Patents

Literature

218results about How to "Avoid degumming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

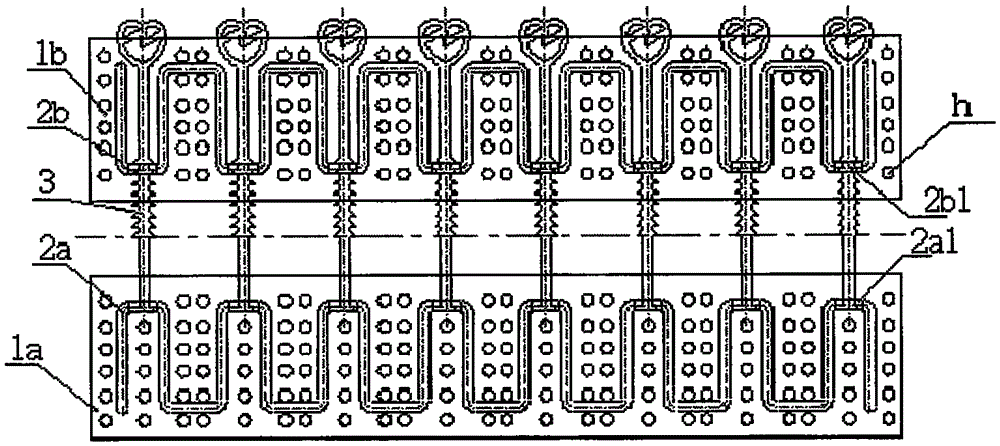

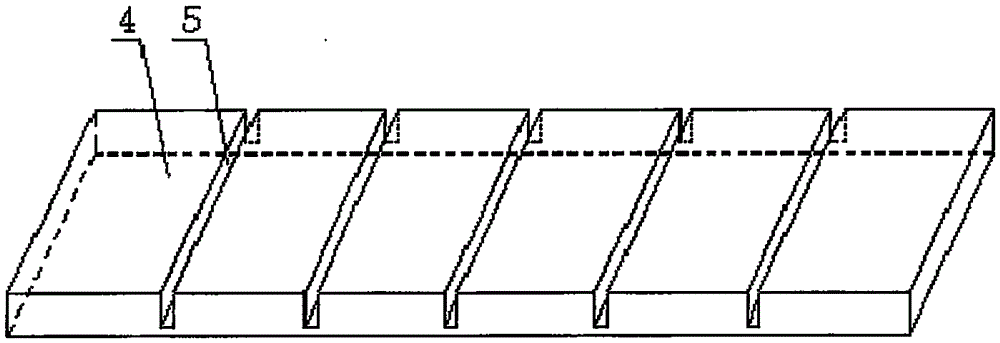

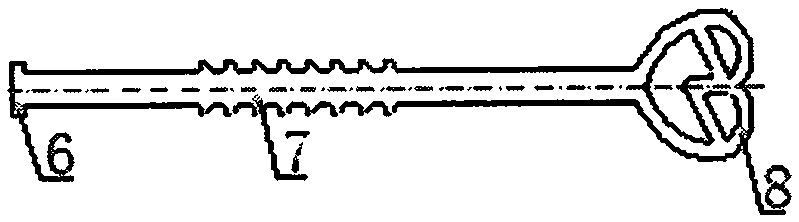

Machining method of thin-wall honeycomb core material curve machining molded surface

ActiveCN106903357AImprove milling efficiencyImprove machining accuracy and surface qualityWorkpiecesMilling equipment detailsThin walledHoneycomb

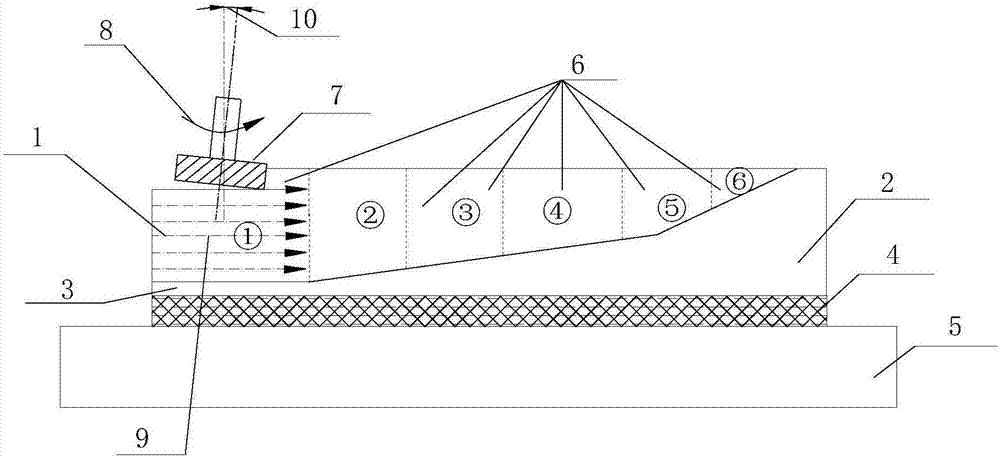

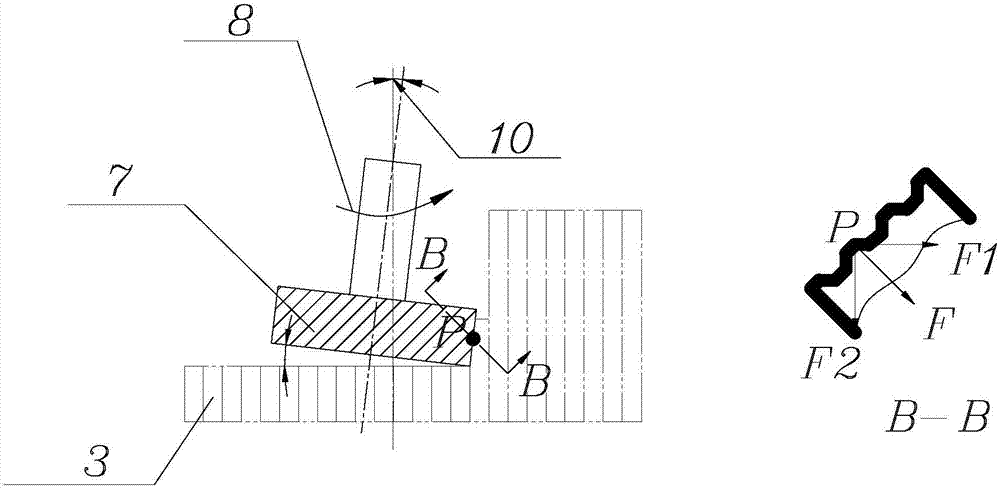

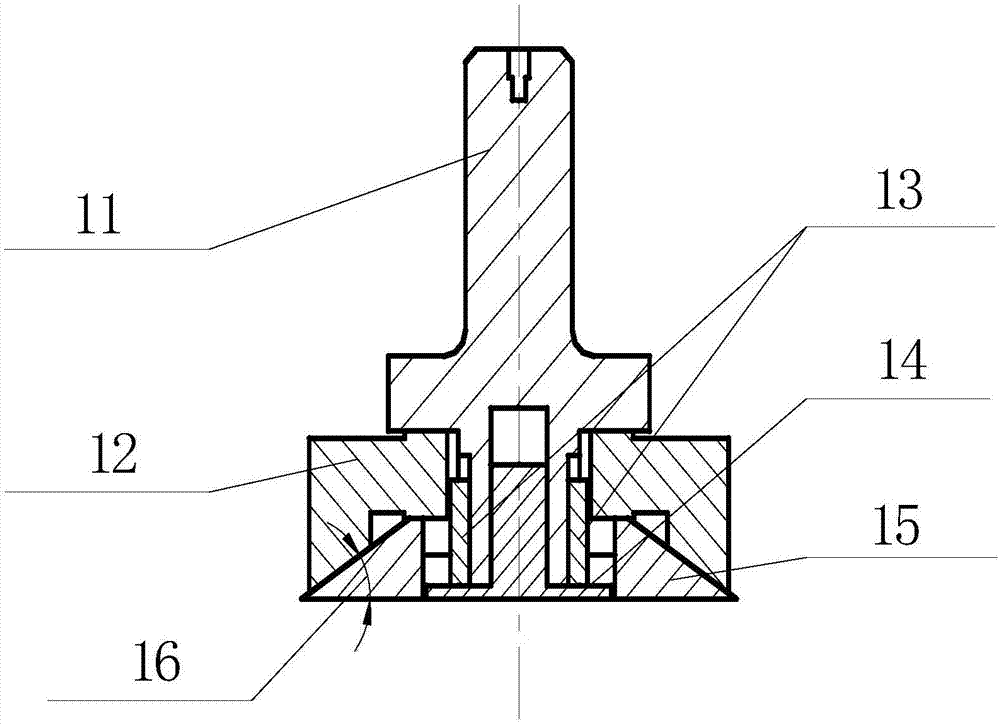

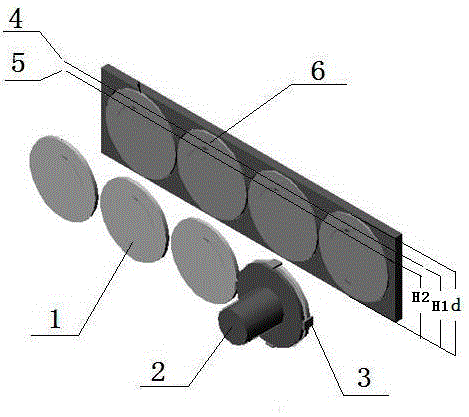

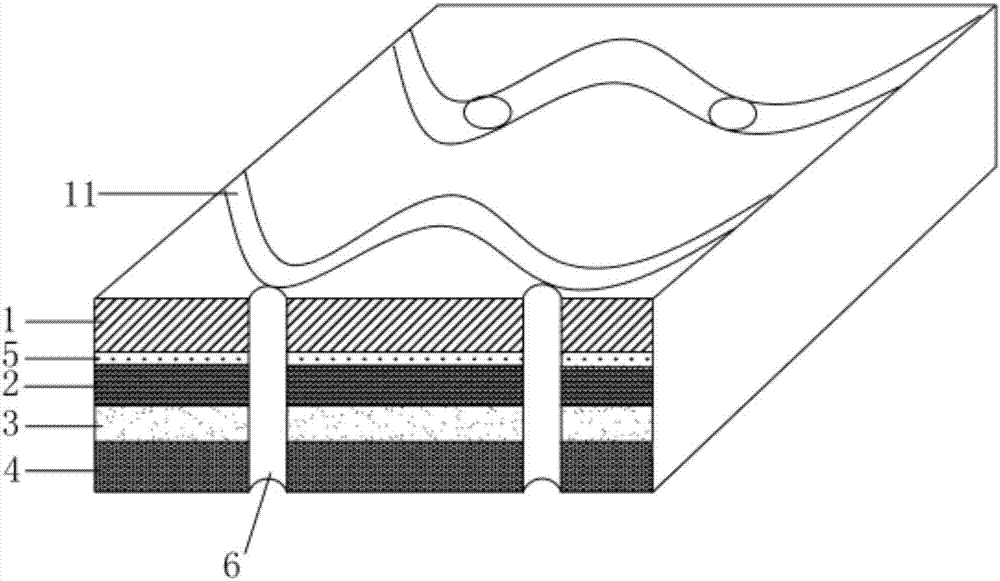

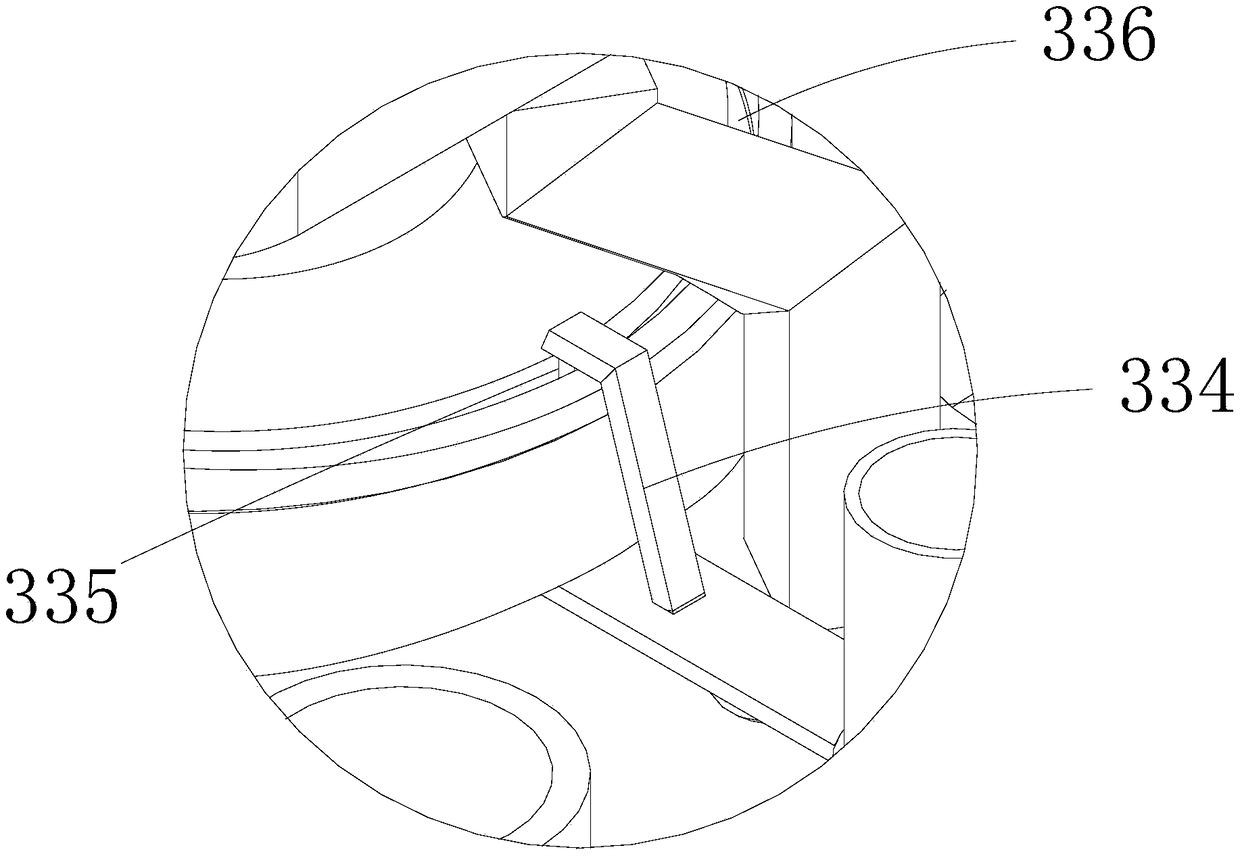

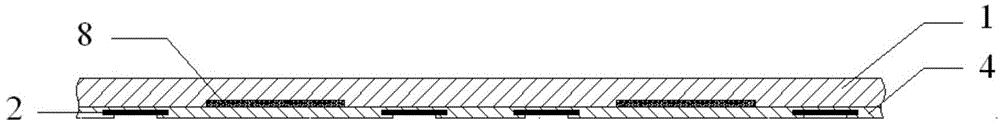

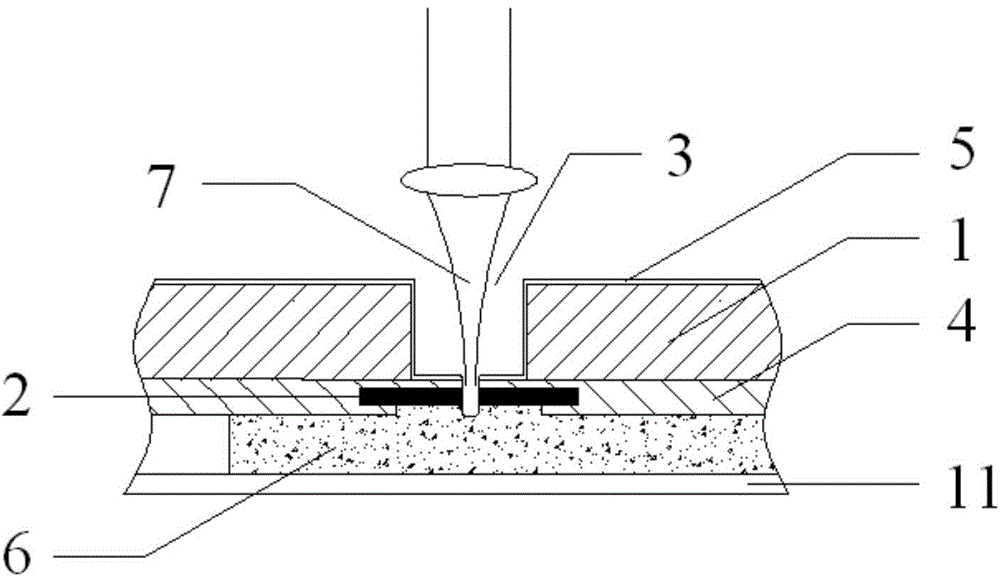

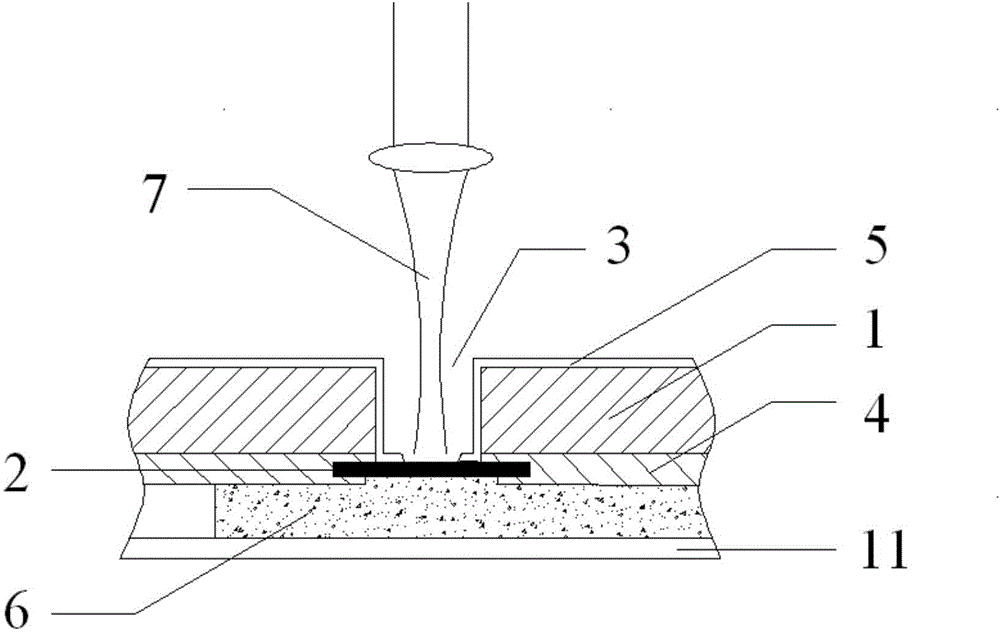

The invention discloses a machining method of a thin-wall honeycomb core material curve machining molded surface, and aims to provide a honeycomb machining method with high milling efficiency and capable of prolonging the life of a special honeycomb combined milling tool. The machining method is realized through the following technical scheme: when a double sided tape fixing state at the earlier stage of honeycomb machining is good, the special honeycomb combined milling tool with a conical disc return milling tool is changed for cutting; the rotating direction of the special honeycomb combined milling tool is changed; the conical disc return milling tool for feeding by a wedged angle of 30-45 degrees through high-speed rotation is used for cutting roughing; according to an anticlockwise tool rotating mode in the tool rotating direction, the downward pressure is applied to a honeycomb thin-edge area (1) through anticlockwise rotation; the part, easy to be pulled and damaged, of the thinnest honeycomb edge of the honeycomb bottom cutting profile is firstly machined; and after the honeycomb thin-edge area (1) of a NOMEX honeycomb part blank is machined, the sequential gradient machining is performed in (2-6) thickness direction of the thick-edge area cutting profile layer by layer, and the other parts are machined.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Method for improving teflon adhesive property and method for producing pressure-sensitive adhesive tape

The invention discloses a method for improving a teflon adhesive property. The method comprises the following steps of washing, wherein at least one kind of methyl alcohol, methyl alcohol, isopropanol, acetone and methylbenzene is adopted, and teflon base materials are washed through ultrasonic oscillation; normal-pressure low-temperature plasma processing, wherein a normal-pressure low-temperature plasma technology based on barometric pressure glow is used for carrying out the normal-pressure low-temperature plasma processing on the washed teflon base materials. The invention further discloses a method for producing pressure-sensitive adhesive tape. The method for improving the teflon adhesive property has the advantages that the adhesive property of the teflon base materials can be effectively improved, the contact angle of the surfaces of the processed materials is 86 degrees, and the adhesive strength is larger than 5.0MPa.

