Concrete pavement material for heavy traffic roads and preparation method thereof

A technology for concrete pavement and heavy traffic, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of difficult repair, long maintenance time, short life, etc. Large volume, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

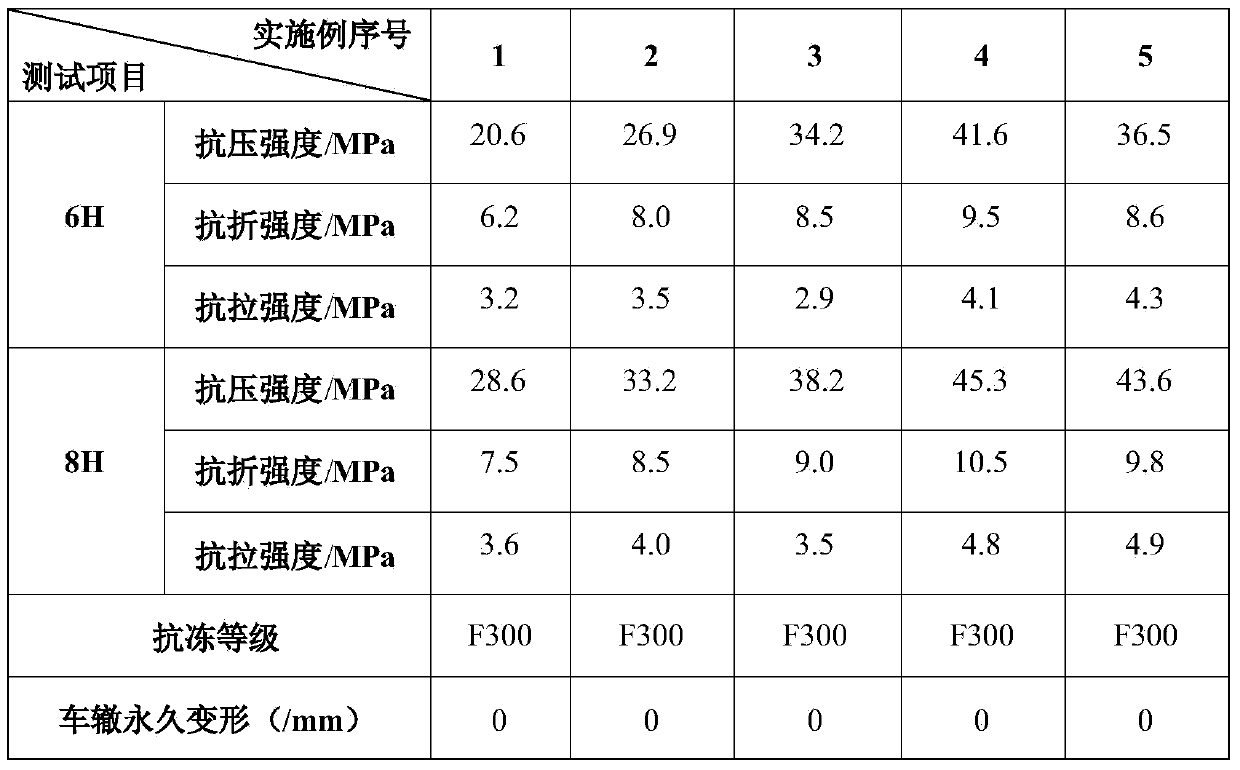

Examples

Embodiment 1

[0027] A concrete pavement material suitable for heavy traffic highways, its composition and preparation method are as follows:

[0028] 1) Preparation of component A: In parts by mass, 80 parts of NPEF-170, 10 parts of elastic modifier QS-P24F (produced by Beijing Jindao Qishi Material Technology Co., Ltd.), 0.2 parts of BYK-066N; BYK- Add 0.2 parts of 163 to the reaction kettle one by one at a speed of 300 rpm, stir for 5 minutes to obtain component A, pack and store;

[0029] 2) Preparation of B component: by mass parts, 650 ﹟ Add 100 parts of low-molecular polyamide, 10 parts of DMP-30, and 1 part of coupling agent KH-550 into the reaction kettle one by one at a speed of 300 rpm, stir for 5 minutes to obtain component B, pack and store;

[0030] 3) Preparation of component C: in parts by volume, add 100 parts of fine stone, 30 parts of fine sand, 80 parts of waste rubber granules, 50 parts of waste rubber powder, and 10 parts of whiskers into the reaction kettle in sequen...

Embodiment 2

[0033] A concrete pavement material suitable for heavy traffic highways, its composition and preparation method are as follows:

[0034] 1) Preparation of component A: in parts by mass, 40 parts of a mixture of epoxy resin E-44 and epoxy resin E-51 (mass ratio 1:2), 20 parts of diglycidyl ether, elastic modification 50 parts of agent QS-P24F (produced by Beijing Jindao Qishi Material Technology Co., Ltd.), 0.2 parts of BYK-066N; 0.2 parts of BYK-163 were added to the reaction kettle in turn, and the rotation speed was 500 rpm, and A was obtained after stirring for 10 minutes. Components, packaging and storage;

[0035] 2) Preparation of component B: by parts by mass, the modified phenalkamine T5 and 650 ﹟ Mixture of low-molecular polyamide (mass ratio 1:3) 100 parts (modified phenalkamine T5 produced by Henan Tianze Industrial Co., Ltd.), 10 parts of boron trifluoride monoethylamine, coupling agent KH-550 1 part, add to the reaction kettle one by one, rotate at 500 rpm, stir...

Embodiment 3

[0039] A concrete pavement material suitable for heavy traffic highways, its composition and preparation method are as follows:

[0040] 1) Preparation of component A: In parts by mass, 70 parts of epoxy resin E-44, 10 parts of phenyl glycidyl ether, 20 parts of elastic modifier QS-P24F (Beijing Jindao Qishi Material Technology Co., Ltd. Production) ﹑ BYK-066N 0.2 parts; BYK-163 0.2 parts, add to the reaction kettle in turn, the rotation speed is 400 rpm, stir for 7 minutes to get the A component, pack and store;

[0041] 2) Preparation of component B: in parts by mass, add 100 parts of modified aliphatic amine 1622T (produced by Beijing Qingda Qishi New Material Technology Co., Ltd.), 1 part of coupling agent KH-550 into the reaction kettle in sequence, Rotate at 400 rpm, stir for 7 minutes to get component B, package and store;

[0042] 3) Preparation of component C: by volume, add 100 parts of fine stone, 100 parts of fine sand, 200 parts of waste rubber granules, 50 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com