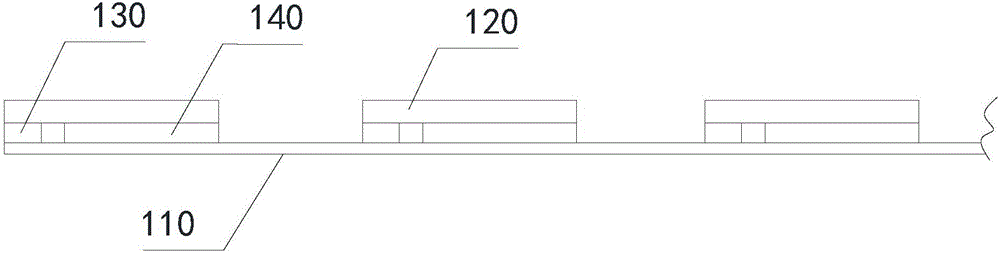

Method for laminating solar battery module

ActiveCN102152594AAvoid degummingImprove yieldFinal product manufactureLaminationCushioningEngineering

The invention discloses a method for laminating a solar battery module, which comprises the following steps of: (1) firstly, laying non-adhesive cloth on a heating table of a laminator; (2) secondly, placing the laminated semi-product of the solar battery module on the non-adhesive cloth on the heating table; (3) thirdly, providing four cushioning bars on the four sides of the semi-product of the solar battery module, wherein the distance from each cushioning bar to the edge of the semi-product of the solar battery module is 10 to 20mm; (4) fourthly, laying non-adhesive cloth on the semi-product of the solar battery module and the cushioning bars; and (5) fifthly, vacuuming, warming and pressurizing the materials into a whole in the cavity chamber of the laminator to obtain the solar battery module. In the laminating process, the concentrated stress points are transplanted to the cushioning bars, so that the phenomena of adhesive failure, bubbling, battery sheet displacement, module damage and the like are avoided; the yield is improved; and the production cost is greatly reduced.

Owner:CSI SOLAR POWER GROUP CO LTD +1

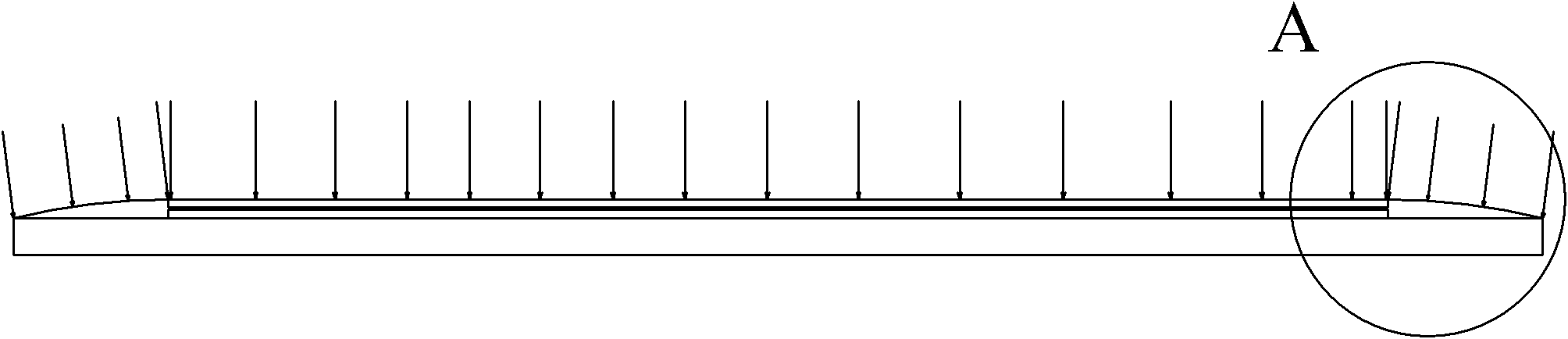

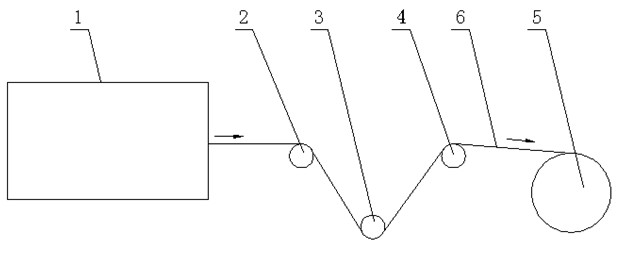

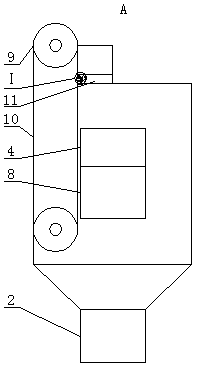

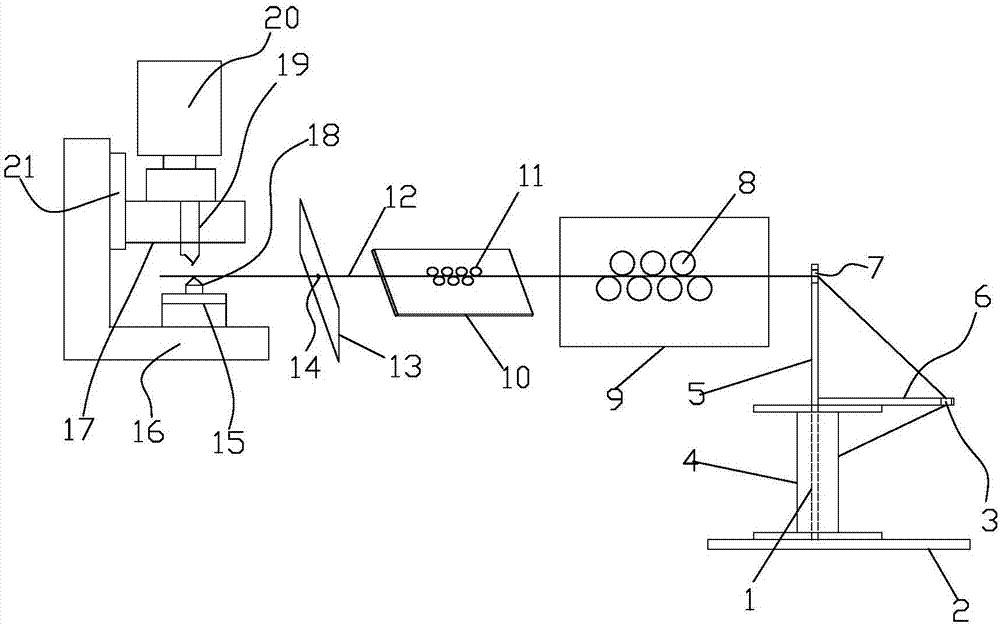

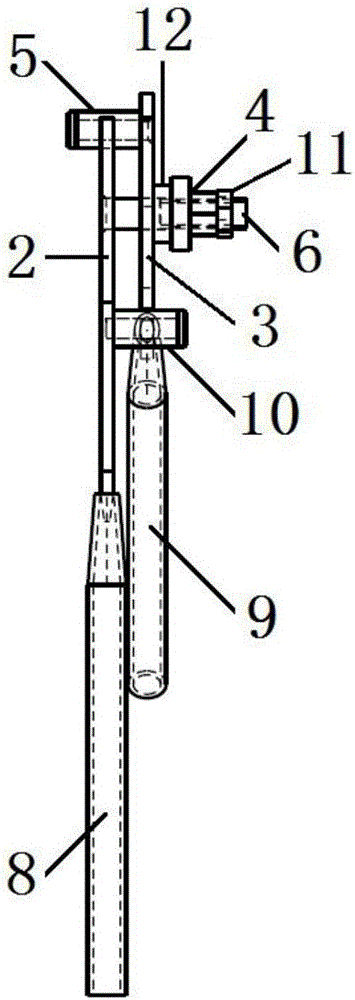

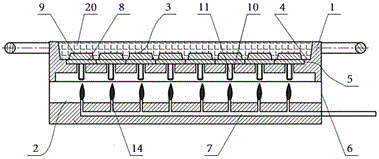

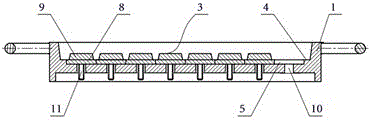

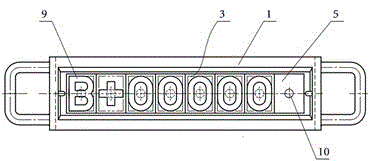

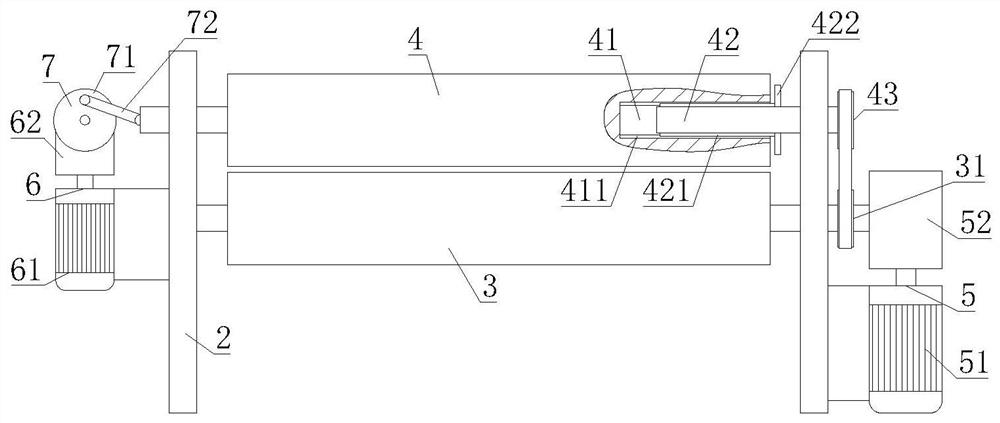

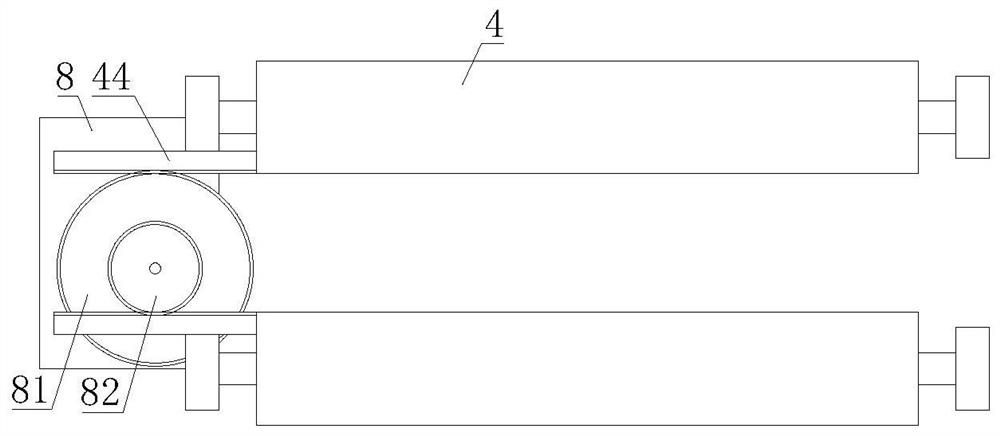

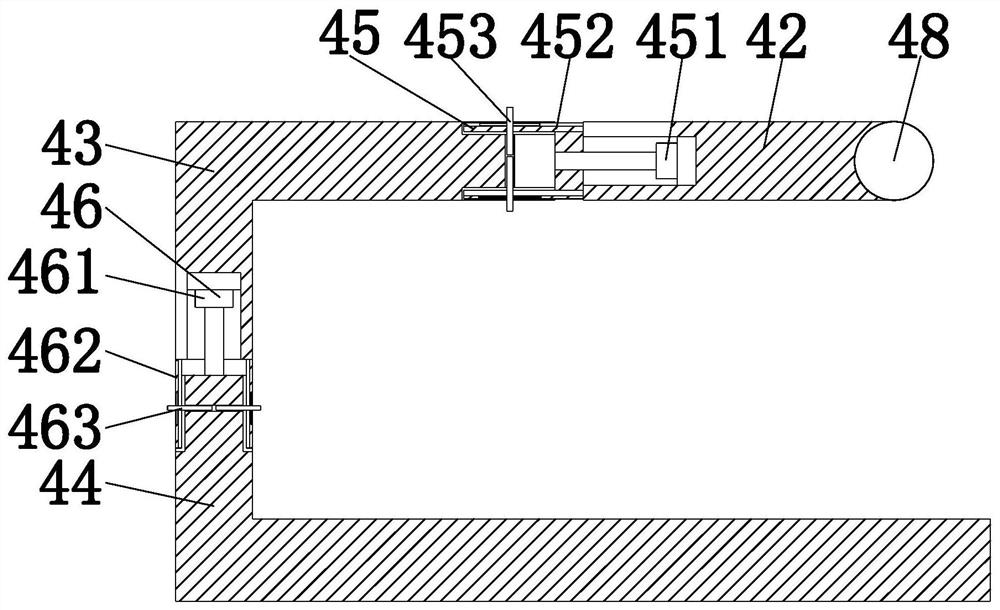

Buffering device for producing optical cables

InactiveCN106927294AAvoid breakage etc.Function indicatorsWebs handlingEngineeringMechanical engineering

The invention discloses a buffering device for producing optical cables. The buffering device comprises a machine frame, sliding blocks, a first guide roller, a second guide roller, first magnetic force blocks and second magnetic force blocks, wherein the machine frame is provided with sliding rails; each sliding block is movably matched with the corresponding sliding rail; the first guide roller is rotatably mounted on the machine frame; the second guide roller is rotatably mounted on the sliding blocks; the first magnetic force blocks are mounted on the machine frame; the second magnetic force blocks are mounted on the second guide roller or the sliding blocks; each first magnetic force block is mutually matched with the corresponding second magnetic force block; and through magnetic force, the second guide roller has movement tendency of being away from the first guide roller. According to the buffering device disclosed by the invention, each sliding block is movably matched with the corresponding sliding rail, and the second guide roller is rotatably mounted on the sliding blocks, so that when the tension of a metal belt is changed, the second guide roller can move, the distance between each first magnetic force block and the corresponding second magnetic force block can also be changed, the magnetic force is changed until the magnetic force and the tension are rebalanced, in the process, the stress of the metal belt is slowly changed, and the occurrence of situations of cracking and the like caused by too large instantaneous stress in the prior art can be effectively avoided.

