Anti-blocking inclined plate sedimentation basin

A technology of inclined plate sedimentation and sedimentation tank, which is applied in the direction of flocculation/sedimentation water/sewage treatment, settling tank, etc. It can solve problems such as blockage, large area occupation, and unsmooth mud discharge, and achieve enhanced sedimentation effect, good sedimentation effect, The effect of guaranteed concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

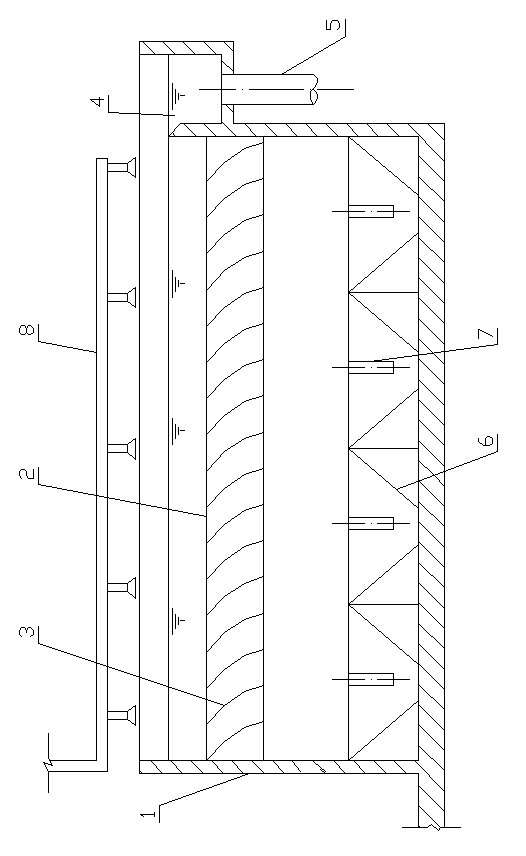

[0019] as attached figure 1 Shown: the anti-blocking inclined plate sedimentation tank of the present invention includes a sedimentation tank body 1, a group of inclined plates 3 are connected to the sedimentation tank body through horizontally and vertically staggered connecting ribs 2, and a sump is arranged on the sedimentation tank body 4. The outlet pipe 5 is installed at the end of the sump, and the sedimentation bucket 6 and the mud discharge pipe 7 are installed under the sedimentation tank body. The inclined plate is composed of three sections. The included angle is 45°-50°, the included angle between the inclined plate located in the middle section and the horizontal plane is 50°-60°, and the included angle between the inclined plate located in the lower section and the horizontal plane is 60°-70°. When the concentration of the liquid or mud to be settled is too high, the content of solid particles is too high, and the specific gravity of the solid particles is large...

Embodiment 2

[0021] The anti-blocking sloping plate sedimentation tank above, the length of the sloping plate is not less than 90cm, and the distance between the sloping plates is 35-50cm.

Embodiment 3

[0023] The anti-clogging sloping plate sedimentation tank above, and there are no less than 6 sedimentation mud buckets. Each settling mud hopper is closely arranged, and each settling mud hopper is equipped with a separate mud discharge pipe, which discharges mud independently without interfering with each other to ensure the concentration of sediment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com