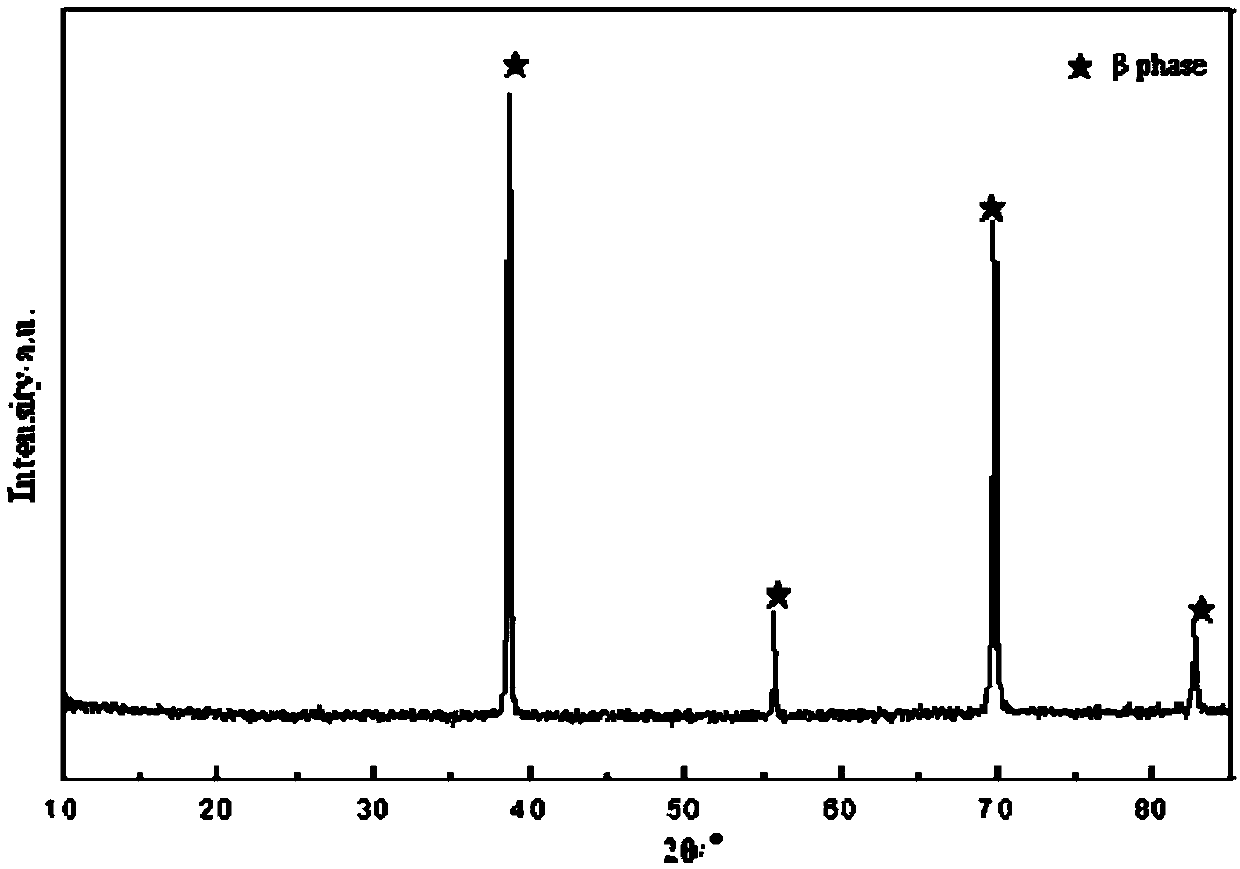

Porous niobium-tantalum-titanium alloy material with controllable pores and preparation method thereof

A technology of tantalum-titanium alloy and porous niobium, applied in the field of porous niobium-tantalum-titanium alloy material and its preparation, can solve the problem of uncontrollable pore porosity, affecting the mechanical properties and biocompatibility of the alloy, and unable to simulate the morphology of human bone tissue and other problems, to achieve excellent bionic properties, excellent biocompatibility, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Mixing of powders: Weigh 30 g of niobium, tantalum, and titanium powders in total, and the powders are in an atomic ratio of Nb:Ta:Ti=50:25:25. When the powder is pre-mixed, the mass ratio of the ball to the material is 1:4, the mixing time is 8 hours, and the speed of the mixer is 200r / min.