Owner:HANGZHOU FUTONG COMM TECH CO LTD

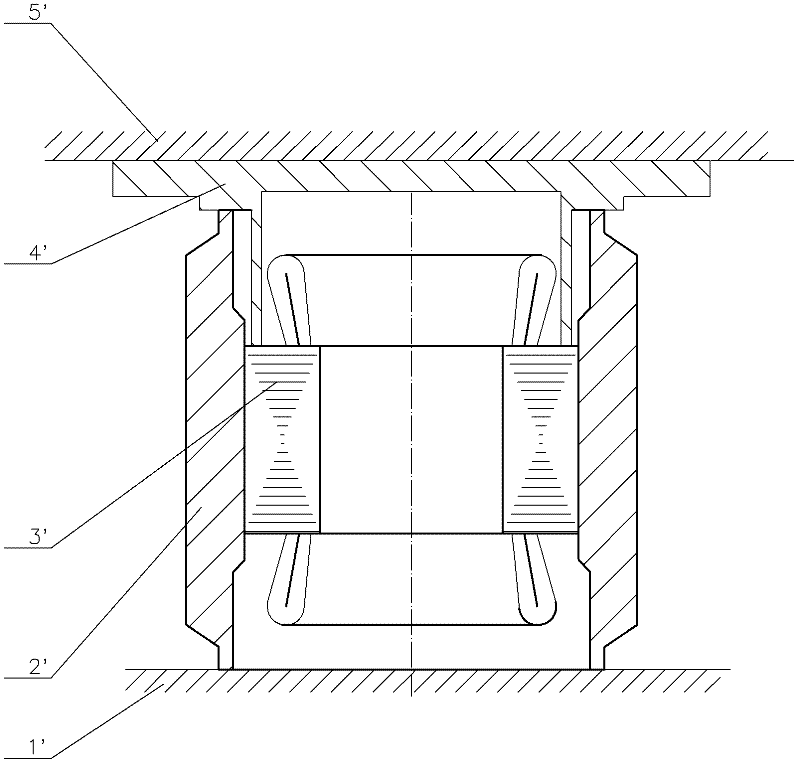

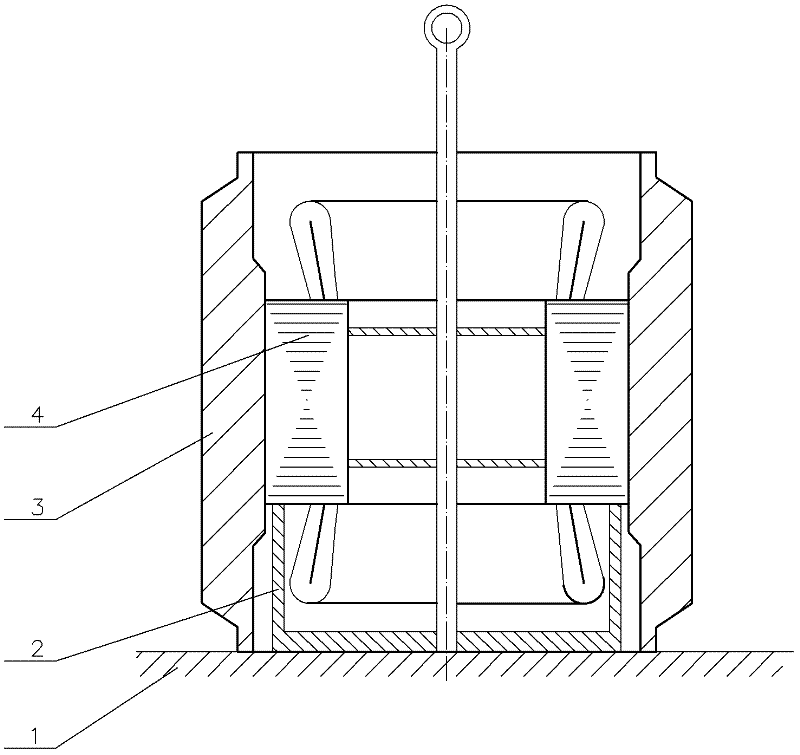

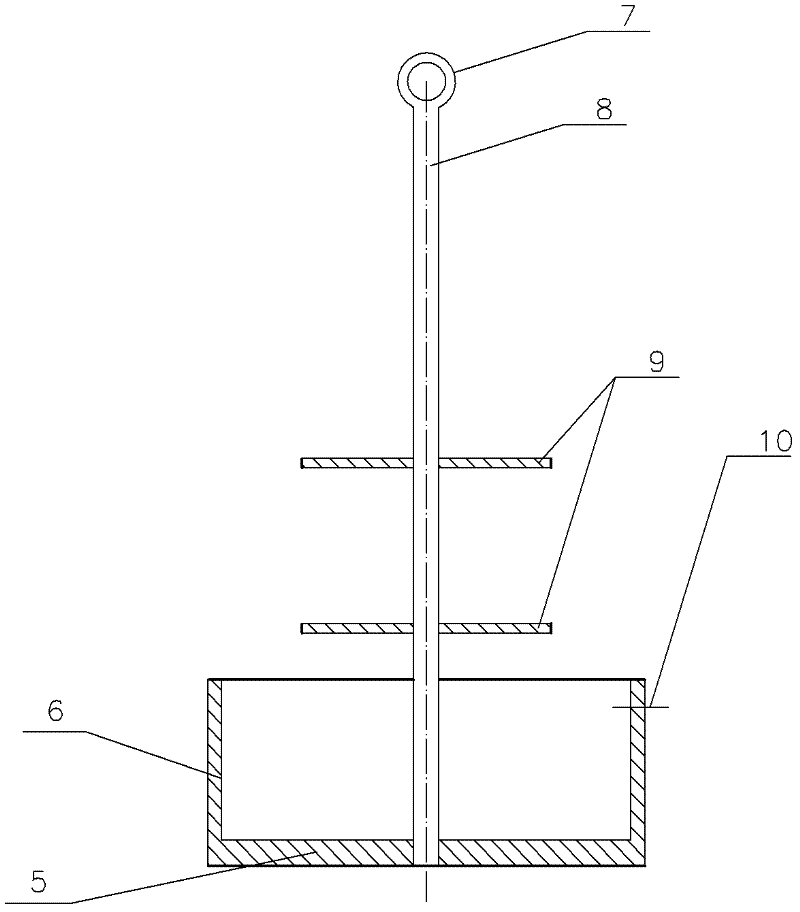

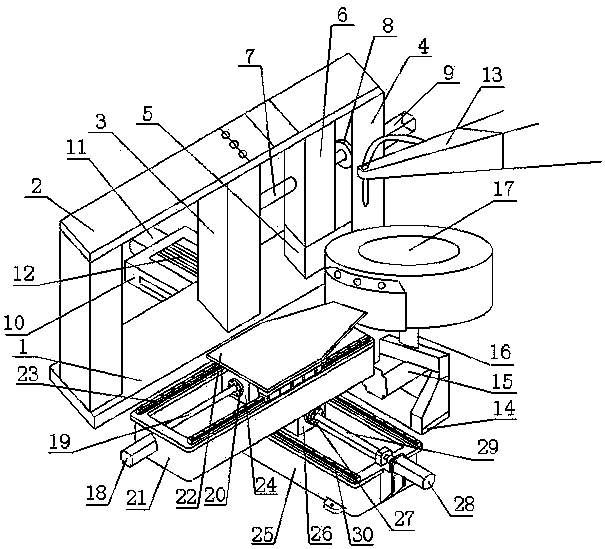

Motor stator assembling apparatus and assembling method

InactiveCN102315729ASimple structureLow investment in equipment and toolingManufacturing stator/rotor bodiesScrew jointEngineering

A motor stator assembling apparatus and an assembling method are disclosed. Current motor stator assembling has the following problems: a special press and a hoisting fixture are needed; costs are high; during a pressing process, coil damage or engine base rupture can be easily caused. The motor stator assembling apparatus comprises: a supporting bar, which is provided with a circle on a top; a disc-shaped base plate, which is vertically connected with the supporting bar; a supporting cylinder, which is connected with an outer ring of a seat board; a complex number of locating plates, which are connected with the supporting bar. A middle part of the base plate is connected with a lower end of the supporting bar. The locating plates are parallel to the base plate. The supporting cylinder is arranged above the base plate. The locating plates are arranged above the supporting cylinder. A screw hole, which is used for a screw joint hoisting ring, is arranged on an outer wall of the supporting cylinder. By using a technical scheme of the invention, the coil damage or the engine base rupture can be avoided. The motor stator assembling apparatus possesses a simple structure and good versatility. Equipment and tooling input is low. The special hoisting fixture does not need. The costs are low.

Owner:WOLONG ELECTRIC GRP CO LTD +1

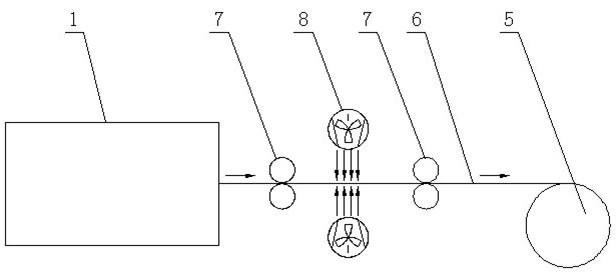

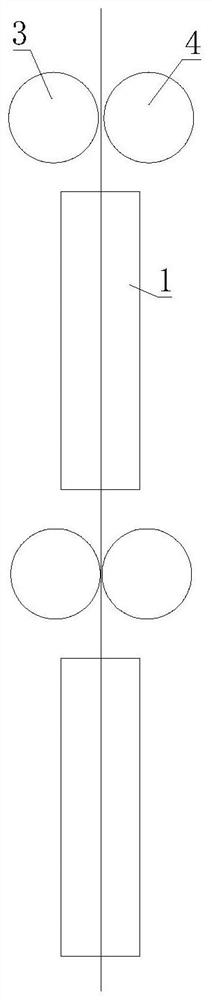

Winding device for ultrathin metal lithium strip

The invention discloses a winding device for an ultrathin metal lithium strip. The device comprises a winding machine and two pairs of pinch rollers, wherein the two pairs of pinch rollers are parallelly arranged; and one pair of pinch rollers is connected with the die orifice of a metal lithium strip extruder, and the other pair of pinch rollers is connected with the winding machine. The two pairs of pinch rollers are arranged in front of the winding machine and used for controlling the tension of the metal lithium strip, and the metal lithium strip can be uniformly stressed during winding and cannot be subjected to overhigh stress during roll changing, so that the ultrathin metal lithium strip can be smoothly wound, and the phenomena that the ultrathin metal lithium strip is subjected to tensile deformation or broken during winding or roll changing are avoided; and in addition, the pinch rollers are water-cooled rollers, and a forced cooling device is arranged between the two pairs of pinch rollers and used for cooling the metal lithium strip which flows out of the die orifice of the metal lithium strip extruder, so that the strength of the cooled metal lithium strip is increased, and the phenomena that the metal lithium strip is subjected to tensile deformation or broken during winding or roll changing are avoided.

Owner:CHONGQING UNIV

Moisturizing shampoo composite

InactiveCN101536965AAvoid thickeningAvoid yellowingCosmetic preparationsHair cosmeticsSodium acetateCoconut oil

The invention relates to a moisturizing shampoo composite. In addition to water, the moisturizing shampoo composite comprises: (A) composite of laurinol ammonium sulphate and laurinol polyoxyethylene ether ammonium sulphate accounting for 5-40 percent of the weight of the moisturizing shampoo composite; (B) composite of coconut oil sodium acetate and cocamidopropyl betaine accounting for 1.0-10.0 percent of the weight of the moisturizing shampoo composite; (C) maleic acid castor grease accounting for 0.05-1.0 percent of the weight of the moisturizing shampoo composite; (D) cationic polymer accounting for 0.05-3.0 percent of the weight of the moisturizing shampoo composite; and (E) cation surface active agent accounting for 0.25-6.0 percent of the weight of the moisturizing shampoo composite.

Owner:LAFANG CHINA CO LTD

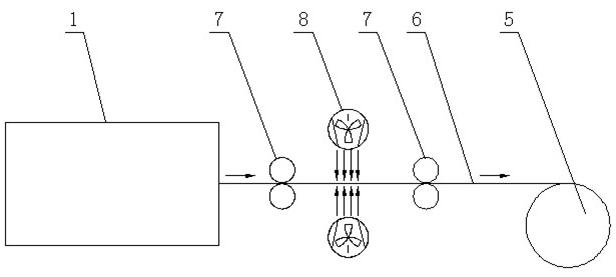

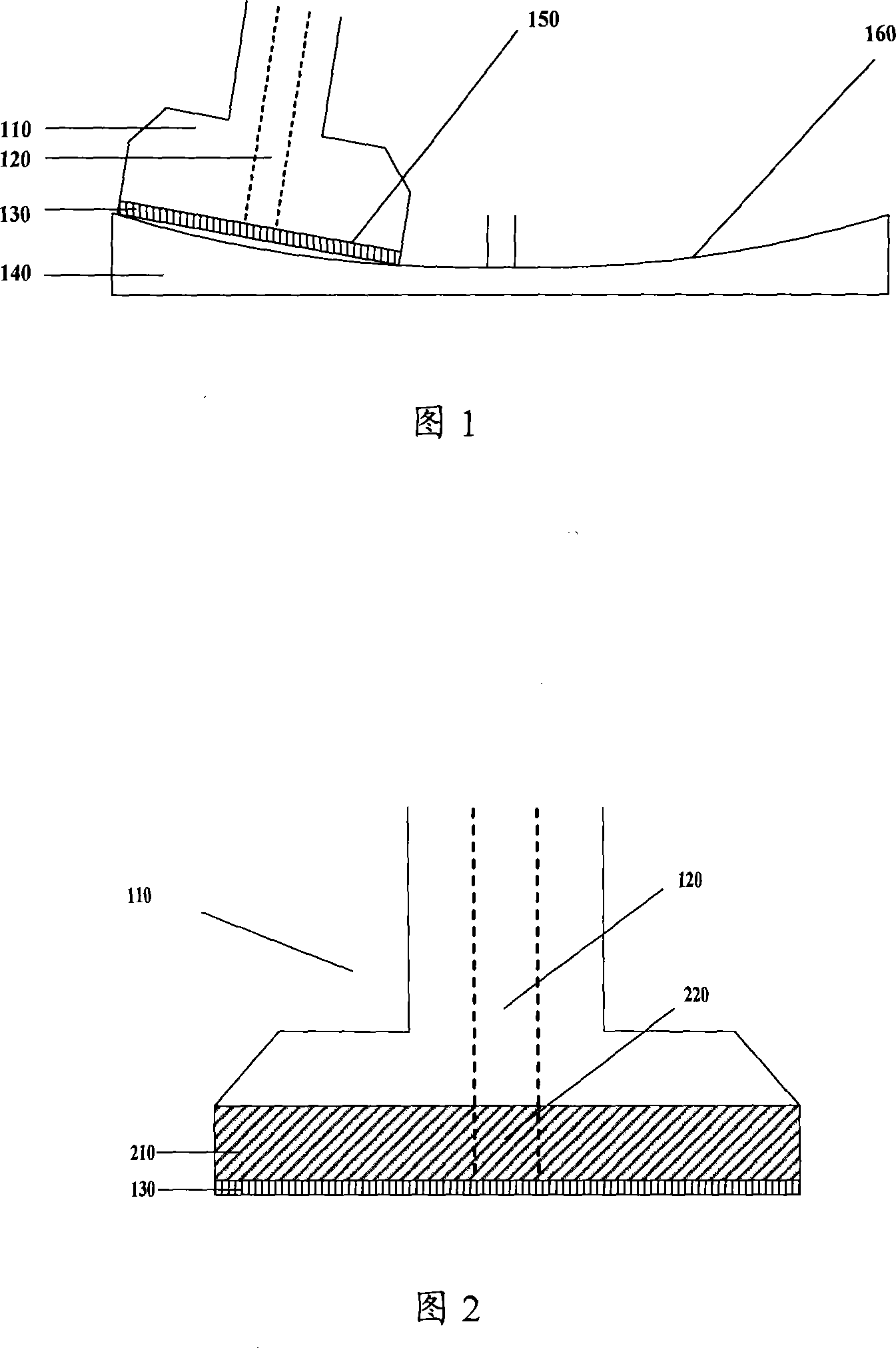

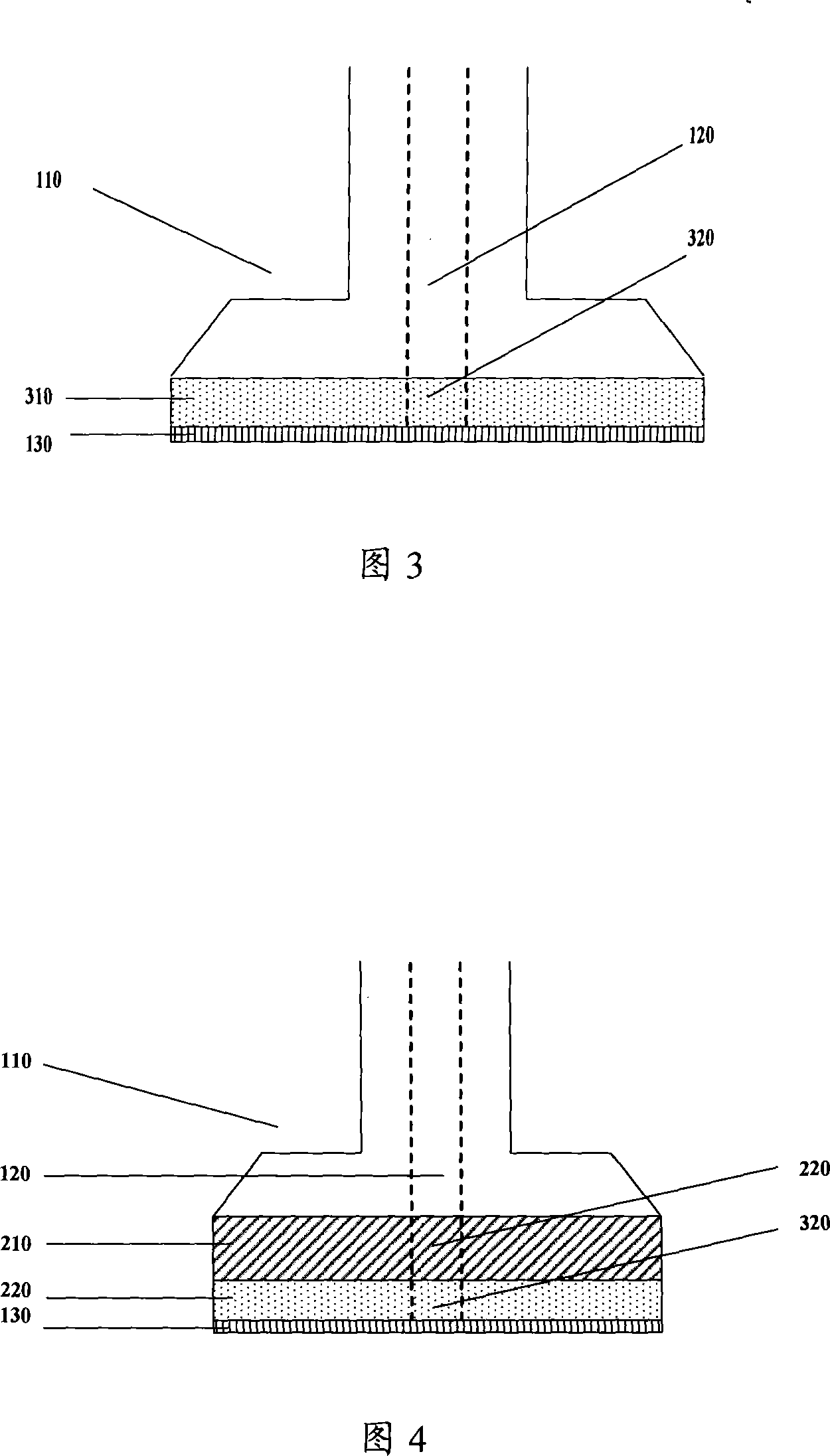

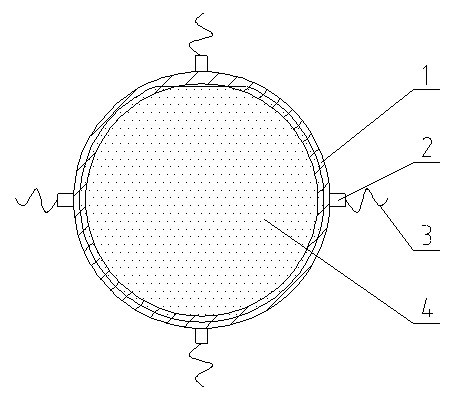

Angle lapping device for silicon chip edge

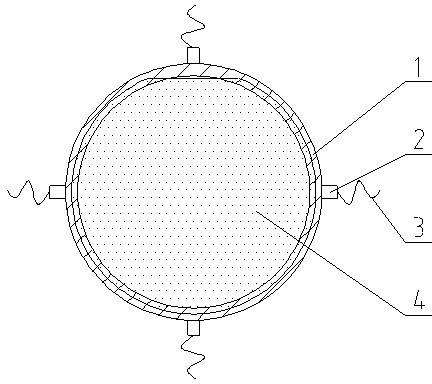

InactiveCN101214625AAvoid breakage etc.Low costEdge grinding machinesGrinding machine componentsCushioningSilicon chip

