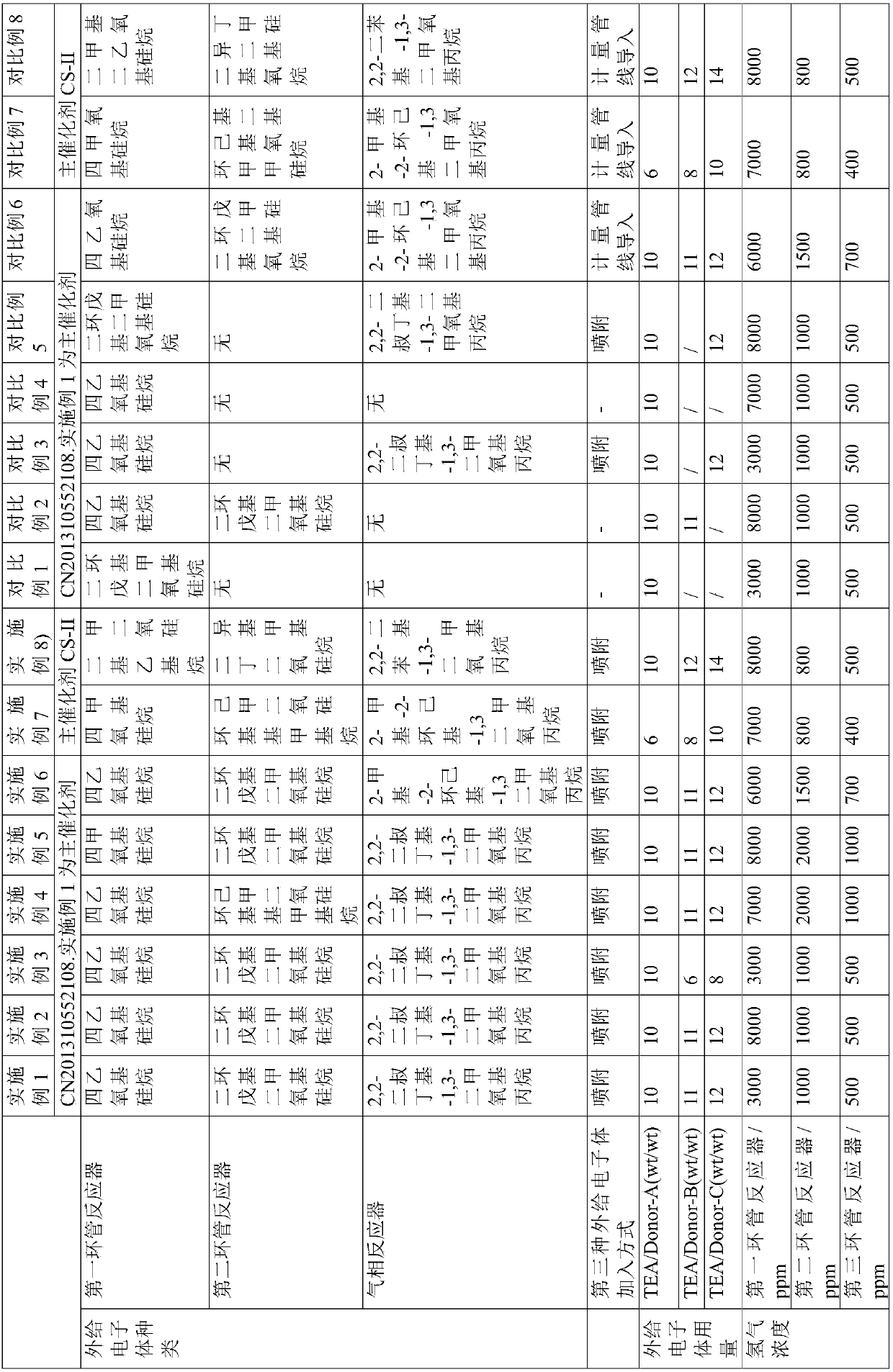

Patents

Literature

406results about How to "Improve melt index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

