A preparation method of a multi-layer composite artificial blood vessel with adjustable compliance

A multi-layer composite and artificial blood vessel technology, applied in the field of artificial blood vessels, can solve problems such as difficult bionic human blood vessels, suture fatigue, solvents are difficult to completely remove, etc., to achieve the effect of overcoming the easy formation of thrombus, not easy to form thrombus, and enhancing patency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A composite foam tube is made of PCL, PLA and TPU blended and foamed at a mass ratio of 80:10:10.

[0044] The composite material foam tube is prepared by the following method:

[0045] (1) PCL, PLA and TPU are blended and granulated according to the mass ratio of 80:10:10 on a twin-screw extruder;

[0046] (2) Set the temperature of the flat vulcanizing machine to 190°C. After the temperature is reached, put the pellets in a hollow steel plate with a thickness of 0.5mm, cover the upper and lower planes with a polytetrafluoroethylene film, put it into the heating plate, and wait for about 15 minutes. Melt, squeeze for about 5 minutes after melting, and take out the thin slice; perform secondary extrusion on the hot press to obtain a film with a thickness of about 0.2mm;

[0047] (3) Wrap a layer of aluminum foil paper (made of two layers of aluminum foil paper) around a solid cylinder with a diameter of 7mm, then wrap a film outside the layer of aluminum foil paper, an...

Embodiment 2

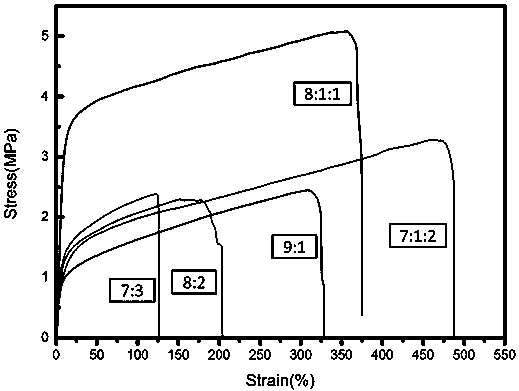

[0051] A composite material foam tube is made by blending and foaming PCL and PLA according to the mass ratio of 80:20, and its preparation method is the same as that of Example 1. The obtained product is designated as sample 2.

[0052] It was determined that the cell rate of the above sample 2 was 84.71%, the average size of the internal cell size was 10.06 μm, the cell size distribution was 10.06±3.3 μm, and the cell density was 2.55X10 8 piece / cm 3 , the modulus of elasticity is 4.86MPa, the tensile strength is 1.36MPa, and the elongation at break is 203%.

Embodiment 3

[0054] A composite material foam tube, which is made by blending and foaming PCL and PLA according to the mass ratio of 90:10, is designated as sample 3.

[0055] For the preparation process, refer to Example 1. The difference from the preparation process of Example 1 is that the diameter of the solid cylinder is 5.5 mm, and the inner diameter of the hollow cylinder is 6.5 mm.

[0056] It was determined that the cell rate of the above sample 3 was 88.52%, the average size of the internal cell size was 10.67 μm, the cell size distribution was 10.67±3.03 μm, and the cell density was 1.75×10 8 piece / cm 3 , the modulus of elasticity is 4.49 MPa, the tensile strength is 1.25 MPa, and the elongation at break is 326%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com