The present invention relates to a bevelling device of the edge of a silicon chip. The present invention comprises a wheelhead and an abrading disk; the lower surface of the wheelhead is of a circular plane, and a vacuum pipeline arranged in the wheelhead can absorb the silicon chip on the outer layer of the lower circular surface of the wheelhead; the wheelhead also comprises a magnet layer and a cushioning layer, and the magnet layer and the abrading disk generate magnetic attraction which ensures that the silicon chip is uniformly stressed; the cushioning layer ensures that the silicon chip and the wheelhead are tightly combined together and not injured by collision. The upper surface of the abrading disk is provided with a concave surface, in the process of bevelling, the silicon ship is absorbed by the wheelhead to be contacted with the concave surface of the abrading disk, the wheelhead and the abrading disk relatively rotate, and meanwhile, the edge of the silicon chip is bevelled on the abrading disk. The present invention resolves the problems that the traditional manual bevelling operation process is inaccurate, errors can be easily produced, and the bevelled mesa is uneven, so the present invention ensures that the operation is simple, the accuracy is improved, the cost is greatly saved, and the efficiency is increased.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

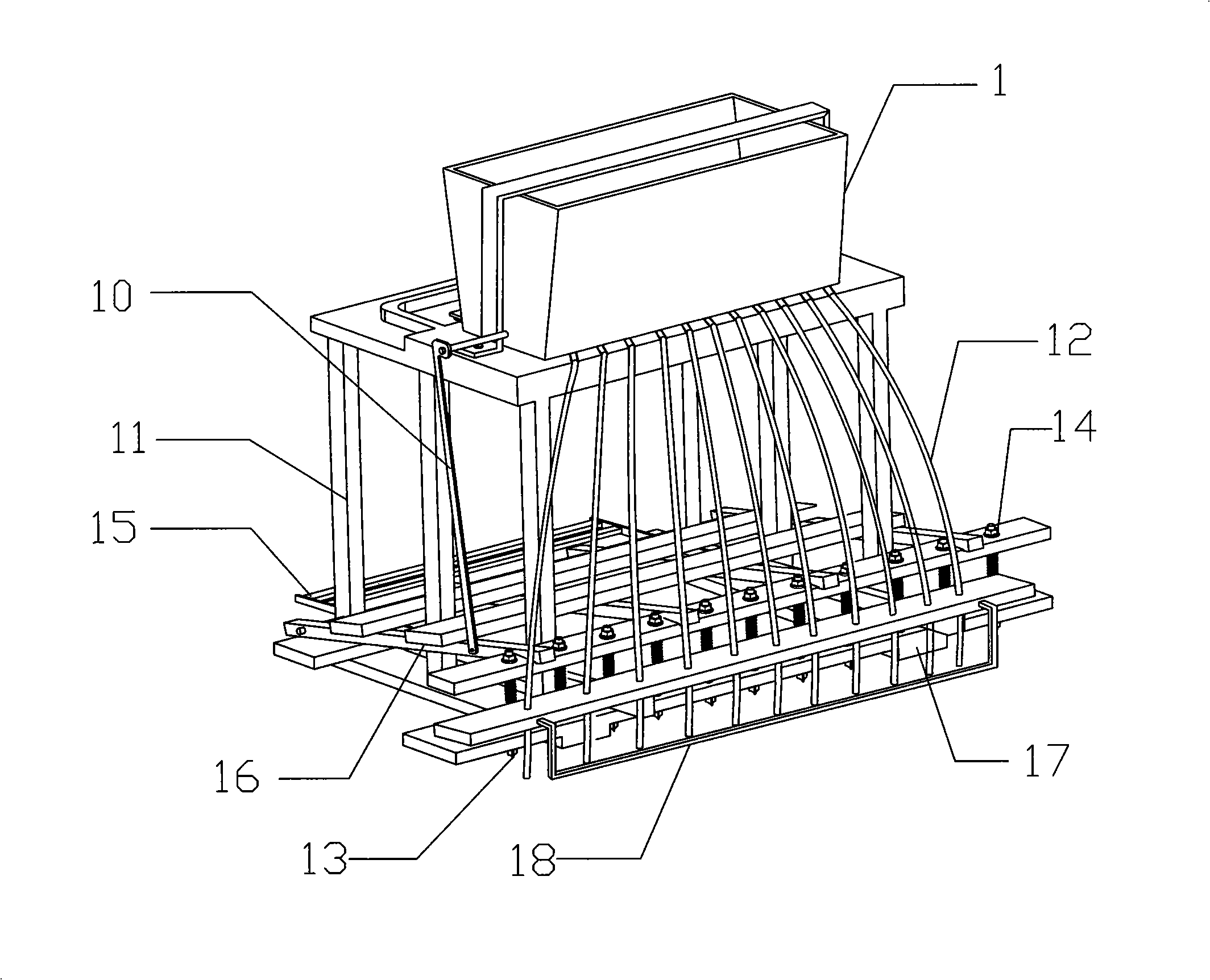

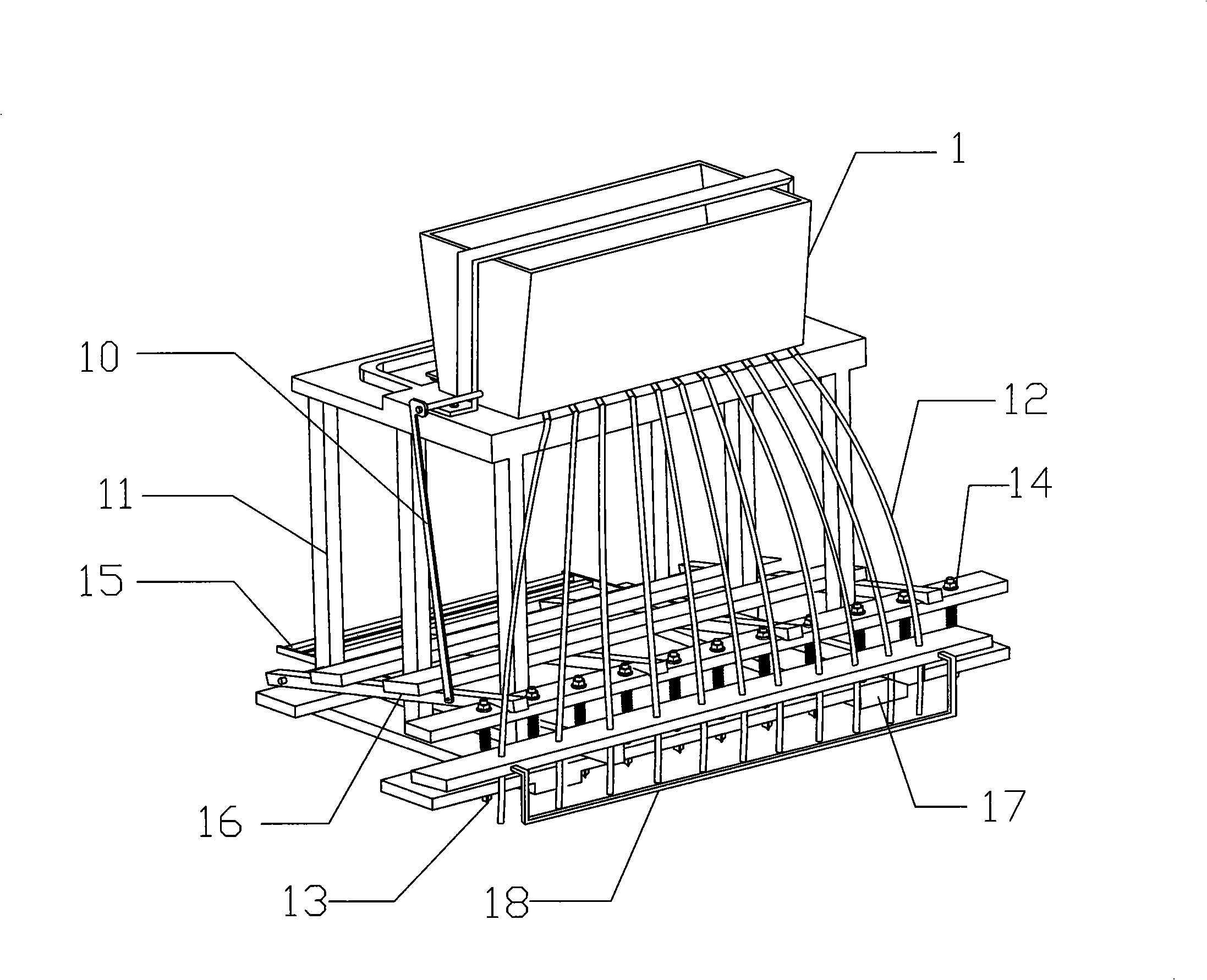

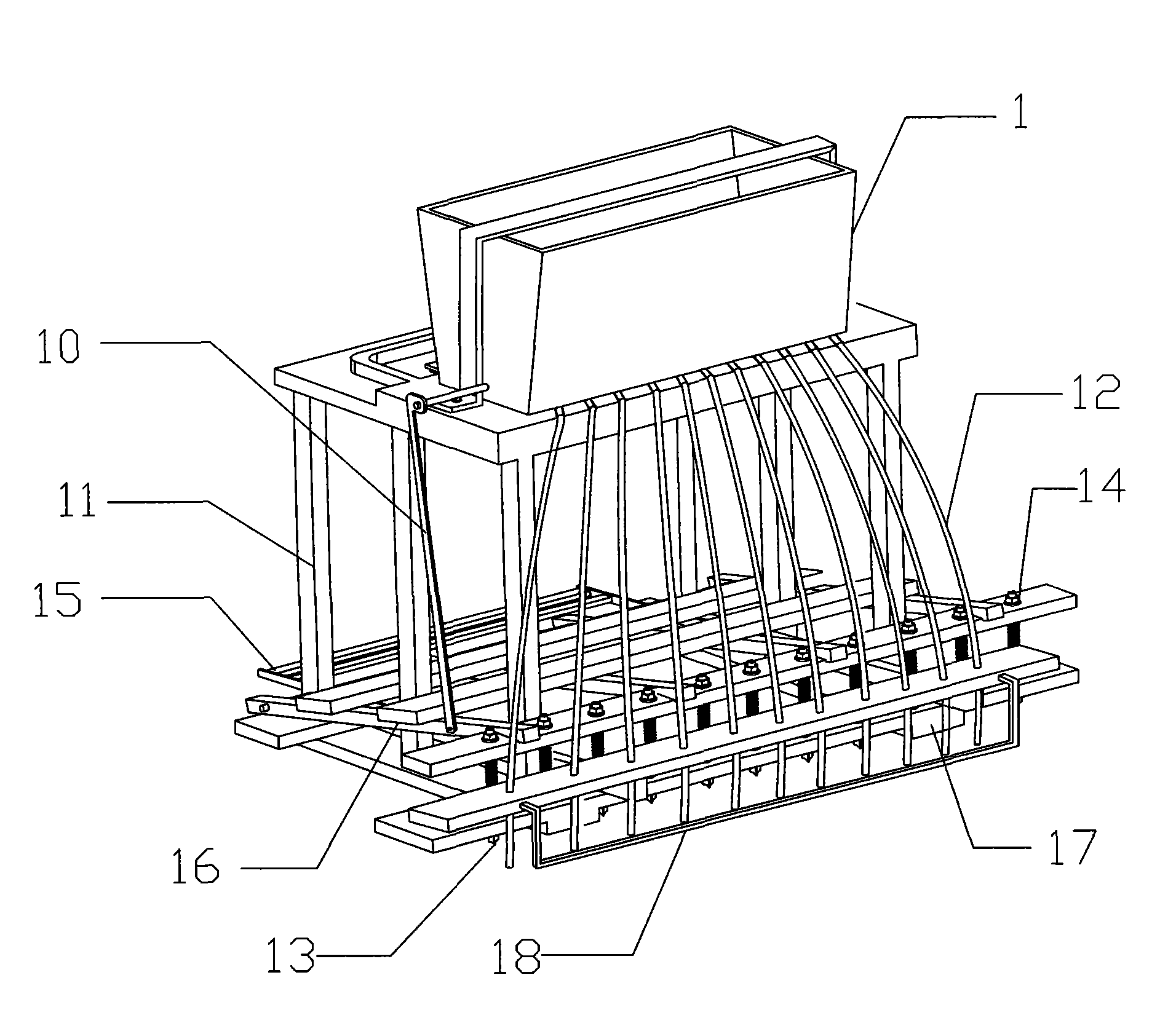

Seeder

InactiveCN101513157APrecisely control the quantityDo not waste seed resourcesSeed depositing seeder partsRegular seed deposition machinesSeederPunching

The invention relates to an agricultural machine, in particular to a seeder, comprising a frame, a seed box mounted on the top of the frame, a seed carrying assemble mounted under the seed box and a seed distributing assemble mounted at the front end of the frame, wherein a displacement assemble is mounted at the bottom end of the frame, an open for placing the seed is arranged on the seed box, a punching assemble is mounted at the lower end of the frame and connected with a motion assemble, a positioner capable of locking the moving distance of the displacement assemble is mounted at the displacement assemble. In the invetnion, the seed distributing shaft, the seed pushing rod and the seed carrying shaft are imbined, so that the amount of the seeds falling into each cavity can be precisely controlled by the drawing of the seed pushing rod in the sowing process, the seed distributing amount is precise and less.

Owner:南通全通建筑机械有限公司

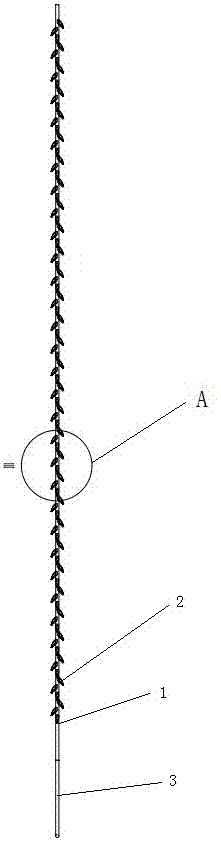

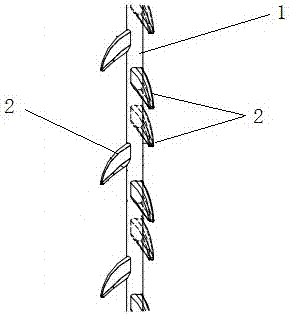

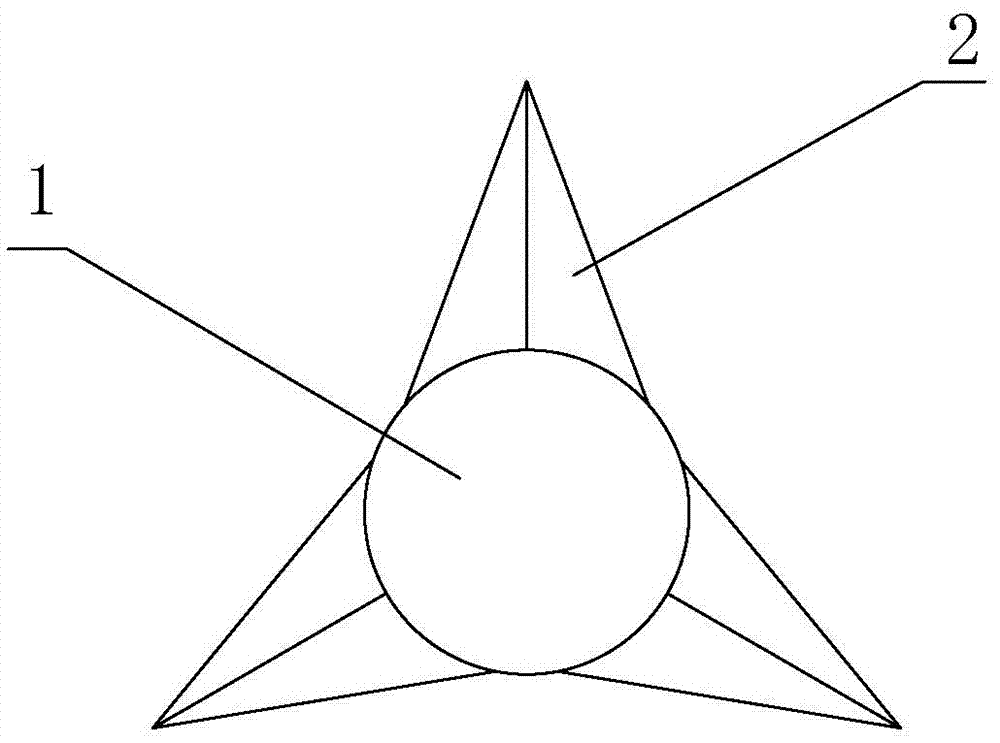

Cosmetic barb string

The invention discloses a cosmetic barb string. The cosmetic barb string is characterized by comprising a string body (1) made of PCL or PP or PLGA, the peripheral side wall of the string body (1) is provided with 3-5 rows of barbs (2), the string body (1) and the barbs (2) are integrally formed through the hot-pressing injection molding process, one barb in one row of barbs (2) and two adjacent barbs in the other two rows of barbs (2) are spirally distributed on the peripheral side wall of the string body (1), the two ends of the string body (1) are each provided with a smooth section without barbs, and the barb body of each barb (2) is a triangular prism, wherein the barb tips are bent in the same direction. In the use process of the cosmetic barb string, general anesthesia is not needed, the cosmetic barb string is implanted in the cortex of the human body through a minimally invasive incision, no scar is left, the effect is improved and is natural and lasting, and the cosmetic barb string is especially suitable for people who refuse surgery or can not undergo surgery but need cosmetology. The cosmetic barb string can be absorbed by the human body and gradually degraded and metabolized without residues, is safe to the human body and guarantees the safety without worries about future.

