Full-degradable injection molding composite material and preparation method thereof

A composite material and fully degradable technology, applied in the field of biodegradable materials, can solve the problems of high product cost and high price, and achieve the effect of solving color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

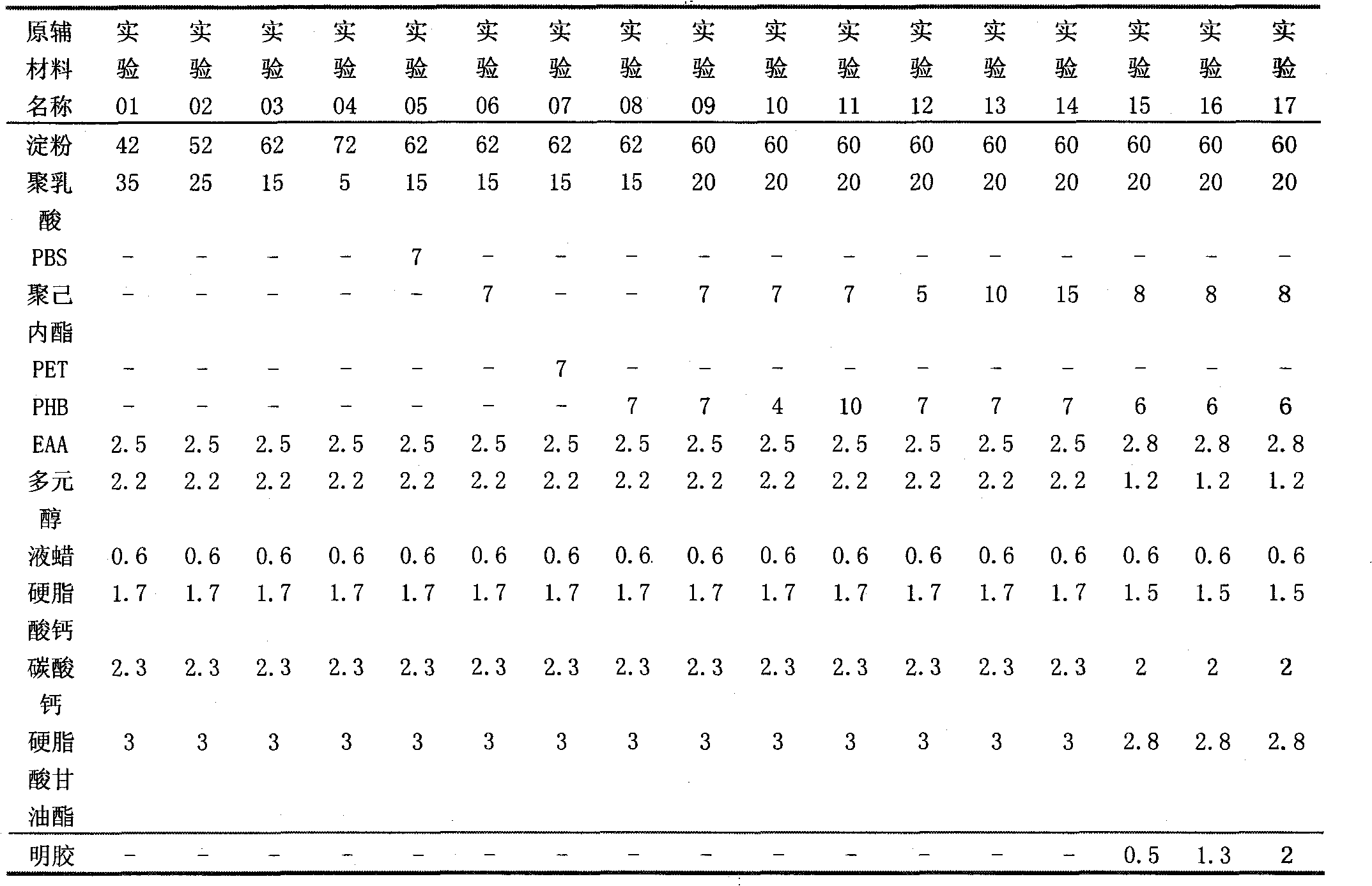

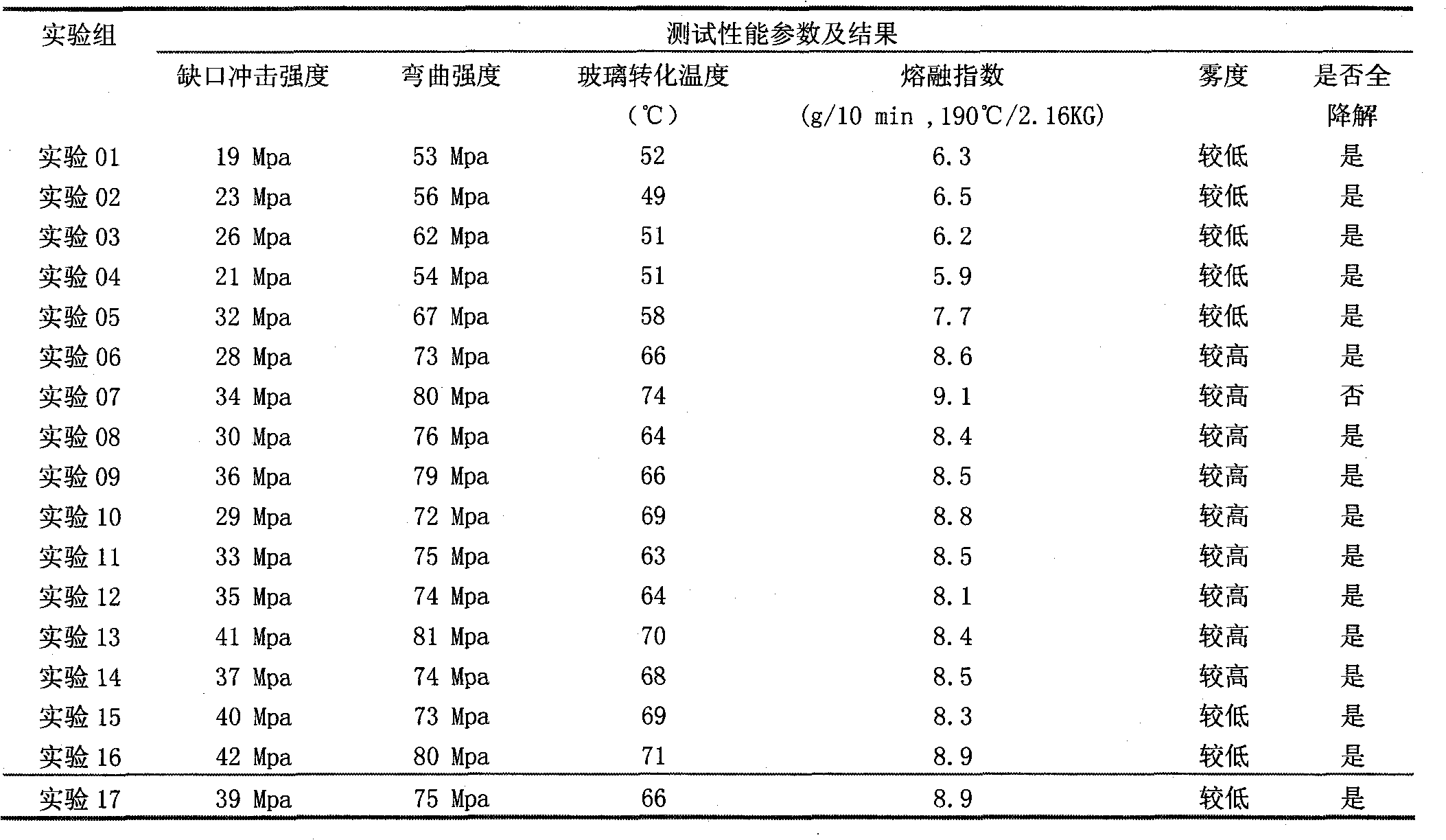

Method used

Image

Examples

Embodiment 1

[0089] Embodiment 1: Preparation process of injection molding composite material of the present invention

[0090] Modified starch 60kg Polylactic acid PLA 20kg

[0091] Polycaprolactone PCL 8kg Poly-beta-hydroxybutyrate PHB 6kg

[0092] Ethylene Acrylic Acid Copolymer EAA 2.8kg Glycerin 1.2kg

[0093] Gelatin 1.3kg Liquid wax 0.6kg

[0094] Calcium stearate 1.5kg Calcium carbonate 2kg

[0095] Glyceryl stearate 2.8kg.

[0096] Dry the above-mentioned modified starch at 55°C for 3 hours in advance, put it into a high-efficiency drum mixer, then add PCL, PHB and EAA, and mix at 65°C at 240rpm for 5 minutes; continue to add PLA and polyol components , gelatin, liquid wax, calcium stearate, calcium carbonate and glyceryl stearate, raise the temperature to 120°C, mix at a speed of 135rpm for 4 minutes, and carry out melting shear at the same time; reduce the temperature to 90°C, and keep the speed constant change, continue to stir for 3 minutes; then lower the temperature to ...

Embodiment 2

[0097] Embodiment 2: Preparation process of injection molding composite material of the present invention

[0098] Modified starch 50kg Polylactic acid PLA 18kg

[0099] Polycaprolactone PCL10kg Poly-β-hydroxybutyrate PHB 7kg

[0100] Ethylene Acrylic Acid Copolymer EAA 2.5kg Glycerin 4kg