[0036] 2. Preparation of slurry: Weigh 3g of polyvinyl alcohol and fully dissolve it in deionized water, and mix the Nb-Ta-Ti composite powder with an organic solvent evenly to form a slurry. The prepared slurry needs to be placed in an electromagnetic stirrer Stir for 1 hour to ensure uniform dispersion of the metal powder.

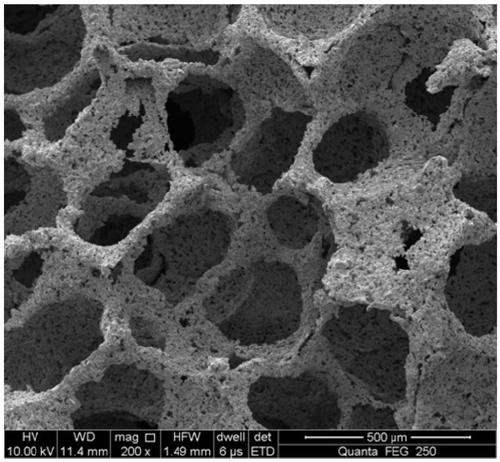

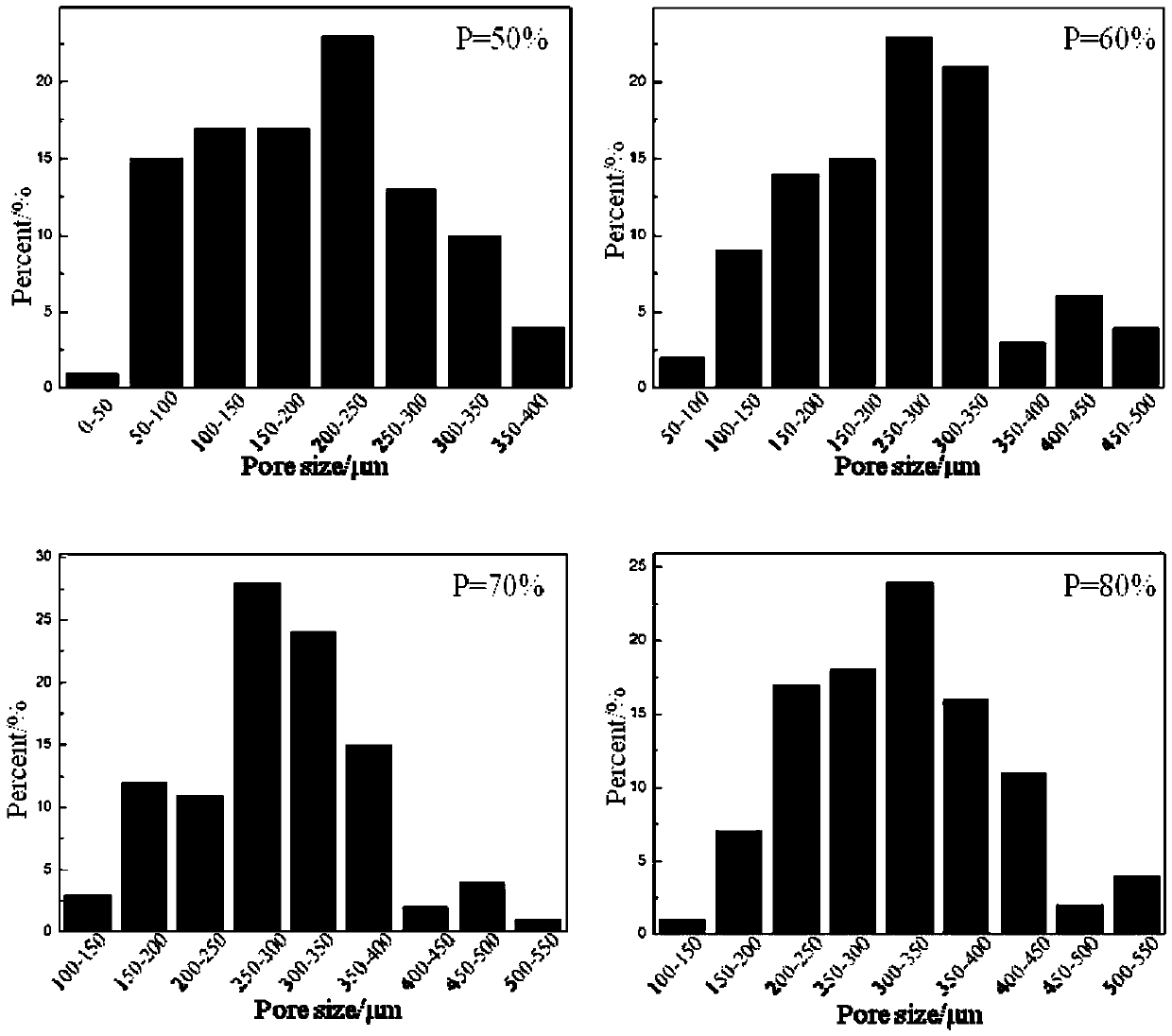

[0037] 3. Impregnation process: Cut the polyurethane template to And pretreatment in 10% NaOH aqueous solution for 30min, the treatment temperature is 40°C. Fill the Nb-Ta-Ti composite powder slurry into the polymer porous template with a solid content ratio of 3g / ml, and dry it sufficiently to obtain a porous alloy scaffold containing the Nb-Ta-Ti ter...

Embodiment 2

[0043] 1. Mixing of powders: Weigh 30 g of niobium, tantalum, and titanium powders in total, and the powders are in an atomic ratio of Nb:Ta:Ti=50:25:25. When the powder is pre-mixed, the mass ratio of the ball to the material is 1:4, the mixing time is 8 hours, and the speed of the mixer is 200r / min.

[0044] 2. Preparation of slurry: Weigh 3g of polyvinyl alcohol and fully dissolve in deionized water, configure Nb-Ta-Ti composite powder and mix with organic solvent evenly to form a slurry. The prepared slurry needs to be stirred in an electromagnetic stirrer 1 hour to ensure the uniformity of metal powder dispersion.

