A special auxiliary lifting device for special-shaped building components

A technology for building components and hoisting devices, used in safety devices, transportation and packaging, load hoisting components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

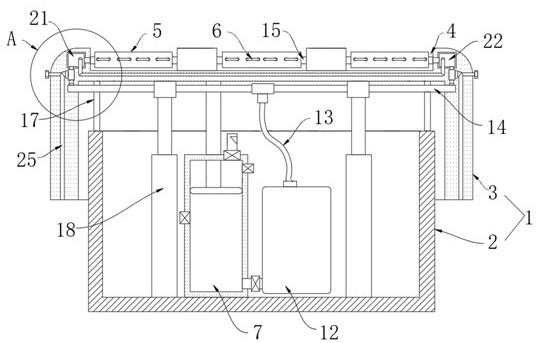

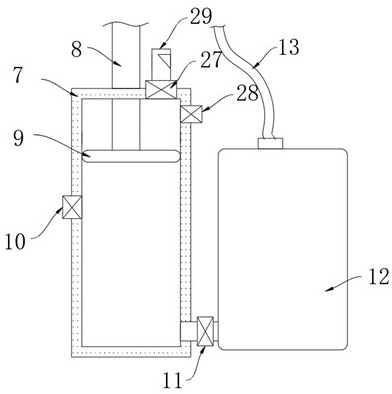

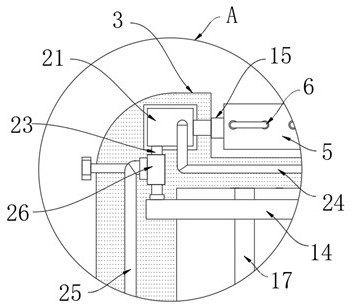

[0027] refer to Figure 1-7 , a special-purpose auxiliary lifting device for special-shaped building components, including an auxiliary platform 1, the auxiliary platform 1 is composed of a bottom platform 2 and a top platform 3, the top platform 3 is set on the upper end of the bottom platform 2 in an inverted concave shape and wraps it, the bottom The upper edge of the table 2 is provided with a plurality of jacks, and guide rods 17 are plugged into the inside of the jacks. An elastic telescopic mechanism is provided, and the elastic telescopic mechanism includes a telescopic sleeve 18, an inner rod 19 is arranged inside the telescopic sleeve 18, and a return spring 20 is arranged between the bottom of the inner rod 19 and the telescopic sleeve 18.

[0028] The upper surface of the top table 3 is provided with a through groove 4, the inside of the through groove 4 is provided with a threading conveyor belt 5, the inside of the top table 3 is provided with a driving mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com