[0101] Gelatin 1.5kg Liquid wax 0.6kg

[0102] Calcium stearate 1.3kg Calcium carbonate 2kg

[0103] Glyceryl stearate 2.5kg;

[0104] Dry the above-mentioned modified starch at 55°C for 3 hours in advance, put it into a high-efficiency drum mixer, then add PCL, PHB and EAA, and mix at 65°C at 260rpm for 5 minutes; continue to add PLA and polyol components , gelatin, liquid wax, calcium stearate, calcium carbonate and glyceryl stearate, raise the temperature to 125°C, mix at a speed of 135rpm for 4 minutes, and carry out melting shear at the same time; reduce the temperature to 90°C, and keep the speed constant change, continue to stir for 4 minutes; then lower the temperature to room ...

Embodiment 3

[0105] Embodiment 3: Preparation process of injection molding composite material of the present invention

[0106] Modified starch 70kg Polylactic acid PLA 8kg

[0107] Polycaprolactone PCL 6kg Poly-beta-hydroxybutyrate PHB 9kg

[0108] Ethylene Acrylic Acid Copolymer EAA 3.5kg Propylene Glycol 2kg

[0109] Gelatin 0.8kg Liquid wax 0.8kg

[0110] Calcium stearate 1.8kg Calcium carbonate 1.5kg

[0111] Glyceryl stearate 1.5kg.

[0112] Dry the above-mentioned modified starch at 55°C for 3 hours in advance, put it into a high-efficiency drum mixer, then add PCL, PHB and EAA, and mix at 65°C for 4 minutes at 240rpm; continue to add PLA and polyol components , gelatin, liquid wax, calcium stearate, calcium carbonate and glyceryl stearate, raise the temperature to 115°C, mix at a speed of 130rpm for 4 minutes, and carry out melting shear at the same time; reduce the temperature to 90°C, and keep the speed constant change, continue to stir for 3 minutes; then lower the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com