Method for laminating solar battery module

A technology of solar cells and components, applied in the direction of lamination, lamination devices, electrical components, etc., to achieve the effect of easy realization, extremely low production cost, and avoid degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] see Figure 3~5 Shown, a kind of lamination method for solar cell module, comprises the steps:

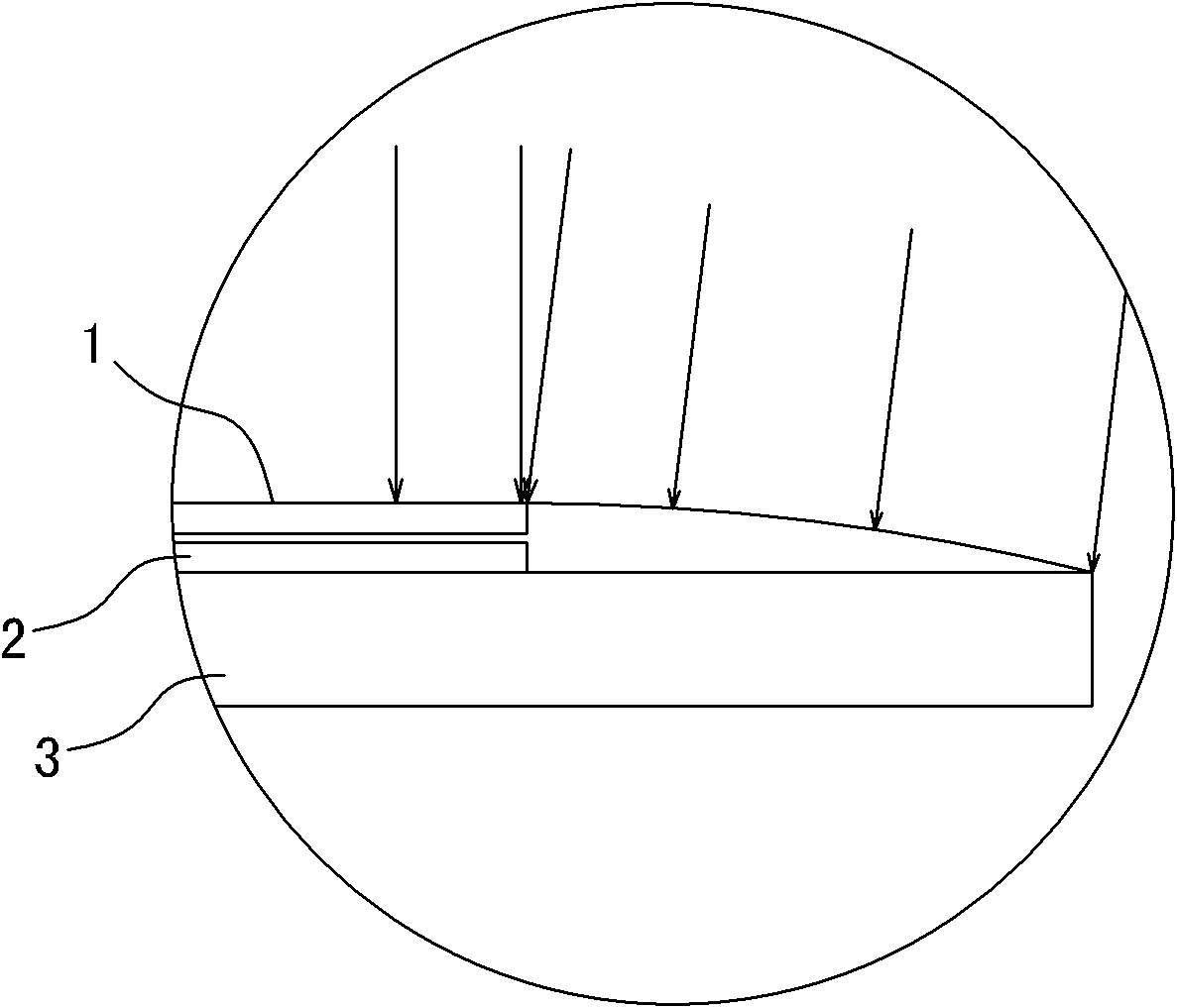

[0028] (1) Laying non-stick cloth on the heating table 3 of the laminator;