Owner:成都同明创新科技有限公司

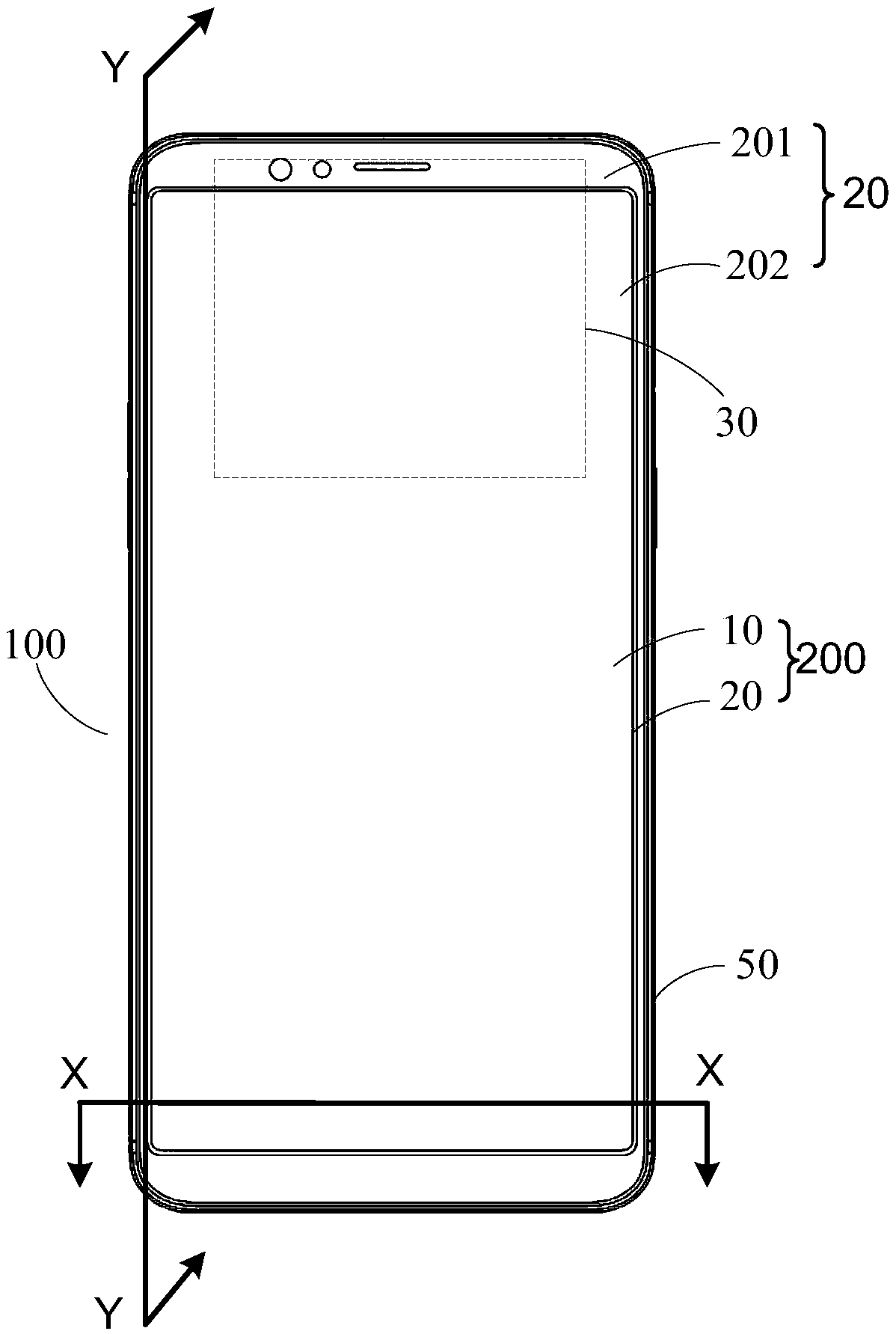

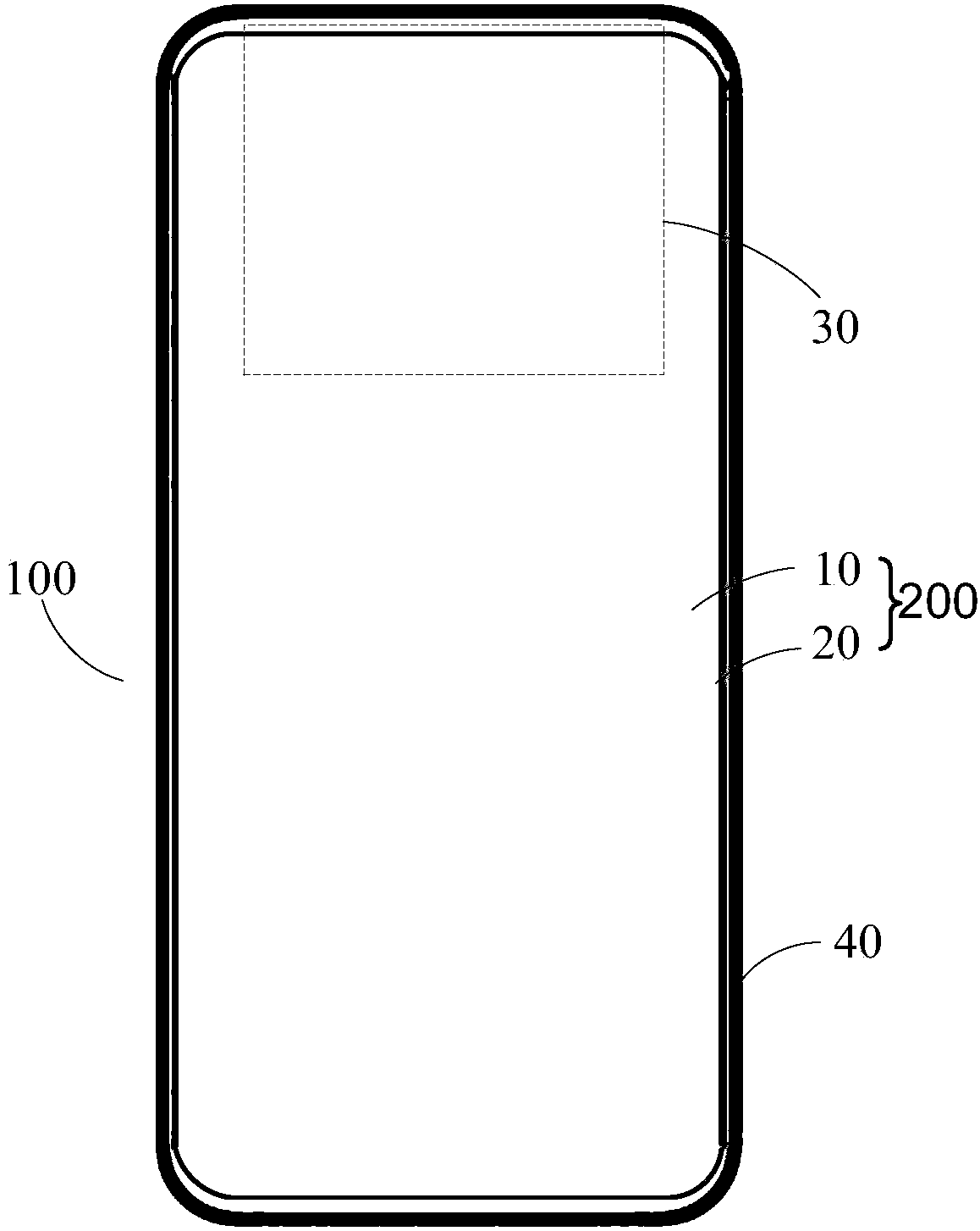

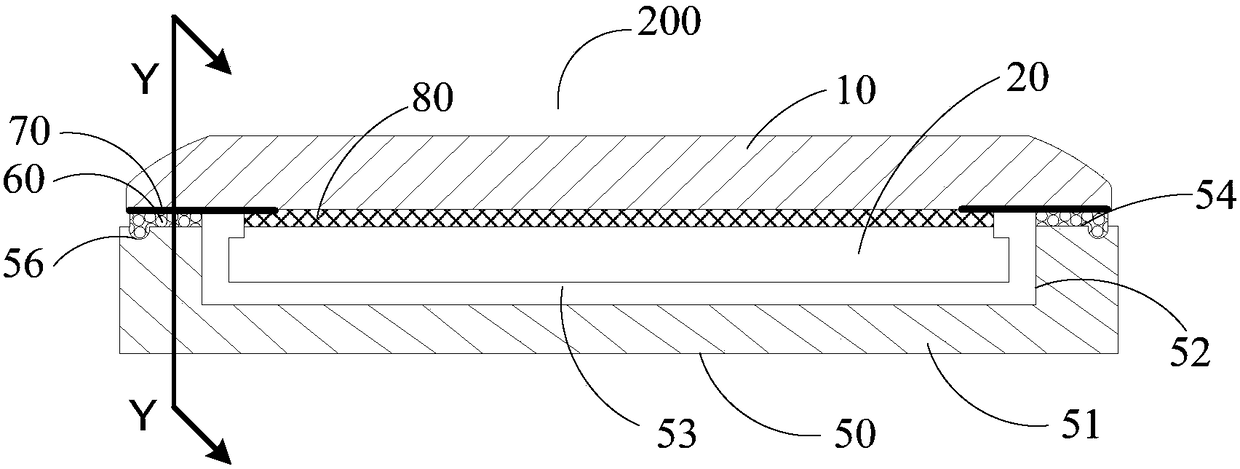

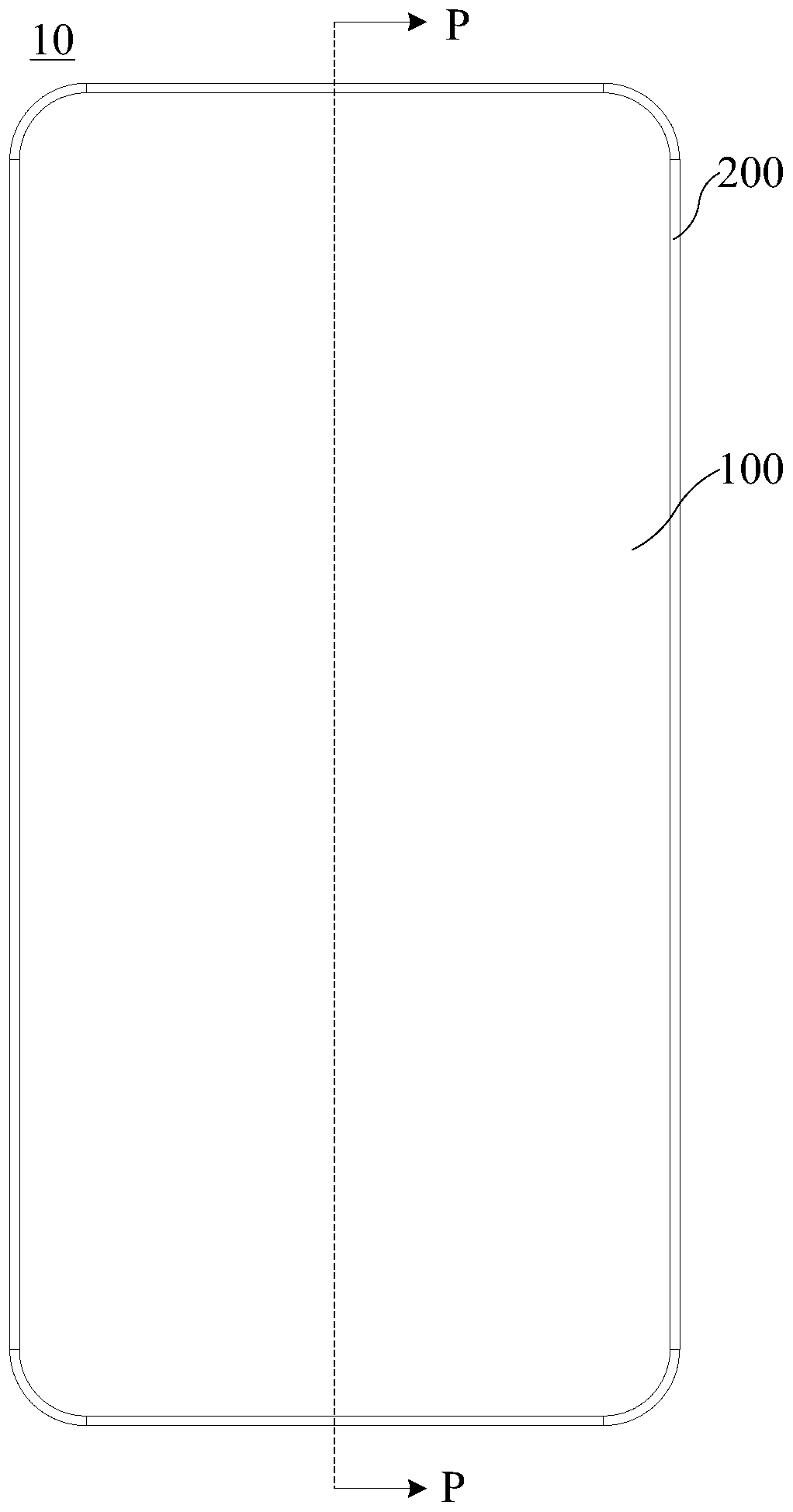

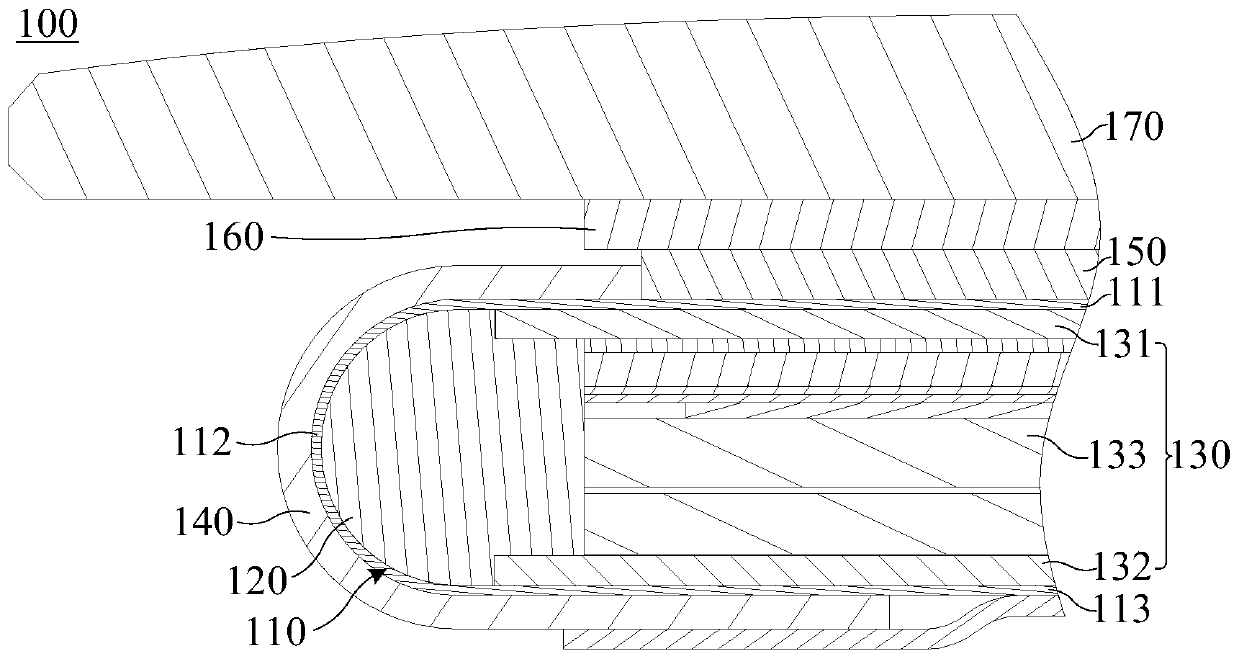

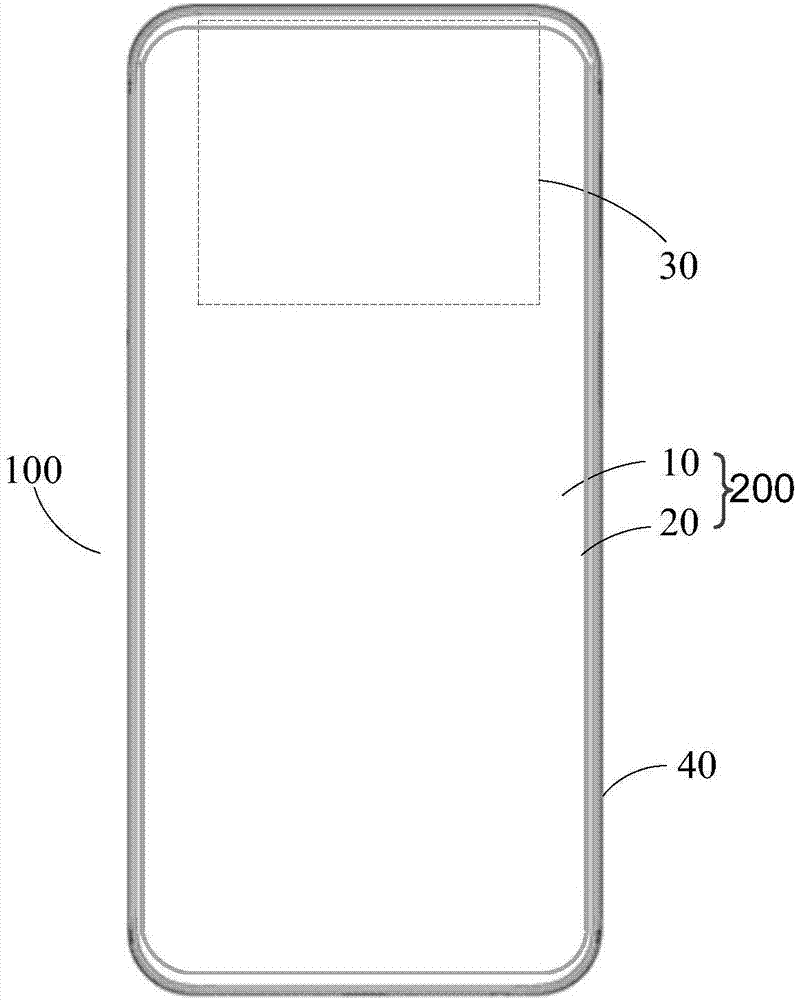

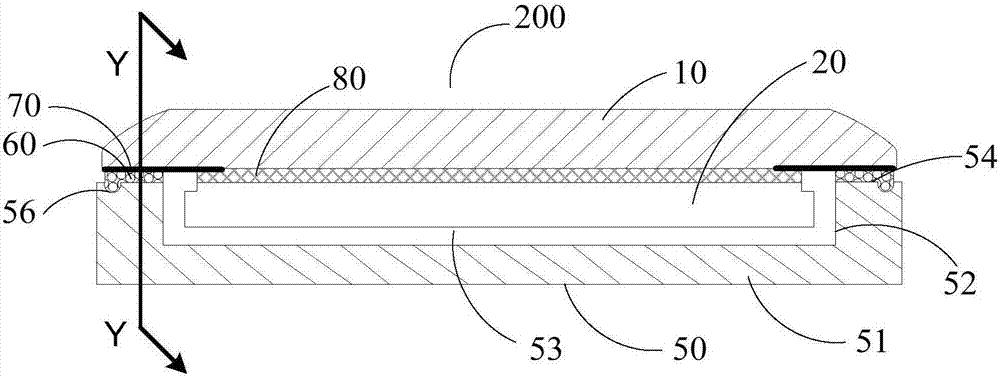

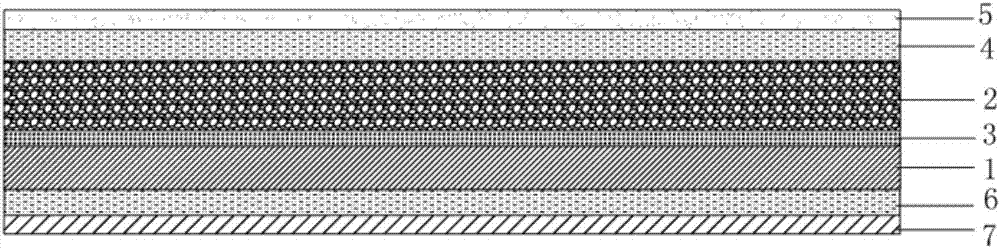

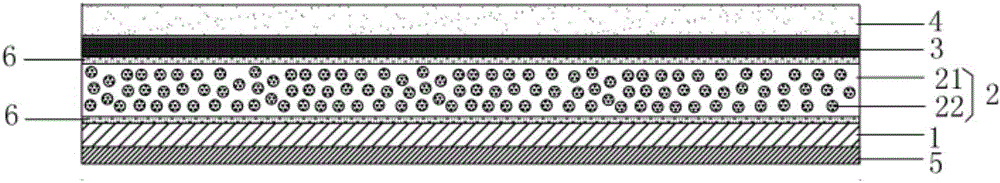

Electronic equipment

ActiveCN108282570AIncrease bonding areaAvoid degummingTelephone set constructionsGlass coverAdhesive

The application discloses electronic equipment. The electronic equipment comprises a shell, a glass cover board and a display module; the shell comprises a substrate and a side wall extending from theperipheral edge of the substrate; the side wall surrounds to form an accommodation space; the glass cover board is covered on the side wall of the shell; the display module is arranged below the glass cover board and positioned in the accommodation space; an adhesive is arranged between the glass cover board and the shell; an adhesive fixing structure is arranged on the adhesive dispersing surface on the glass cover board, which is in contact with the adhesive; an adhesive overflow groove is formed on the contact surface on the shell, which is in contact with the adhesive; and the adhesive fixes the glass cover board on the shell by adhering the adhesive dispersing surface to the contact surface. According to the embodiment of the application, by arranging the adhesive fixing structure onthe adhesive dispersing surface of the glass cover board and forming the adhesive overflow groove on the contact surface of the shell, an adhesion area between the glass cover board or the shell andthe adhesive can be increased, adhesive strength between the glass cover board of a touch screen and the shell is effectively improved, and an adhesive failure of the touch screen is prevented, thereby achieving a waterproof effect.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

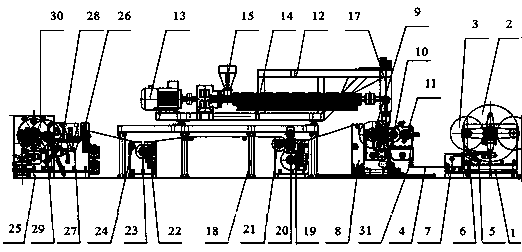

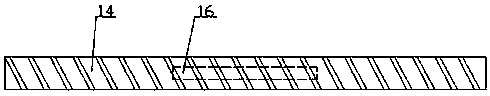

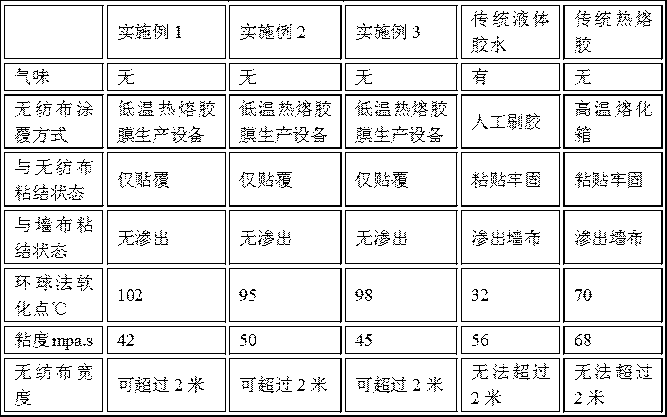

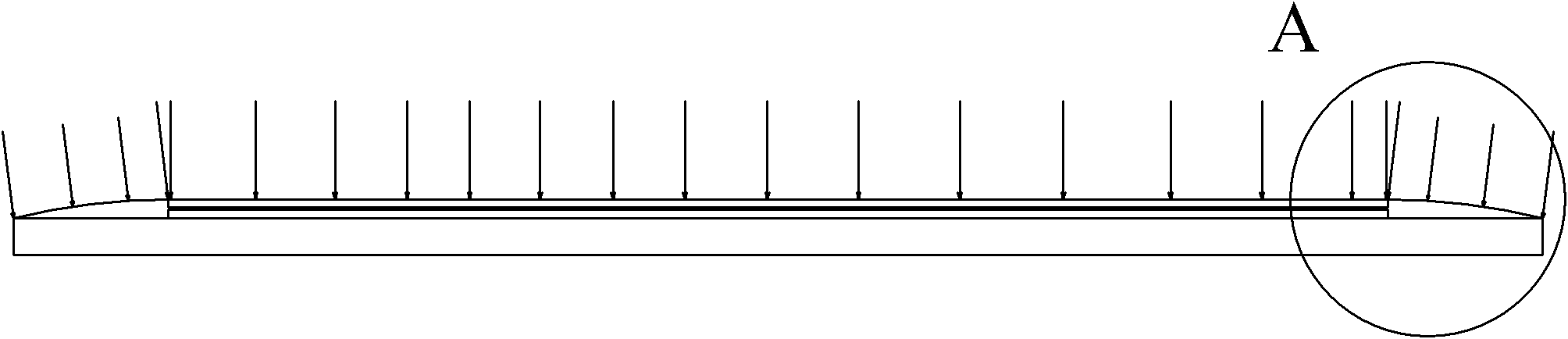

Non-woven fabric coated with hot melt glue and hot gluing process of non-woven fabric

ActiveCN107663783AGuaranteed viscosityModerate viscosityLaminationLamination apparatusMetallurgyPlasticizer

