Wheelbarrow capable of assembling-disassembling abrasive wheel on vehicle

A technology of trolleys and grinding wheels, which is applied in the direction of trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of grinding wheel fragmentation, damage to grinding wheel block equipment, personal safety, and potential safety hazards, so as to prevent bursting and scrapping of grinding wheels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Through the following description of the embodiments of the present invention combined with the accompanying drawings, the purpose, specific structural features and advantages of the present invention can be further understood.

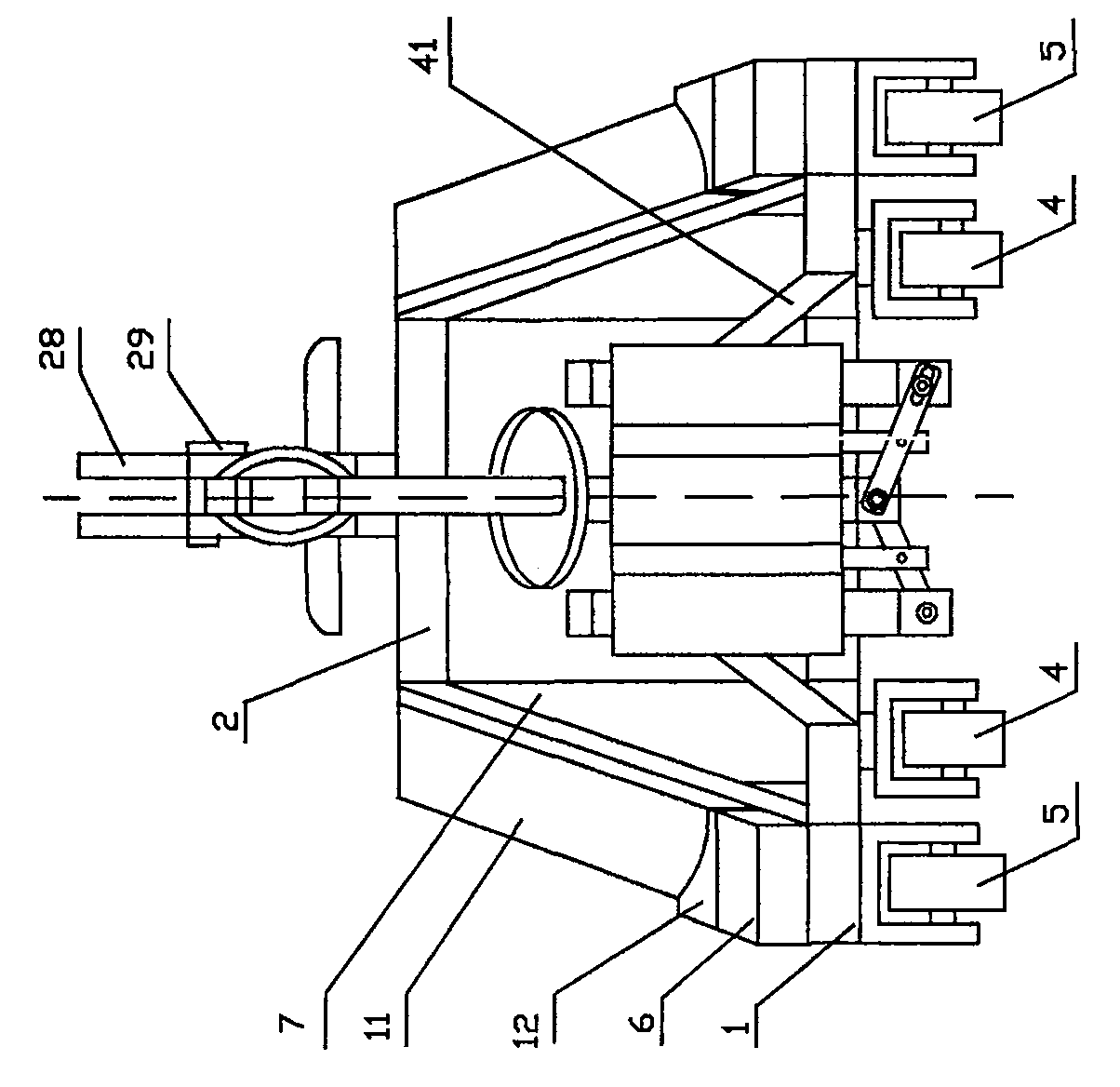

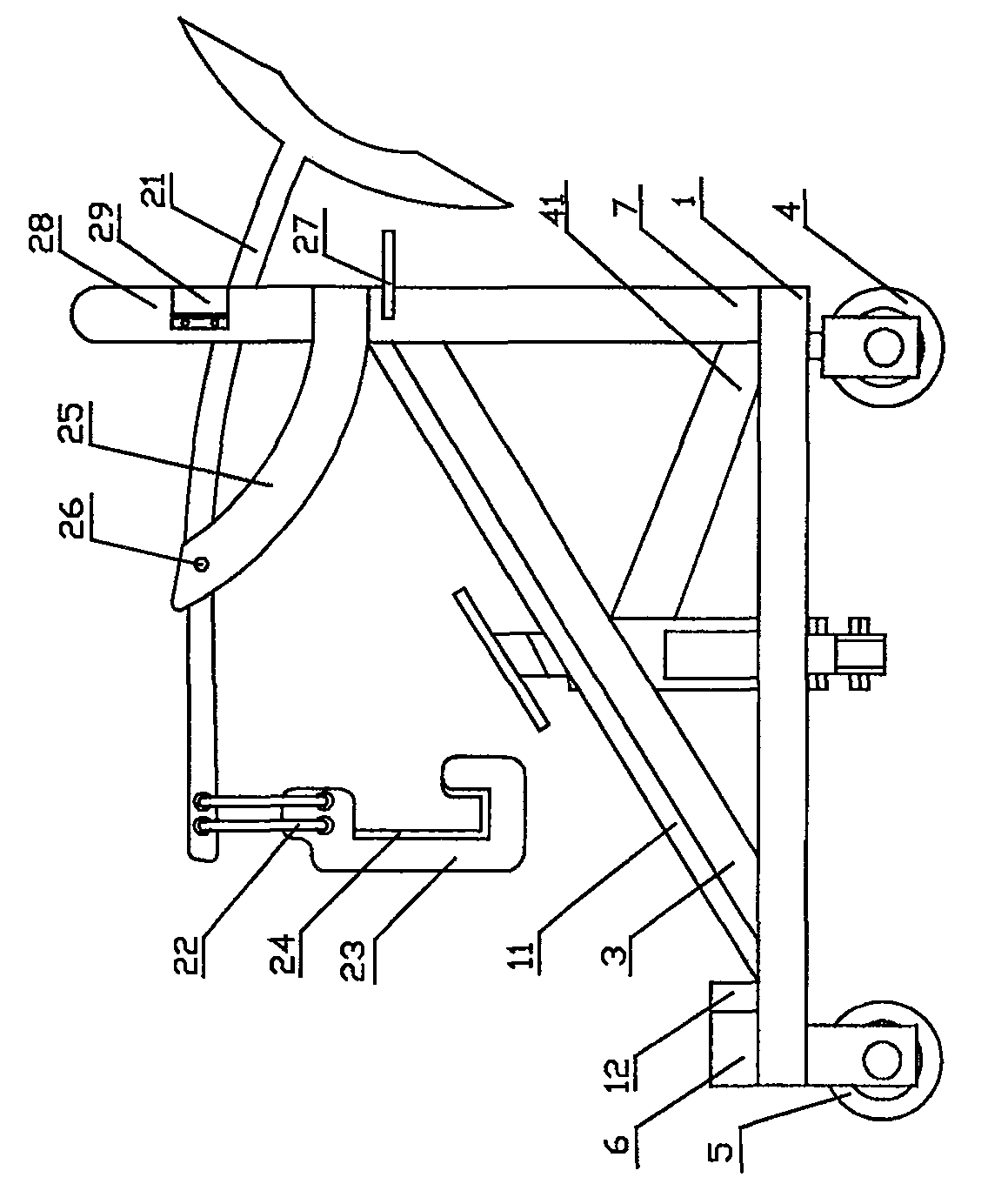

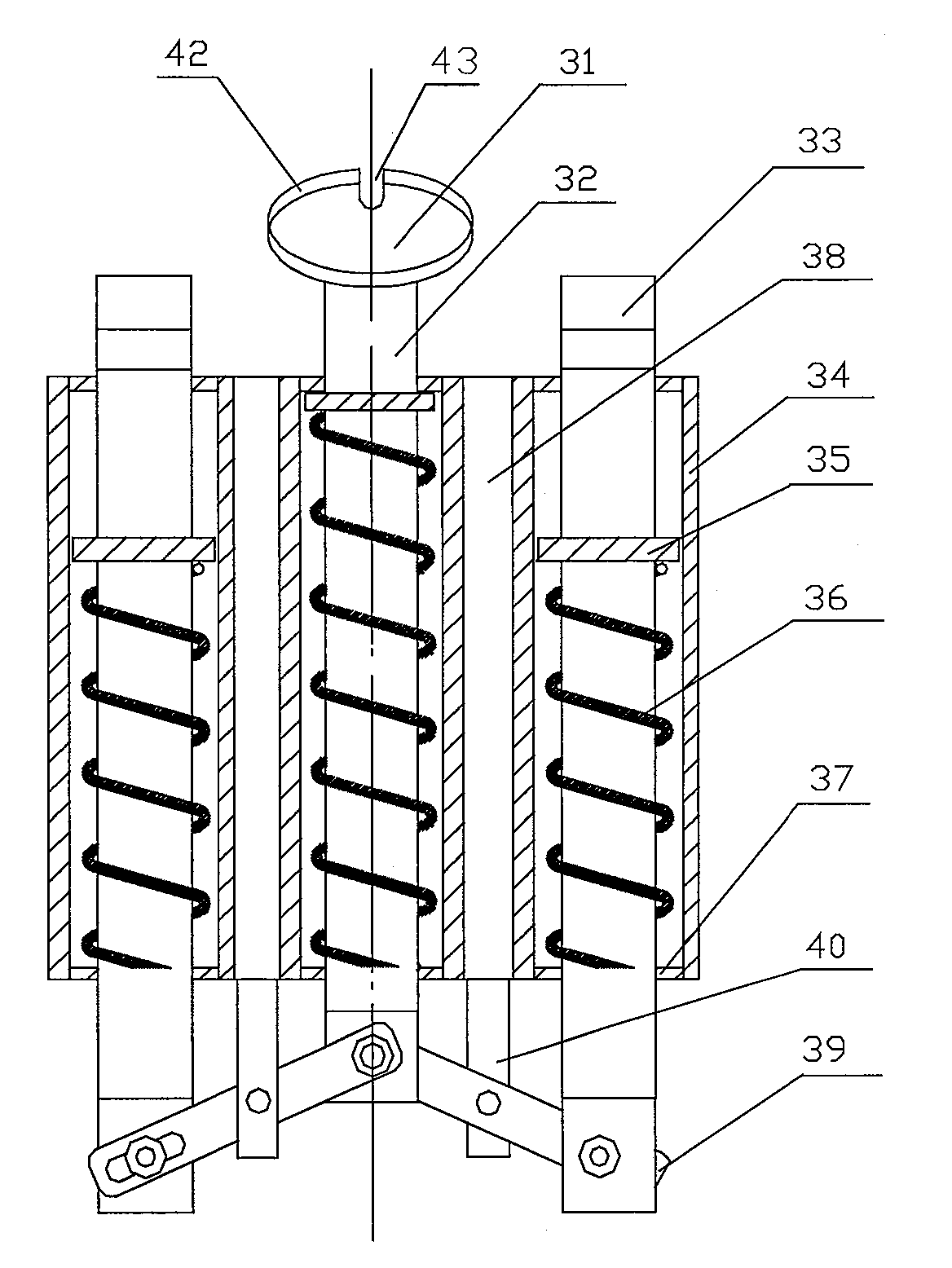

[0034] see figure 1 , figure 2 , a trolley that can disassemble the grinding wheel on the car, including a car body, a handle control device, and a lifting device. The car body includes a car frame, fixed wheels 5, universal wheels 4, and stoppers 6; Rod 1, two left and right slanting bars 3, two upper and lower rear frame cross bars 2 and two left and right vertical rear bars 7 are welded with hollow square steel; two fixed wheels 5 are respectively installed at the bottom of the front ends of the two bottom bars 1; Two universal wheels 4 are respectively installed at the bottom of the rear ends of the two bottom bars 1; two stoppers 6 are respectively welded to the tops of the front ends of the two bottom bars 1; for ease of operation, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com