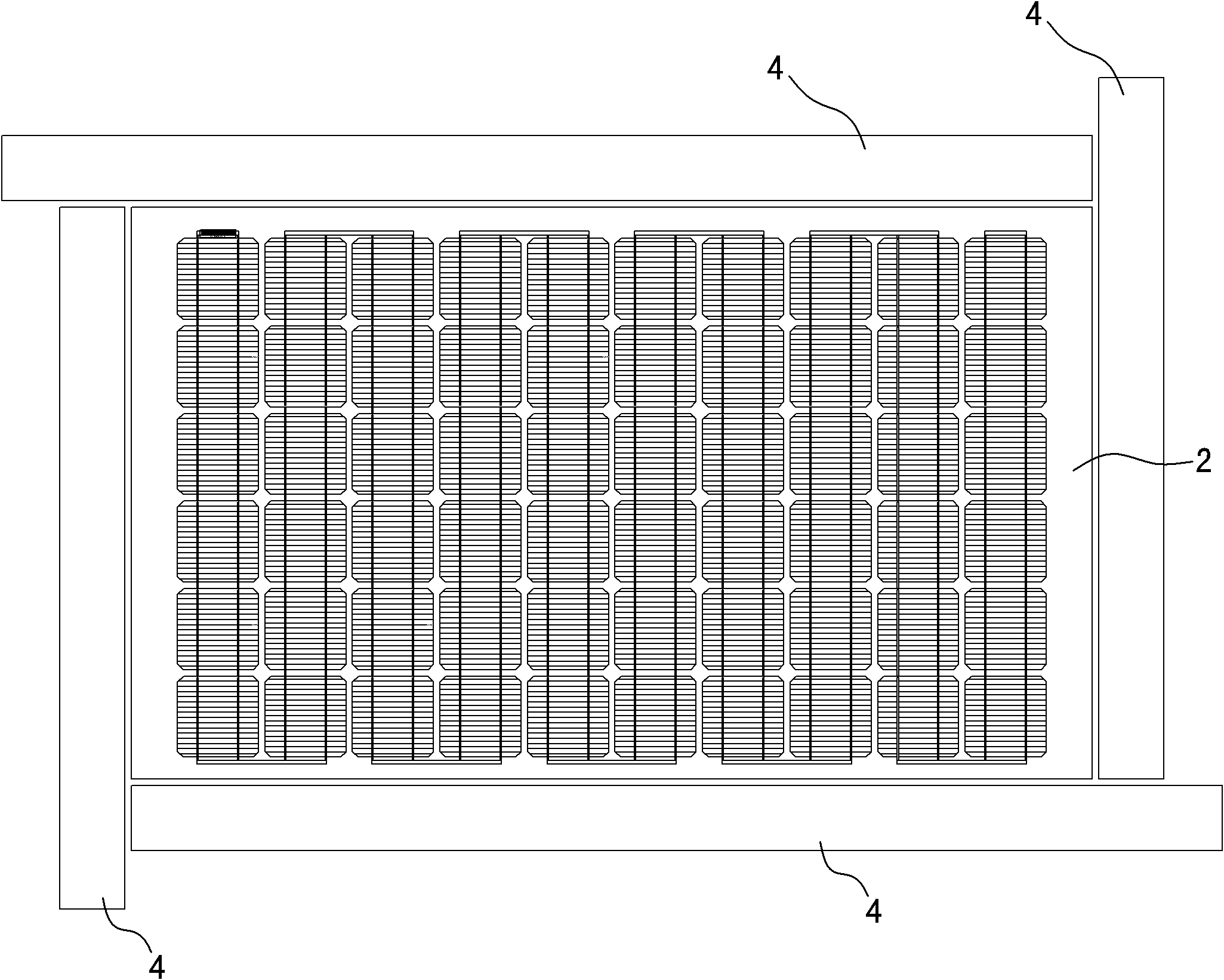

[0029] (2) Place the stacked semi-finished solar cell module 2 on the non-stick cloth of the heating table;

[0030] (3) Four spacers 4 are arranged around the semi-finished solar cell module; the distance between each spacer and the edge of the semi-finished solar cell module is 10-20 mm, and the thickness of the spacer is smaller than that of the semi-finished solar cell module. The thickness is 1~2 mm smaller;

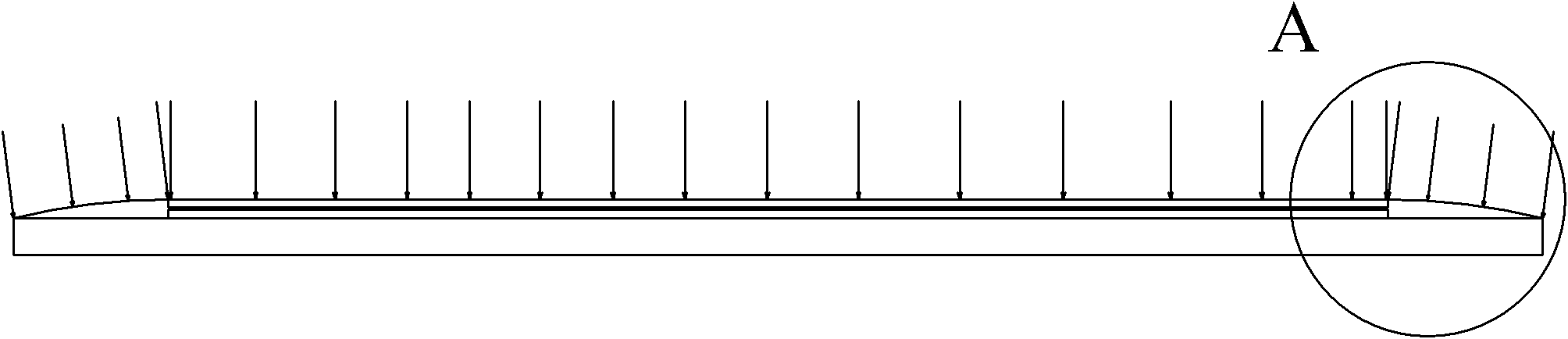

[0031] (4) laying non-stick cloth 1 on the described semi-finished solar cell module and pad strip then;

[0032] (5) Finally, vacuumize, heat, and pressurize in the chamber of the laminator to form a whole, and then obtain the solar cell module.

[0033] The semi-finished solar cell module refers to the module to be laminated after being prepared for sorting, single welding, series w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com