Earthquake prevention fixed base for electric pole

A technology for fixing bases and poles, which is applied in the field of transmission lines, can solve problems such as uneven settlement, easy settlement of bases, time-consuming and labor-intensive installation process, etc., to improve structural stability and reliability, reduce oxidation or corrosion, and prevent fractures The effect of damage or dump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

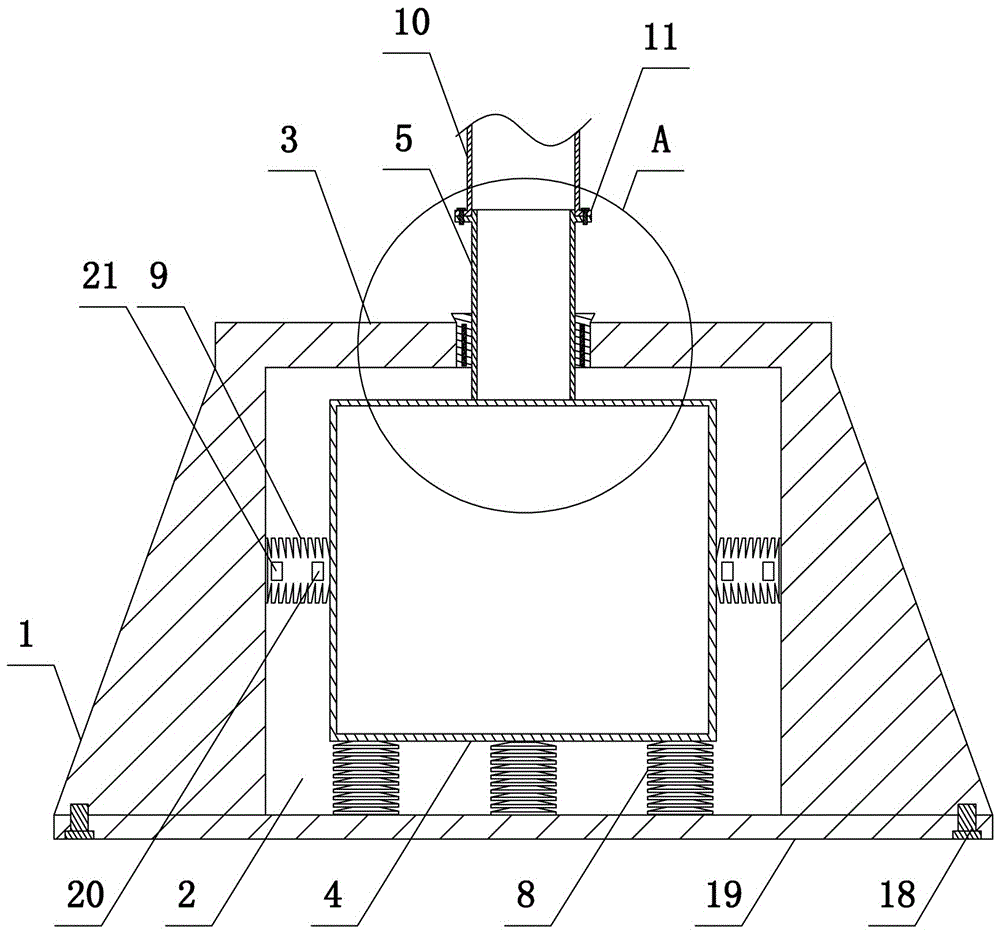

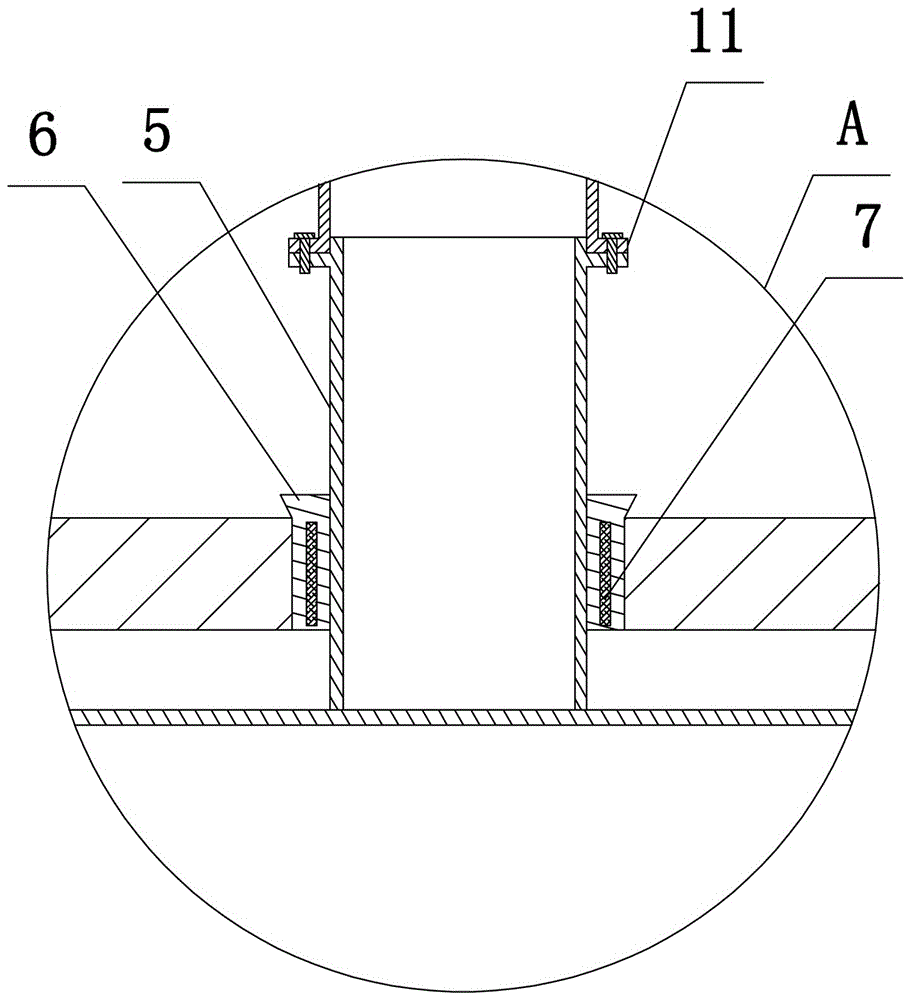

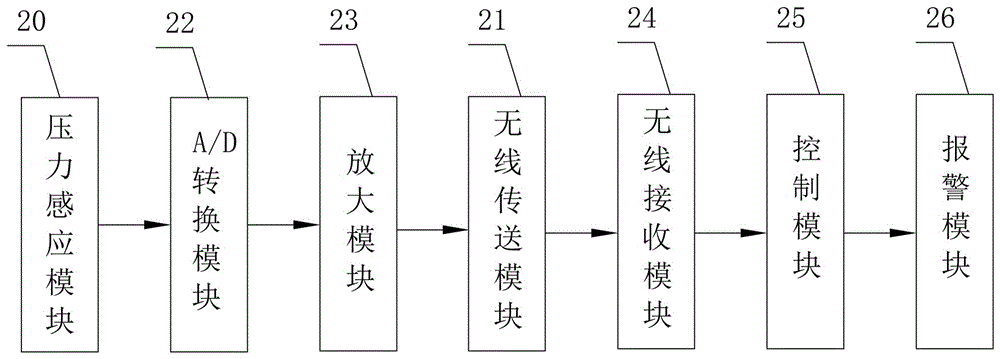

[0028] Such as Figure 1 to Figure 3As shown, the present invention includes a support base 1, a shock absorbing structure and an adapter structure 10. The adapter structure 10 can use a columnar hollow steel pipe. Cuboid columnar structure, the upper end surface of the support base 1 is integrally formed with a cover plate 3, a through hole is set in the center of the cover plate 3, the through hole is a circular structure, the width of the accommodation cavity 2 is greater than the diameter of the through hole; the shock absorbing structure includes setting a shock absorbing seat 4 and the connecting rod 5, the shock-absorbing seat 4 is a rectangular columnar structure, the connecting rod 5 is a circular structure, the shock-absorbing seat 4 is installed in the accommodation chamber 2, and the lower end of the connecting rod 5 extends into the accommodation chamber 2 and is fixed with the shock-absorbing seat 4 connection, the upper end of the connecting rod 5 extends out of...

Embodiment 2

