Sound-absorption and waterproof attapulgite board and preparation method

A technology of waterproof board and attapulgite, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc. It can solve the problems that the sound-absorbing board cannot achieve the effect and the base layer loses its effect, so as to avoid adding bonding The effect of the agent process, the preparation method is simple, and the performance is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

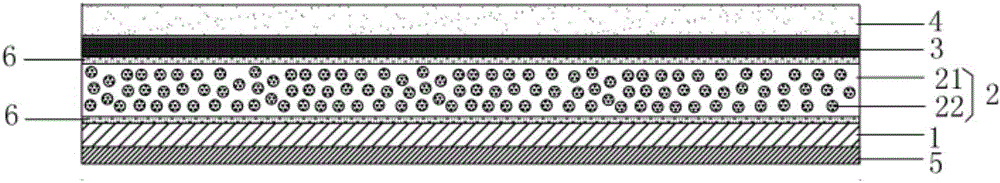

[0031] Such as figure 1 As shown, a kind of attapulgite sound-absorbing waterproof board and its preparation method according to the preferred embodiment of the present invention;

[0032] The attapulgite sound-absorbing waterproof board includes a board body 1, and also includes a sound-absorbing layer 2 arranged on the upper surface of the board body 1. The upper surface of the sound-absorbing layer 2 is provided with a rubber buffer layer 3, and the upper surface of the rubber buffer layer 3 is provided with There is a wear-resistant waterproof layer 4, and the lower surface of the board body 1 is also provided with a waterproof protective layer 5, the board body 1 is a board body prepared with attapulgite clay as a base material, and the sound-absorbing layer 2 includes an elastic layer 21 and sound-absorbing filler 22, wherein the elastic layer 21 is provided with a plurality of small holes, and the sound-absorbing filler 22 is filled in the small holes, and the sound-abs...

Embodiment 2

[0046] An attapulgite sound-absorbing waterproof board according to a preferred embodiment of the present invention and its preparation method;

[0047] The attapulgite sound-absorbing and waterproof board includes a board body and a sound-absorbing layer arranged on the upper surface of the board body. The upper surface of the sound-absorbing layer is provided with a rubber buffer layer, and the upper surface of the rubber buffer layer is provided with a wear-resistant and waterproof layer. The lower surface of the board body is also provided with a waterproof protective layer, the board body is a board body prepared with attapulgite clay as a base material, and the sound-absorbing layer includes an elastic layer and a sound-absorbing filler, wherein the elastic layer is provided with A plurality of small holes, the sound-absorbing filler is filled in the small holes, the sound-absorbing filler is a filler prepared from attapulgite clay as a base material, the gap between the ...

Embodiment 3

[0061] The structure of the attapulgite sound-absorbing and waterproof board is the same as in Example 1, except for its preparation method, which is as follows:

[0062] (1) Preparation of the board: Weigh 20 parts of high-viscosity attapulgite clay and 20 parts of paste-like attapulgite clay and mix evenly, then add 10 parts of diatomite, 8 parts of graphite and hair 3 parts of foaming agent, mixed evenly, and then molded the mixed material, dried it after opening the mold, calcined and raised to 800°C, then roasted at constant temperature for 5 hours, cooled, and cut to obtain the board;

[0063] (2) Preparation of sound-absorbing filler: Weigh 20 parts of high-viscosity attapulgite clay, 20 parts of paste-like attapulgite clay, 10 parts of heat-modified attapulgite clay and 8 parts of graphite, stir and mix evenly, and then Granulating the mixture, drying the pellets, and then roasting at 500°C for 5 hours, then grinding the roasted pellets and sieving to obtain the sound-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com