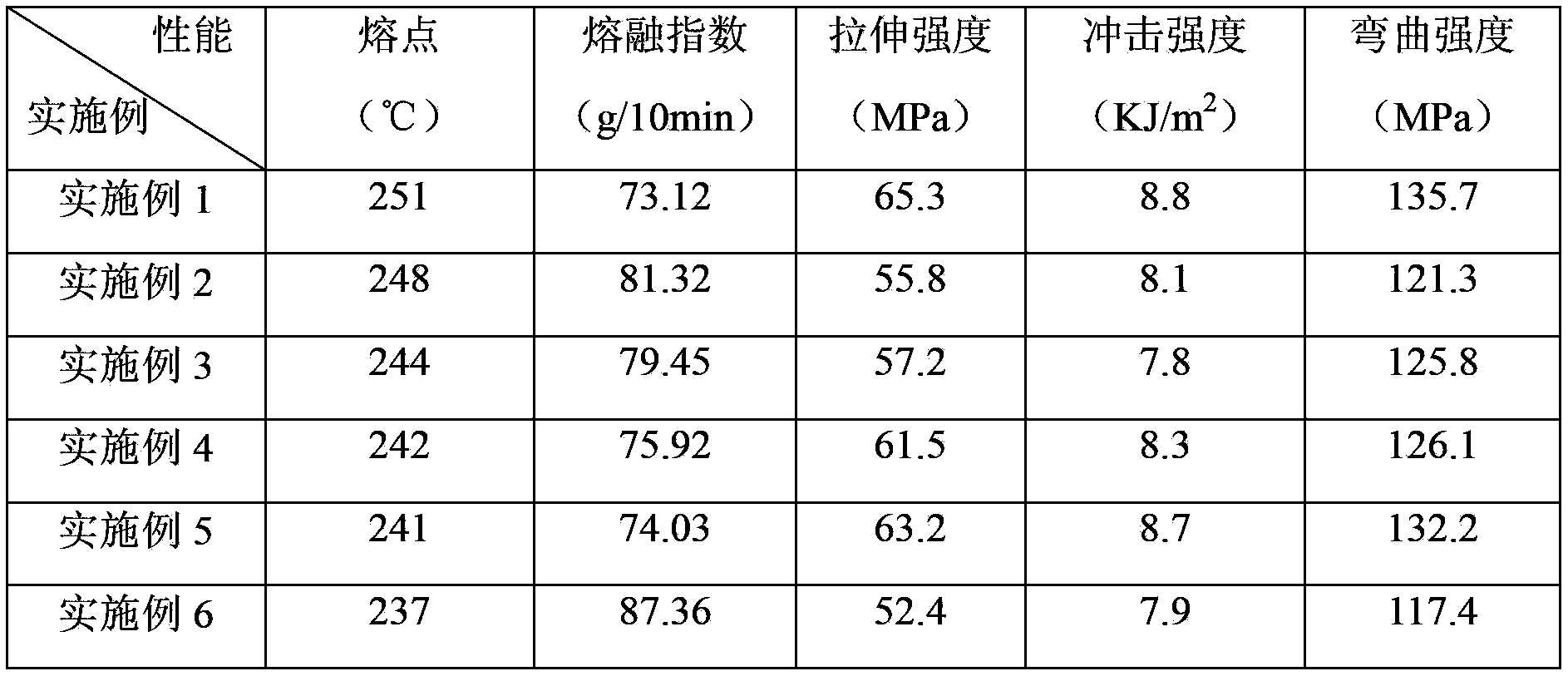

Impact-resistant high-melt-index high-rigidity polypropylene composite material

InactiveCN104292654AImprove melt indexImprove impact resistancePolypropylene compositesPolymer science