Owner:王月玲

Urban pipeline channel construction device

InactiveCN107899717AImprove bearing capacityReduce work intensitySievingScreeningCrushed stoneEngineering

The invention discloses an urban pipeline channel construction device. The urban pipeline channel construction device comprises a material storage box, the upper portion and the lower portion of the material storage box are both opened, the lower portion of the material storage box is funnel-shaped, the bottom surface of the material storage box is fixedly connected with the top surface of a material falling box, the upper portion and the lower portion of the material falling box are both opened, and the material falling box communicates with the interior of the material storage box; the two sides of the inner wall of the material storage box are connected with the two sides of a sieve through rotating shafts, a vibration motor is fixedly arranged on one side of the material storage box, and an output shaft of the vibration motor is fixedly connected with one rotating shaft of the sieve; a rectangular groove is formed in one side of the material storage box, the inner side of the rectangular groove communicates with the interior of the material storage box, and the bottom surface of the rectangular groove is flush with the top surface of the sieve; and sliding chutes are formed inthe front face and the back face of the inner wall of the material storage box respectively, the two sliding chutes are located above the sieve and are parallel to each other, and a sliding block is movably arranged in each sliding chute. According to the urban pipeline channel construction device, crushed stone blocks can be evenly scattered into channels, and the crushed stone blocks do not needto be separately screened, so that a lot of time is saved, working efficiency is improved, and working intensity of workers can be reduced.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

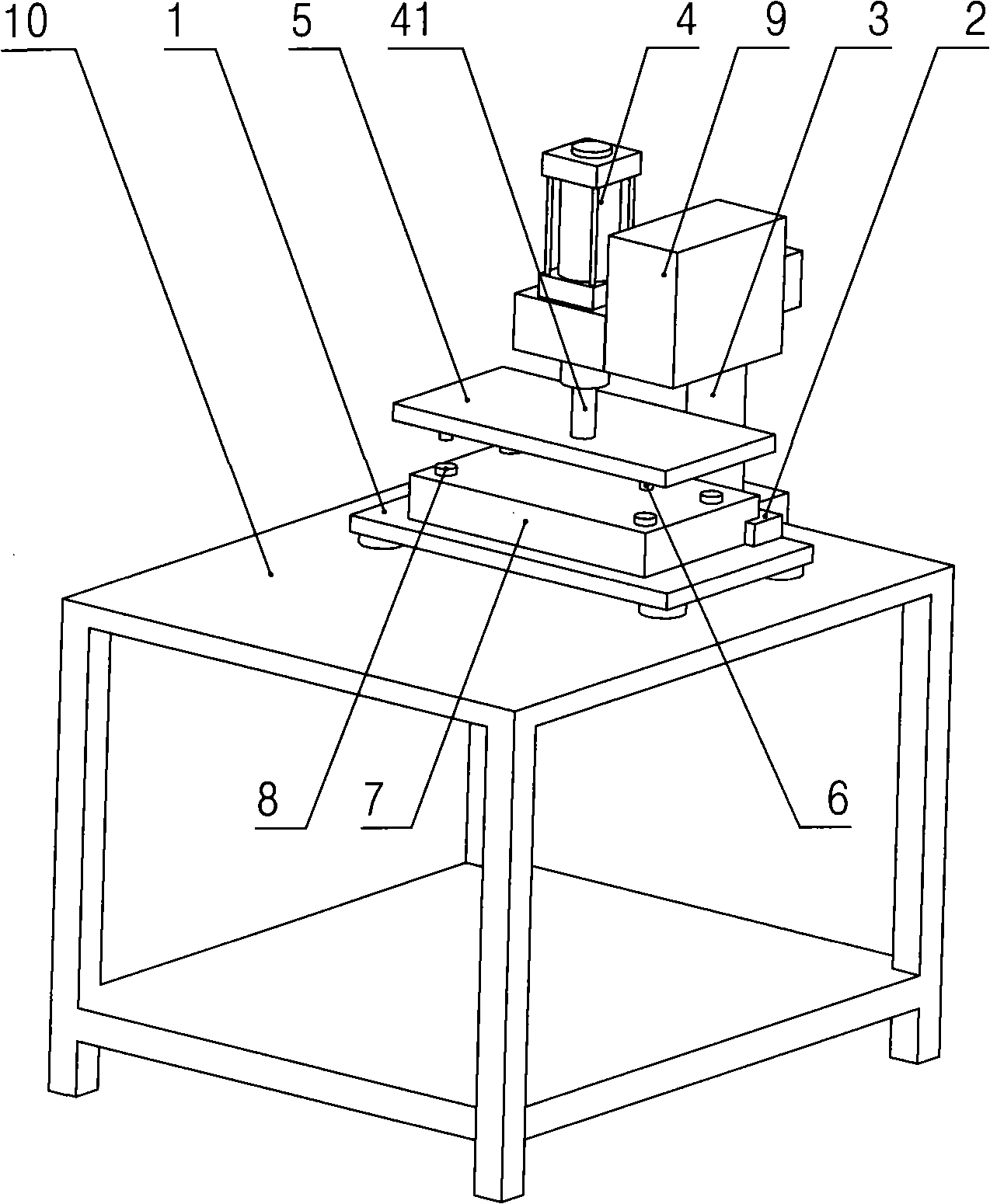

Undercarriage assembling frock

InactiveCN101357458AAssembly specifications and shortcutsEasy to installMetal-working hand toolsMechanical engineeringPiston rod

The invention discloses a machine leg assembly device which has the advantages that operation is regulated and quick, and production efficiency can be improved and cost can be lowered accordingly. The device comprises a base, the base is provided with a supporting arm and a locating device used for locating a case, the supporting arm is provided with a driving cylinder, a pressing board is arranged at the terminal of the piston rod of the driving cylinder, a pressing head which is corresponding to the machine leg inserted in the base plate of the case is arranged on the bottom surface of the pressing board. The device reduces production cost greatly and improves efficiency of assembly.

Owner:JIANGSU YINHE ELECTRONICS

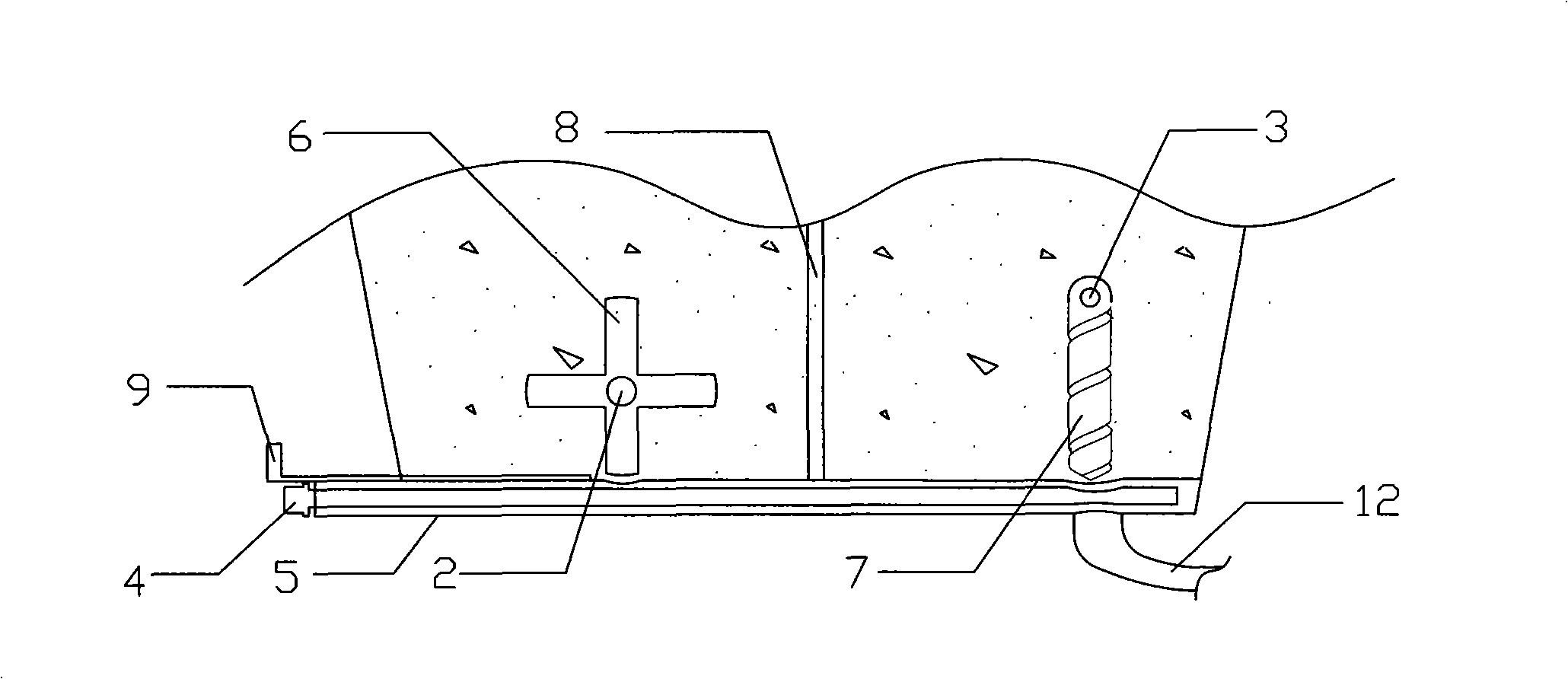

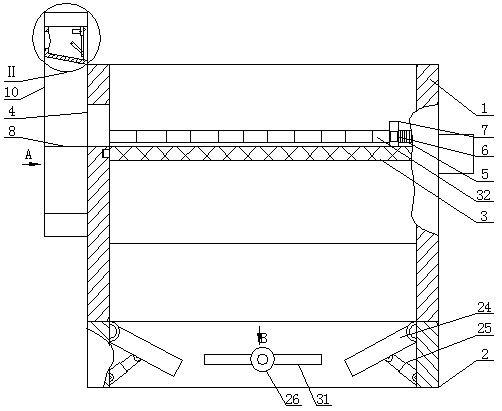

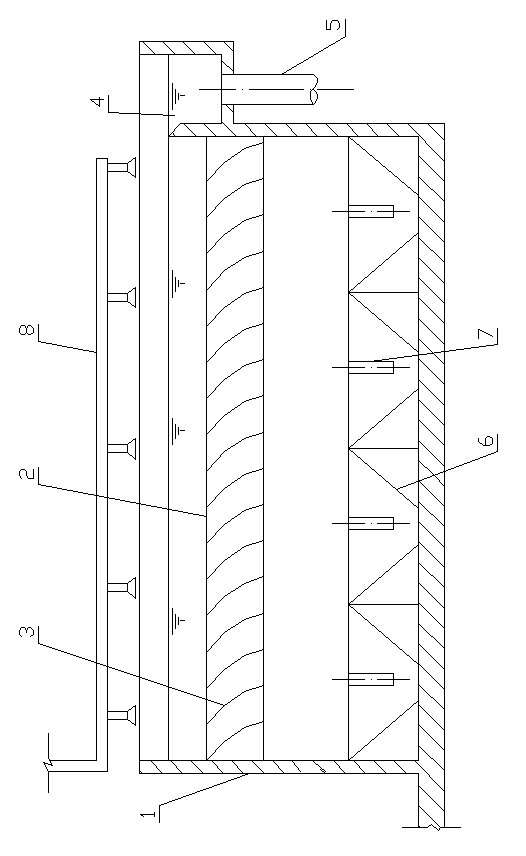

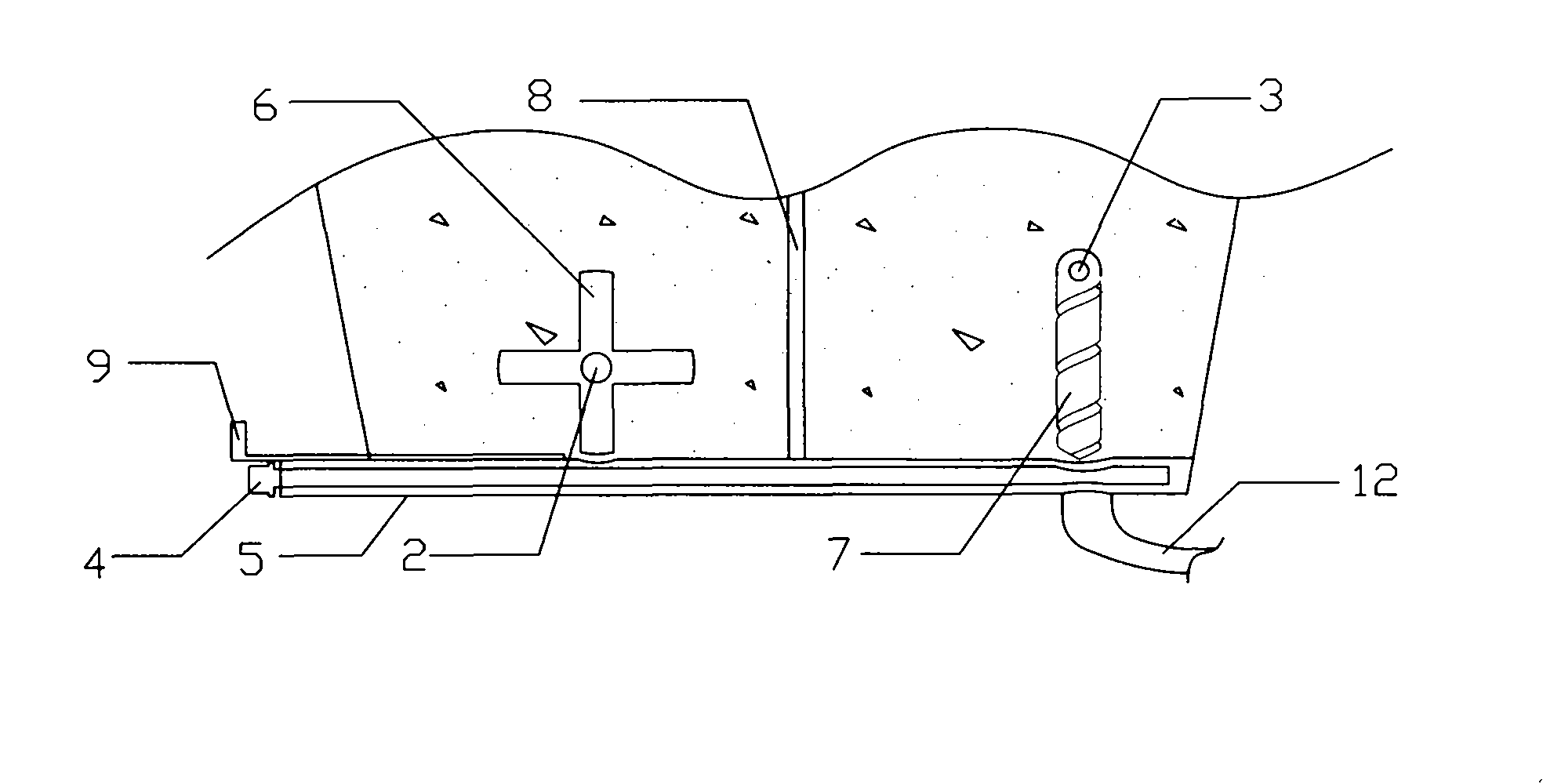

Anti-blocking inclined plate sedimentation basin

InactiveCN102794035AAvoid crushing accidentsReduce maintenance rateWater/sewage treatment by flocculation/precipitationSedimentation settling tanksEngineeringWater treatment

The invention provides an anti-blocking inclined plate sedimentation basin. After the inclined plate sedimentation basin is operated for a period of time, mud is seriously deposited between an inclined pipe and the inclined plates to cause blocking, even the inclined pipe and the inclined plate are crushed. The anti-blocking inclined plate sedimentation basin comprises a sedimentation basin body (1); the sedimentation basin body is connected with one group of the inclined plates (3) through connecting ribs (2) which are transversely and vertically crossed; a water collecting groove (4) is arranged above the sedimentation basin body and a water outlet pipe (5) is mounted at the tail end of the water collecting groove; sedimentation mud buckets (6) and mud discharging pipes (7) are mounted below the sedimentation basin body; the inclined plates are formed by three sections; the included angle between the inclined plate at the upper section and the horizontal plane is 45-50 degrees; the included angle between the inclined plate at the middle section and the horizontal plane is 50-60 degrees; and the included angle between the inclined plate at the lower section and the horizontal plane is 60-70 degrees. The anti-blocking inclined plate sedimentation basin disclosed by the invention is used for the fields of water treatment, chemical engineering or wet-method metallurgy and the like.

