Liquid crystal display screen protective film and preparation method

A screen protective film and liquid crystal technology, applied in the direction of chemical instruments and methods, lamination, electronic equipment, etc., can solve the problems such as the cleanliness of the production environment is not up to standard, the coating process is not perfect, and the high-definition is affected, so as to achieve good electrostatic Shielding effect, avoiding radiation damage, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

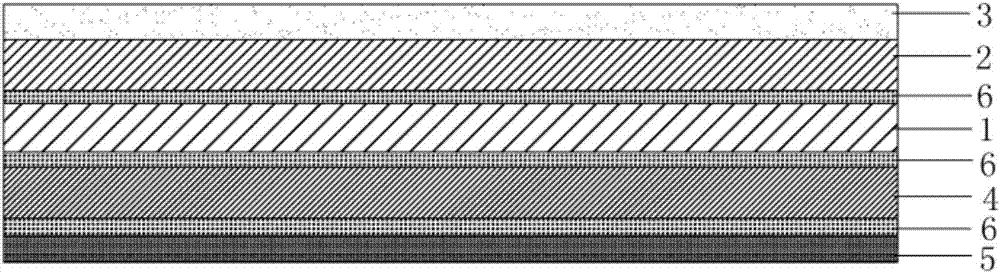

[0024] like figure 1 As shown, a liquid crystal screen protective film and a preparation method thereof are preferred embodiments of the present invention;

[0025] The liquid crystal screen protective film includes a base material layer 1, the upper surface of the base material layer 1 is provided with a scratch-resistant layer 2, the upper surface of the scratch-resistant layer 2 is provided with a dust removal layer 3, and the base material layer 1. The lower surface is provided with a radiation protection layer 4, the lower surface of the radiation protection layer 4 is provided with a release film 5, the base material layer 1 and the scratch-resistant layer 2, the radiation protection layer 4 and the radiation protection layer 4 and the release film The films 5 are connected by an adhesive layer 6 .

[0026] Wherein, the base material layer is a polyethylene terephthalate transparent film, that is, a PET transparent film, which has good toughness and transparency; the sc...

Embodiment 2

[0029] A liquid crystal screen protective film and a preparation method according to a preferred embodiment of the present invention;

[0030] The liquid crystal screen protective film includes a base material layer, the upper surface of the base material layer is provided with a scratch-resistant layer, the upper surface of the scratch-resistant layer is provided with a dust removal layer, and the lower surface of the base material layer is provided with an anti-scratch layer. The radiation layer is provided with a release film on the lower surface of the radiation protection layer, and the base material layer is connected with the scratch-resistant layer, the radiation protection layer, and the radiation protection layer and the release film through an adhesive layer.

[0031]Wherein, the base material layer is a polyethylene terephthalate transparent film, that is, a PET transparent film, which has good toughness and transparency; the scratch-resistant layer is a graphene-mo...

Embodiment 3

[0034] The structure of the liquid crystal screen protective film is the same as that of Example 1, except that the preparation method of the liquid crystal screen protective film includes the following steps: coating a layer of graphene modified epoxy resin adhesive on the upper surface of the PET transparent film , and then bond the graphene-modified natural rubber transparent film layer on the upper surface of the adhesive, and the thickness of the modified transparent film layer is 0.06 mm; and then coat the upper surface of the modified transparent film layer with nano-self-cleaning paint, and the coating thickness is 0.02 mm mm; coat the adhesive layer on the lower surface of the PET transparent film, and then bond the radiation protection layer, that is, the PET / graphene nanocomposite material layer, with a thickness of 0.08 mm, and then coat the adhesive on the lower surface of the radiation protection layer layer, and bond the release film to obtain the liquid crystal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com