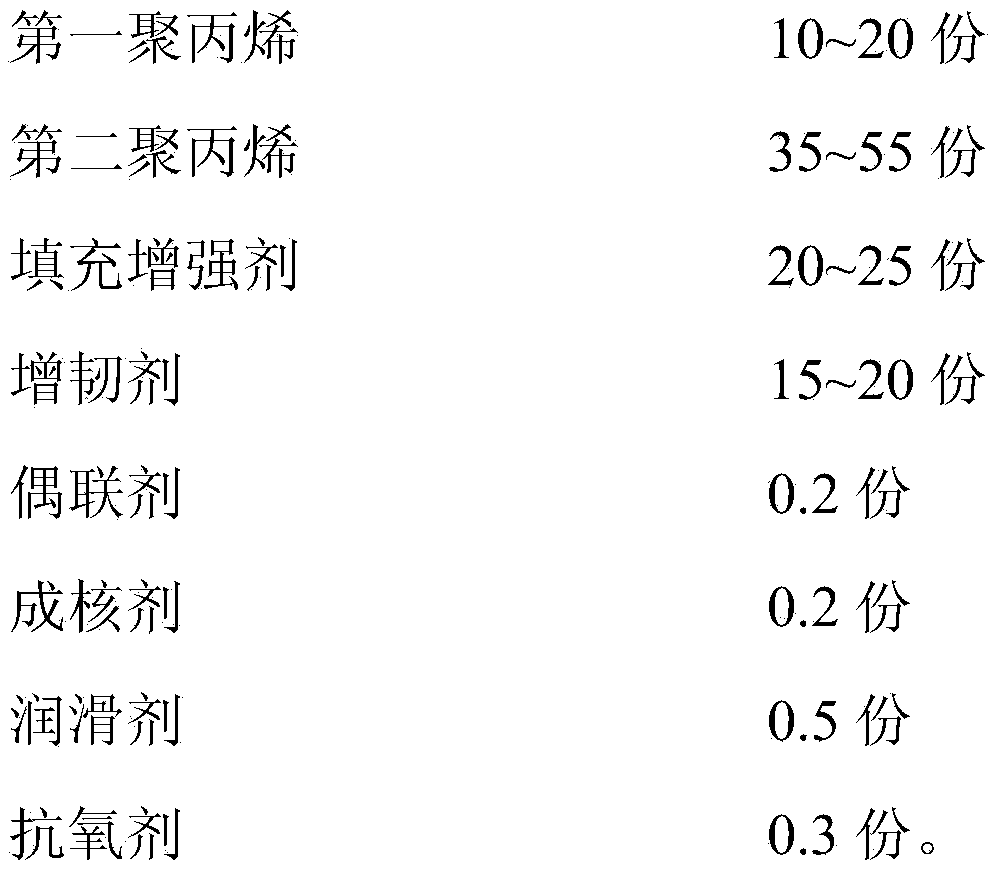

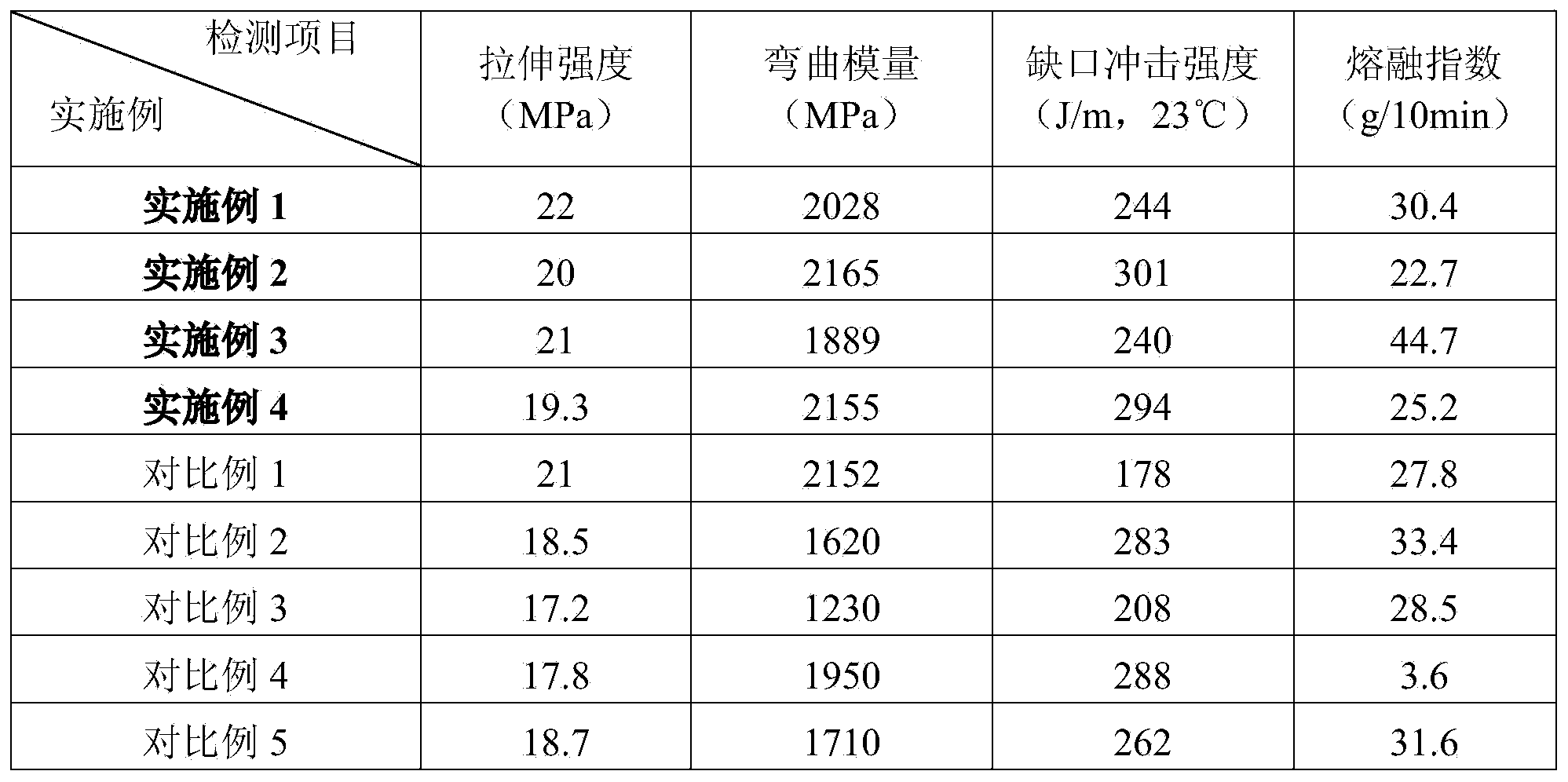

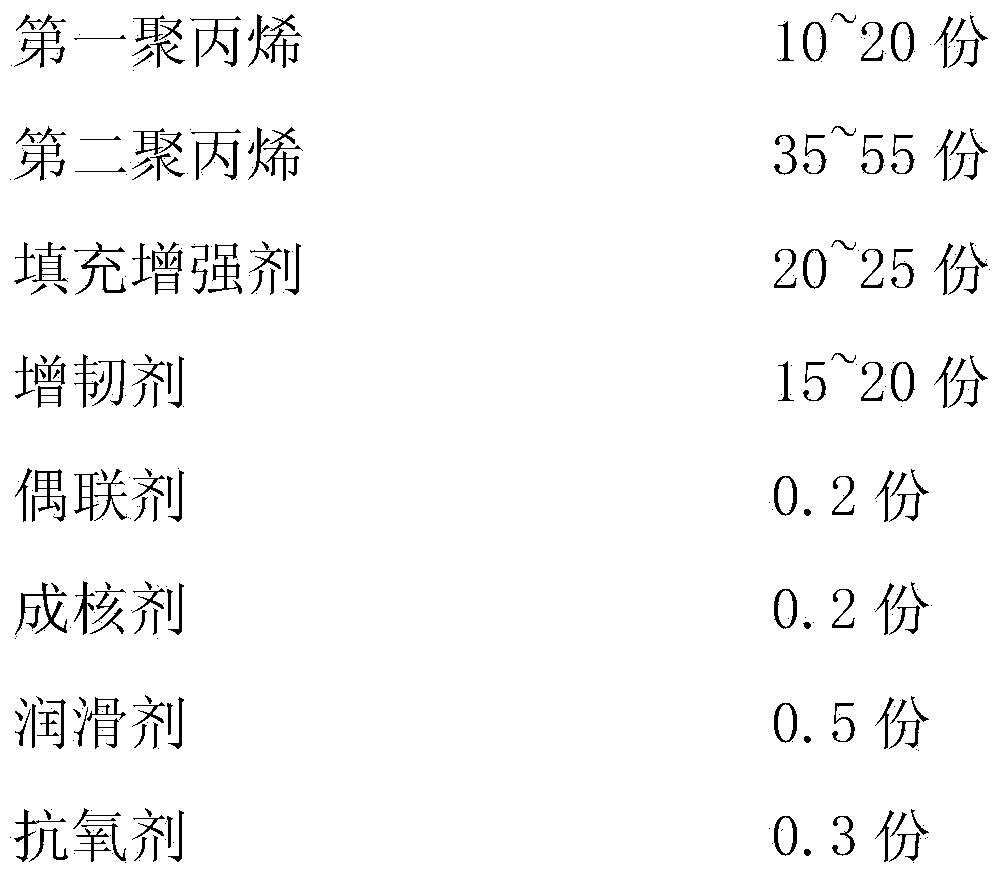

The invention discloses an impact-resistant high-melt-index high-rigidity polypropylene composite material. The impact-resistant high-melt-index high-rigidity polypropylene composite material is prepared from the following components in parts by weight: 10-20 parts of first polypropylene, 35-55 parts of second polypropylene, 20-25 parts of a filling and reinforcing agent, 15-20 parts of a toughening agent, 0.2 part of a coupling agent, 0.2 part of a nucleating agent, 0.5 part of a lubricating agent and 0.3 part of antioxidant, wherein the first polypropylene is medium-melt-index polypropylene, and the melt index of the first polypropylene (230 DEG C, 2.16Kg) is 25-35g per 10 minutes; the second polypropylene is high-melt-index co-polyproplene, and the melt index of the second polypropylene (230 DEG C, 2.16Kg) is 50-110g / min. Compared with the