Owner:NANJING FUCHANG ENVIRONMENTAL PROTECTION

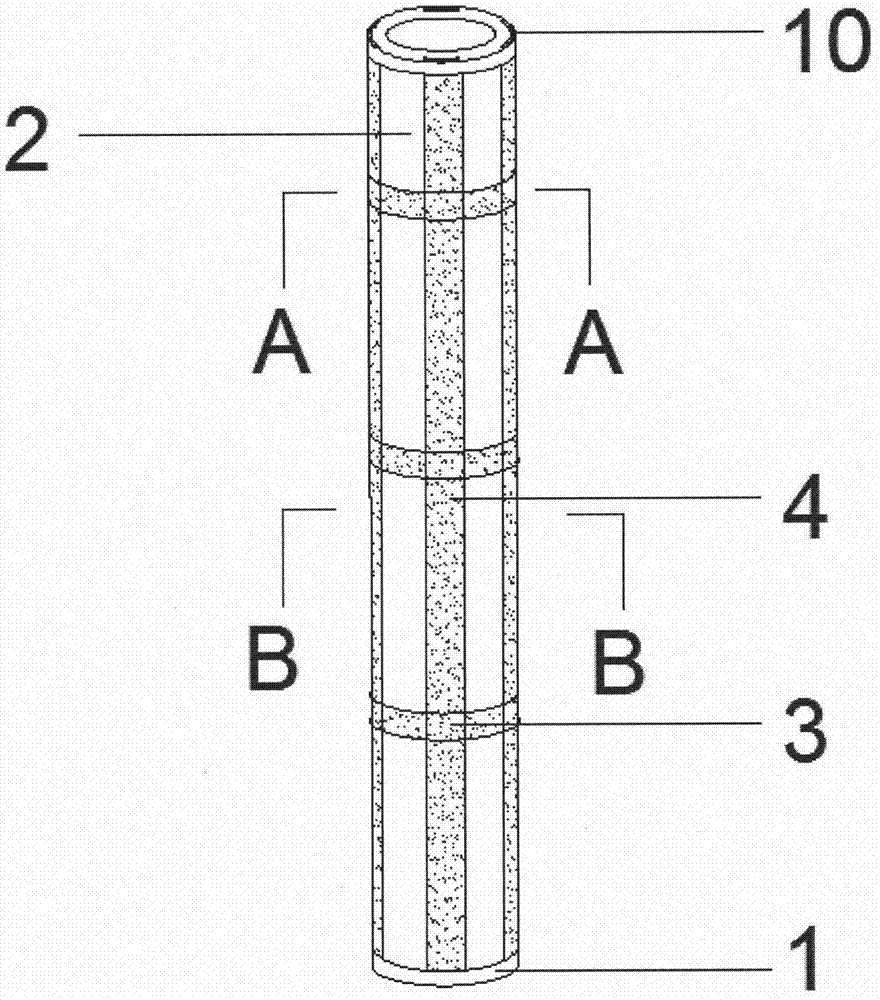

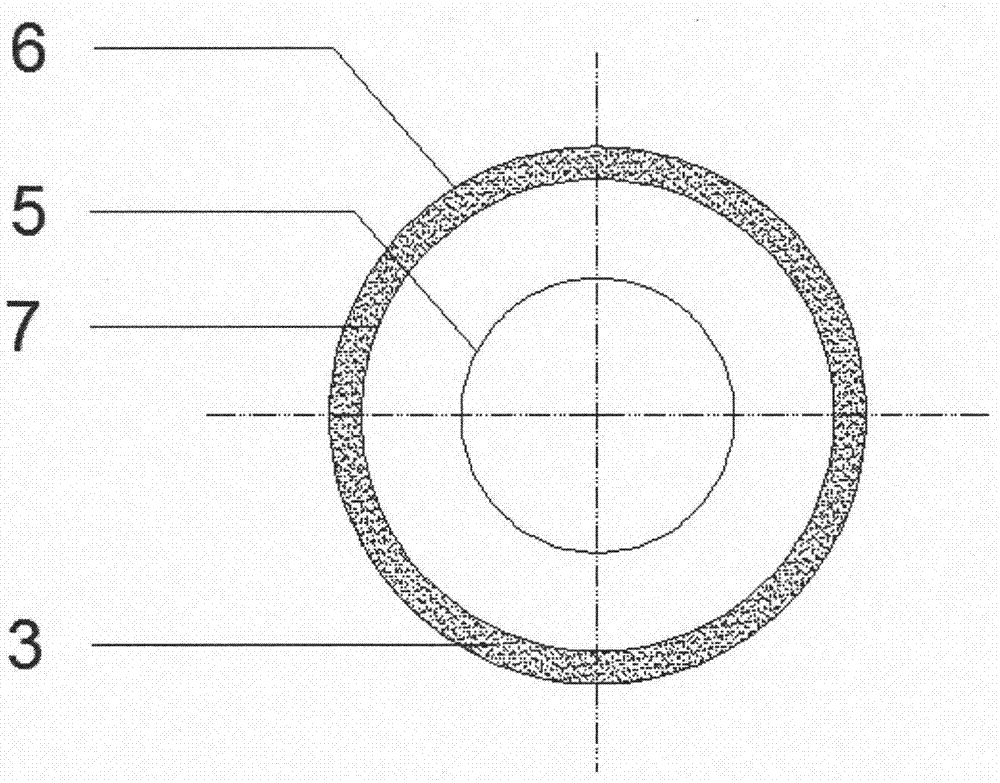

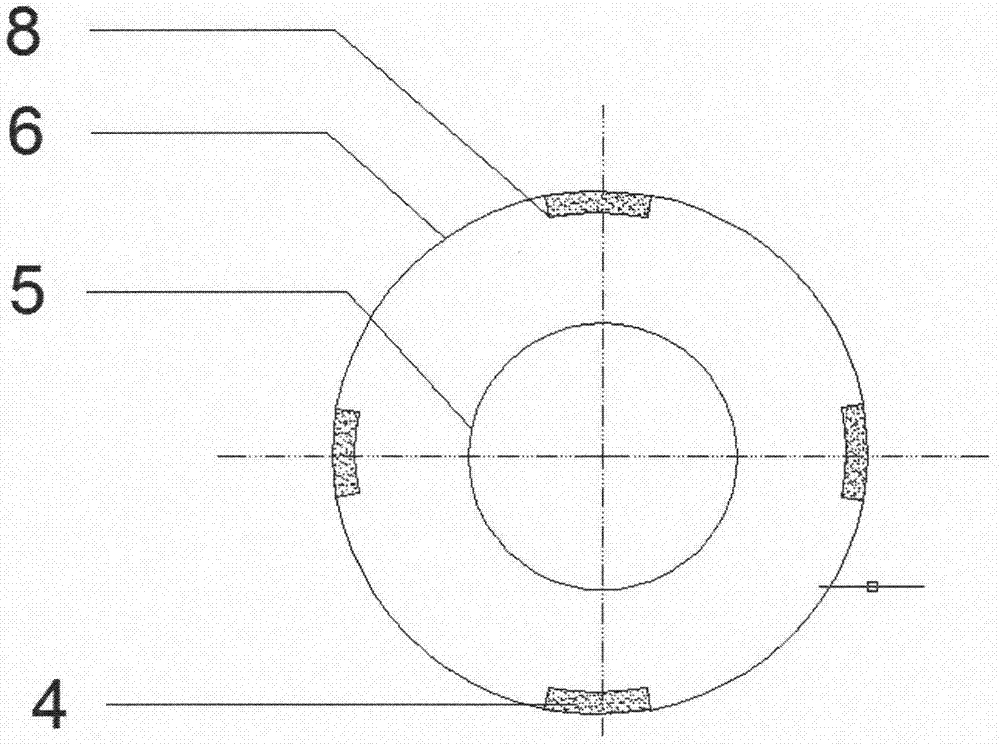

Novel precast drainable tube pile and preparing construction method thereof

InactiveCN107059854AAccelerated consolidationAccelerated dissipationShaping reinforcementsBulkheads/pilesSurface layerTransverse groove

The invention discloses a novel precast drainable tube pile and a preparing construction method thereof, which belong to the field of geotechnical engineering. The novel precast drainable tube pile comprises a precast tube pile body, longitudinal and transverse reserved grooves in the pile surface, a pervious concrete layer and corresponding tube pile end plates, etc. The longitudinal and transverse reserved grooves in the side wall of the pile body of the precast tube pile are filled with pervious concrete as drainage passages for pore water in a soil mass, and by performing inter-pile connection on the corresponding tube pile end plates designed by the present invention, smoothness of the drainage paths after pile connecting can be ensured. By applying the novel precast drainable tube pile, a soil compaction effect in a pile sinking process can be reduced, consolidation of the soil mass among the piles can be accelerated, a pile side friction can be increased, vertical and horizontal displacements of adjacent pile bodies can be effectively reduced, and a pile base bearing capacity can be increased; and a settling volume and a negative friction resistance of the pile side soil mass after construction can be reduced. The novel precast drainable tube pile is simple in structure, can be industrially produced and is high in construction efficiency and obvious in actual social and economic benefits.

Owner:NANJING UNIV OF TECH

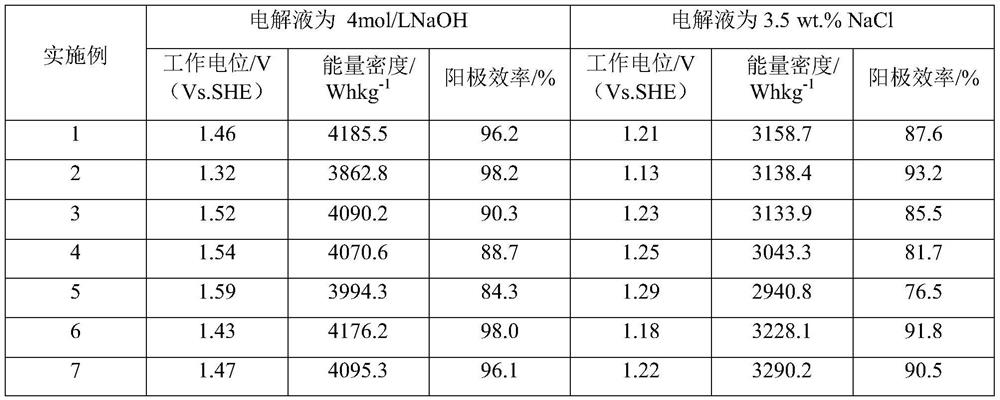

Aluminum alloy anode material for aluminum-air battery and preparation method

PendingCN112952079AImprove discharge activityImprove corrosion resistanceFuel and primary cellsNegative electrodesZr alloyBattery cell

The invention provides an aluminum alloy anode material for an aluminum-air battery and a preparation method, and the aluminum alloy anode material comprises the following components in percentage by mass: 0.1%-3.6% of Mg; 0.005% to 2.0% of Sn; 0.05% to 0.50% of Mn; 0.05% to 1.0% of Sc; 0.025% to 0.50% of Zr; 0 to 2.0% Ga; and the balance of Al. The aluminum alloy anode material is prepared through the procedures of smelting, degassing, slagging-off, casting, homogenizing, rolling and heat treatment, the aluminum alloy anode material adopts industrial pure aluminum as a raw material, Mg and Sn alloy elements capable of improving the corrosion resistance and activity of the anode material are added, and a Mn alloy element capable of eliminating the adverse effect of impurity Fe is added; in addition, Sc and Zr alloy elements capable of refining grains and improving the alloy anode structure uniformity are further added, and the aluminum alloy anode material has the advantages of being good in discharge activity, high in anode utilization efficiency, long in service life, good in discharge process stability, easy to prepare and the like.