[0045] 3. Impregnation process: Cut the polyurethane template to And pretreatment in 10% NaOH aqueous solution for 30min, the treatment temperature is 40°C. The Nb-Ta-Ti alloy slurry is filled into the polymer porous template with a solid content ratio of 4.5g / ml, and after being fully dried, the green body of the porous alloy stent containing the Nb-Ta-Ti ...

Embodiment 3

[0051] 1. Mixing of powders: Weigh 30 g of niobium, tantalum, and titanium powders in total, and the powders are in an atomic ratio of Nb:Ta:Ti=50:25:25. When the powder is pre-mixed, the mass ratio of the ball to the material is 1:4, the mixing time is 8 hours, and the speed of the mixer is 200r / min.

[0052] 2. Preparation of slurry: Weigh 5g of polyvinyl alcohol and fully dissolve it in deionized water, configure Nb-Ta-Ti composite powder and mix with organic solvent evenly to form a slurry. The prepared slurry needs to be stirred in an electromagnetic stirrer 1 hour to ensure the uniformity of metal powder dispersion.

[0053] 3. Impregnation process: Cut the polyurethane template to And pretreatment in 10% NaOH aqueous solution for 30min, the treatment temperature is 40°C. The Nb-Ta-Ti alloy slurry is filled into the polymer porous template with a solid content ratio of 4.5g / ml, and after being fully dried, the green body of the porous alloy stent containing the Nb-Ta-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com