Ground source heat pump mounting auxiliary device

An installation-assisted, ground-source heat pump technology, applied in heat pumps, lighting and heating equipment, refrigeration components, etc., can solve the problem that the drilling machine cannot perform drilling operations, affect the construction progress, reduce the drilling speed, etc., and achieve convenient field conditions. work, improve the burial speed, and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

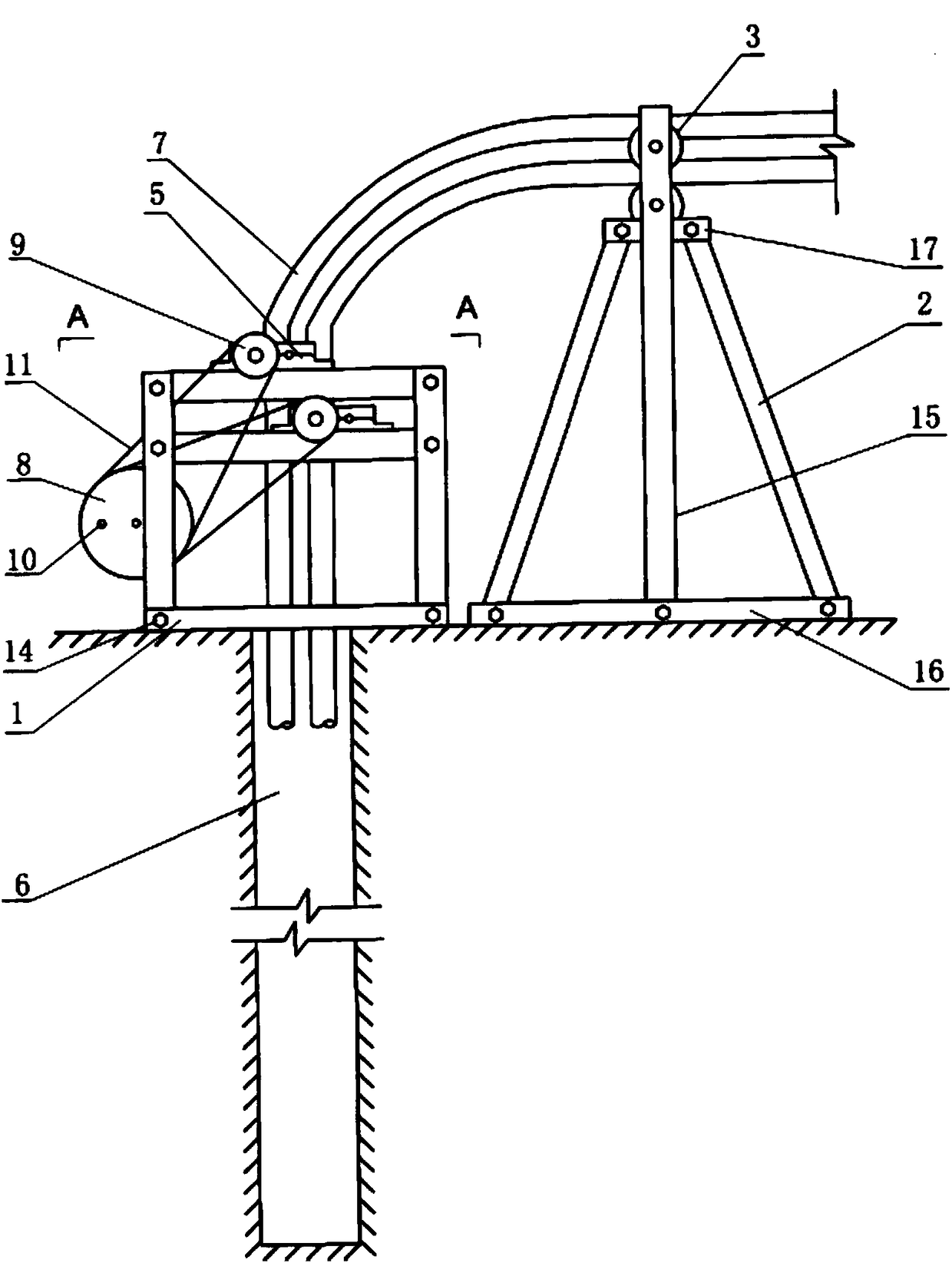

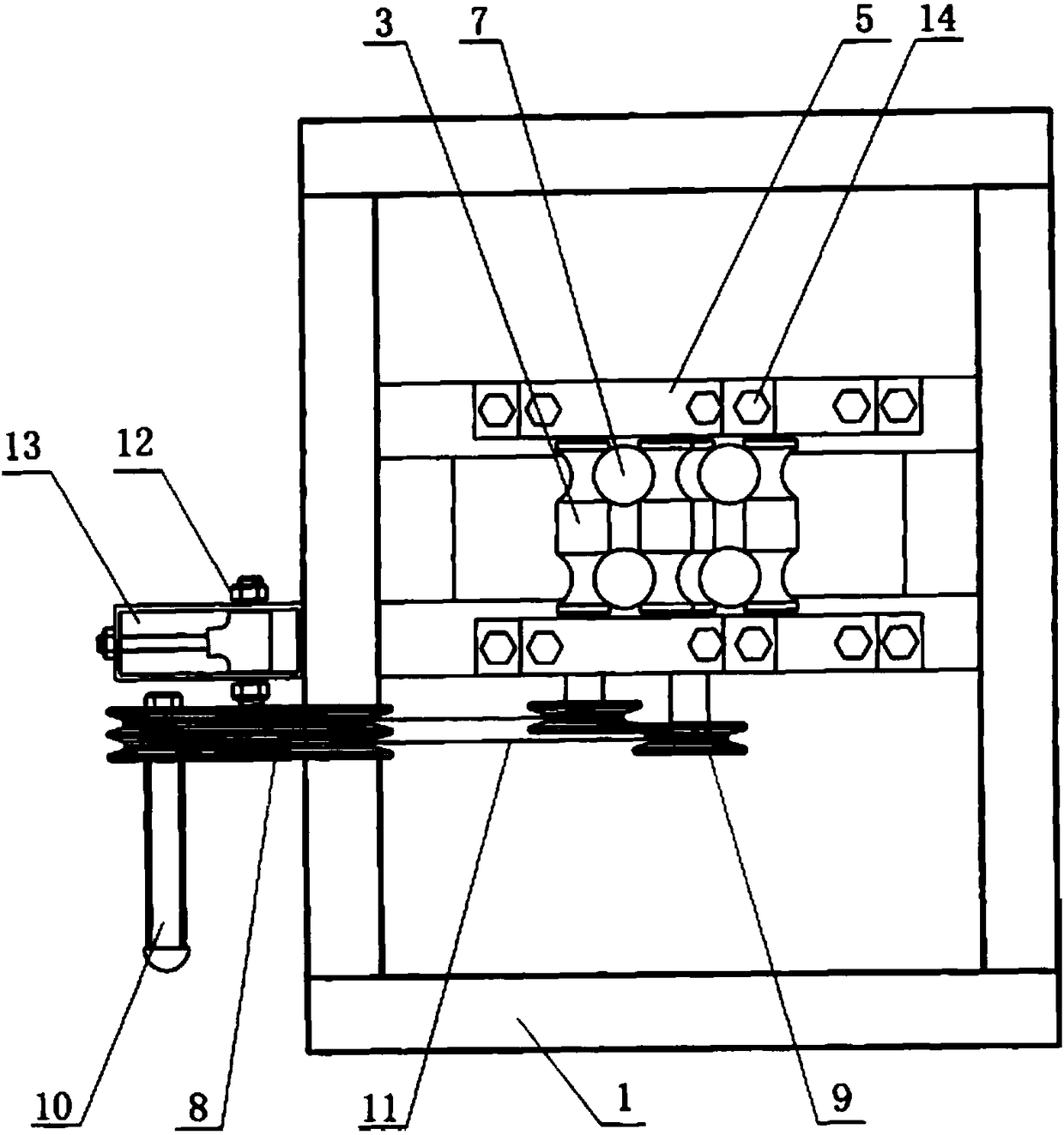

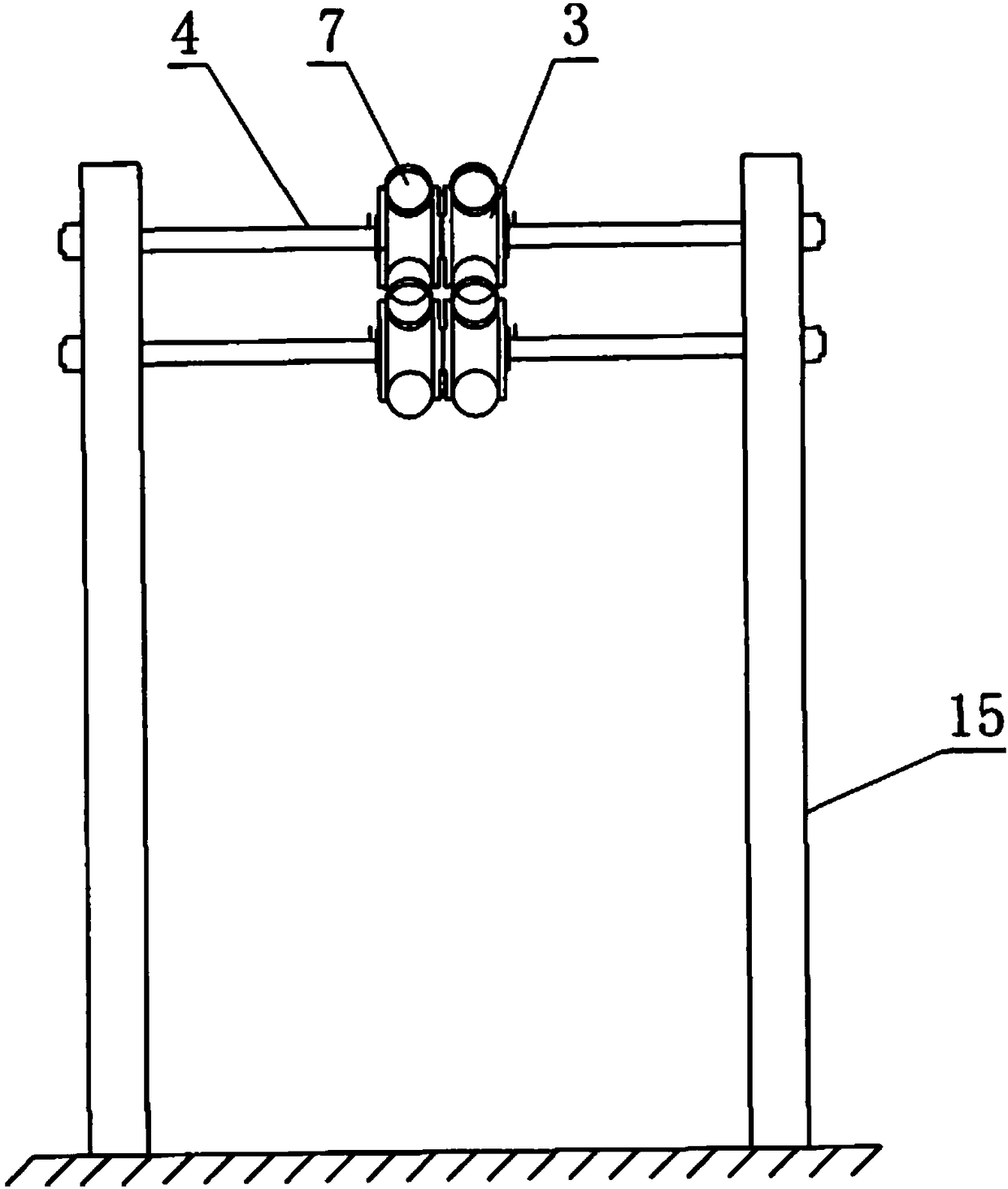

[0020] Such as figure 1 , 2 As shown in , 3, a ground source heat pump installation auxiliary device is mainly composed of a bracket 1, an arc groove roller shaft 3, a handle 10, a driving wheel 8, a driven wheel 9, a support frame and the like. The bracket 1 is made of angle steel, and is assembled into a detachable bracket by bolts and nuts 14, and its height is 800 mm. In the middle of the upper