Owner:NORTHEASTERN UNIV

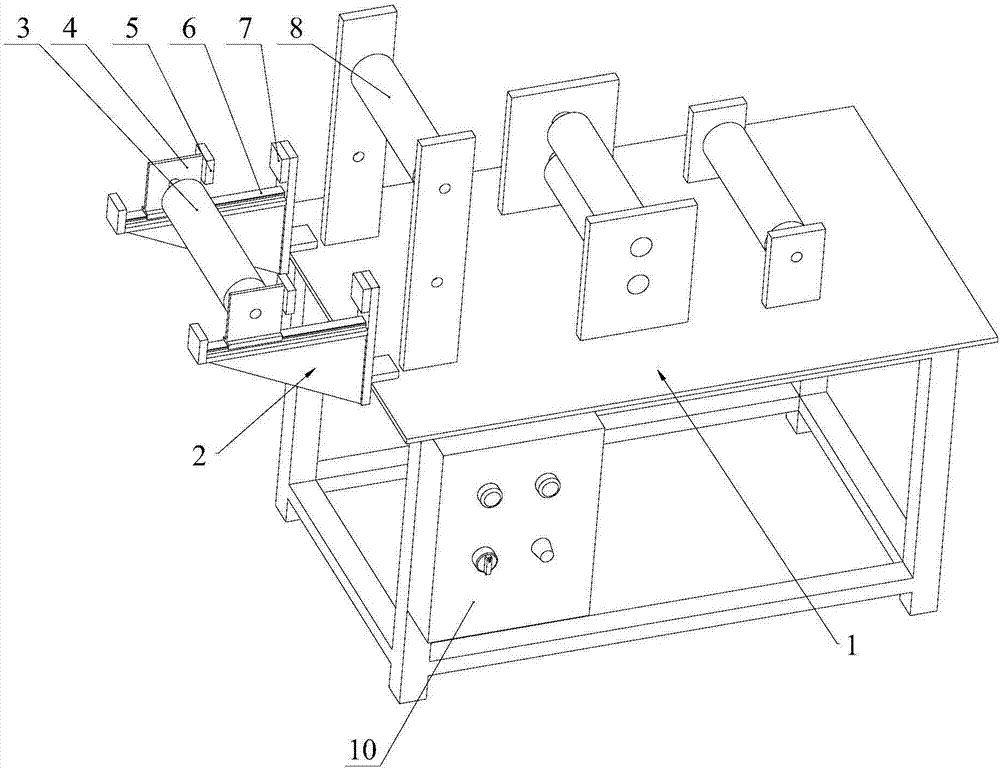

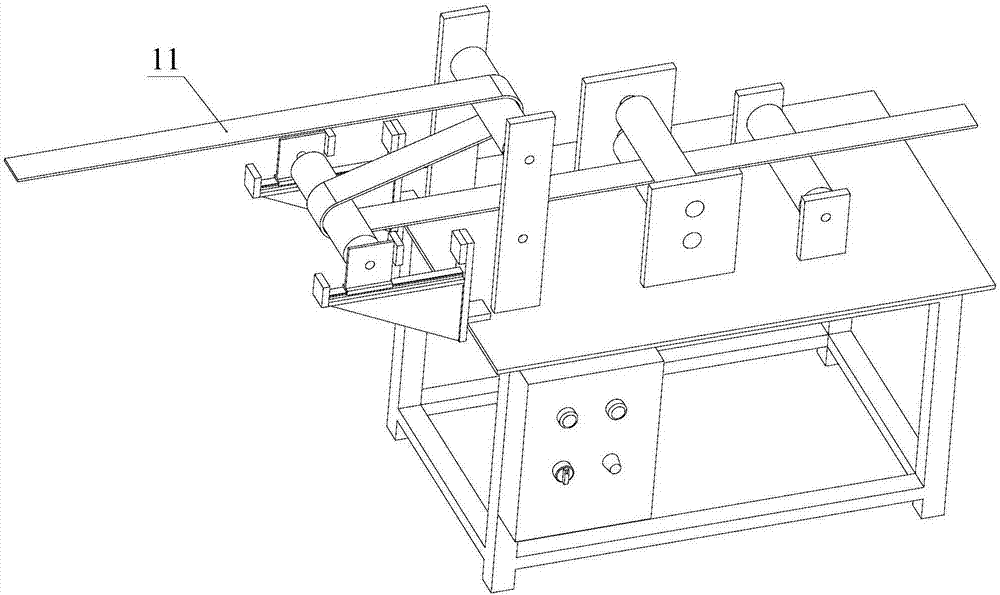

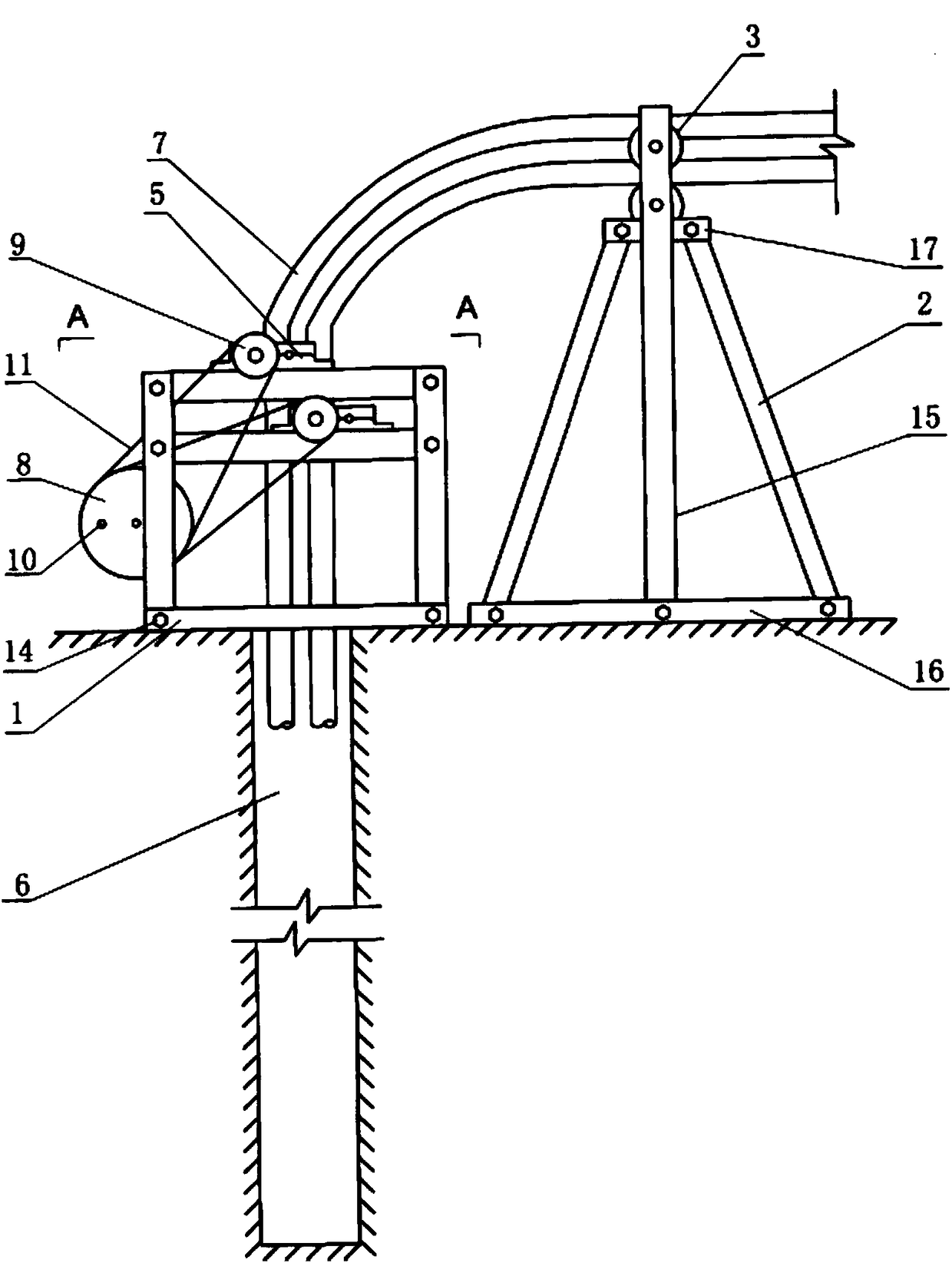

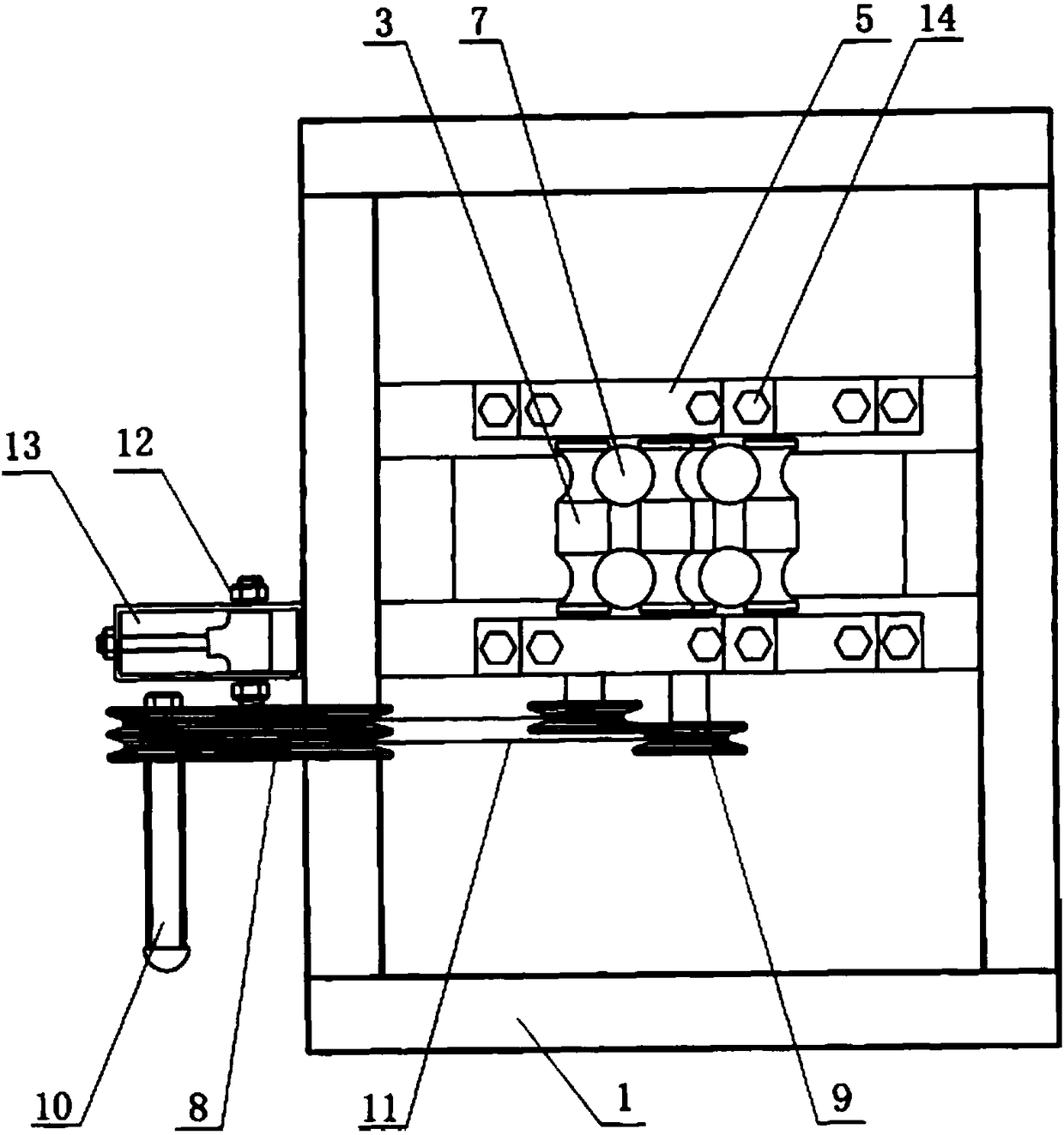

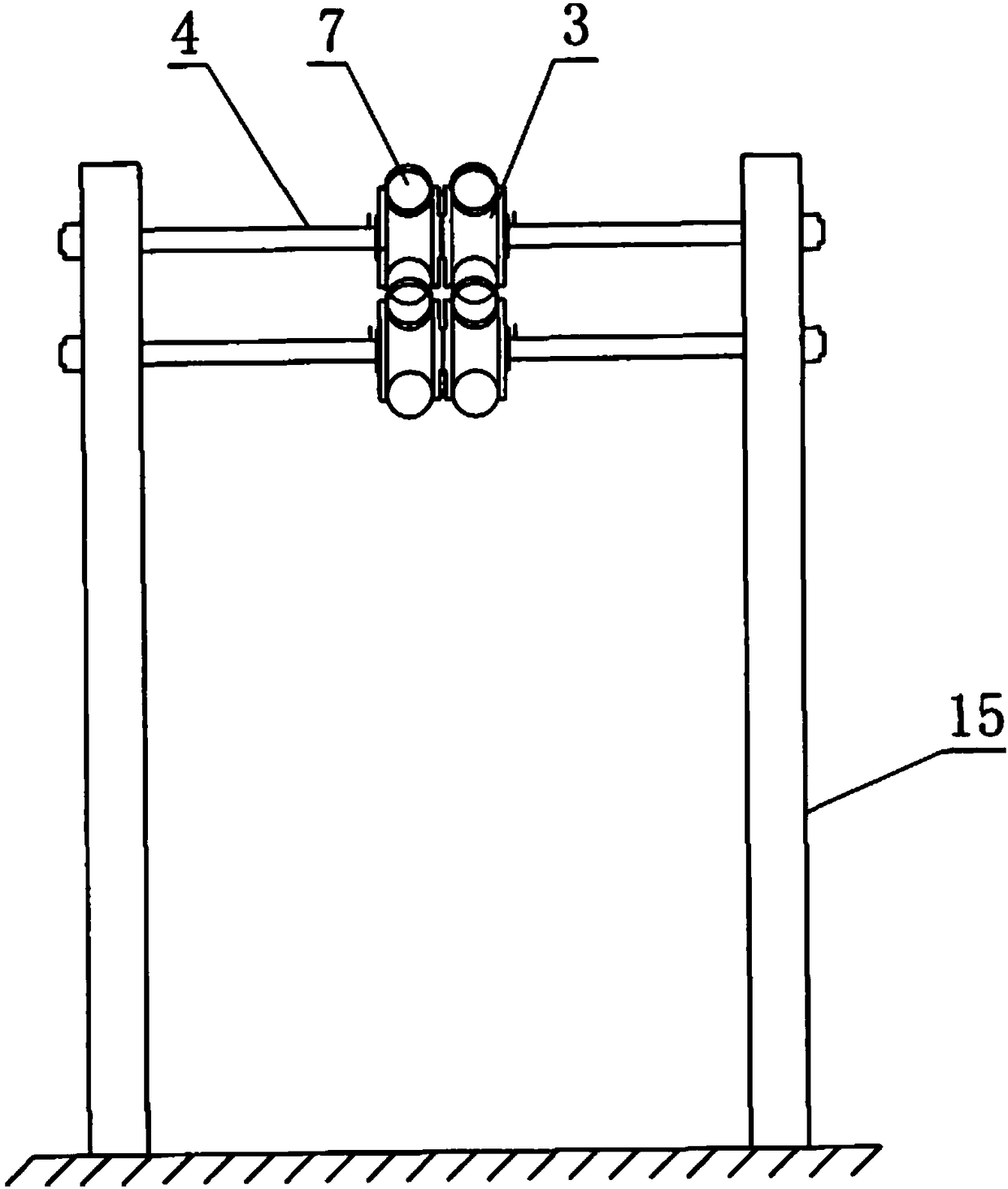

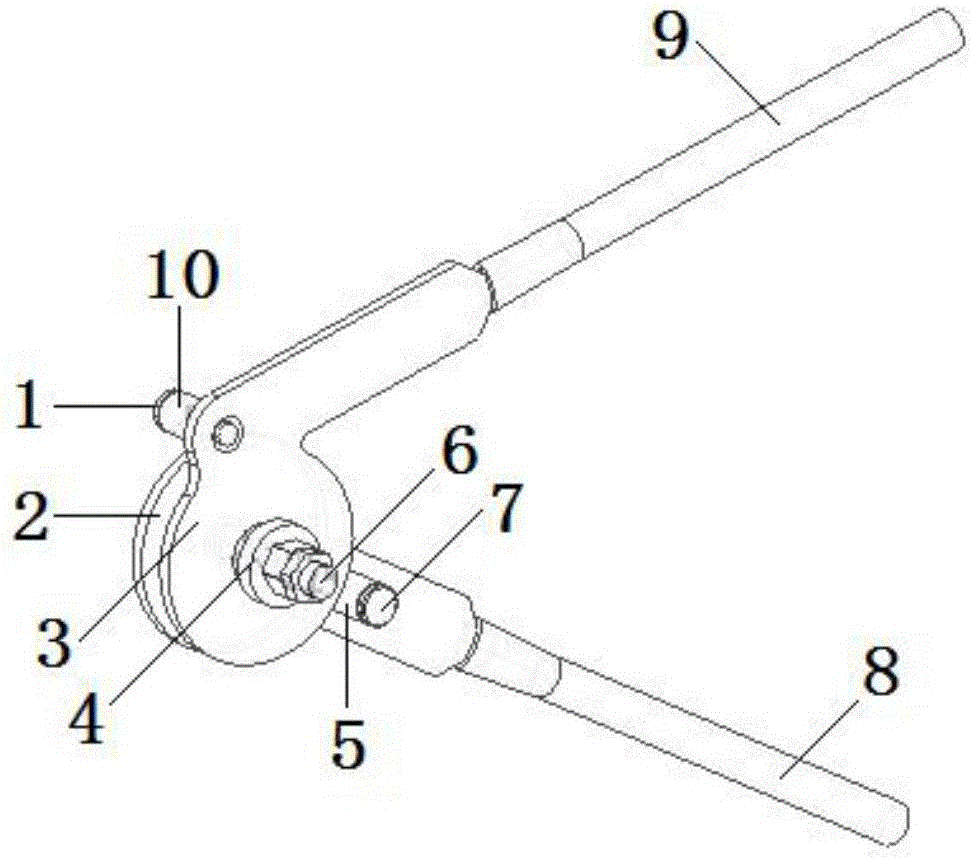

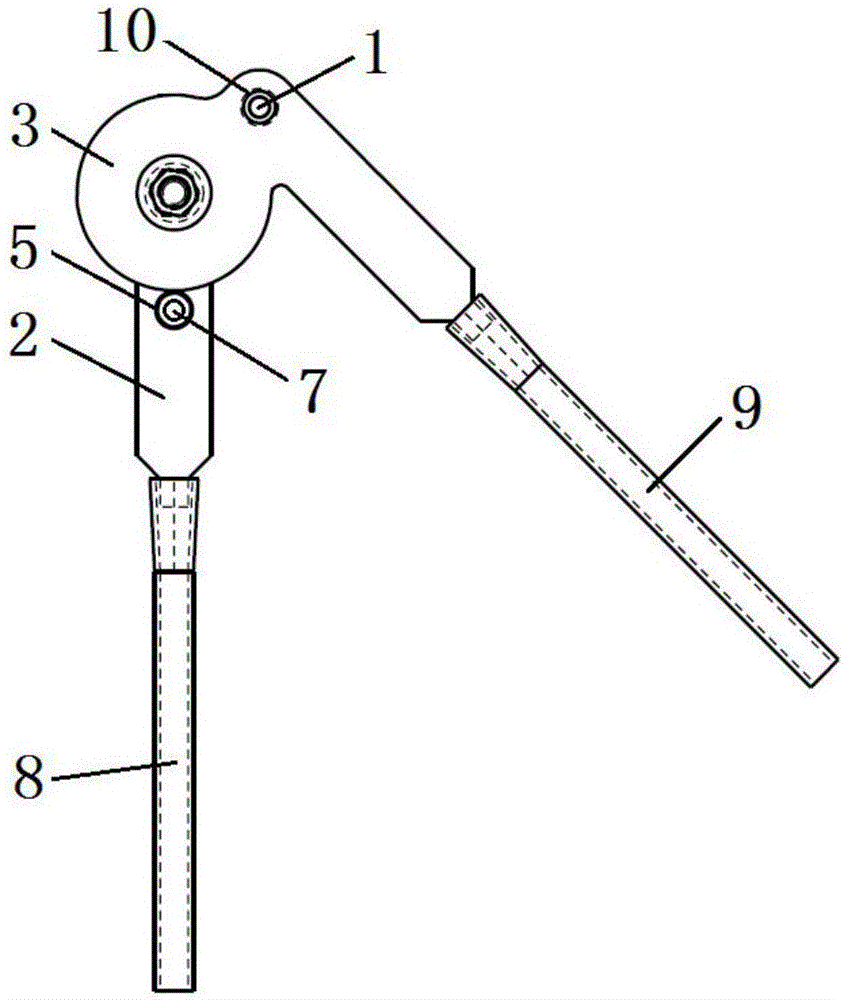

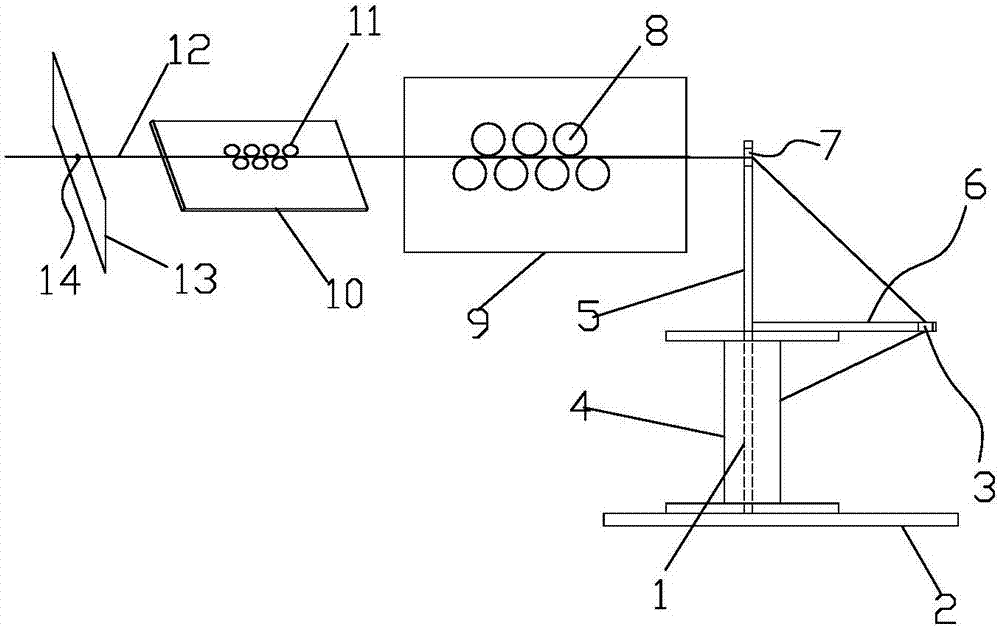

Ground source heat pump mounting auxiliary device

The invention provides a ground source heat pump mounting auxiliary device, and relates to an auxiliary device for vertical burying of a ground source heat pump underground heat exchanger. The groundsource heat pump mounting auxiliary device is mainly composed of a bracket, an arc groove roller shaft, a handle, a driving wheel, a driven wheel, a supporting frame and the like. The ground source heat pump mounting auxiliary device can increase the burying speed of the ground source heat pump underground heat exchanger, can ensure the construction quality, and further has the characteristics ofbeing in simple in operation, capable of saving energy, convenient to operate in a field, low in cost, convenient to apply and popularize and the like. The ground source heat pump mounting auxiliary device can be widely applied to vertical burying of the ground source heat pump underground heat exchangers all over the country.