[0031] The present invention includes a support base 1, a shock absorbing structure and a transfer structure 10. The support base 1 is a circular truncated structure, and the center of the support base 1 is provided with an accommodation cavity 2, which is a rectangular columnar structure, and the upper end surface of the support base 1 is integrally formed with a cover plate. 3. A through hole is set in the center of the cover plate 3, the through hole is a circular structure, and the width of the accommodating cavity 2 is larger than the diameter of the through hole; the shock absorbing structure includes a shock absorbing seat 4 and a connecting rod 5, and the shock absorbing seat 4 is a rectangular parallelepiped column structure, the connecting rod 5 is a circular structure, the shock-absorbing seat 4 is installed in the accommodation chamber 2, the lower end of the connecting rod 5 extends into the accommodation chamber 2 and is fixedly connected with the shock-absorbing s...

Embodiment 3

[0034] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 5 As shown, four first protrusions 12 (two are shown in the figure) are arranged on the outer wall of the shock absorber 4, four second protrusions 13 are arranged on the inner wall of the accommodation cavity 2, and the air spring 9 is four and its The two ends are respectively socketed with the first protrusion 12 and the second protrusion 13 . During installation, the air spring 9 is retracted by the hydraulic or pneumatic clamping device in the prior art, and it is sleeved on the first protrusion 12 and the second protrusion 13. When an earthquake occurs, this structural design is conducive to improving the air spring. 9 Stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com