Hole Forming Technology of Radial Well Construction with Low-Pressure Jet Pullback

A low-pressure injection and radial well technology, which is applied in drilling with liquid/gas injection, drilling equipment, drilling equipment and methods, etc., can solve problems such as affecting construction effect and construction progress, decreasing permeability and decreasing coal seam porosity, etc. Achieve the effect of alleviating high-load operation, improving service life and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

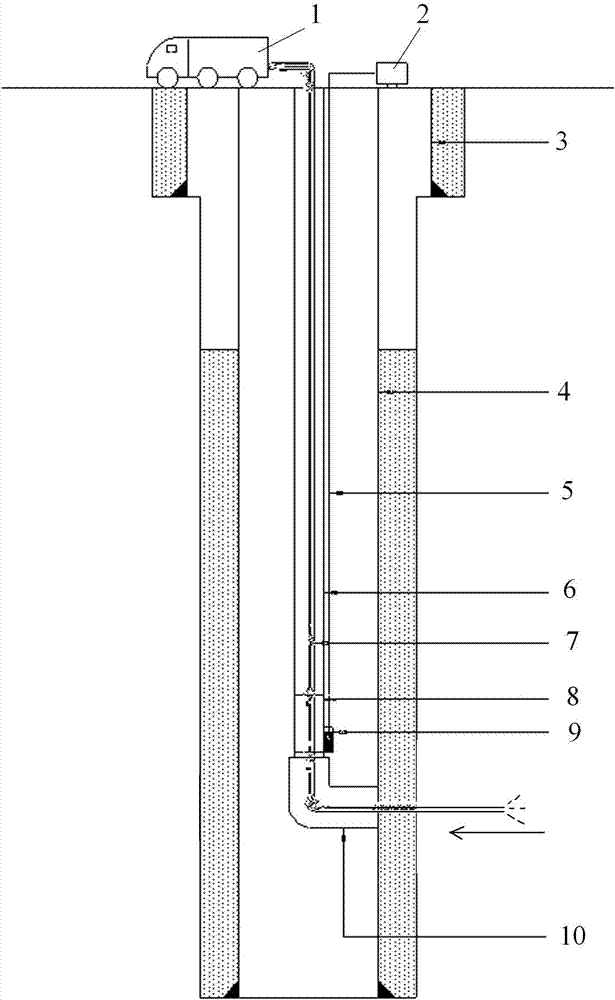

[0015] In the radial well operation process of individual coalbed methane wells, due to accidental factors, the high-pressure pump in the process of jet pullback is abnormal, so that the pullback process is completed at low pressure, but the flowback effect and permeability of pulverized coal are better than those of Radial well construction effect of pullback process under conventional high-pressure water jet conditions. Therefore, in the radial well construction process of coalbed methane wells, after the construction of a single radial hole is completed, when the coiled tubing is pulled back, the pressure of the nozzle water jet should be reduced (lower than the pressure of the coal reservoir) to avoid the high-pressure water jet from blowing the coal powder The particles are pressed into the coal seam fractures, thereby reducing the overall effectiveness of the radial well construction. Combined with the accompanying drawings, its specific construction work is further expl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com