Acrylic emulsion and preparation method therefor

A technology of acrylic emulsion and anionic emulsifier, applied in the direction of adhesive types, film/sheet adhesives, adhesives, etc., can solve the problems that adhesives cannot be well attached and degummed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

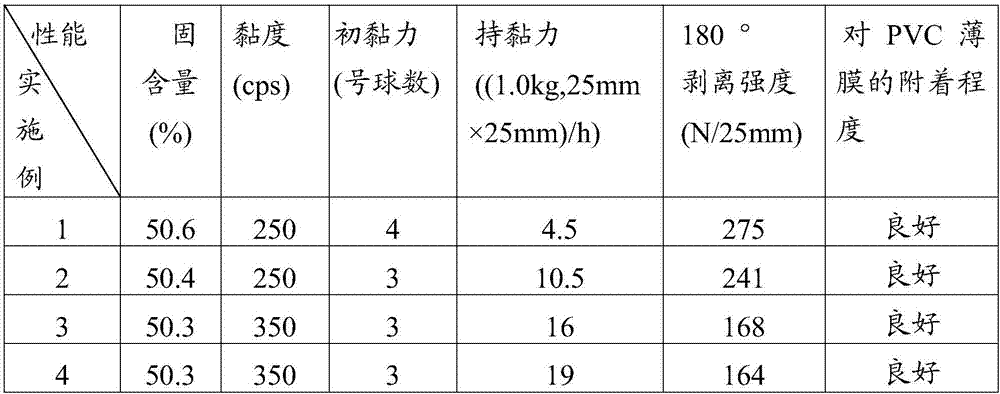

Examples

preparation example Construction

[0033] The present invention also proposes a kind of preparation method of acrylic acid emulsion, comprises the following steps:

[0034] Provide solvents, soft monomers, some hard monomers, functional monomers, molecular weight regulators, anionic emulsifiers and reactive emulsifiers for pre-emulsification in preset proportions to form pre-emulsions;

[0035] Provide non-ionic emulsifier and buffer, mix with part of pre-emulsion and part of initiator, and heat at 75℃~80℃;

[0036] Provide another part of pre-emulsion and another part of initiator, and maintain the temperature at 83-85°C;

[0037] Provide another part of the hard monomer;

[0038] Provides oxidizing and reducing agents.

[0039] The present invention pre-emulsifies according to a preset ratio through solvents, soft monomers, part of hard monomers, functional monomers, molecular weight regulators, anionic emulsifiers and reactive emulsifiers, first provides non-ionic emulsifiers and buffers, and Mix with a p...

Embodiment 1

[0045] By weight, provide 19.3 parts of deionized water, 35.5 parts of isooctyl acrylate, 4.5 parts of methyl methacrylate, 1.1 parts of styrene, 2.3 parts of hydroxyethyl acrylate, 3 parts of acrylic acid, and 0.9 parts of vinyltriethoxysilane part, 0.06 part of dodecyl mercaptan, 0.2 part of nonylphenol ethoxylate ammonium sulfate, and α-sulfur-ω-[1-[(4-nonylphenoxy)methyl]-2-( 0.13 parts of 2-propenyl-1-oxy)ethoxy]-poly(oxy-1,2-ethylenediyl)ammonium salt, put into the pre-emulsification tank for emulsification, and after all the raw materials are evenly dispersed, stop stirring to form pre-emulsion;

[0046] Provide 30 parts of deionized water, 0.2 part of polyoxyethylene lauryl ether, and 0.1 part of sodium bicarbonate, drop into a four-necked flask equipped with agitator, thermometer, condenser and burette, drop into 0.1 part of ammonium persulfate and 2.2 parts of pre-emulsion solution, heated to 77°C;

[0047] Titrate the remaining pre-emulsion and 0.1 part of ammoniu...

Embodiment 2

[0053] By weight, provide 19.3 parts of deionized water, 35.5 parts of isooctyl acrylate, 4.5 parts of methyl methacrylate, 1.1 parts of styrene, 2.3 parts of hydroxyethyl acrylate, 3 parts of acrylic acid, and 0.9 parts of vinyltriethoxysilane Parts, 0.04 parts of dodecyl mercaptan, 0.2 parts of nonylphenol polyoxyethylene ether ammonium sulfate and α-sulfur-ω-[1-[(4-nonylphenoxy)methyl]-2-(2 -propenyl-1-oxy)ethoxy]-poly(oxy-1,2-ethylenediyl)ammonium salt 0.13 parts, put into the pre-emulsification tank for emulsification, after all the raw materials are evenly dispersed, stop stirring to form a pre-emulsification tank Emulsion;

[0054] Provide 30 parts of deionized water, 0.2 part of polyoxyethylene lauryl ether and 0.1 part of sodium bicarbonate and drop into a four-necked flask equipped with agitator, thermometer, condenser and burette, drop into 0.1 part of ammonium persulfate and pre- 2.2 parts of emulsion, heated to 77°C;

[0055] Titrate the remaining pre-emulsion a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com