Pressure maintaining device

A technology of pressure-holding device and die, which is applied in metal processing, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

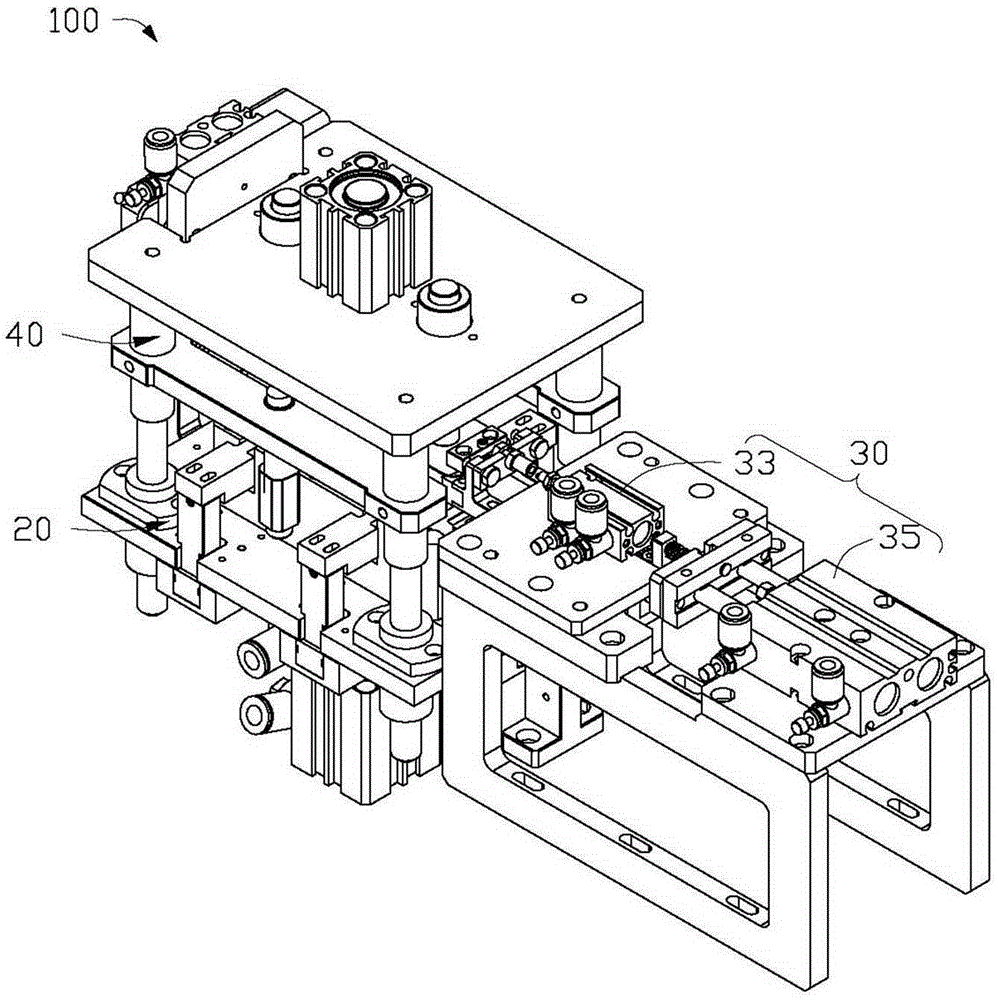

[0019] The pressure maintaining device according to the embodiment of the present invention is used for automatically maintaining pressure on the back glue on the casing of the electronic product.