The invention discloses a non-woven fabric coated with a hot melt glue and a hot gluing process of the non-woven fabric. The hot melt glue is pasted and covered on the surface of the non-woven fabric;a raw material of the hot melt glue is EVA (Ethylene-Vinyl Acetate) particles; the EVA particles are prepared from the following components in parts by weight: 50 to 60 parts of ethylene-vinyl acetate (EVA), 30 to 60 parts of modified EVA, 15 to 20 parts of tackifying resin, 5 to 10 parts of plasticizer, and 0.1 to 5 parts of function additive. The hot gluing process of the non-woven fabric coated with the hot melt glue comprises the following concrete steps of (1) building low-temperature hot melt glue membrane production equipment; (2) preparing the EVA particles; (3) running the non-wovenfabric on production equipment; (4) laying off the EVA particles; (5) casting, extruding, pressing, covering and sizing; (6) cooling and rolling. The non-woven fabric coated with the hot melt glue andthe hot gluing process of the non-woven fabric provided by the invention have the following advantages that the time and the labor are saved, the environmental protection property is improved, the width of a hot melt glue membrane is ensured to exceed 2m, and the product stability and the precision of the thickness uniformity are improved.

Owner:江苏和和新材料股份有限公司

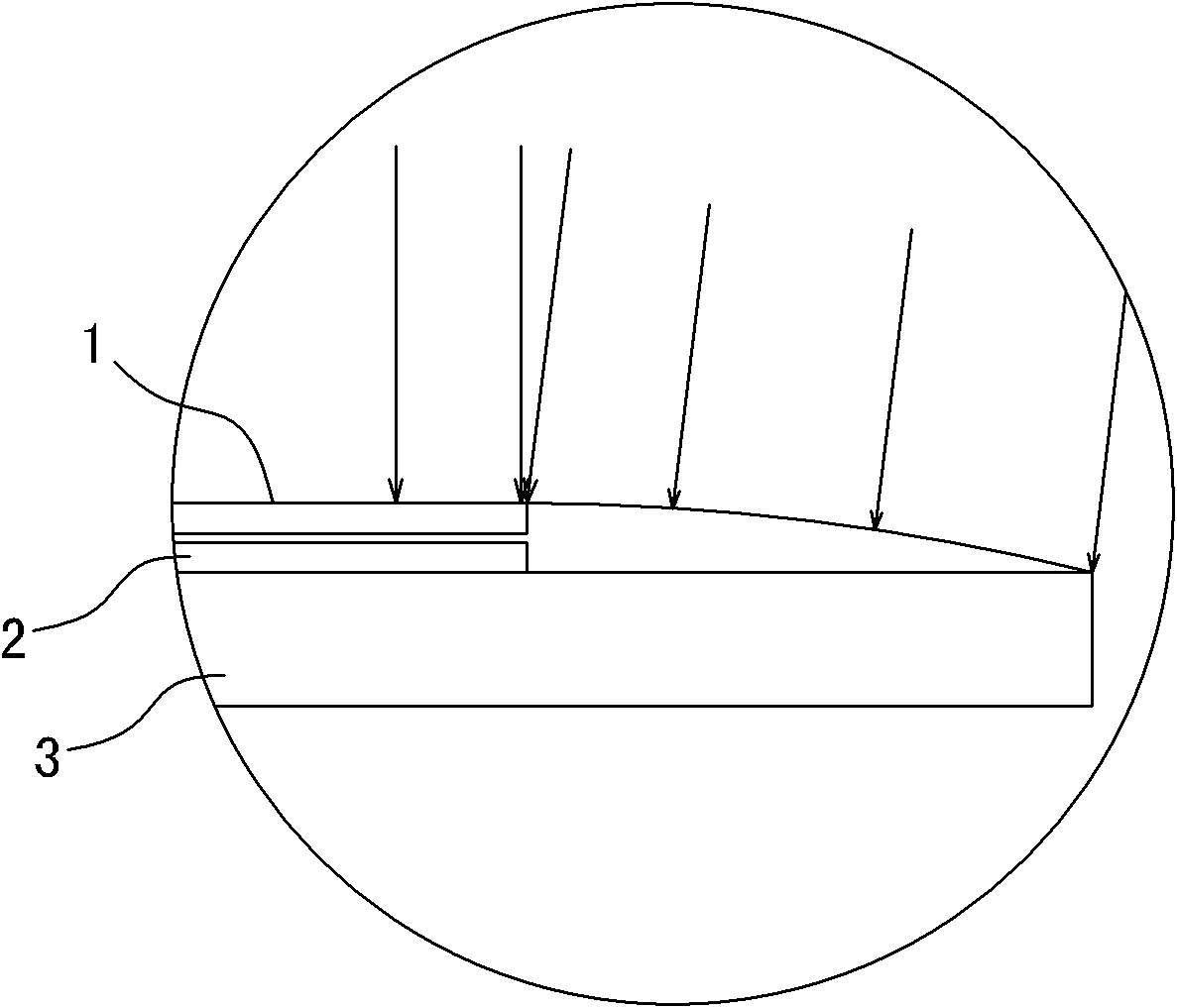

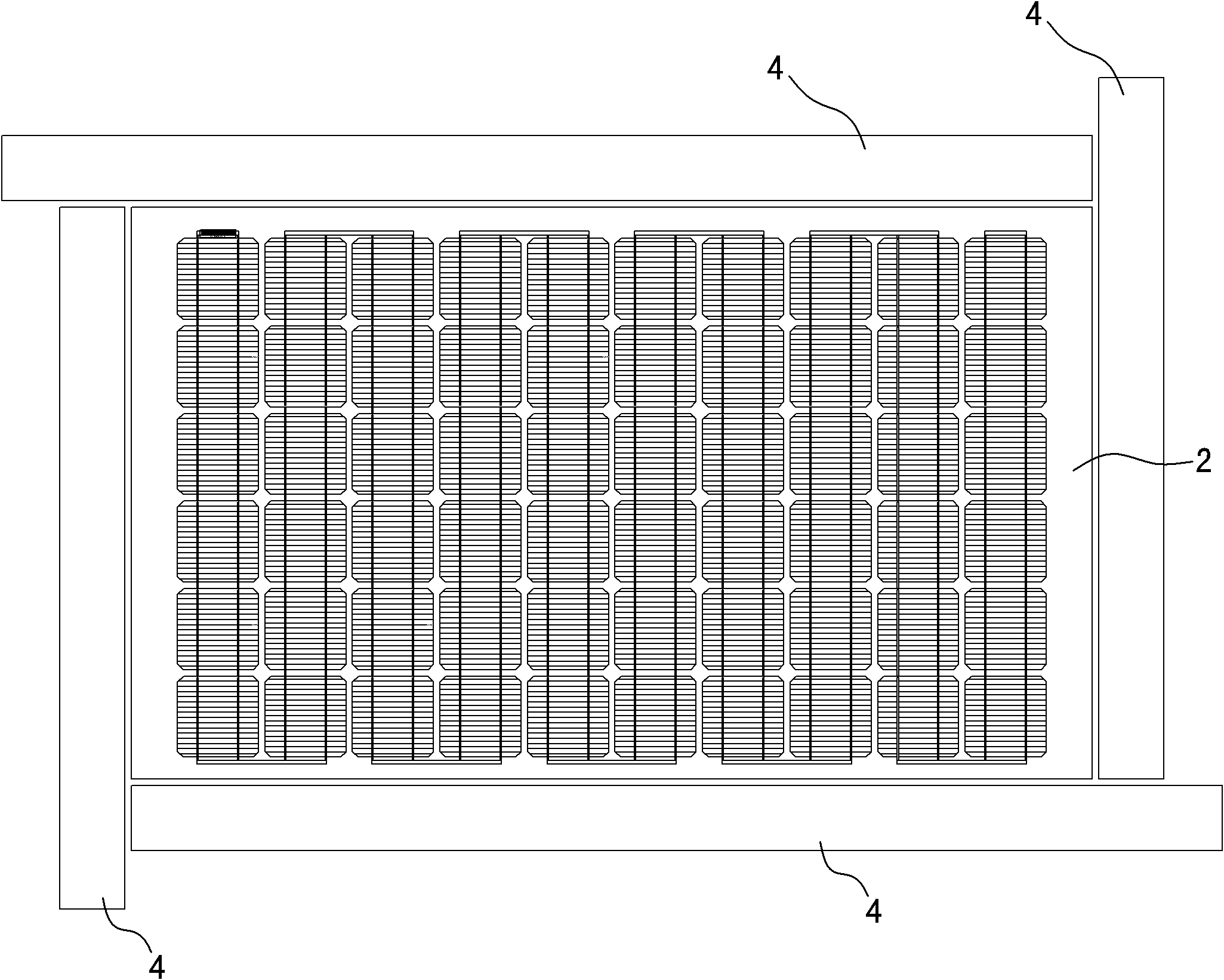

Method for laminating solar battery module

ActiveCN102152594AAvoid degummingImprove yieldFinal product manufactureLaminationCushioningEngineering

The invention discloses a method for laminating a solar battery module, which comprises the following steps of: (1) firstly, laying non-adhesive cloth on a heating table of a laminator; (2) secondly, placing the laminated semi-product of the solar battery module on the non-adhesive cloth on the heating table; (3) thirdly, providing four cushioning bars on the four sides of the semi-product of the solar battery module, wherein the distance from each cushioning bar to the edge of the semi-product of the solar battery module is 10 to 20mm; (4) fourthly, laying non-adhesive cloth on the semi-product of the solar battery module and the cushioning bars; and (5) fifthly, vacuuming, warming and pressurizing the materials into a whole in the cavity chamber of the laminator to obtain the solar battery module. In the laminating process, the concentrated stress points are transplanted to the cushioning bars, so that the phenomena of adhesive failure, bubbling, battery sheet displacement, module damage and the like are avoided; the yield is improved; and the production cost is greatly reduced.