Owner:山东一源能源科技开发有限公司

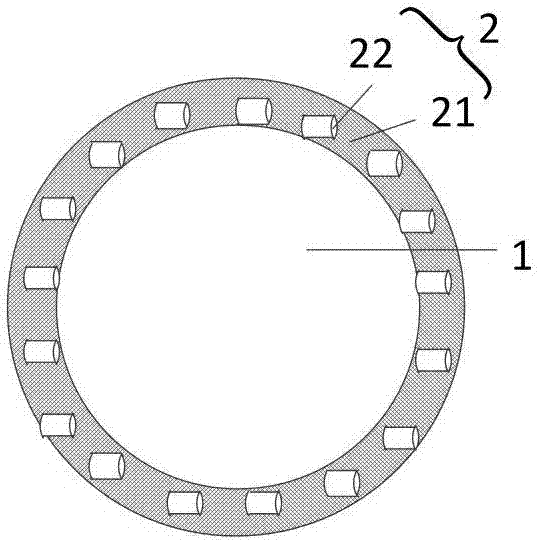

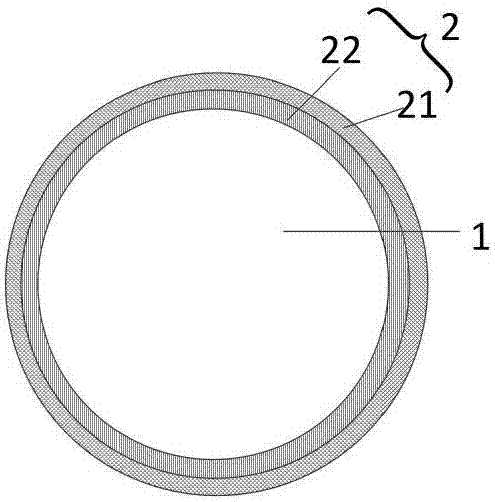

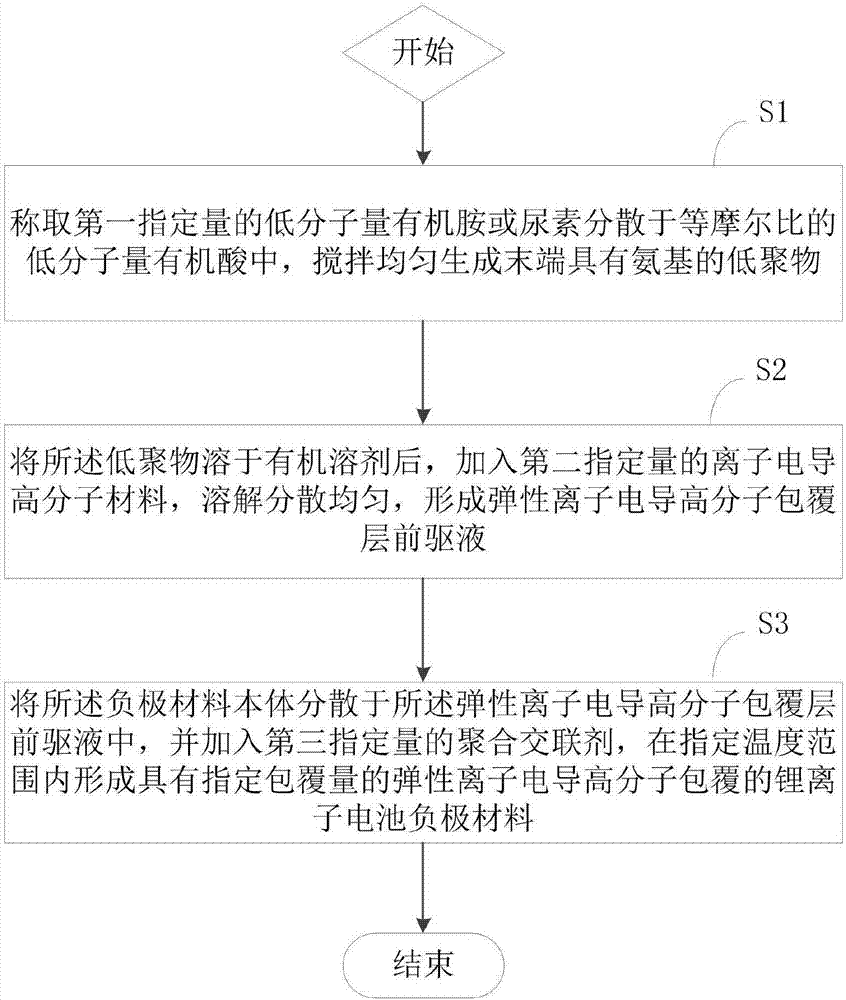

Lithium-ion battery negative electrode material and preparation method thereof

ActiveCN107579221AInhibit thickeningReduce Thickness BounceCell electrodesSecondary cellsLithium electrodePolymer coatings

The invention discloses a lithium-ion battery negative electrode material and a preparation method thereof. The lithium-ion battery negative electrode material comprises a negative electrode materialbody and an elastic ionic conductance polymer coating layer, wherein the negative electrode material body is coated with the elastic ionic conductance polymer coating layer; the elastic ionic conductance polymer coating layer comprises an elastic polymer material and an ionic conductance polymer material. The lithium-ion battery negative electrode material is subjected to performance improvement by adopting the elastic ionic conductance polymer coating layer, the elastic ionic conductance polymer coating layer can bear great stress expansion, and the interface stability of the negative electrode material body in the charging and discharging process is maintained, so that thickening of an SEI (Solid Electrolyte Interphase) film is inhibited, and thickness rebound of the negative pole piecein the circulating process is reduced; moreover, due to the ionic conductance characteristic of the elastic ionic conductance polymer coating layer, reductive decomposition of electrolyte on the surface of the negative electrode material body can be inhibited, and the cycling stability of the lithium-ion battery is improved while the lithium-ion migration rate is improved.

Owner:欣旺达惠州动力新能源有限公司

Chip back side drape tin eutectic technology and loading method thereof

InactiveCN102593010AOvercome size limitationsAvoid torsional driftSemiconductor/solid-state device manufacturingTinningAlloy

The invention relates to a chip back side drape tin eutectic technology and a loading method thereof. The method comprises the following steps: step (1), carrying out backside silver or backside gold processing on a chip back side; step (2), carrying out tinning or tin alloy work on a backside silver surface or a backside gold surface of a chip which is subjected to the backside silver or backside gold processing in the step (1); step (3), cutting the chip whose backside silver surface or backside gold surface is subjected to the tinning or tin alloy work in the step (2); step (4), employing eutectic technology to install the chip which is cut in the step (3) to a basic island to complete loading. According to the chip back side drape tin eutectic technology and the loading method, there is no requirement to chip dimension, after the chip back side is coated with a layer of tin or tin alloy, since the thickness of the tin or tin alloy can be controlled, the thickness of the tin or tin alloy can effectively absorb different stresses between the chip and the basic island, and lamination and rupture problems of a traditional eutectic chip are solved.

Owner:CHANGJIANG ELECTRONICS TECH CHUZHOU

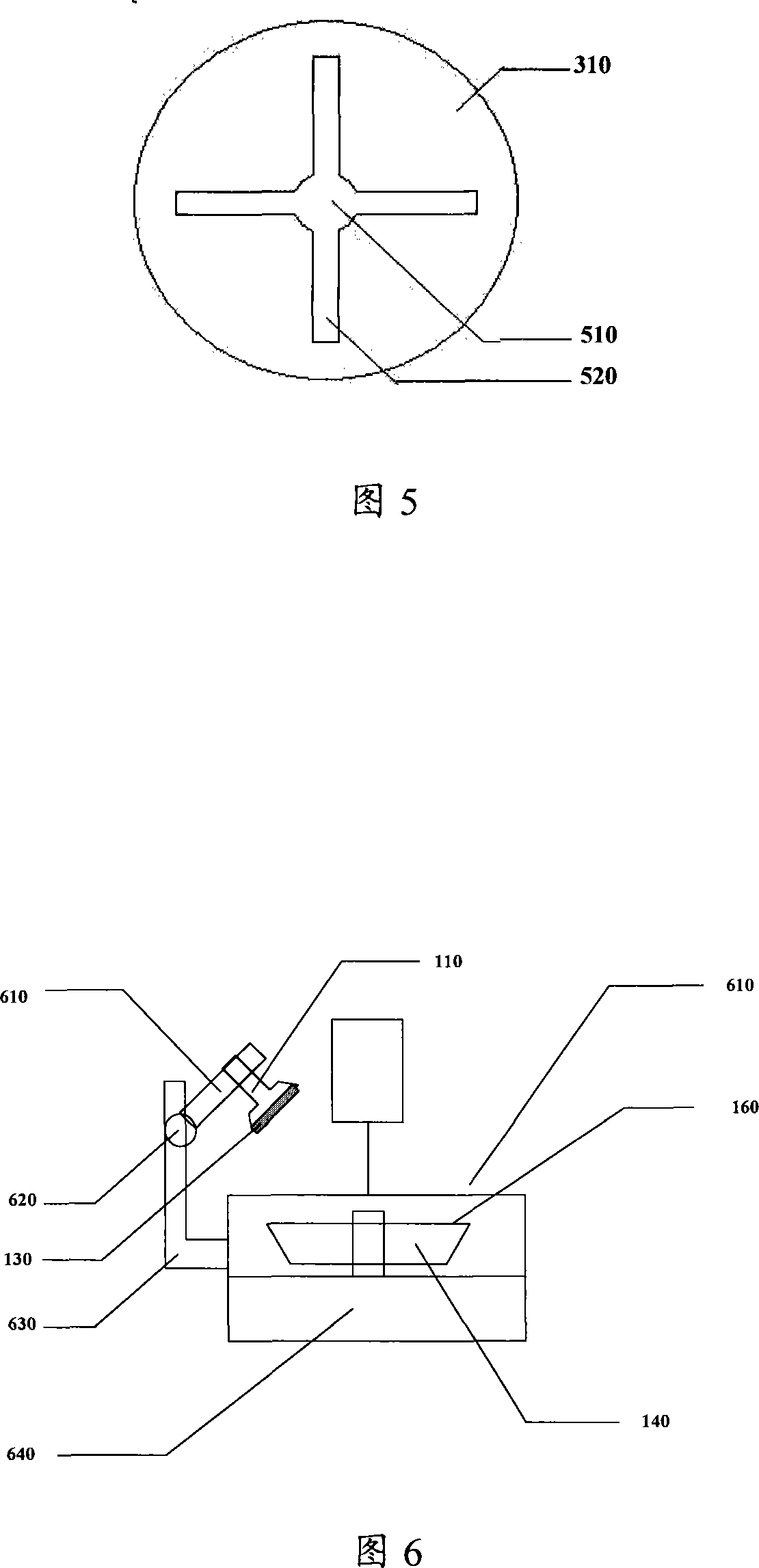

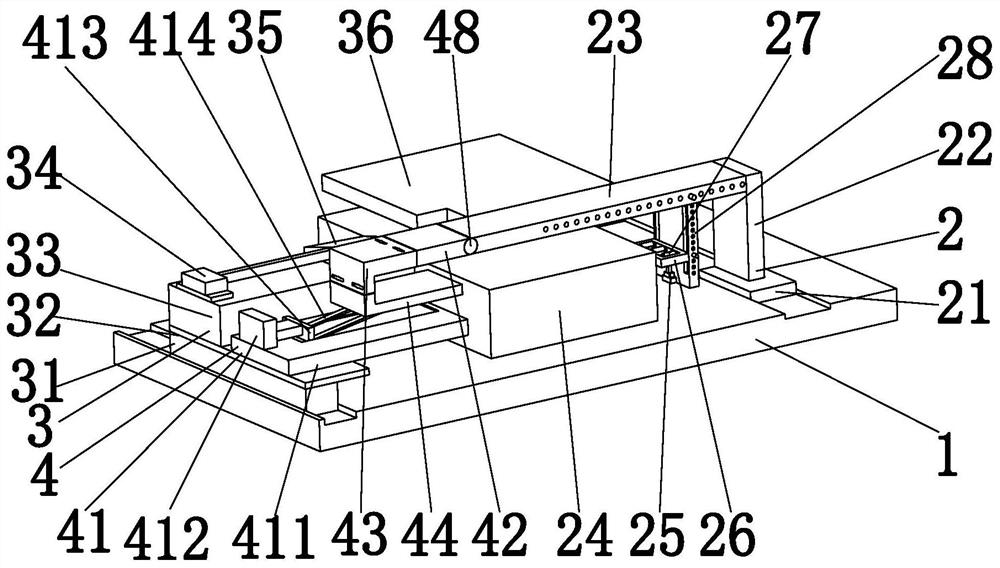

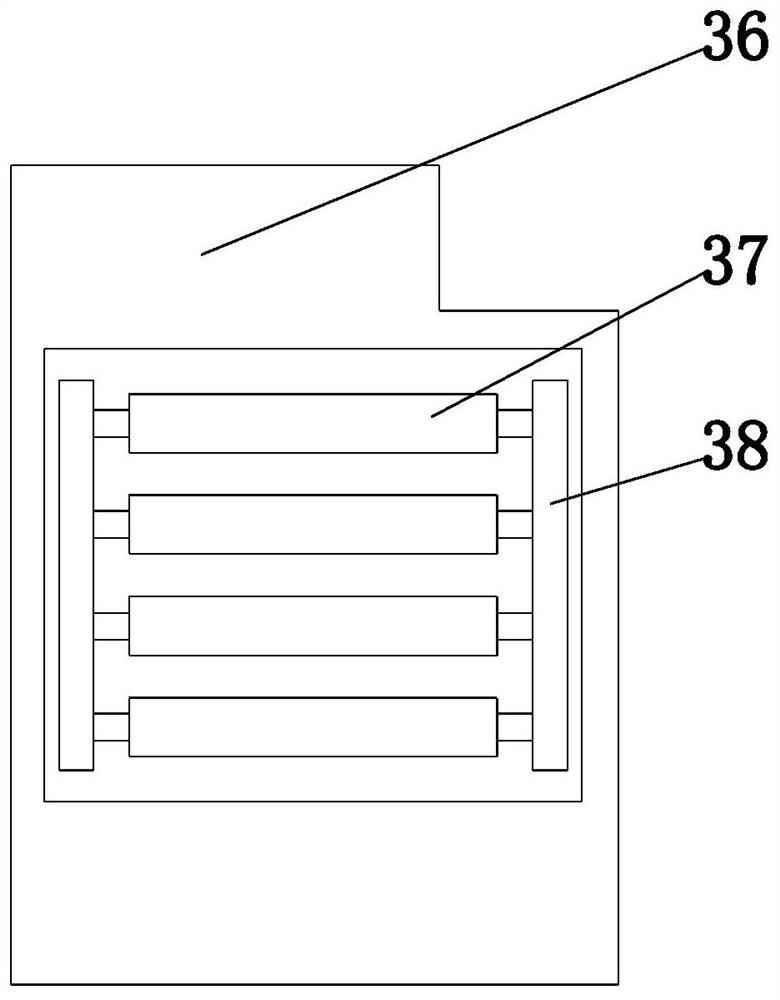

Wafer assembly system

ActiveCN103531505ARealize self-positioningNo human intervention requiredSemiconductor/solid-state device manufacturingConveyor partsEngineeringManipulator

The invention relates to a wafer assembly system, which comprises a longitudinal lead translation assembly, a transverse lead translation assembly, a workbench moving assembly, a wafer tray positioning assembly, a wafer tray X / Y axis translation assembly and a wafer picking manipulator (13), wherein the longitudinal lead translation assembly and the transverse lead translation assembly are used for driving a lead to perform transverse or longitudinal translation so as to realize self-positioning welding of a wafer; in the self-positioning sucking process of the wafer, the wafer tray positioning assembly is used for supporting a wafer extraction disk (17); the wafer tray X / Y axis translation assembly is used for driving the wafer extraction disk (17) to move towards an X axis or a Y axis so as to realize self-positioning sucking of the wafer; the wafer picking manipulator (13) is used for sucking a wafer to be welded and completing an action of welding the wafer onto a lead. According to the wafer assembly system, self-positioning of a wafer assembly position is realized via the transverse / longitudinal lead translation assembly, self-positioning sucking of the wafer is realized through the wafer tray X / Y axis translation assembly, an entire assembly process is full-automatic, and high assembly speed and high positioning assembly are achieved.

