A method for prevention and control of delamination water damage on the coal seam roof of a mine

A coal seam roof and separation layer technology, which is applied in mining equipment, earthwork drilling, mining equipment, etc., can solve problems such as easy loosening and breaking of surrounding rock, flooded working face, and poor overall rock stability, so as to avoid economic losses and reduce Flooded, avoiding the effects of crushing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

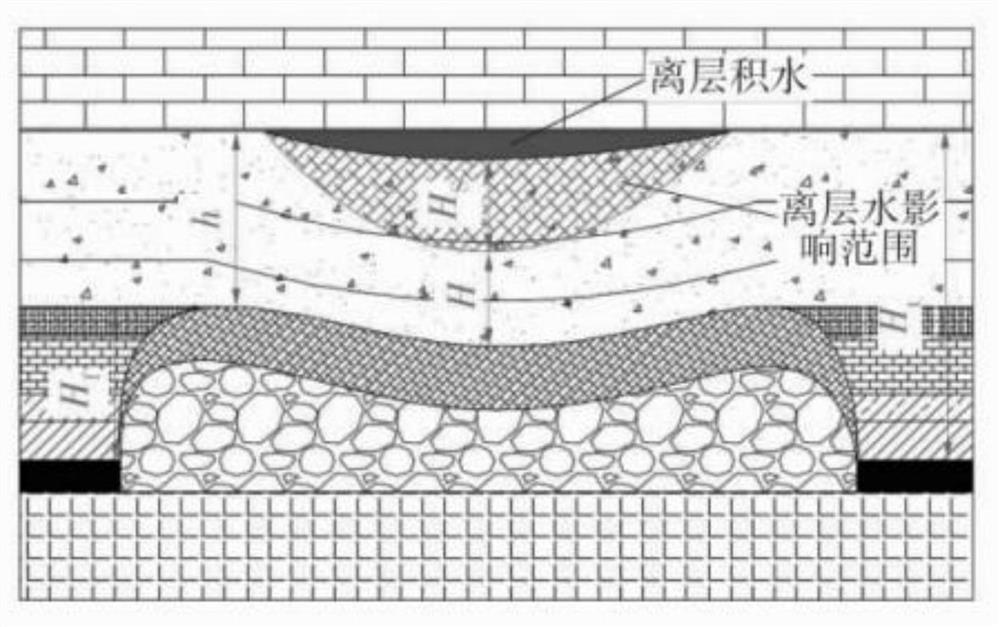

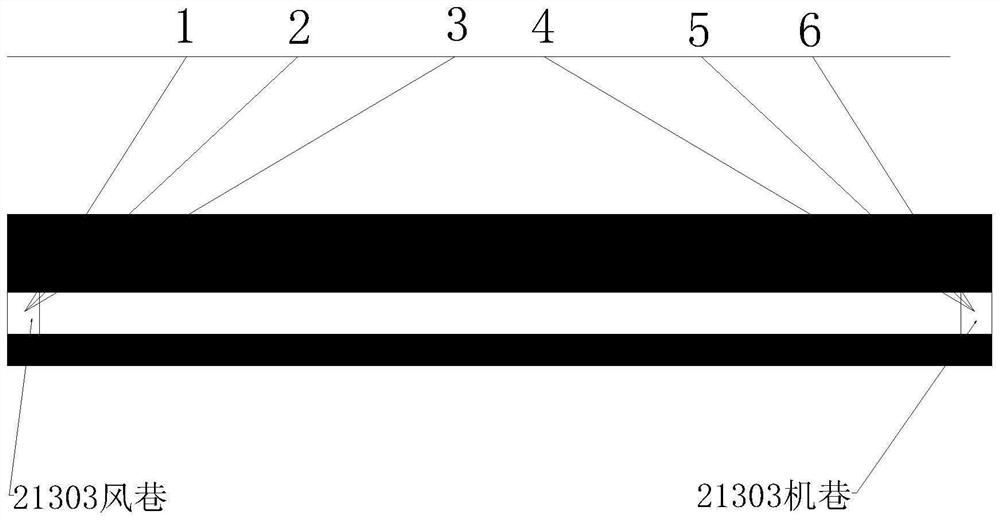

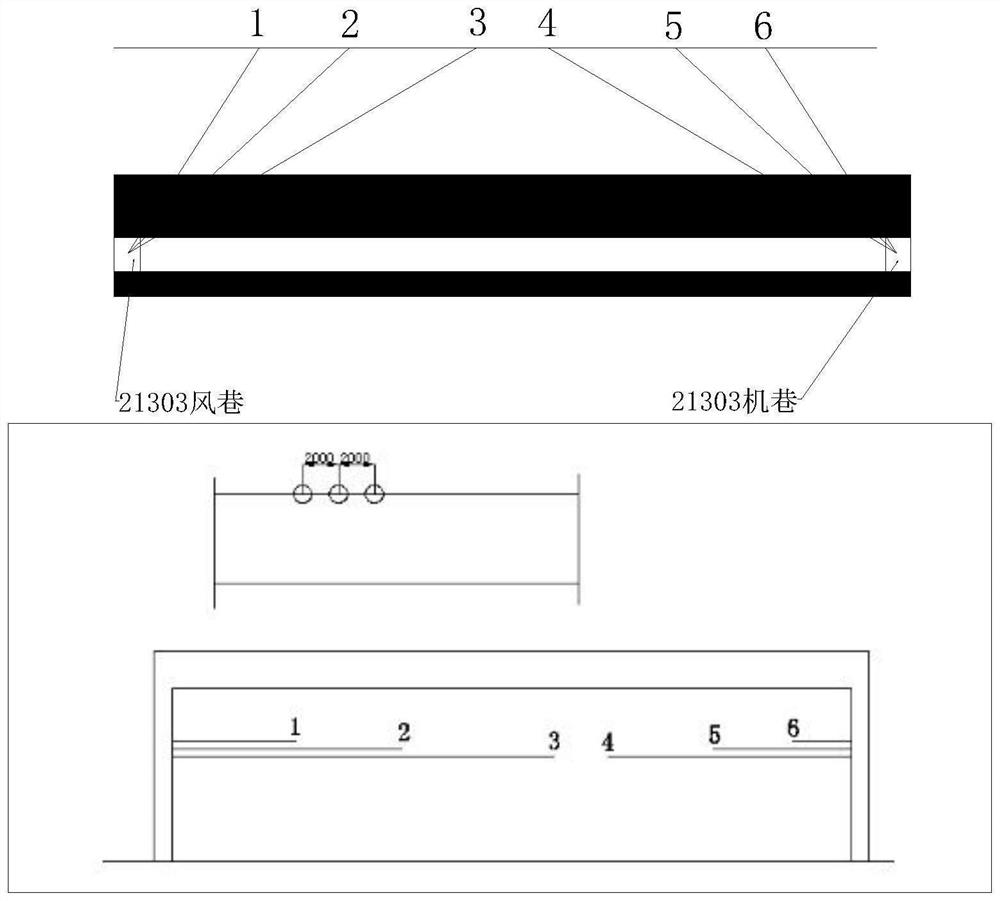

[0032] The invention relates to a method for preventing and controlling water damage of a water-rich thick hard roof in a coal seam from layer separation. The area is filled with solid filling to avoid the accumulation of abscission water. The two-way multi-stage "V" type drilling method is adopted in the roadway, and the tunnel is drilled into the roof rock body at the same time in the working face and the machine roadway - charging - sealing Blocking - detonation; with this blasting hole arrangement, while the roof forms a complete blasting damage zone, the advantages of the V-shaped undercut can be fully utilized, so that part of the blas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Elevation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com