end of the bracket 1, it is divided into upper and lower layers, and two angle steels are fixed by bolts and nuts 14 respectively. The length of the shaft 3 is determined, and holes are respectively arranged in the middle of the opposite inner surfaces of the four angle steels. There are two pairs (i.e. 4) of arc groove roller shafts 3, each of which is formed by round steel at both ends of the roller shaft 3 with concave arc grooves, and is provided with thread. The size and spacing of the arc grooves at both ends are determined according to the outer diameter of the straight p...

Embodiment 2

[0022] An auxiliary device for installing a ground source heat pump is the same as in Embodiment 1, and is characterized in that the height of the bracket 1 is 900 mm. The spacing between the upper and lower layers of angle steel of support 1 is 90mm. The driven wheel 9 is 50mm in diameter, and the driving wheel 8 is 160mm in diameter. The height of the two straight columns 15 is 1450 mm, the distance between them is 450 mm, and the distance between the two circular through holes at the top of the two straight columns 15 is 90 mm. The length of the angle steel cross-arm 17 welded respectively on the top of the straight post 15 (i.e. below the through hole) is 10mm.

Embodiment 3

[0024] An auxiliary device for installing a ground source heat pump is the same as that in Embodiment 1, and the feature is that the height of the bracket 1 is 700mm. The spacing between the upper and lower layers of angle steel of the support 1 is 70mm. The driven wheel 9 is 70mm in diameter, and the driving wheel 8 is 140mm in diameter. The height of the two straight columns 15 is 1400 mm, the distance between them is 400 mm, and the distance between the two circular through holes at the top of the two straight columns 15 is 70 mm. The length of the angle steel cross-arm 17 welded respectively on the top of the straight post 15 (i.e. below the through hole) is 7mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com