Owner:CSI SOLAR POWER GROUP CO LTD +1

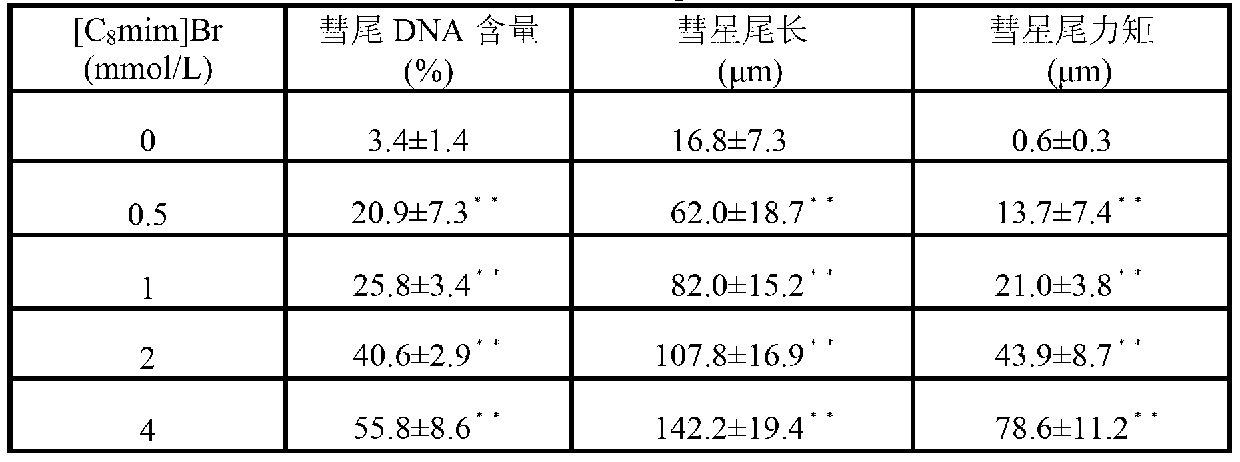

Preparation method of sample for conveniently and rapidly detecting deoxyribonucleic acid (DNA) cell damage and kit using same

InactiveCN103276048ANot easy to degummingEasy to operateMicrobiological testing/measurementFluorescenceA-DNA

The invention discloses a preparation method of a sample for conveniently and rapidly detecting deoxyribonucleic acid (DNA) cell damage. The method mainly comprises a gel sheet-making step, a cell lysis step, a DNA melting step, an electrophoresis step, a neutralizing step and a dyeing step, wherein in the gel sheet-making step, two layers of gels need to be spread; and in the dyeing step, a GelRed nucleic acid gel dye with high sensitivity and low toxicity is used. The invention also provides a kit using the method. The kit comprises normal melting-point agarose, low melting-point agarose, a cell lysis solution, an electrophoretic buffer solution, the DNA gel dye and a frosted edgeglass slide. According to the method, fluorescence dyeing is carried out by using the GelRed nucleic acid gel dye, and the GelRed nucleic acid gel dye is high in sensitivity, low in toxicity and stable, and environment pollution cannot be caused by wastes, so that the method is safe and environment-friendly; and because of only two layers of the spread gels, compared with a sandwich gel-spreading method used in the traditional comet assay, the preparation method is easy to operate and difficult to degum, and is uniform in dyeing; and moreover, the obtained electrophoresis image is relatively clear and objective.

Owner:JIANGSU UNIV

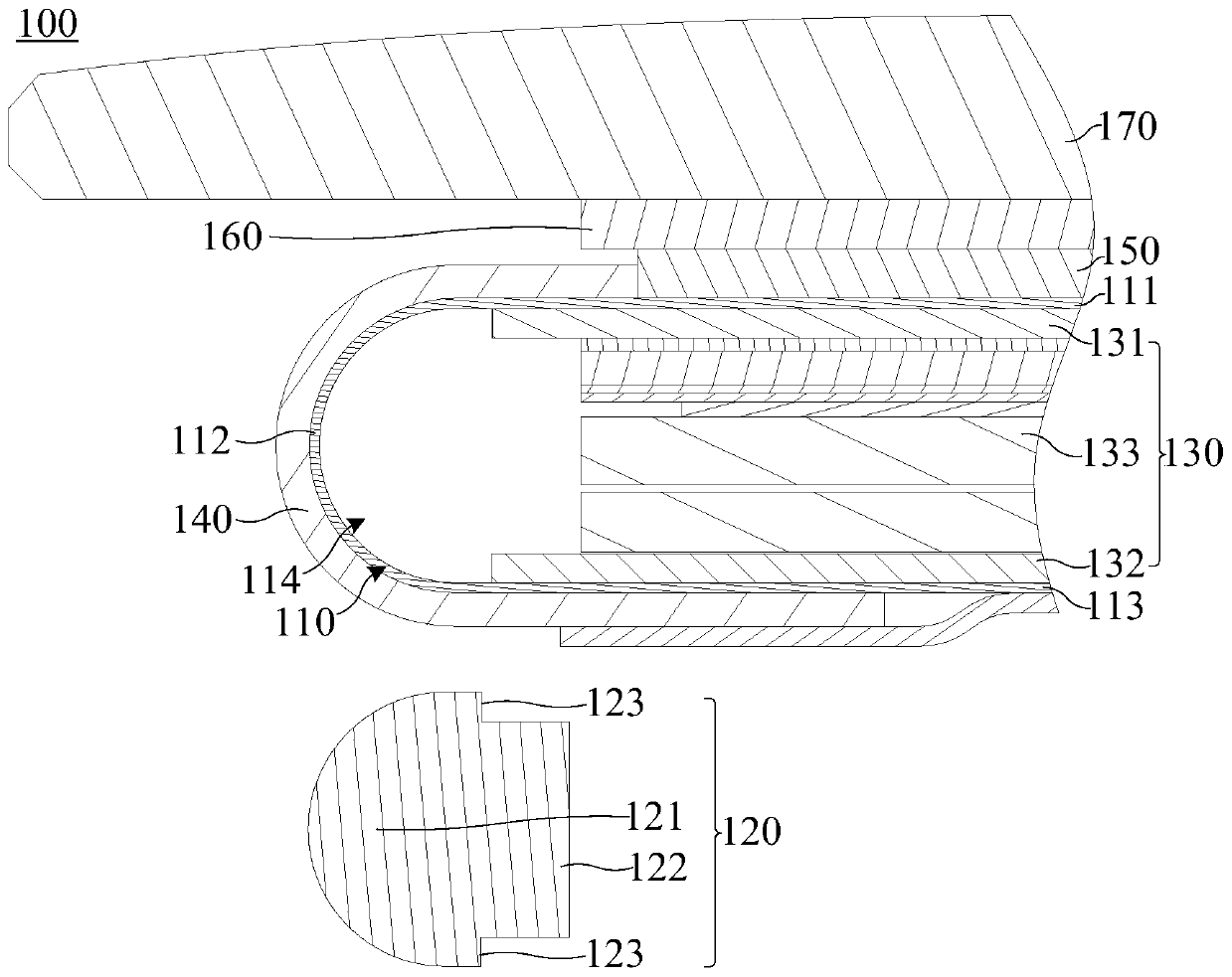

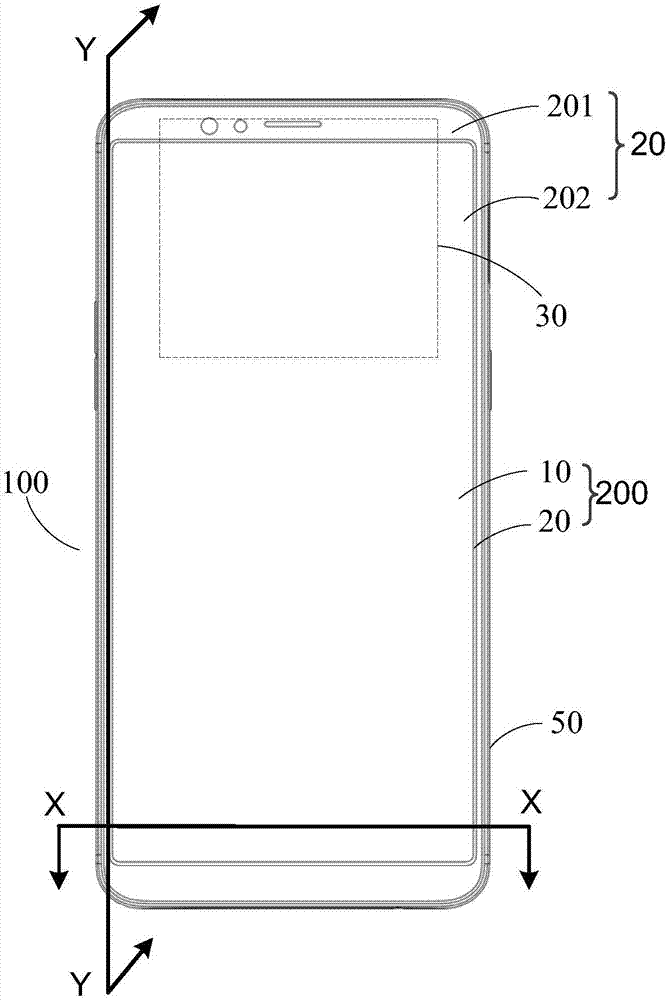

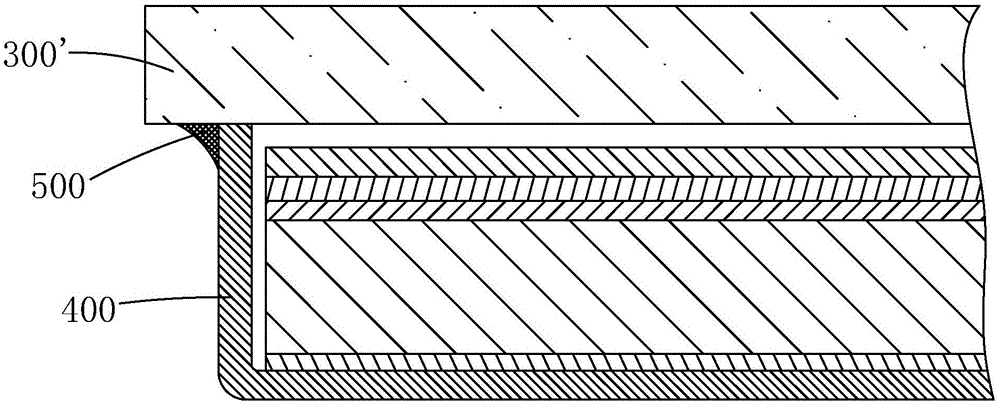

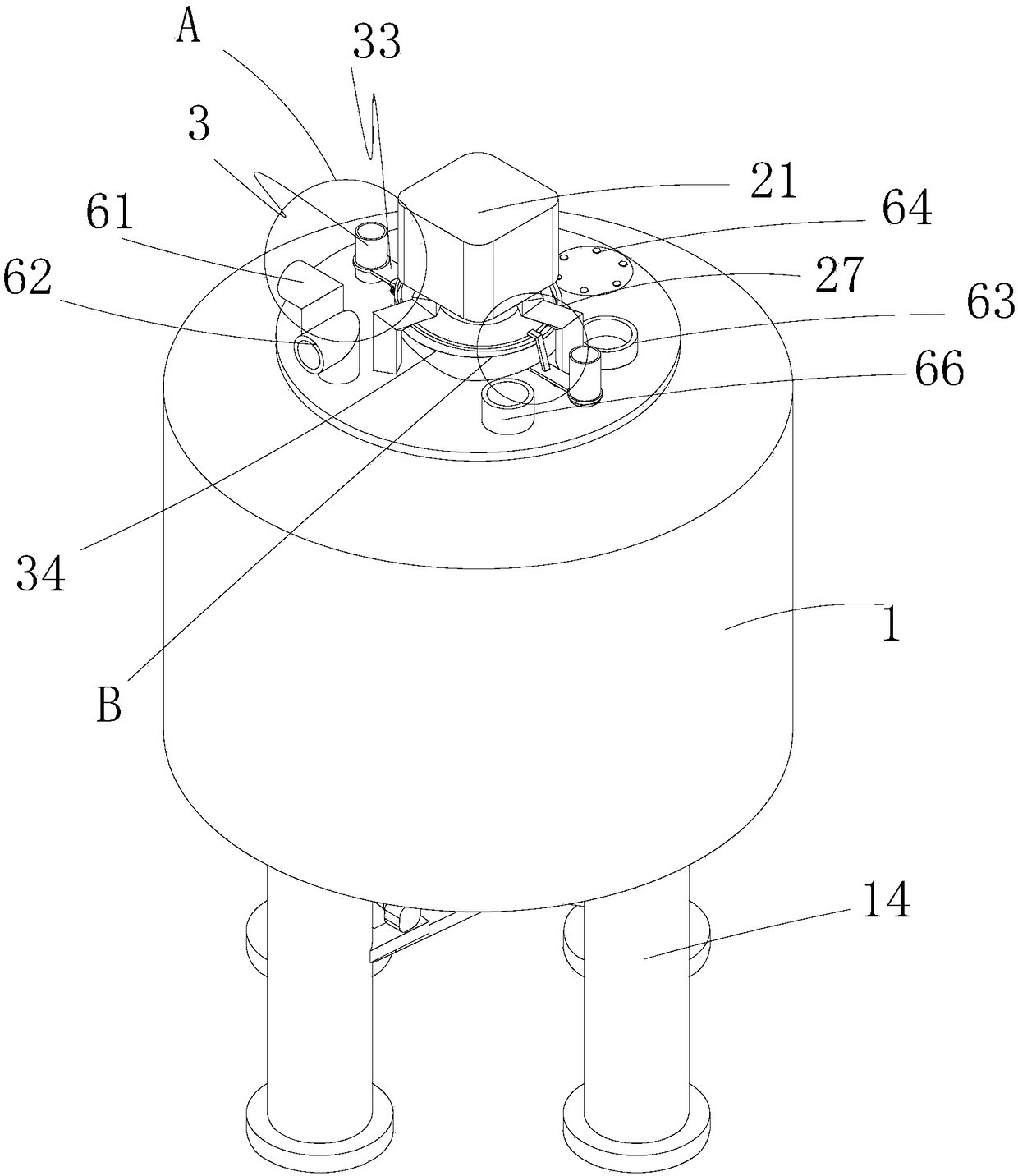

Electronic equipment, display screen assembly and processing method of display screen assembly

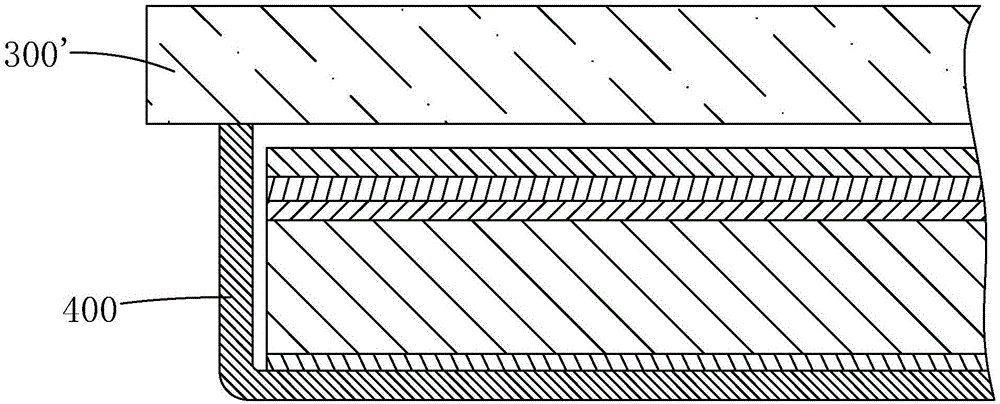

ActiveCN110022388APrevent debonding or damageRealize soft supportTelephone set constructionsElectronic equipmentColloid

The embodiment of the invention provides electronic equipment, a display screen assembly and a processing method of the display screen assembly, the display screen assembly comprises a flexible screen, and the flexible screen comprises a display part arranged on the display surface of the display screen assembly and used for displaying pictures; an extension part arranged on the non-display surface of the display screen assembly; a bending part located in a non-display area of the display screen assembly, wherein the display part and the extending part are connected through the bending part, the display part, the bending part and the extending part form a cavity on the display screen assembly, the cavity is filled with colloid, and the colloid can deform under stress so as to form a soft support for the flexible screen. The embodiment of the invention can prevent the bending part of the flexible screen from being degummed.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

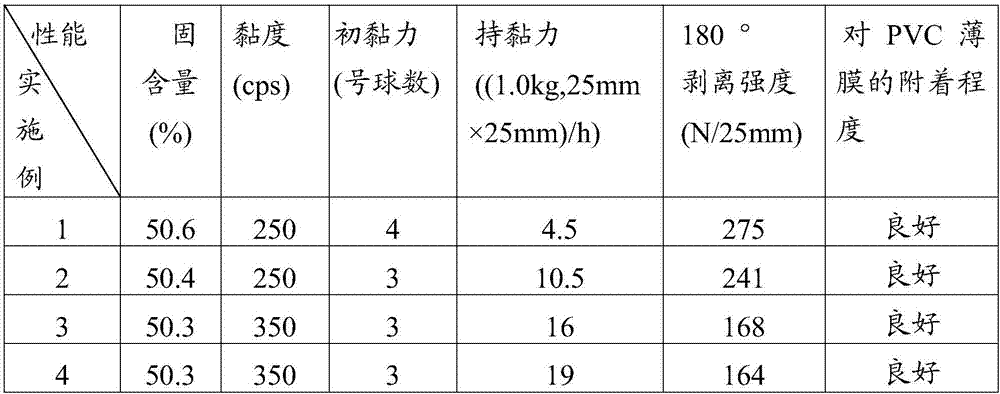

Acrylic emulsion and preparation method therefor

InactiveCN107163181AEnhance sticking powerAvoid degummingFilm/foil adhesivesEster polymer adhesivesEmulsionFunctional monomer

The invention discloses an acrylic emulsion and a preparation method therefor. The acrylic emulsion is prepared from the ingredients in parts by weight: 45-90 parts of flexible monomer, 1-40 parts of hard monomer, 1-10 parts of functional monomer, 0-1 part of molecular weight regulator, 30-55 parts of solvent, 0.1-3 parts of initiator, 0.1-2 parts of buffering agent, 0.1-1 part of reducer, 0.1-1 part of oxidant, 0.1-10 parts of anion emulsifier, 0.1-5 parts of nonionic emulsifier and 0.1-5 parts of reaction type emulsifier. The acrylic emulsion disclosed by the invention has high holding power with a polyvinyl chloride film, and adhesive failure can be prevented.

