Special metal rubber shock absorber for spacecraft

A metal rubber, shock absorber technology, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., to achieve remarkable effects, long fatigue aging life, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

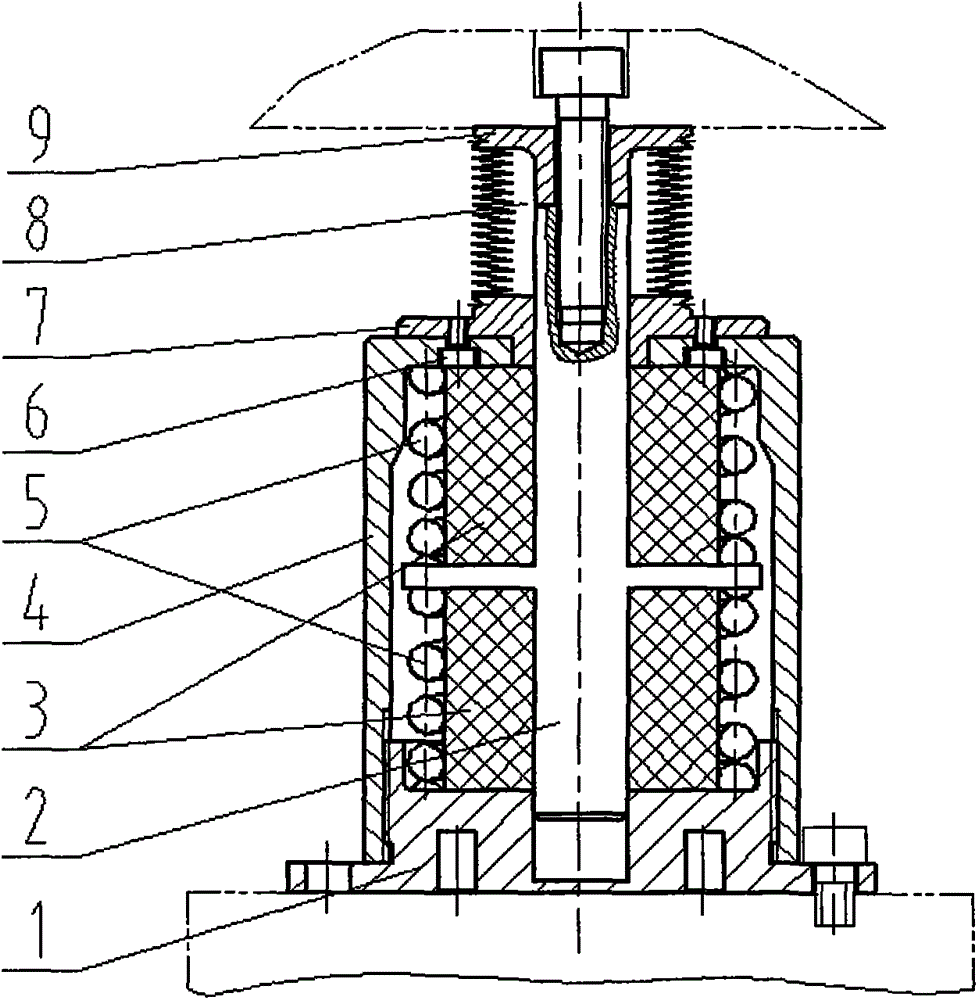

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] The special metal rubber shock absorber for spacecraft shown in the accompanying drawings includes: a shell 4, a bottom cover 1, a central shaft 2, a shock absorbing element and a bellows protective cover.

[0024] The casing 4, the bottom cover 1, and the central shaft 2 are all made of high-strength aluminum, which reduces the weight of the shock absorber while ensuring the strength of the shock absorber.

[0025] The housing 4 is connected to the bottom cover 1 through threads, and the inner cavity is used to contain and protect the vibration damping element.

[0026] The bottom cover 1 is disc-shaped, and four cylindrical through holes are evenly distributed on the outer surface. When the present invention is applied, the bottom cover 1 is fixed on the substrate by bolts.

[0027] A cylindrical groove is also processed in the center of the top sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com