Owner:SICHUAN BLUE COLOR ELECTRONICS TECH

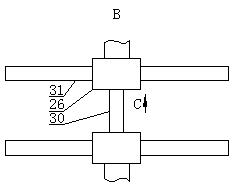

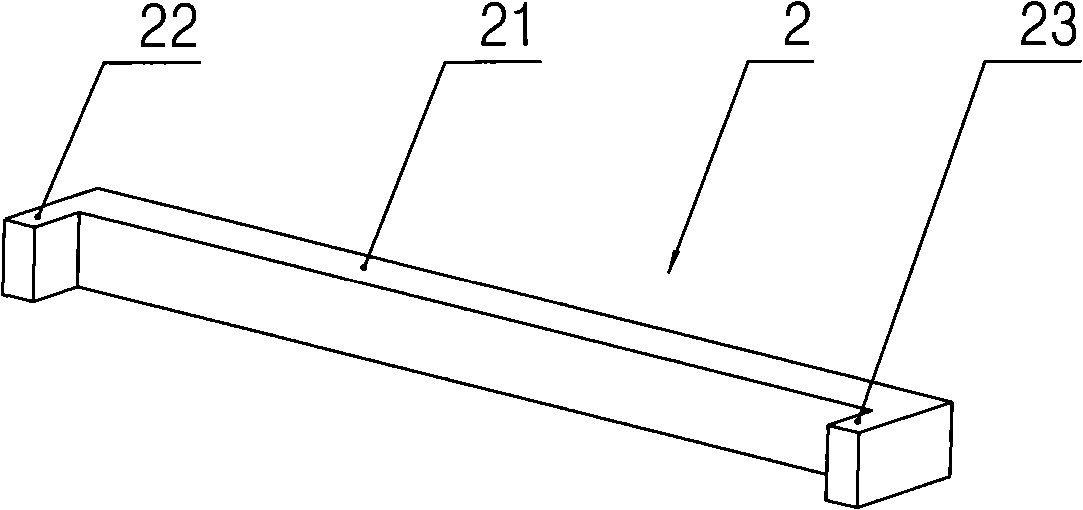

Metal wire releasing and cutting device

The invention discloses a metal wire pay-off and cutting device, which comprises a pay-off mechanism, a straightening mechanism and a cut-off mechanism connected in sequence; The I-shaped wheel is provided with a through hole matched with the vertical rod, the top of the I-shaped wheel is provided with a horizontal bar connected to the vertical rod, the outer end of the horizontal bar is provided with a first guide hole, and the upper end of the vertical rod is provided with a second guide hole. Two guide holes; the straightening mechanism includes a first fixed plate, a second fixed plate and a traction plate arranged in sequence, two sets of first clamping wheels are arranged on the first fixed plate, and two sets of first clamping wheels are arranged on the second fixed plate. Set of second clamping wheels, the traction plate is provided with a threading hole; the cutting mechanism includes an L-shaped base, a fixed block is provided on the L-shaped base, a fixed cone is provided on the fixed block, and the side of the L-shaped base is provided with The connecting block is provided with a support beam, the support beam is provided with a cylinder, and the cylinder is connected with a cutting knife corresponding to the fixed cone.

Owner:HUZHOU NANXUN RONGYE METAL MATERIAL

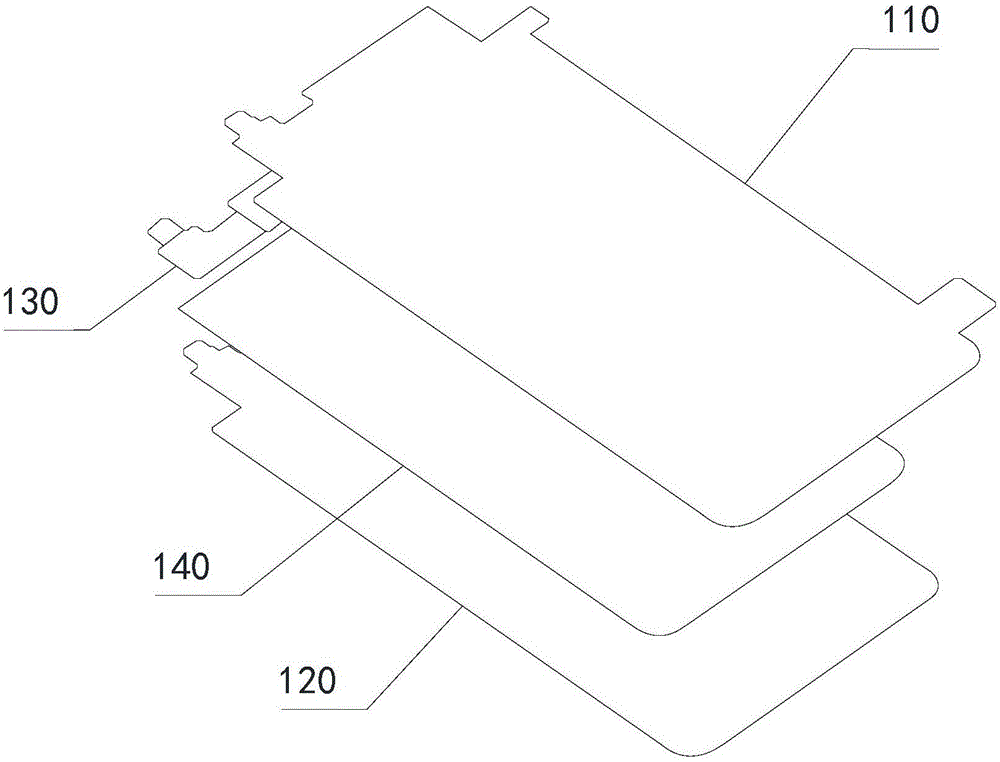

Integrated protective film and integrated film covering process

Owner:LENS TECH CHANGSHA

Manual bending tool

The invention provides a manual bending tool. The manual bending tool comprises a stud, a plate II, a T-shaped column I, a T-shaped column II, a handle I and a handle II, wherein the stud is arranged on the central axis of a plate I, the plate II is rotatably connected with the plate I through the stud, the T-shaped column I and the T-shaped column II are arranged on opposite sides of the plate I and the plate II, the handle I and the handle II are connected with the tail end of the plate I and the tail end of the plate II correspondingly, and the plate II and the plate I can be disassembled. According to the manual bending tool provided by the invention, slow and smooth transition of a right-angle bend is achieved; and the structure is simple, light and handy, operation is convenient, the degree of damage to a coil wire can be reduced to the maximum extent while the right-angled bend is slowly manufactured through bending, copper exposure is avoided, and a wire film is not damaged. On the small aspect, the work of removing all insulating materials of the wire and checking the wire by an operator and the rework of re-binding are avoided, and time and labor are saved. On the big aspect, the situation that burrs are generated due to friction or the insulating film is broken in the bending process of the wire is avoided, the potential safety hazards such as coil short and transformer halts are reduced.

Owner:山东输变电设备有限公司

Metal wire releasing and straightening device

The invention discloses a metal wire releasing and straightening device. The device comprises a wire releasing mechanism and a straightening mechanism connected in sequence; the wire releasing mechanism comprises a substrate; a vertical rod is arranged on the substrate, and is sleeved with a spool; the spool is provided with a through hole matched with the vertical rod; a cross bar connected to the vertical rod is arranged above the spool; a first guide hole is formed in the outer end of the cross bar; a second guide hole is formed in the upper end of the vertical rod; the straightening mechanism comprises a first fixed plate, a second fixed plate and a traction plate arranged in sequence; two sets of first clamping wheels are arranged on the first fixed plate; two sets of second clamping wheels are arranged on the second fixed plate; and a wire penetrating hole is formed in the traction plate. The device has the characteristics of high production efficiency and better machining quality.

Owner:HUZHOU NANXUN RONGYE METAL MATERIAL

All-ceramic self-locking bracket and opening method and locking method thereof

PendingCN108158675AResilientExcellent self-locking structure designArch wiresBracketsBiocompatibility TestingCeramic brackets

The invention relates to an all-ceramic self-locking bracket and an opening method and locking method thereof and belongs to an orthodontic component. The traditional orthodontic brackets are mostly metal brackets. The metal brackets do not have the invisible effect in use, are not beautiful enough and have insufficient biocompatibility. The color of the ceramic bracket is close to that of the teeth so that it is not easy to notice when used, and the ceramic bracket has good biocompatibility. The ceramic material has low strength, large brittleness and fracture easiness relative to the metal bracket. The all-ceramic self-locking bracket comprises a bracket body, a sliding block and a positioning pin. The positioning pin is disposed on the bracket body. The positioning pin is located in thesliding groove of the sliding block. The sliding block slides so that the bracket is opened and locked. The all-ceramic self-locking bracket is prepared from a tough ceramic material, has a color ofmilky white similar to the human teeth color, and has an invisible function. The locking and opening switching of the bracket body is convenient and smooth. The slip sheet is not easy to break.

Owner:桐庐宏远医疗器械有限公司

Eutectic process for coating tin on substrate and chip mounting method thereof

InactiveCN102623364AUniform thicknessLow costSemiconductor/solid-state device manufacturingElectroplatingBall bonding

The invention relates to a eutectic process for coating tin on a substrate and a chip mounting method thereof. The chip mounting method includes the following process steps: step one, utilizing an existing process to manufacture a metal portion of a lead frame; step two, performing ball bonding area plating on the lead frame manufactured in the step one; step three, coating tin or tin alloy at the chip mounting position of the lead frame which finishes ball bonding area plating in the step two; and step four, performing eutectic chip mounting on the lead frame which finishes coating operation, and enabling the chip mounting position of the frame to be combined together with a back gold chip and a back silver chip. The eutectic process for coating tin on the substrate and the chip mounting method of the eutectic process have no requirements for the chip size. After a layer of tin or tin alloy is coated on the substrate, due to the fact that the thickness of the tin or the tin alloy can be controlled, the thickness of the tin or the tin alloy layer can effectively absorb different stress between the chip and the substrate, and problems of delamination and cracking of a traditional eutectic chip are solved.

Owner:CHANGJIANG ELECTRONICS TECH CHUZHOU

Bagged bean product food and marinating process thereof

PendingCN111903774AImprove the marinating effectAvoid breakage etc.Cheese manufactureGreen peasSoya bean

The invention discloses a bagged bean product food. The bagged bean product food is prepared from the following raw materials in percentage by weight: 60-65% of soybeans, 5-6% of rice, 15-18% of peasand 15-20% of peanuts. A bean product is prepared by the following steps of: (1), processing a bean curd selecting high-quality soybeans, rice, peas and peanuts, cleaning, soaking, grinding intothick liquid, boiling into thick liquid, performing pressure forming to prepare the bean curd base, putting the bean curd base in alkaline solution to soak, and then performing drying treatment. According to the bagged bean product food and the marinating process thereof in the invention, preliminary frying is firstly carried out when the bean product is processed; subsequent cutting and hole pricking are conveniently carried out; then, the formed bean product is subjected to cutting and hole pricking; deep frying is carried out after cutting and hole pricking; the cut bean product can be formed deeply; therefore, the parts, making contact with the outside, of the bean product are fried to form a layer of fried skin after cutting and hole pricking; marinating and flavouring during subsequent marinating of marinating soup are facilitated; compared with traditional direct marinating of the bean product, the bean product is more flavourful; and the marinating effect of the bean product can be effectively improved.

Owner:ANHUI HEXIAN SUN ISLAND FOOD

Seeder

InactiveCN101513157BPrecisely control the quantityDo not waste seed resourcesSeed depositing seeder partsRegular seed deposition machinesSeederPunching

The invention relates to an agricultural machine, in particular to a seeder, comprising a frame, a seed box mounted on the top of the frame, a seed carrying assemble mounted under the seed box and a seed distributing assemble mounted at the front end of the frame, wherein a displacement assemble is mounted at the bottom end of the frame, an open for placing the seed is arranged on the seed box, a punching assemble is mounted at the lower end of the frame and connected with a motion assemble, a positioner capable of locking the moving distance of the displacement assemble is mounted at the displacement assemble. In the invetnion, the seed distributing shaft, the seed pushing rod and the seed carrying shaft are imbined, so that the amount of the seeds falling into each cavity can be precisely controlled by the drawing of the seed pushing rod in the sowing process, the seed distributing amount is precise and less.

Owner:南通全通建筑机械有限公司

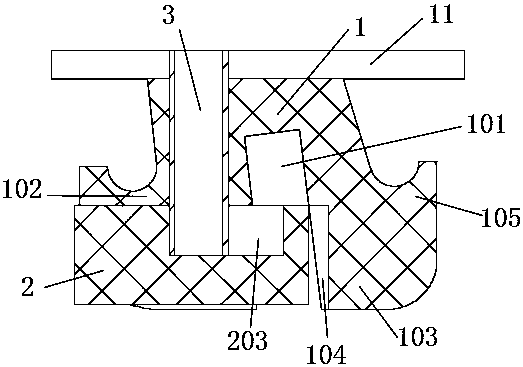

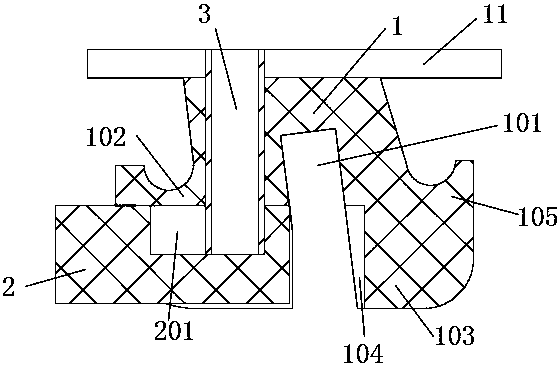

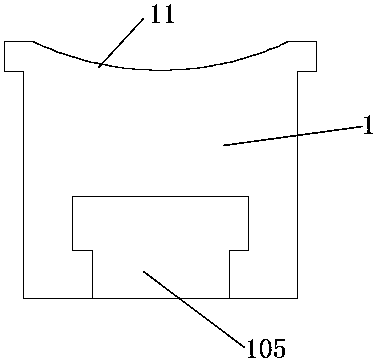

Pre-coated sand typecasting sand core manufacturing device and method for manufacturing typecasting sand core by precoated sand typecasting sand core manufacturing device

ActiveCN106734942AImprove molding rateImprove molding qualityFoundry mouldsFoundry coresMaterials scienceCalcium stearate

The invention discloses a precoated sand typecasting sand core manufacturing device. The precoated sand typecasting sand core manufacturing device consists of a hot core box 1, a supporting frame 2 and a typecasting mold 3, wherein the hot core box is in a box body structure of which the bottom surface 4 is a plane; a typecasting mold inlaying groove 5 is formed in the bottom surface 4; the supporting frame 2 consists of a hot core box support 6 and a heating mechanism 7; the typecasting mold 3 comprises a typecasting base block 8 and a typecasting body 9; and the thickness of the typecasting base block 8 is the same as the depth of the typecasting mold inlaying groove 5. The invention further discloses a method for manufacturing a typecasting sand core by the precoated sand typecasting sand core manufacturing device. In the method, precoated sand consisting of silica sand, phenolic resin, urotropin and calcium stearate is adopted, and a self-hardening technology of ester hardening water glass sand is replaced with the hot hardening technology of the precoated sand; and in the manufacturing and production of the typecasting sand core, manufacturing labor hours can be reduced, production efficiency is improved, the molding rate of the typecasting sand core is increased, the molding quality of the sand core and the molding quality of workpiece typecasting are improved, production consumption is reduced, and manufacturing cost is reduced.

Owner:MUDANJIANG JINYUAN DRAW GEAR & DRAFT GEAR MFG LIMITED

High-strength foam brick and preparation method thereof

The invention discloses a high-strength foam brick. The high-strength foam brick is characterized by being prepared from the following raw materials in parts by weight: 30-40 parts of waste glass, 6-8 parts of rutile titanium dioxide, 5-10 parts of high aluminum powder, 8-12 parts of zircon power, 4-8 parts of alumina silicate fiber, 2-4 parts of triisopropanolamine, 4-6 parts of ethylene diamine tetraacetic acid, 1-2 parts of erythritol, 1-2 parts of citric acid, 1-2 parts of bone glue, 0.5-1 part of seaweed gel, 1-2 parts of sodium lignosulphonate, 0.5-1 part of sodium lignin sulfonate, 2-4 parts of coconut oil fatty acid glycine potassium, 6-10 parts of composite filler and 40-60 parts of water. According to the foam brick disclosed by the invention, through strength improvement, the crushing resistance and the fracture resistance are improved; the phenomena such as edge failure and fracture are avoided; the product quality is relatively good; and the durability is relatively high.

Owner:HEFEI KANGLING HEALTH TECH

A multi-stage drafting device for polyphenylene sulfide fibers

Owner:重庆普力晟新材料有限公司

A large-scale steel bending equipment and bending process

The invention relates to a large-scale steel bending equipment and a bending process, comprising a bottom frame, a guiding mechanism, a bending mechanism and a shaping mechanism. The present invention can solve the following problems in the steel processing process: a. During the bending process of most steel materials, the steel materials are moved and the processing equipment is fixed. For large steel products, the existing equipment is used for processing The required site is large, and the realization process is relatively difficult. b. Most steel materials adopt a one-time forming method during the bending process. The stress generated during the bending process is relatively large, and it is easy to break just now. Insufficient treatment leads to uneven distribution of materials near the bending point, which affects subsequent use.

Owner:杭州川禾冷拉型钢有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com