Owner:TAICHANG RESIN FOSHAN

Environment-friendly material for shoes and preparation method and application thereof

ActiveCN103435899ANot harmful to healthThe production process is simpleNon-macromolecular adhesive additivesEnvironmental resistanceAntioxidant

The invention relates to the technical field of environment-friendly materials and provides an environment-friendly material for shoes, which is high in adhesive strength, long in shelf life and low in cost, and can effectively eliminate the degumming phenomenon and avoid environment pollution. The invention also provides a preparation method of the environment-friendly material for shoes, which has a simple preparation process. The preparation method includes the steps of mixing and granulating the following ingredients in parts by weight: 100 parts of EVA (Ethylene vinyl-acetate copolymer), 0-50 parts of an EVA compatilizer, 0.1-5 parts of a peroxide vulcanizing agent and 0-10 parts of an antioxidant, processing the ingredients into powder with 20-1000 meshes, uniformly spreading the powder on a membrane with thickness of 0.01mm-0.075mm, heating the membrane to be at 90-200 DEG C and cooling to obtain the environment-friendly material for shoes. The invention also provides application of the environment-friendly material for shoes. The environment-friendly material is applied to rubber outsoles and EVA insoles to manufacture integrated soles.

Owner:李良团

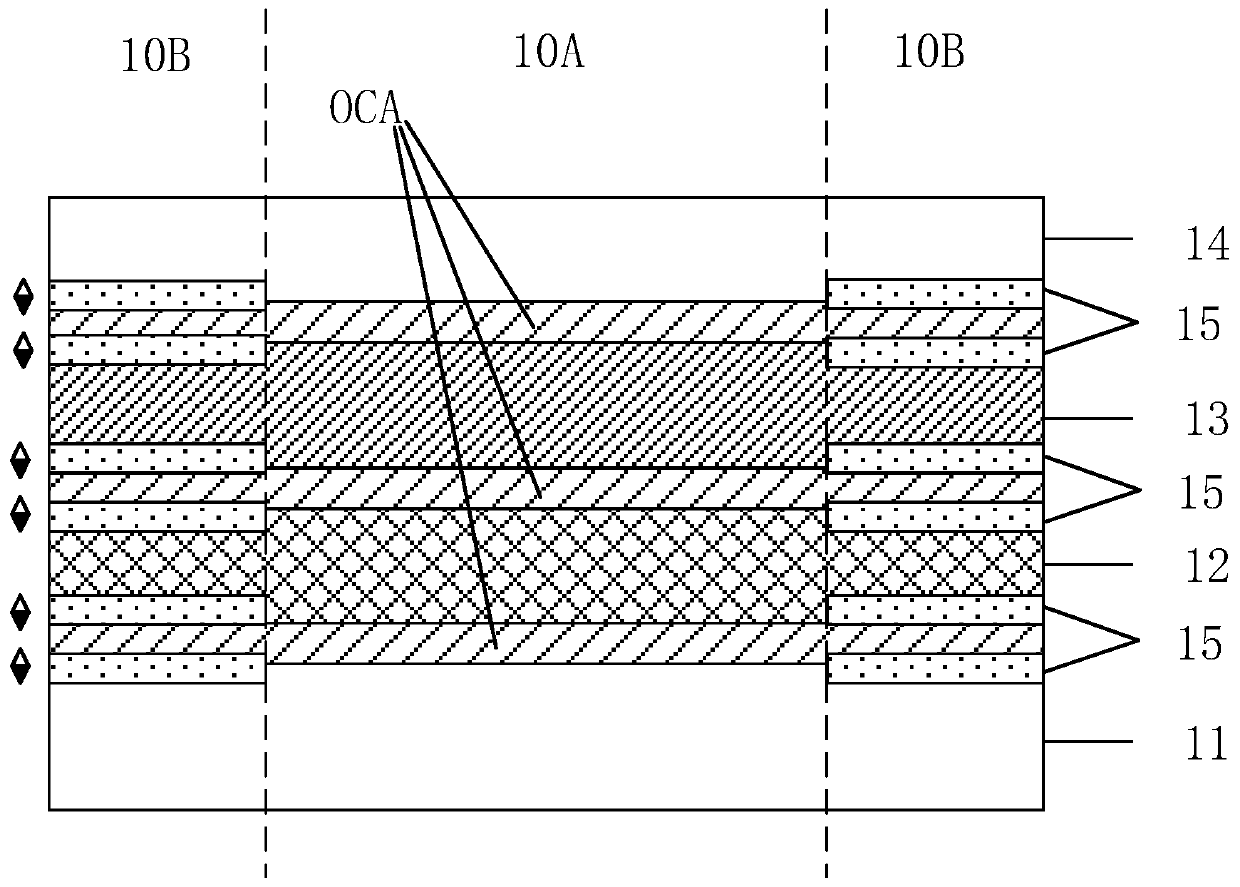

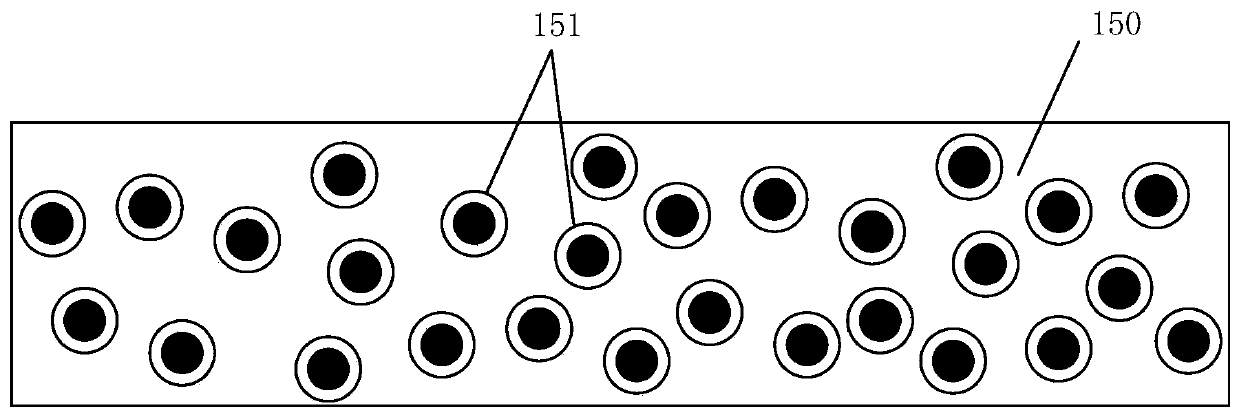

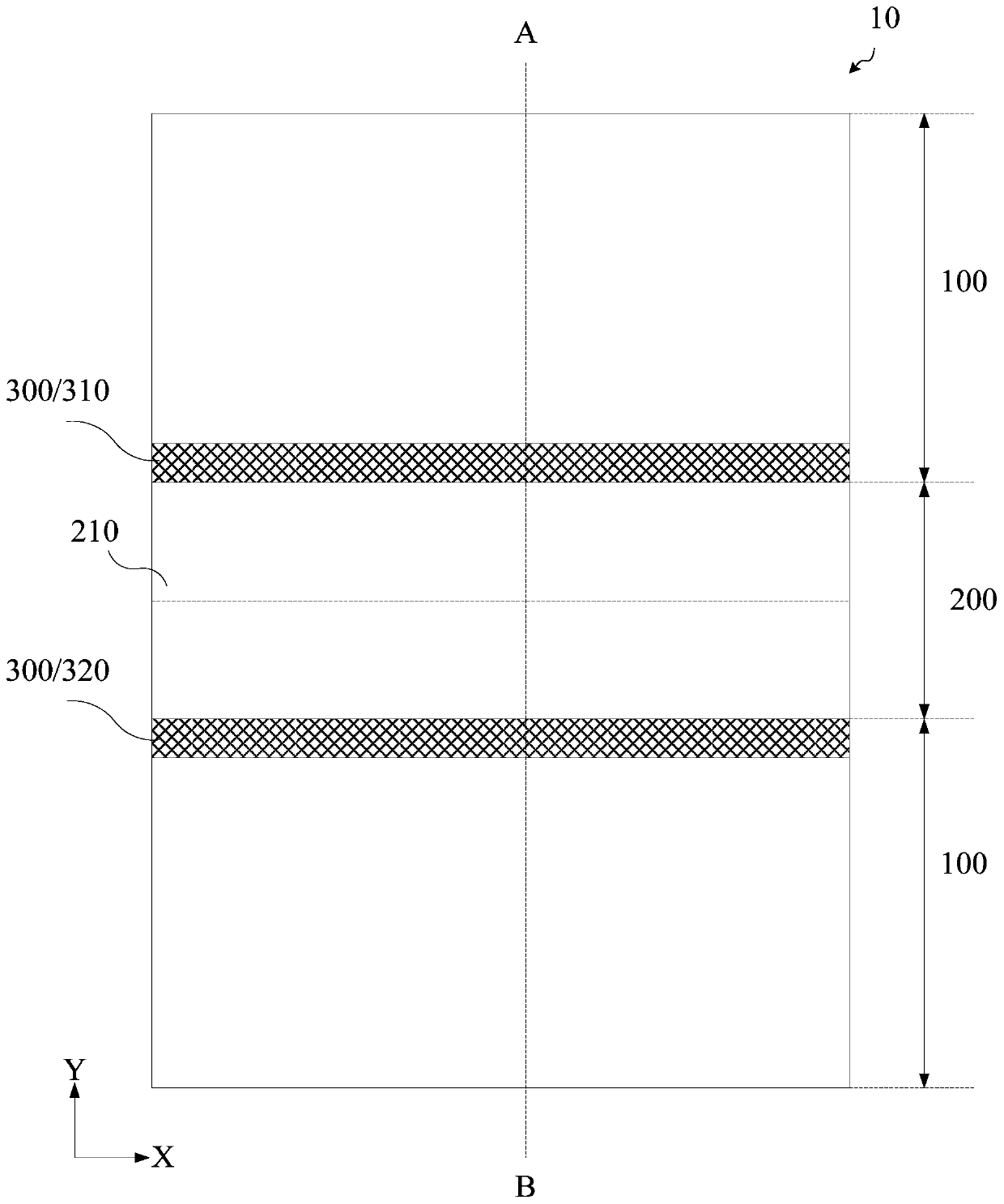

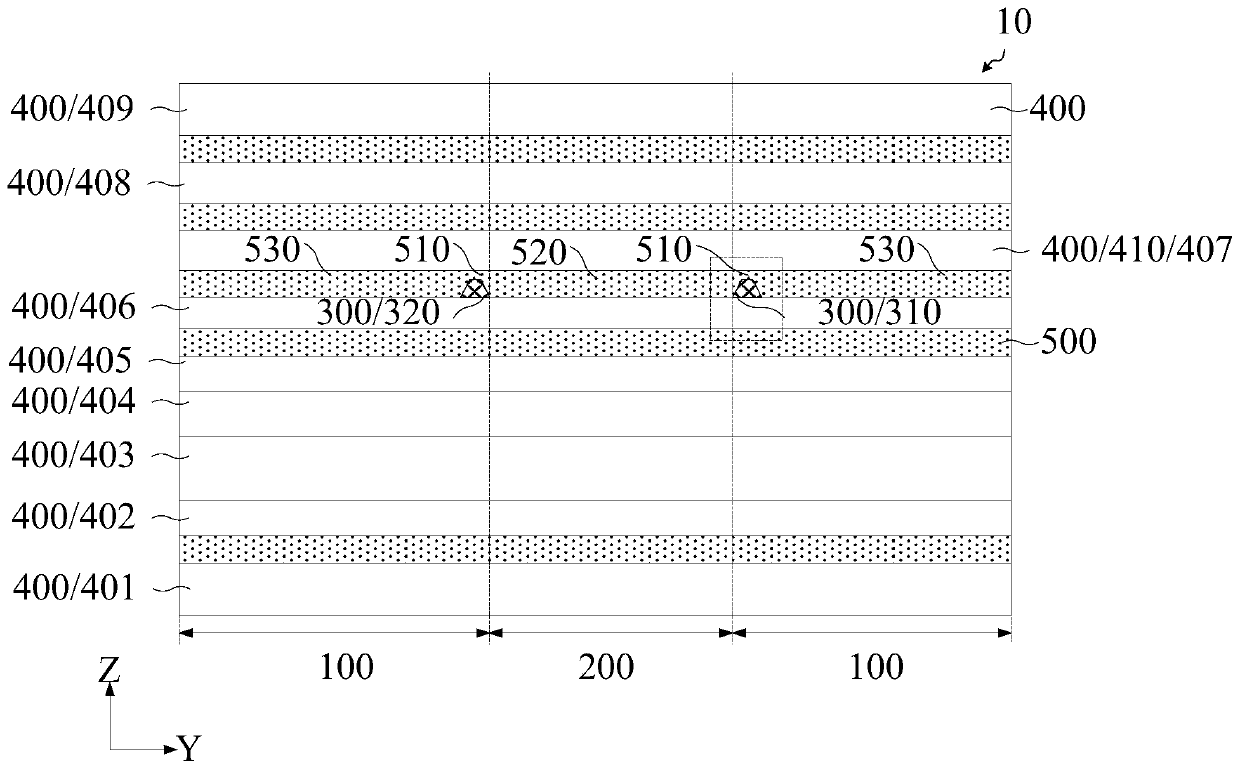

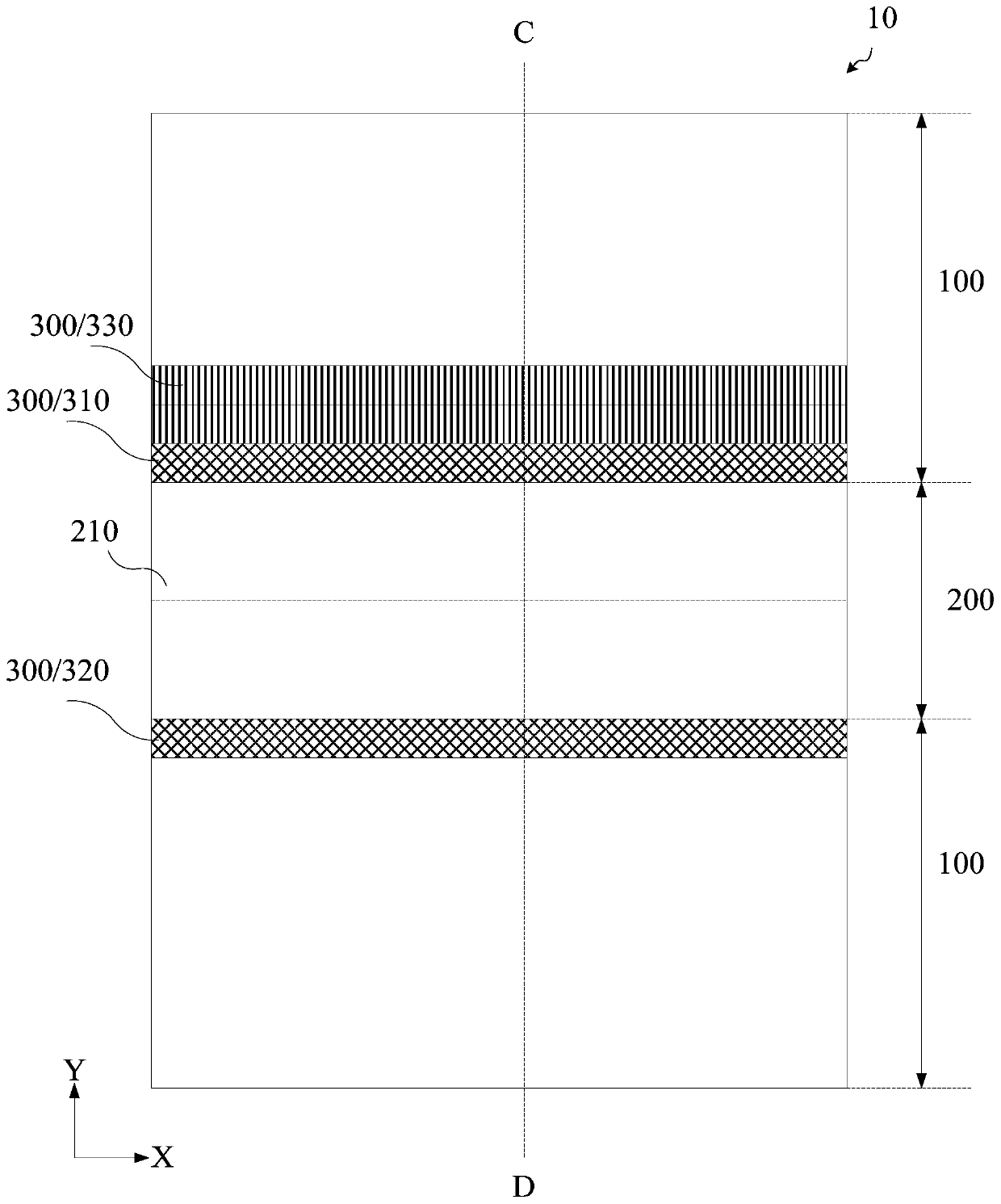

Flexible display module, manufacturing method thereof and flexible display device

The invention discloses a flexible display module, a manufacturing method thereof and a flexible display device. In the flexible display module, magnetic material layers are arranged on two sides of apart, located in a non-display area, of an optical adhesive layer, and the magnetic pole directions of the magnetic material layers are the same. According to the principle of opposite attraction, the magnetic material layers attract the part, located in the non-display area, of the optical adhesive layer, so that the binding force of the edge part of the optical adhesive layer is increased, andthe situation that an semi-cured optical adhesive layer is degummed at the edge part, and consequently the flexible display module fails is avoided. Meanwhile, the magnetic material layers are arranged in the non-display area, so that the influence of the arrangement of the magnetic material layers on the display of the flexible display module is avoided.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Preparation technology for edge-sealing strip subjected to co-extrusion molding

InactiveCN104015324AImprove adhesionReduce production processNon-macromolecular adhesive additivesMacromolecular adhesive additivesMedium density fiberboardCo extrusion

The invention relates to the technical field of preparation of edge-sealing strips, and concretely relates to a preparation technology for an edge-sealing strip subjected to co-extrusion molding. The preparation technology comprises the following technological steps: step A, performing co-extrusion on a substrate-layer raw material and a hot-melt-adhesive-layer raw material possessing a same color, so as to prepare the edge-sealing strip possessing the substrate layer and the hot-melt-adhesive layer; B, cooling and curing the edge-sealing strip; and C, for usage, using hot wind or a hot gas or laser to melt the hot-melt-adhesive layer of the edge-sealing strip, so as to enable the face of the edge-sealing strip, which possesses the hot-melt-adhesive layer, to be adhered to a product to be subjected to edge sealing. The adhesive force of the hot-melt-adhesive layer is high, and degumming phenomenon is avoided. By employing hot wind or the hot gas or laser for melting the hot-melt-adhesive layer, edge sealing is performed. Seamless connection between the edge-sealing strip and a product to be subjected to edge sealing, such as medium density fiberboards, shaving boards, plywood and other artificial plates, is realized, and a hot melt adhesive is not needed for coating, so that a production process of coating a hot melt adhesive is saved, the product quality and the production efficiency are substantially improved, the production and application cost is reduced, and the preparation technology is relatively suitable for industrialized production.

