Structural adhesive

A structural adhesive and modified technology, applied to structural adhesives. It can solve the problems of reducing the water absorption of ordinary superabsorbent resins, achieve good adhesion performance, increase the use temperature, and have good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

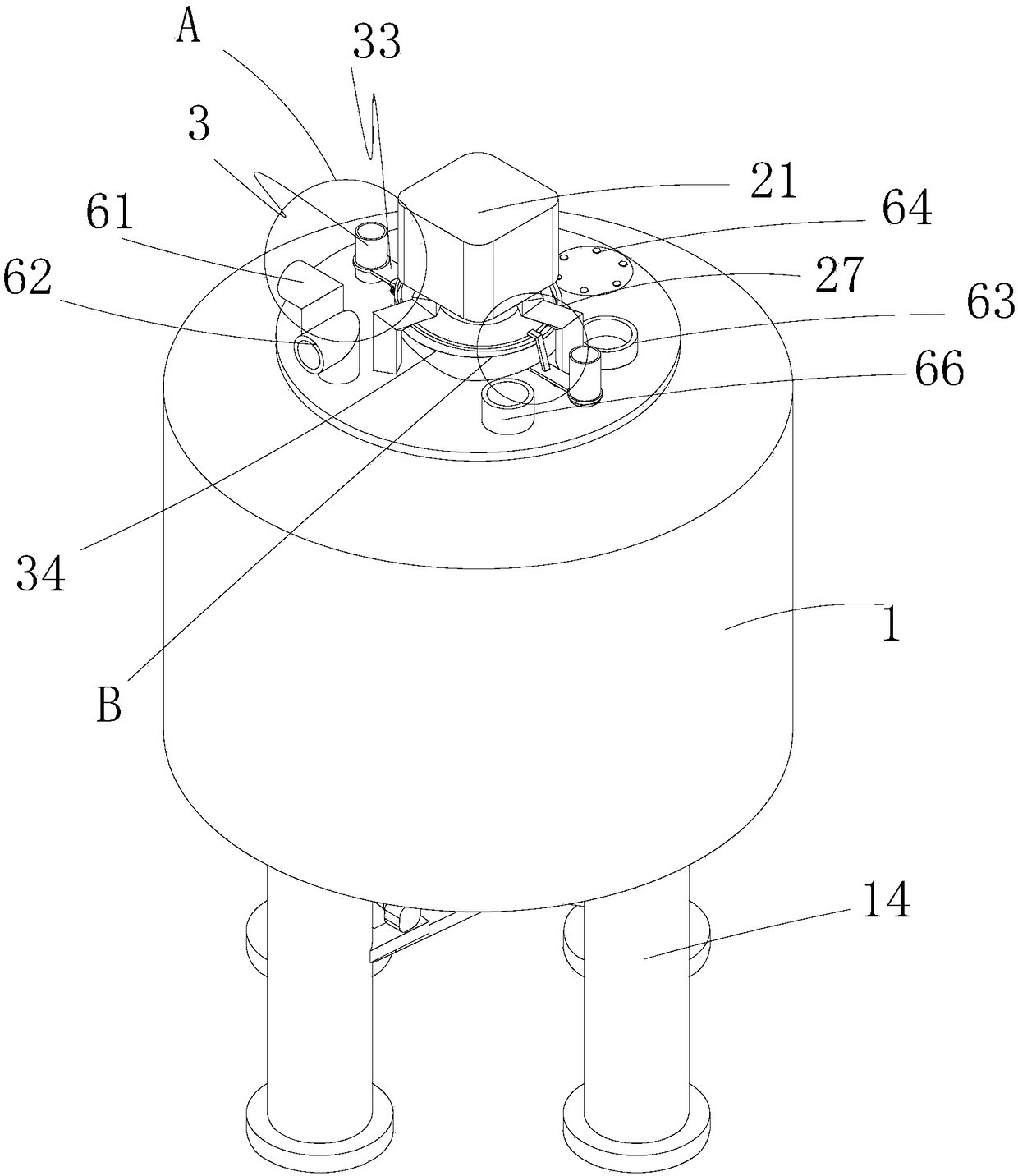

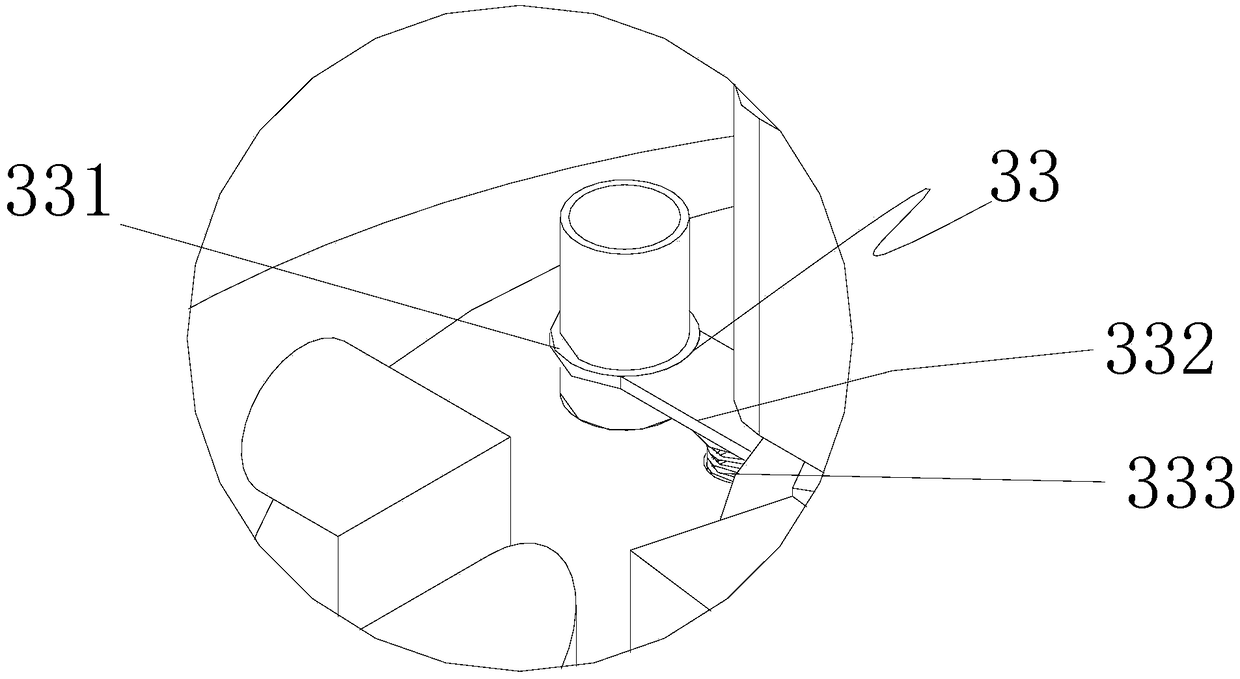

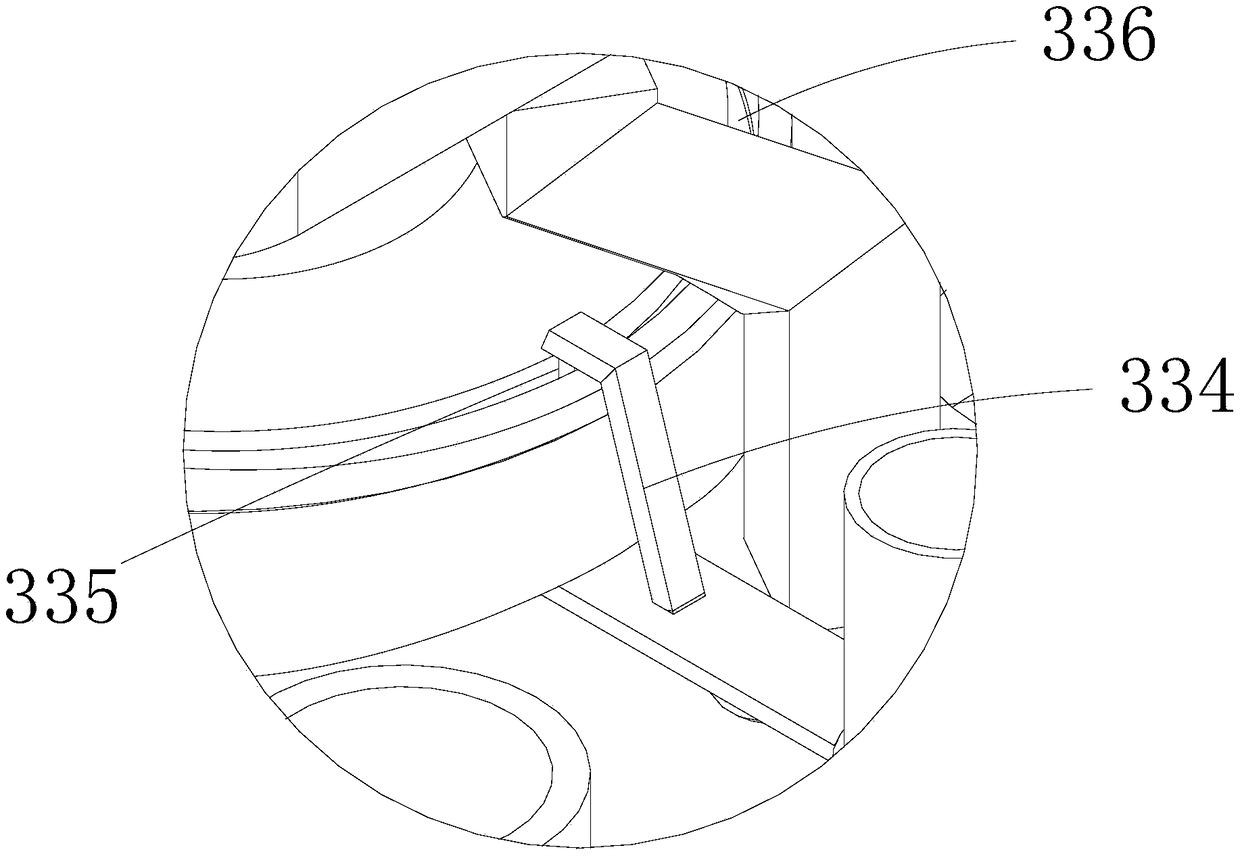

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

[0038] Preparation of Modified Hydrogenated Petroleum Resin

[0039] Add C5 cyclopentadiene to 20 parts of octane solvent, add palladium catalyst at the same time, then pass hydrogen gas at a rate of 10ml / min, react for 15h, remove the catalyst by filtration, distill the filtrate to collect fractions at 180-184°C, and obtain raw material A , stand-by; add aluminum trichloride catalyst and solvent (mixed solution of cyclohexane and xylene) in autoclave, dropwise add raw material A and butadiene, after dropwise addition, then constant temperature reaction 2h, then add Remove the catalyst with methanol, and wash with deionized water to obtain C5 hydrogenated petroleum resin; add maleic anhydride to the obtained C5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com