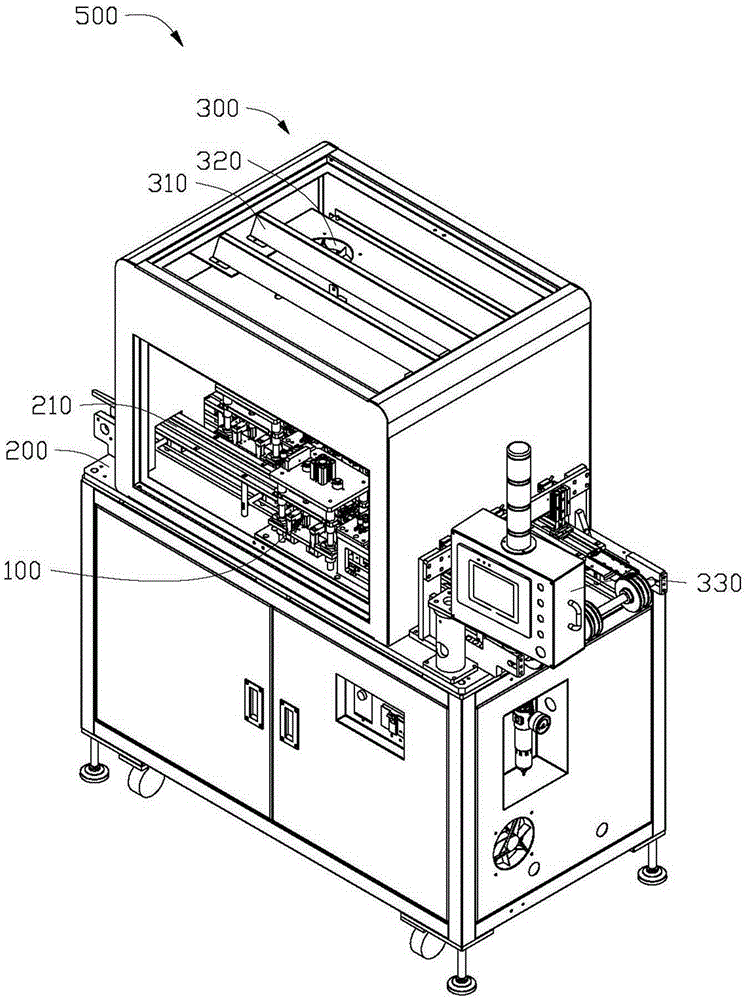

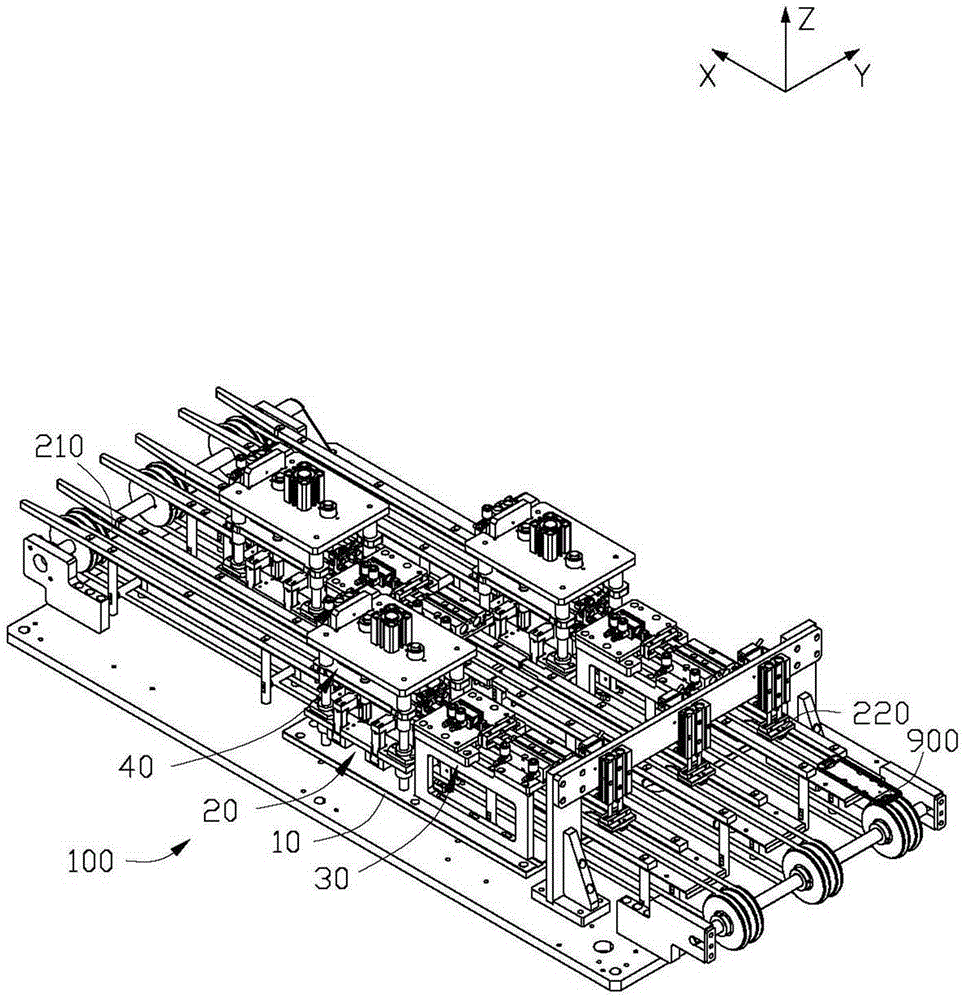

[0020] Please also refer to Figure 1 to Figure 3 , the pressure maintaining device 500 according to the embodiment of the present invention includes a pressure maintaining mechanism 100 , a workbench 200 carrying the pressure maintaining mechanism 100 , and a heating chamber 300 located above the pressure maintaining mechanism 100 .

[0021] A conveyor belt 210 is provided on the workbench 200, and the conveyor belt 210 is used to automatically transport the workpiece 900. In this embodiment, the workpiece 900 is a casing of an electronic product, and the number of conveyor belts 210 is three, but not limited thereto. One end of the workbench 200 is also provided with an anti-stacking piece 220, which is used to prevent workpieces from being stacked. In this embodiment, the anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com