Owner:DONGGUAN HUALI INDUSTRIES CO LTD

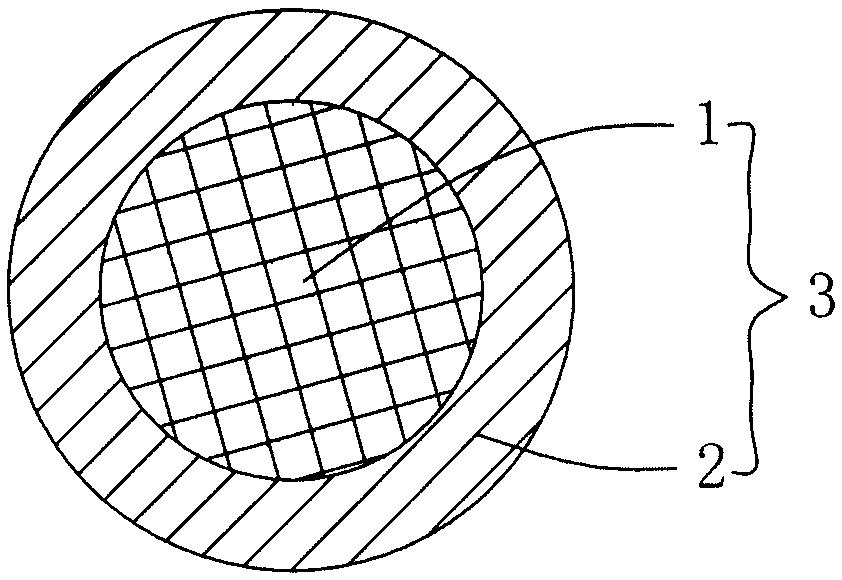

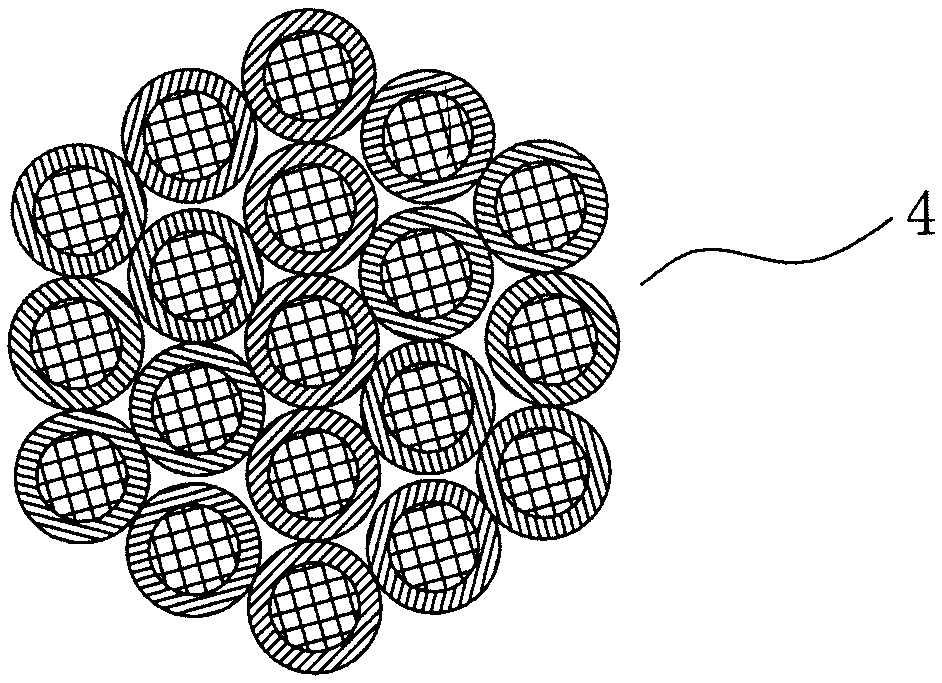

Method for manufacturing microporous fiber bar

InactiveCN106945321AAvoid pollution and waste of energyAvoid degummingDomestic articlesConjugated synthetic polymer artificial filamentsCopolyesterYarn

The invention provides a method for manufacturing a microporous fiber bar. The method includes the following steps that firstly, polymers of two components continuously form composite fibers for a skin layer and a core layer correspondingly in the longitudinal direction of fibers; secondly, a plurality of skin-core composite fiber filaments are selected to be combined into a skin-core composite fiber filament bundle; and thirdly, the skin-core composite fiber filament bundle is made to pass through a mold with the proper temperature at a proper speed, the surface layers of skin layer materials of the surface-core composite fiber filaments are melted or semi-melted, and the surface-core composite fiber filaments are promoted to be bonded together to form the microporous fiber bar. The filaments are bonded mutually after the copolyester materials of the skin layers of the skin-core composite fibers are heated to be melted or semi-melted, and thus the procedures of impregnation, drying, curing and the like in existing manufacturing technologies are omitted, environment pollution and energy waste are avoided, more energy is saved, and the environment is better protected.

Owner:余姚市创辉树脂笔头厂

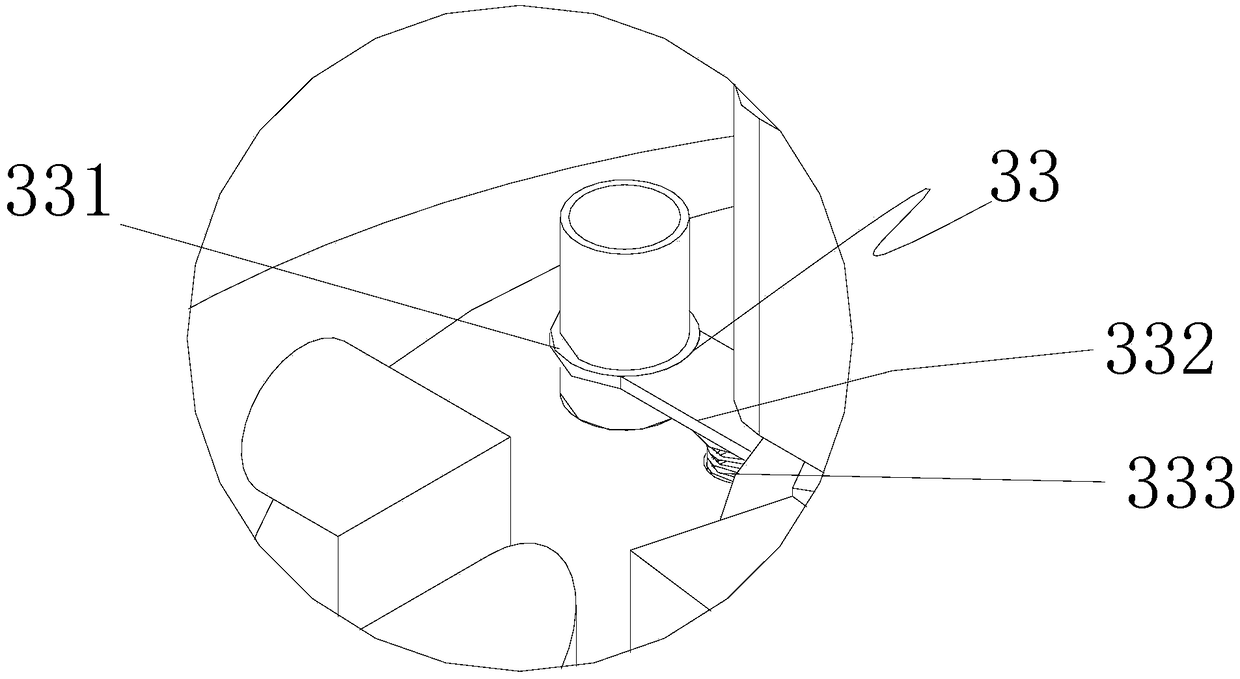

Electronic device

PendingCN108008780AGood adhesionAvoid degummingDigital data processing detailsInput/output processes for data processingGlass coverEngineering

The application discloses an electronic device comprising a shell, a glass cover plate and a display module. The electronic device is characterized in that the shell comprises a substrate and a side wall extending from the periphery of the substrate; an accommodation space is formed when the side wall forms a circle; the glass cover plate is covered on the side wall of the shell; the display module is disposed below the glass cover plate and located in the accommodation space; a first groove is arranged on a contact face of the glass cover plate and the shell; colloid is arranged between the glass cover plate and the shell; at least part of the colloid is accommodated in the first groove to form a bending structure.The electronic device has the advantages of effectively increasing adhesionbetween the glass cover plate of a touch screen and the shell with the contact face of the shell provided with the first groove used for accommodating the colloid to form the bending structure, realizing ultra-narrow frame dispensing technology, increasing screen occupation ratio, prevent the touch screen degumming, and achieving waterproof effect.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

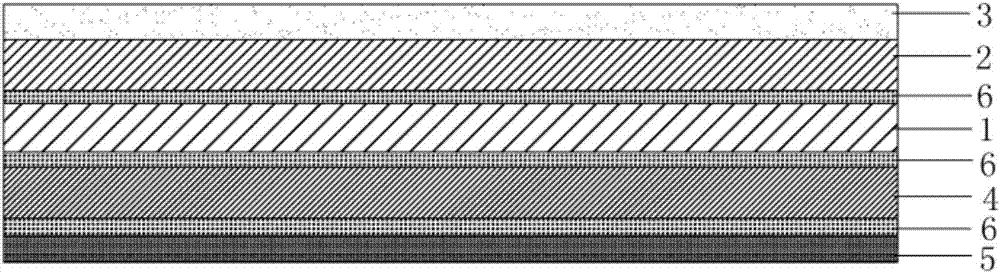

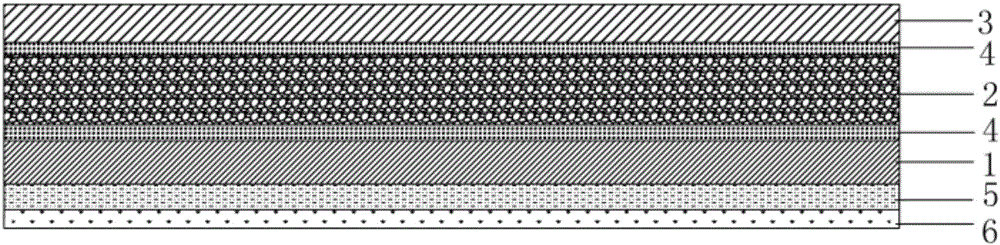

Heat-insulating, anti-freezing and waterproof roll material and preparation method

InactiveCN106891587AGood heat insulationIncrease elasticitySynthetic resin layered productsLaminationGlass fiberAnti freezing

The invention discloses a heat-insulating, anti-freezing and waterproof coiled material and a preparation method thereof, belonging to the technical field of waterproof coiled materials. The heat-insulating, anti-freezing and waterproof coiled material includes a base material layer of glass fiber felt, and also includes a heat-insulating layer arranged on the upper surface of the glass fiber felt, and the glass fiber felt and the heat-insulating layer are connected by an adhesive layer, The upper surface of the heat insulation layer is provided with a first waterproof layer, the upper surface of the first waterproof layer is provided with a heat insulation coating, and the lower surface of the glass fiber felt layer is also provided with a second waterproof layer, and the second waterproof layer A protective layer is provided on the lower surface of the layer. The heat-insulating, anti-freezing and waterproofing membrane material of the present invention not only has a good waterproof effect, but also has an excellent heat-insulating and anti-freezing effect, can greatly reduce the temperature exchange inside and outside the building, and reduce energy consumption. In addition, the preparation method is simple and easy, It has good application value.

Owner:HEFEI ZHONGKE FUHUA NEW MATERIAL

Sound-absorption and waterproof attapulgite board and preparation method

ActiveCN106799873AImprove sound absorptionImprove waterproof performanceSynthetic resin layered productsRubber layered productsWeather resistanceAdhesive

The invention discloses a sound-absorption and waterproof attapulgite board and a preparation method, which belong to the technical field of attapulgite. The sound-absorption and waterproof attapulgite board comprises an abrasion-resistance and waterproof layer, a rubber buffer layer, a sound absorption layer, a board body and a waterproof protection layer in sequence from top to bottom, wherein the board body is prepared by taking attapulgite as a basic material; the sound absorption layer comprises an elastic layer and sound absorption fillers; a plurality of small holes are formed in the elastic layer and are filled with the sound absorption fillers; the sound absorption fillers are prepared by taking attapulgite as a basic material; the sound absorption layer is connected with the board body by adhesive; the sound absorption layer is connected with the rubber buffer layer by adhesive. The sound-absorption and waterproof attapulgite board has comparatively good sound-absorption, sound-insulation and waterproof effects and has the comparatively good characteristics of stable performance, high strength and good weather resistance; in addition, the preparation method has the characteristics of being simple and being convenient in operation and low in manufacturing cost, so that the current market requirement is met, and the application value is comparatively good.

Owner:杨建鑫

Flexible display panel and flexible display device

InactiveCN110211495AImprove peel forceRapid and relatively complete recovery of deformationSolid-state devicesIdentification meansEngineeringFlexible display

The invention discloses a flexible display panel and a flexible display device. The flexible display panel comprises a bending area and a non-bending area, the bending area comprises a bending shaft,and the bending shaft extends in the first direction; the flexible display panel comprises a plurality of functional film layers, and the every two or more adjacent functional film layers are connected through an adhesive layer; two or more retaining walls are arranged between each adhesive layer and the corresponding adjacent functional film layer and extend in the first direction; each retainingwall comprises a first retaining wall and a second retaining wall; the bending area is arranged to be adjacent to the retaining walls, and in the second direction, the bending area is located betweenthe first retaining walls and the second retaining walls; and the second direction and the first direction are crossed. According to the technical scheme, the retaining walls can achieve the limitingeffect on the adhesive layers in the bending area, the situation that the adhesive layers in the bending area move in the direction of the non-bending area in the bending process is avoided, the thinning phenomenon of the adhesive layers in the bending area is avoided, deformation is easy to restore, and thus the phenomenon of folds or adhesive failure formed in the bending area is avoided.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

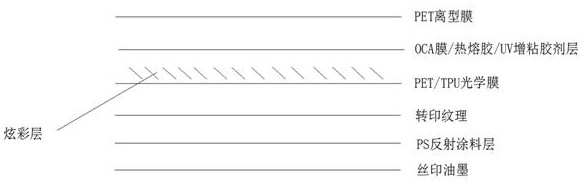

Colorful explosion-proof membrane

InactiveCN112159629AEasy to useExtended service lifeFilm/foil adhesivesReflecting/signal paintsChemistryLiquid crystal

The invention provides a colorful explosion-proof membrane which comprises a PET or TPU layer optical membrane, and the upper surface and the lower surface of the PET or TPU layer optical membrane arecoated with a liquid crystal colorful layer and a PS reflective coating layer which are arranged in a self-orientation mode respectively. An OCA optical film, a hot melt film or a UV tackifier layeris coated between a PET release film and a colorful layer, meanwhile, transfer printing textures are arranged between the optical film and a reflection coating layer, the PS reflection coating layer is a high-reflection sheet-shaped silver or nanometer reflection coating, and roll-to-roll silk-screen printing ink is arranged on the lower surface of the reflection layer. According to the scheme, the use effect of the explosion-proof membrane is effectively improved, the service life of the explosion-proof membrane is effectively prolonged, meanwhile, the production process of the explosion-proof membrane is simplified, an electroplated metal layer is prevented from being adopted, environmental protection is improved, meanwhile, the production quality of the explosion-proof membrane is effectively guaranteed, and the reflection effect on different colors and the blocking effect on infrared rays and ultraviolet rays are improved and stripping of an adhesive layer is avoided.

Owner:HENGSHAN JIACHENG NEW MATERIAL

Method for chemically and mechanically polishing sapphire substrate slices in immersed mode

The invention relates to a method for chemically and mechanically polishing sapphire substrate slices in an immersed mode. The polishing method comprises the following steps that firstly, preprocessing is conducted, wherein the sapphire substrate slices are attached to a hard ceramic disk, the hard ceramic disk is installed on a main shaft of a polishing machine, a polishing gasket is installed on a rotating bottom disk, reverse osmosis pure water and a silicon dioxide polishing solution are mixed and added into the polishing machine, and the liquid level is kept between the upper liquid level line and the lower liquid level line of the polishing liquid; secondly, polishing is conducted, wherein the polishing machine is started for polishing the sapphire substrate slices, the polishing time ranges from 40 min to 80 min, and then the polished sapphire substrate slices are obtained; and thirdly, the finished sapphire substrate slices are washed. According to the chemical and mechanical polishing method, the temperature rising of the surface of the polishing gasket in the polishing process is small, the service life of the polishing gasket and an adsorption gasket is long, and no tiny scratch exists on the surfaces of the sapphire substrate slices in the polishing process.

Owner:TUNGHSU GRP

Wear-resisting antiskid plastic track and preparation method

InactiveCN107090131AGood anti-slip and wear-resistant effectExtended service lifeNon-macromolecular adhesive additivesPaving gutters/kerbsAdhesiveToughness

The invention discloses a wear-resisting antiskid plastic track and a preparation method. The wear-resisting antiskid plastic track sequentially comprises an antiskid wear-resisting layer, a toughness reinforcing layer, a substrate layer and a cement powder stable layer from top to bottom, wherein a figure structure is arranged on the upper surface of the antiskid wear-resisting layer, and the antiskid wear-resisting layer and the toughness reinforcing layer are connected through an adhesive. The preparation method comprises the steps: firstly preparing the antiskid wear-resisting layer, the toughness reinforcing layer and the adhesive respectively; then laying the cement powder stable layer on a soil base layer, laying a self-adhesion SBS modified asphalt layer on the cement powder stable layer, then laying the toughness reinforcing layer on the surface of the asphalt layer, then coating the adhesive on the upper surface of the toughness reinforcing layer and adhering the antiskid wear-resisting layer to obtain the wear-resisting antiskid plastic track. The plastic track not only has better antiskid and wear-resisting performance, but also has better adhering firmness among all the layers; furthermore, the plastic track cannot release toxic gas, is safe and free of pollution and has better practical value.

