Shock-proof waterproof coiled material and preparation method

A waterproof membrane and waterproof layer technology, applied in chemical instruments and methods, lamination, coating, etc., can solve the threat of waterproof membrane integrity, no research on the shockproof effect of waterproof membrane, etc., and achieve enhanced humanized design , good toughness and environmental stability, good shock absorption and buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

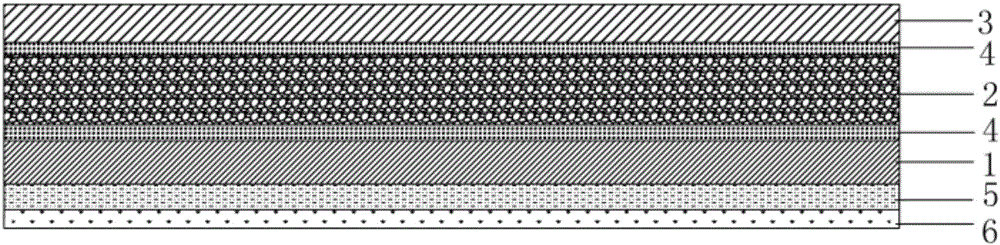

[0025] Such as figure 1 Shown, a kind of anti-vibration waterproof coiled material and preparation method of the preferred embodiment of the present invention;

[0026] The shockproof and waterproof roll material includes a base material layer 1, an elastic buffer layer 2 is provided on the upper surface of the base material layer 1, and a tough waterproof layer 3 is provided on the upper surface of the elastic buffer layer 2, wherein the elastic buffer layer 2 and the base material layer 1 and between the elastic buffer layer 2 and the tough waterproof layer 3 are all connected by an adhesive layer 4; the lower surface of the base material layer 1 is provided with a self-adhesive waterproof layer 5, and the self-adhesive A protective layer 6 is also provided on the lower surface of the waterproof layer 5 .

[0027] Wherein, the base material layer 1 is a glass fiber felt layer, which can enhance the strength of the waterproof coiled material; the elastic buffer layer 2 is an...

Embodiment 2

[0030] A shockproof and waterproof coiled material according to a preferred embodiment of the present invention and its preparation method;

[0031] The shockproof and waterproof coiled material includes a substrate layer, an elastic buffer layer is provided on the upper surface of the substrate layer, and a tough waterproof layer is provided on the upper surface of the elastic buffer layer, wherein the elastic buffer layer and the substrate The layers and between the elastic buffer layer and the tough waterproof layer are all connected by an adhesive layer; the lower surface of the base material layer is provided with a self-adhesive waterproof layer, and the lower surface of the self-adhesive waterproof layer is also provided with a protective layer.

[0032] Wherein, the base material layer is a glass fiber felt layer, which can enhance the strength of the waterproof membrane; the elastic buffer layer is an EVA foam layer, which has light weight and good elasticity, and can ...

Embodiment 3

[0035] The structure of the shockproof and waterproof coiled material is the same as that of Example 1, except that the preparation method of the shockproof and waterproof coiled material is: a layer of graphene modified EVA foam glue bonding layer is coated on the upper surface of the glass fiber mat base material layer, and then The EVA foam layer is bonded on the upper surface of the adhesive layer, and the thickness of the foam layer is 2 mm; the graphene modified EVA foam glue adhesive layer is coated on the upper surface of the EVA foam layer, and then glued on the upper surface of the adhesive layer. A graphene-modified natural rubber layer was formed, and the thickness of the modified natural rubber layer was 0.6 mm; a self-adhesive SBS modified asphalt layer was coated on the lower surface of the glass fiber mat layer, and the thickness of the asphalt layer was 0.4 mm, and the thickness of the asphalt layer was coated on the other side of the asphalt layer. One surface i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com