Owner:合肥市晨雷思建筑材料科技有限公司

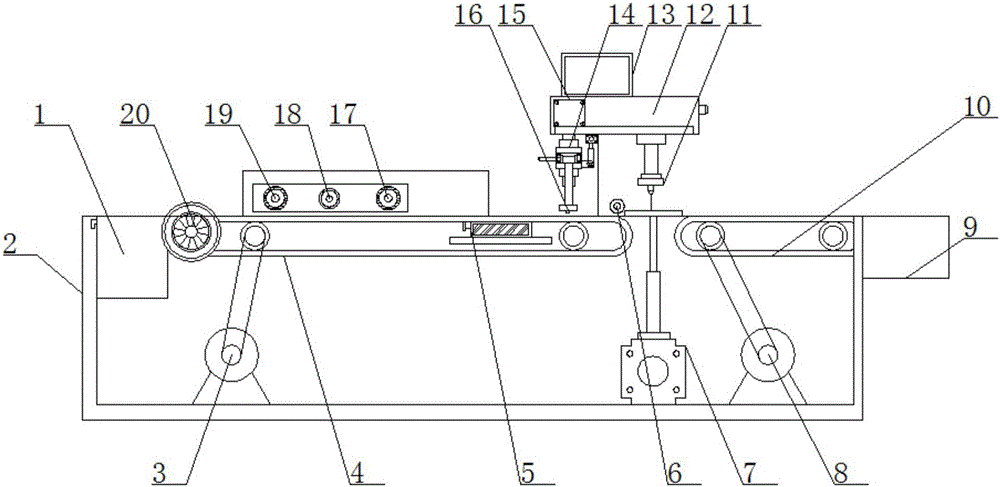

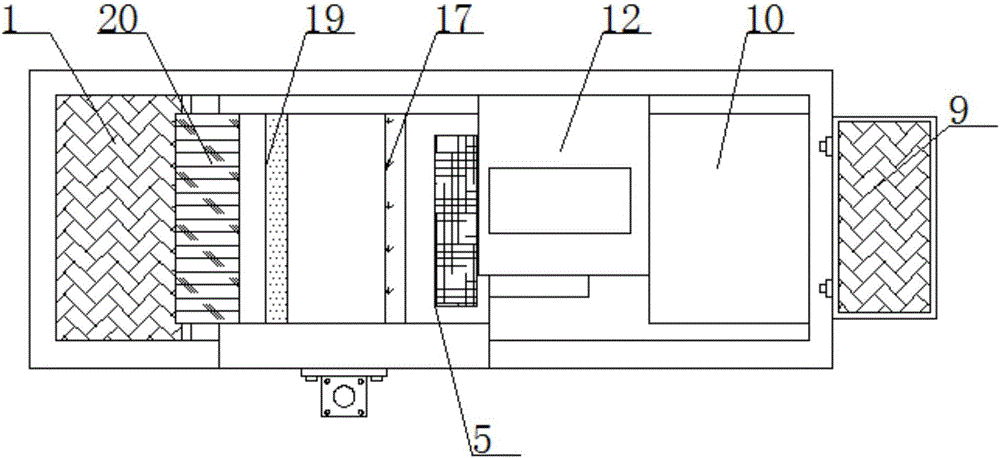

High-intensity processing machine for portable paper bags

InactiveCN106363957AAvoid degummingFit closelyBag making operationsPaper-makingPulp and paper industryHigh intensity

The invention discloses a high-intensity processing machine for portable paper bags. The machine comprises a rack. A paper box is installed in the rack. A conveying roller is arranged on one side of the paper box. A first conveying belt is arranged on one side of the conveying roller. A length sensor is installed in the first conveying belt. A flattening roll is installed in the position, corresponding to the first conveying belt, above the rack. A dust removing brush is arranged on one side of the flattening roll. A third servo motor is installed above the rack. Compared with a traditional paper bag processing machine, the structure is relatively simplified, fast learning and operating by a worker are facilitated, and the production intensity is high; the paper attachment degree is made higher by arranging a negative pressure blower in the conveying roll; the special flattening roll and the dust removing brush are arranged so that paper bag degumming caused by tiny dust can be prevented, and the production quality is improved; and the length sensor and a laser locator operate in linkage to locate round hole punching positions, and locating is accurate.

Owner:重庆乔远环保科技有限公司

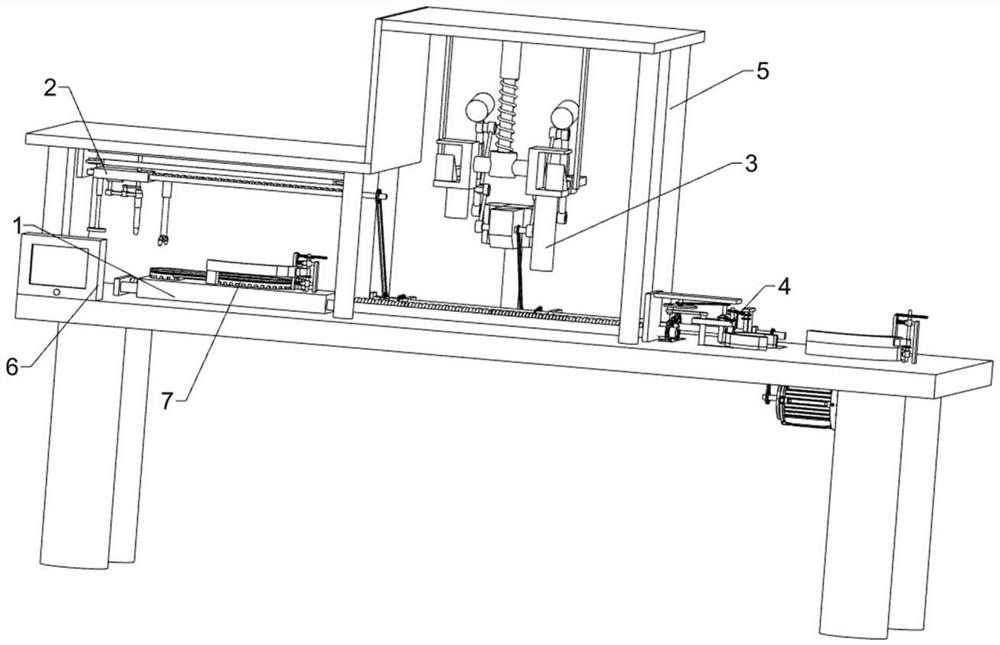

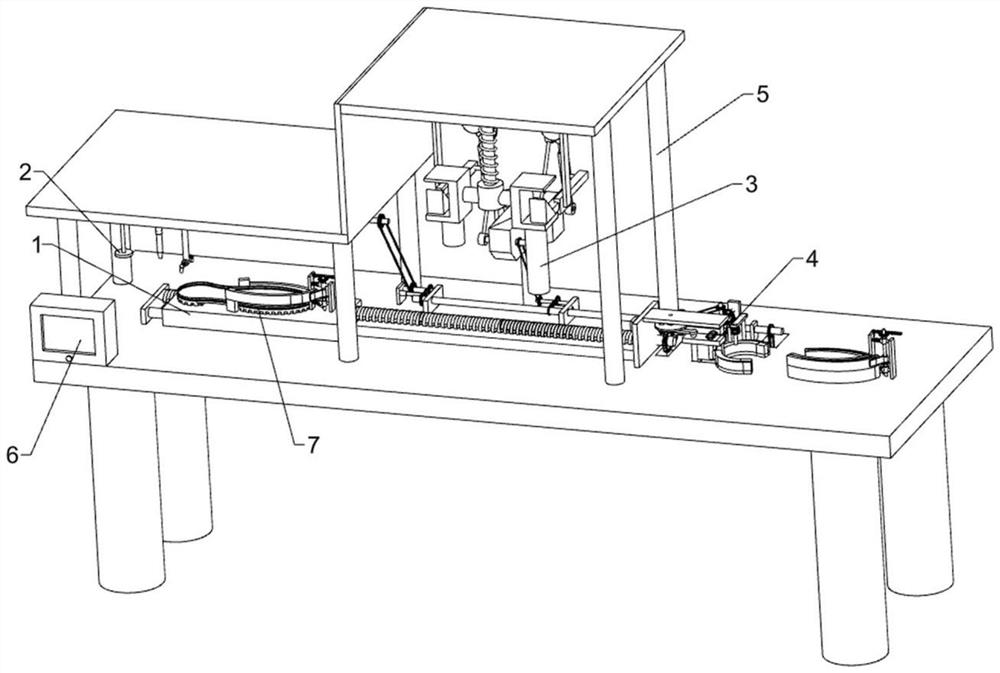

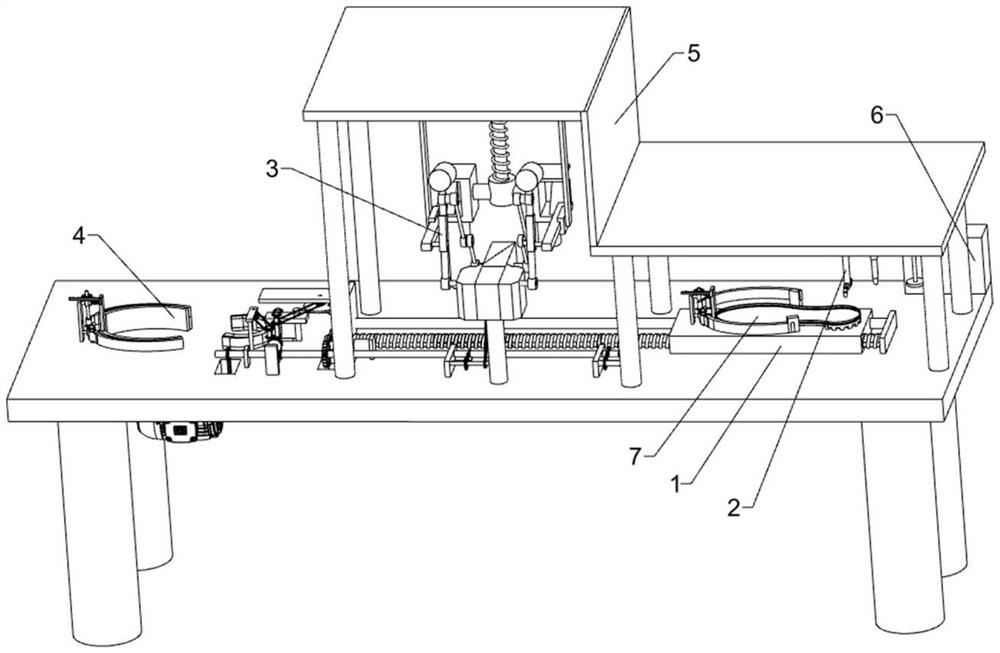

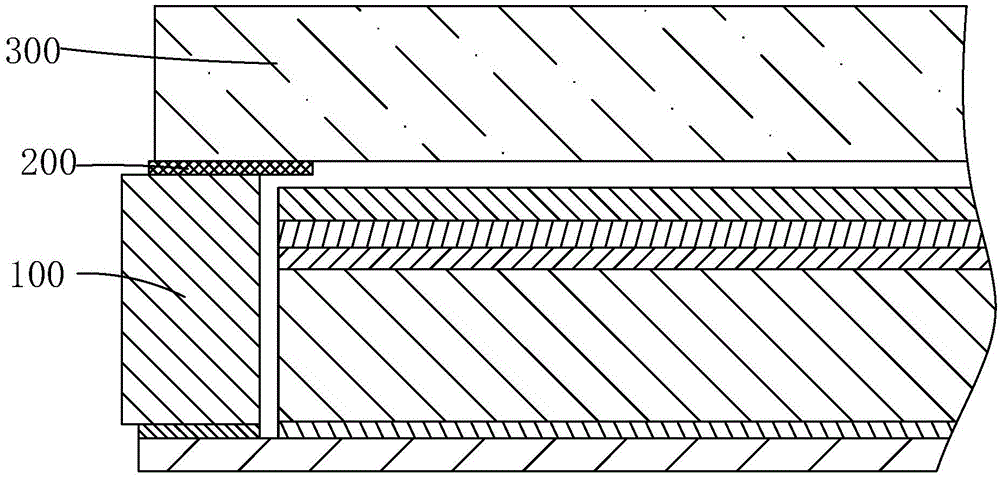

Shoe producing and processing device

InactiveCN111887542ASolve the phenomenon of glue openingAvoid pressingShoe gluingManufacturing engineeringMechanical engineering

The invention relates to the field of shoe production and processing and relates to a shoe production and processing device. According to the technical schemes of the invention, the shoe producing andprocessing device comprises a positioning and conveying mechanism, a gluing and heating mechanism, a secondary pressing mechanism, a side face pressing mechanism and the like; a workbench is connected with the gluing and heating mechanism; and the workbench is connected with the secondary pressing mechanism. According to the shoe production and processing device of the invention, shoe sole positioning is realized; the shoe sole is glued in three directions; an assembled shoe is hammered for the second time; insufficient shoe bonding caused by shoe sole springback is prevented; glue peeling ofthe shoe during use is avoided; the assembling quality of the shoe can be improved; the top and the side face of the shoe can be extruded at the same time; and the working efficiency during the assembling of the shoe is improved.

Owner:孙海红

Immersion non-woven fabrics and method for producing artificial boards by coating films

InactiveCN101591862AGuarantee product qualityTemperature heat conduction balanceWood veneer joiningTextiles and paperPolyurethane adhesiveWear resistant

The invention relates to immersion non-woven fabrics and a method for producing artificial boards by coating films on the immersion non-woven fabrics. The ration of the non-woven fabrics is between 50 and 500 g / m and the thickness is between 0.5 and 5 mm; and a resin adhesive is a phenolic resin adhesive, a melamine resin adhesive or a polyurethane adhesive. The resin content of the immersion non-woven fabrics is between 28 and 36 percent, the volatile content is between 8 and 9 percent, and the pre-cure degree is between 30 and 55 percent. The method for producing the artificial boards by coating films on the immersion non-woven fabrics comprises the following steps: immersing the non-woven fabrics in the resin adhesive, and drying; and coating the films on the surfaces of the artificial boards through hot pressing, wherein the hot-pressing temperature is between 85 and 150 DEG C, the time is between 5 and 10 min, and the pressure is between 0.5 and 1 Mpa. The artificial boards produced by the method are wear-resistant, fire-retardant, neat, rich in color, low in cost, and environment-friendly.

Owner:邱天祥

Backlight module and liquid crystal display device

InactiveCN105093612AIncreased permeable widthPrevent penetrationNon-linear opticsLiquid-crystal displayEngineering

The invention provides a backlight module and a liquid crystal display device. The backlight module comprises a back plate (1). The back plate (1) comprises a bottom plate (101), a side plate (103) perpendicularly connected to the bottom plate (101) from the peripheral edge of the bottom plate (101), and a top plate (105) arranged on the periphery of the side plate (103) and perpendicularly connected to the side plate (103) at the end, away from the bottom plate (101), of the side plate (103). The top plate (105) is provided with a plurality of glue containing holes (1051) used for containing glue so that a liquid crystal panel can be fixed to the back plate (10), and the problems of glue leakage, glue disengagement and the like in the assembling process of the backlight module and the liquid crystal panel can be solved under the premise that square glue is not used for achieving the narrow frame of the liquid crystal display device.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Structural adhesive

InactiveCN109456720AImprove melt indexImprove water absorptionGraft polymer adhesivesAdhesiveAntioxidant

The invention discloses a structural adhesive. The structural adhesive is prepared from the following components in parts by weight: 30 to 65 parts of styrenic thermoplastic elastomer, 5 to 15 part ofmodified thermoplastic elastomer, 25 to 45 parts of modified hydrogenated petroleum resin, 2 to 8 parts of acrylic type polymer absorbent resin, 2 to 6 parts of an antioxidant and 3 to 7 parts of naphthenic oil, wherein a styrenic thermoplastic elastomer is a mixture of a styrene-butadiene-styrene block copolymer (SBS) and a polystyrene-polyethylene-polybutylene-polystyrene block copolymer (SEBS). The structural adhesive is capable of increasing a water-absorbing capacity of a disposable sanitary product, and keeping a good water-absorbing property while absorbing liquid containing salinity,enabling the liquid to be rapidly absorbed by a water-absorbing inner layer of the sanitary product, reducing contact time of skin and the liquid, and preventing the fact that the sanitary product isin supersaturation by absorbing the liquid, so that the liquid penetrates to an outer surface layer and contacts with the skin.

Owner:QUZHOU STANLEY ADHESIVE IND CO LTD

Method for interconnecting back faces of wafer level chips during packaging

InactiveCN104576520AImprove conduction performanceIncrease contact areaSemiconductor/solid-state device manufacturingElectricityLaser etching

The invention discloses a method for interconnecting back faces of wafer level chips during packaging. Blocking materials on a wafer welding cushion are removed through laser etching, a certain area of surface of the welding cushion is exposed to be connected with a metal wiring layer, and electricity of an element area is led to the back faces of wafers. Through the method that the blocking materials on the welding cushion are removed directly through laser etching, the process steps of photoresist coating, photo-etching exposure, developing, photoresist removing and the like are omitted; by selecting an appropriate laser wavelength, adjusting the laser focusing position, adjusting the energy, focus spot area, acting pulse number and other parameters of lasers acting at the bottom of a first opening and controlling laser etching to reach the surface of the welding cushion without penetrating through the welding cushion, a large area of the welding cushion is exposed. The method is convenient to operate, the contact area of the welding cushion and the metal wiring layer is enlarged, and conductivity is more reliable.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

Liquid crystal display screen protective film and preparation method

InactiveCN106903939AAvoid scratchesImprove waterproof performanceSynthetic resin layered productsLaminationTectorial membraneLiquid-crystal display

The invention discloses a liquid crystal screen protective film and a preparation method, belonging to the technical field of screen protective films. The liquid crystal screen protective film comprises a base material layer, the upper surface of the base material layer is provided with a scratch-resistant layer, the upper surface of the scratch-resistant layer is provided with a dust removal layer, the lower surface of the base material layer is provided with a radiation-proof layer, and the radiation-proof layer is A release film is provided on the lower surface, and the substrate layer, the scratch-resistant layer, the radiation protection layer, and the radiation protection layer and the release film are connected through an adhesive layer. The preparation method comprises: coating an adhesive layer on the upper surface of the substrate layer, bonding a scratch-resistant layer on the upper surface of the adhesive; coating a dust release layer on the upper surface of the scratch-resistant layer; coating the lower surface of the substrate layer Cover the adhesive layer, then bond the radiation protection layer, then coat the adhesive layer on the lower surface of the radiation protection layer, and bond the release film. The protective film not only has good scratch resistance, but also has good radiation protection, electrostatic shielding and waterproof effects, provides multi-directional protection for liquid crystal screens, and has good application value.

Owner:HEFEI ZHONGKE FUHUA NEW MATERIAL

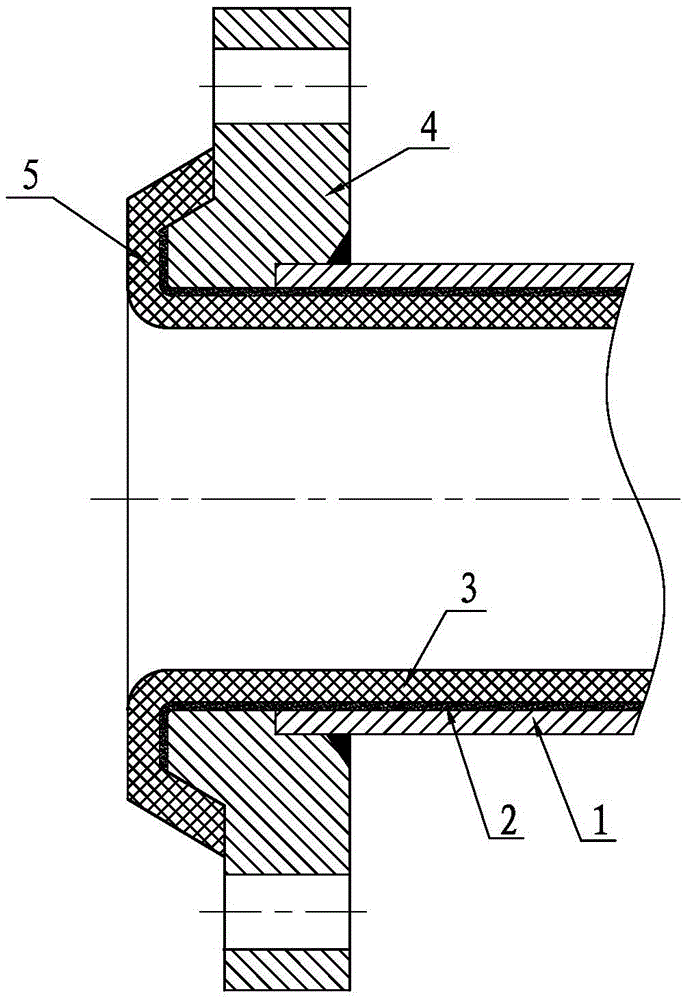

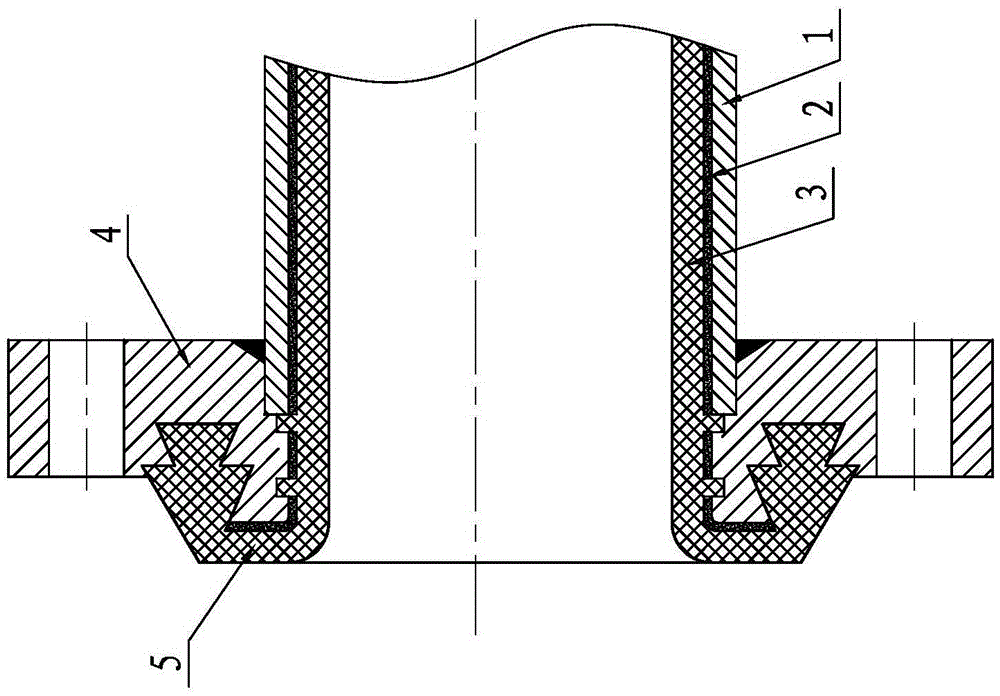

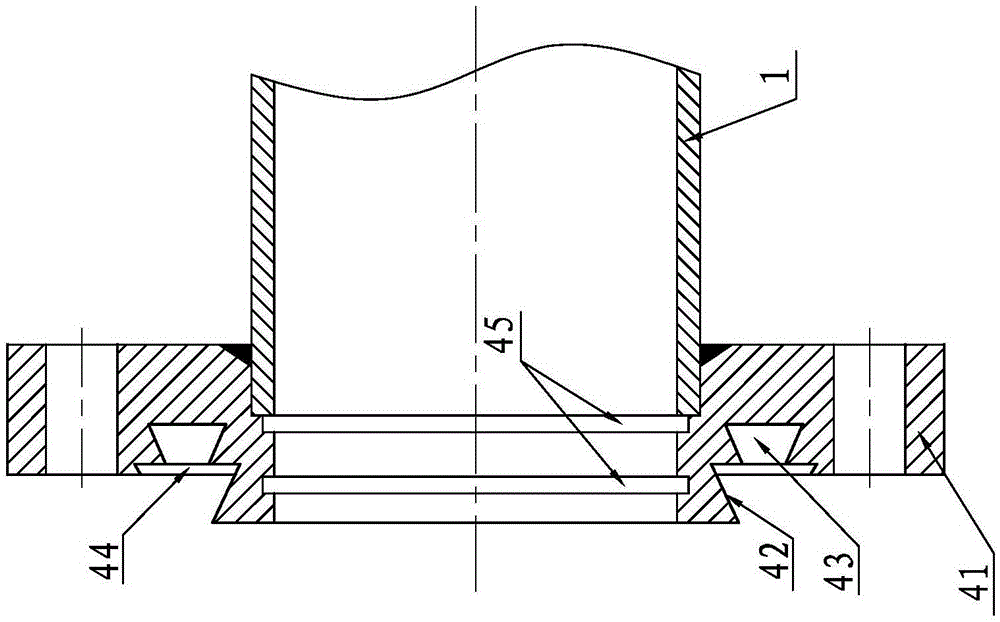

Steel-plastic meshed composite pipe with detachment preventive function

InactiveCN105526432AIncrease internal stressLimited axial elongationPipe elementsRigid pipesEngineeringThermal expansion

The invention discloses a steel-plastic meshed composite pipe with a detachment preventive function. The steel-plastic meshed composite pipe comprises a steel outer pipe, an anti-corrosion inner-layer pipe and a connecting flange, two ends of the anti-corrosion inner-layer pipe form end face turnups on a docking face of the connecting flange by means of hot melting deformation, axial meshing structures are arranged between the end face turnups and the connecting flange, and a radial meshing structure is arranged between the anti-corrosion inner-layer pipe and an inner hole of the connecting flange. When environment temperature changes greatly, although a plastic inner pipe deforms greatly due to heat expansion and cold contraction, two ends of the anti-corrosion inner-layer pipe are limited by the axial meshing structures of the connecting flange and cannot extend outwards, deformation due to heat expansion and cold contraction of the anti-corrosion inner-layer pipe is converted into internal stress, and compactness of the anti-corrosion inner-layer pipe and improvement on mechanical performance of the same are facilitated, so that displacement, degumming and detachment defects between the anti-corrosion inner-layer pipe and the steel outer pipe are eliminated structurally.

Owner:JIANGSU KAIXING PIPELINE CO LTD

Shock-proof waterproof coiled material and preparation method

InactiveCN106671537AImprove shock absorption and cushioning effectSolve the difficulty of handlingSynthetic resin layered productsLaminationAdhesiveProtection layer

The invention discloses a shock-proof waterproof coiled material and a preparation method, which belongs to the technical field of the waterproof coiled material. The shock-proof waterproof coiled material comprises a base material layer, wherein the upper surface of the base material layer is provided with an elastic buffer layer, the upper surface of the elastic buffer layer is provided with a flexible waterproof layer, and the elastic buffer layer is respectively connected with the base material layer and the flexible waterproof layer by virtue of an adhesive layer; the lower surface of the base material layer is provided with a self-adhesion waterproof layer, and the lower surface of the self-adhesion waterproof layer is also provided with a protection layer. The preparation method comprises the following steps: smearing the adhesion layer on the upper surface of the base material layer, and adhering the elastic buffer layer onto the upper surface of the adhesive; adhering the flexible waterproof layer onto the upper surface of the elastic buffer layer; and smearing the self-adhesion waterproof layer at the lower surface of the base material layer, and then adhering a protective layer. The waterproof coiled material not only has a good waterproof effect, but also has an excellent shock-proof effect, and can protect a building against collision damage; and moreover, the preparation method is simple and easy and has good application value.

Owner:HEFEI ZHONGKE FUHUA NEW MATERIAL

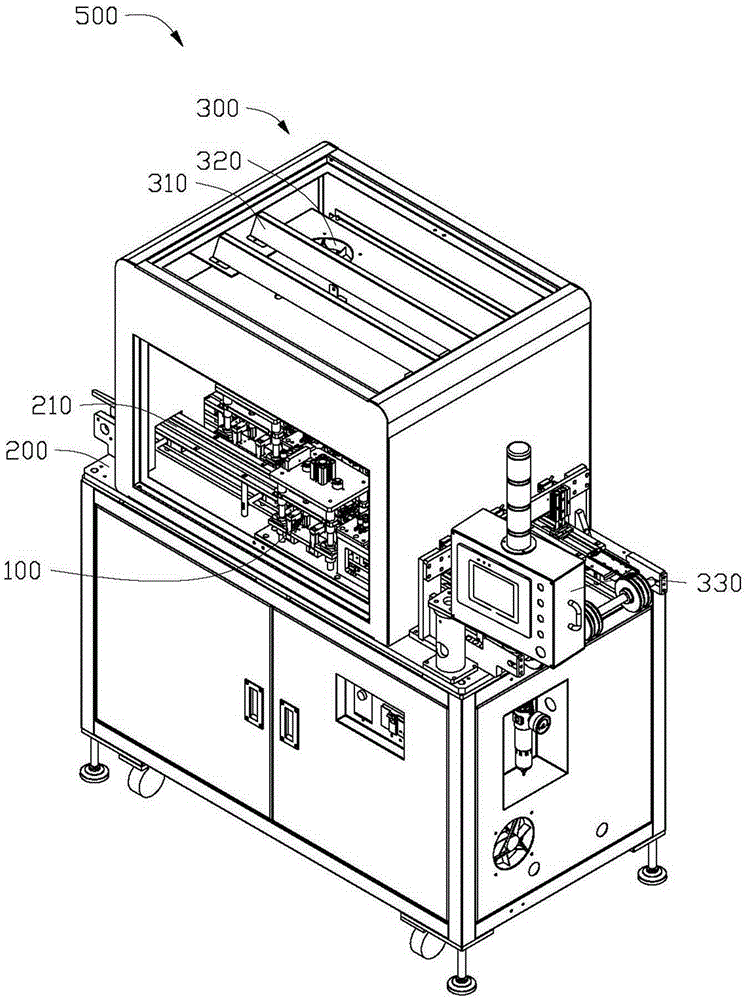

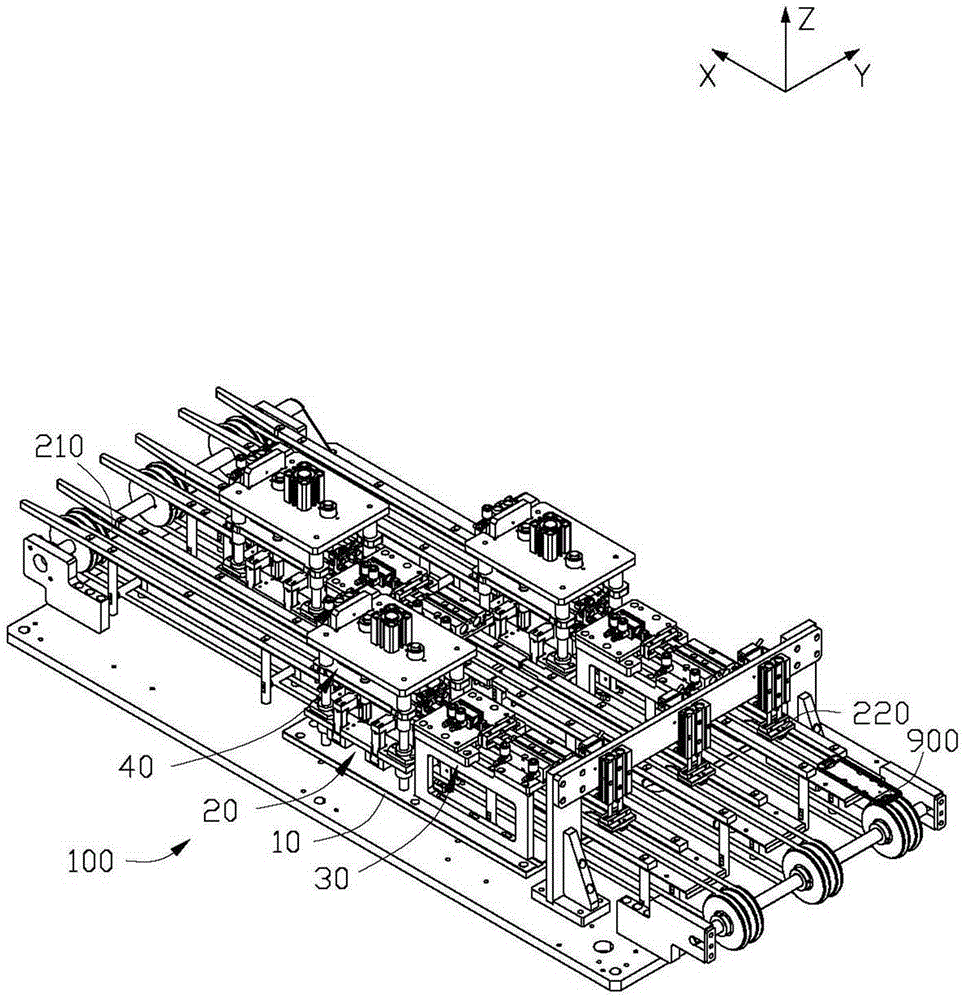

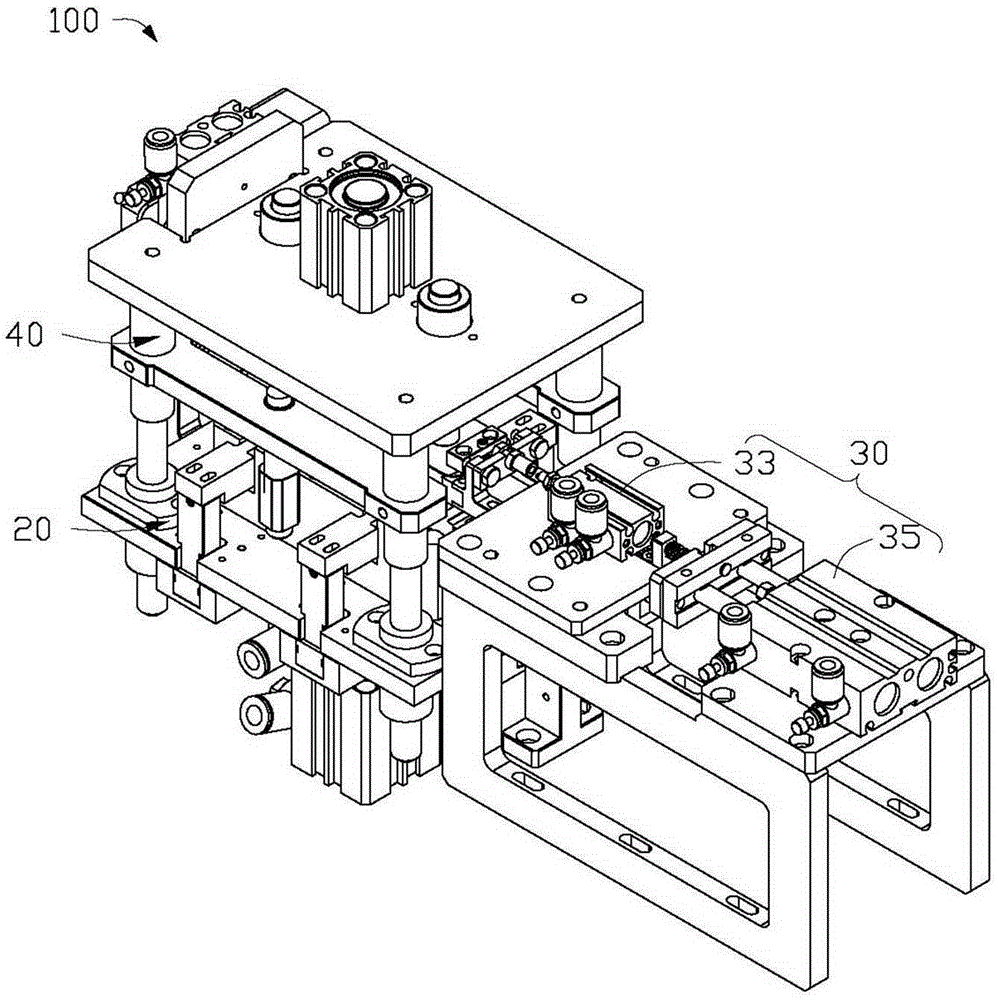

Pressure maintaining device

A pressure maintaining device comprises a bottom plate, a first positioning module and a pressure maintaining module, wherein the first positioning module and the pressure maintaining module are arranged on the bottom plate. The pressure maintaining module comprises a first pressure maintaining air cylinder and a profiling pressing block. The first positioning module comprises a floating plate, limiting columns arranged on the two sides of the floating plate, a first positioning air cylinder fixedly connected with the floating plate, a pair of connecting rod assemblies arranged on one side of the floating plate, and multiple first positioning blocks arranged on the other side of the floating plate. The surfaces, adjacent to the floating plate, of the limiting columns are in a step shape. Each connecting rod assembly comprises a first sliding block, two rotary arms connected to the two sides of the first sliding block in a pivoted manner correspondingly, and two second sliding blocks connected with the two rotary arms in a pivoted manner correspondingly. The first sliding blocks abut against the limiting columns, the first positioning blocks are connected with the second sliding blocks, the first positioning air cylinder is used for driving the floating plate to move in the direction away from or close to the bottom plate, the first sliding blocks drive the second sliding blocks and the first positioning blocks to slide, and accordingly the multiple first positioning blocks can clamp or release workpieces.

Owner:FU DING ELECTRONICSAL TECH JIASHAN

Surgical healing device

InactiveCN105476680AEffectively break down local tensionAvoid relative shearWound clampsEngineeringSurgical department

Owner:BEIJING MED ZENITH MEDICAL SCI CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com