polypropylene composite material prepared by adopting the traditional technique, the impact-resistant high-melt-index high-rigidity polypropylene composite material has the characteristics of excellent impact resistance, high fluidity and high rigidity, and the three characteristics of impact resistance, high melt index and high rigidity are realized at the same time.

Owner:SICHUAN GLARY ASIA PLASTIC TECH

Magnesium halide adduct, preparation and use thereof

ActiveCN101486722BImprove melt indexFine powder (broken) reductionMagnesium organic compoundsArylBromine

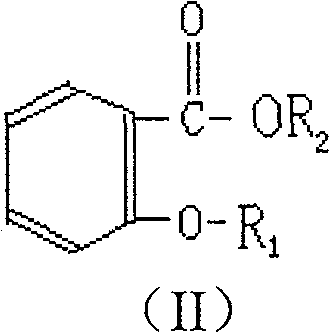

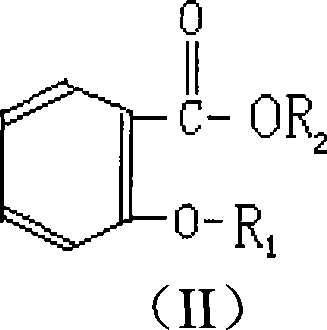

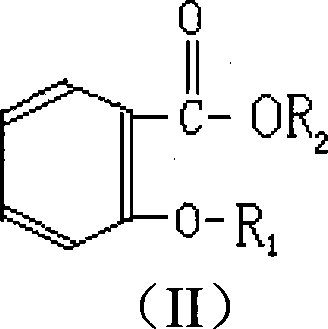

The invention provides a magnesium halide addition compound shown as general formula MgX2-mROH-nE-pH2O, wherein, X represents chlorine or bromine, R represents C1-C12 alkyl, C3-C10 cycloalkyl or C6-C10 aryl; E represents o-alkoxybenzoic ether compound shown in the general formula (II); m is 1 to 5; n is 0.005 to 1.0; and p is 0 to 0.8.

Owner:CHINA PETROLEUM & CHEM CORP +1

Use of stannous benzoate as catalyst

ActiveCN1806919AReduce dosageLow cracking temperatureOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidPolymer science

The invention provides the usage of using the benzoic acid stannous as catalyst. The invention solves the problem that polymerization rate of current catalyst in lactic acid and glycolic acid is slow. The benzoic acid stannous is the catalyst used for preparing low-molecular polymer lactic acid with lactic acid dewatering; benzoic acid stannous is the catalyst used for preparing lactide with low-molecular polymer lactic acid cracking; benzoic acid stannous is the catalyst used for preparing polylactic acid with lactide polymerizing; benzoic acid stannous is the catalyst used for preparing low-molecular polymer glycolic acid with glycolic acid dewatering; benzoic acid stannous is the catalyst used for preparing glycolide with low-molecular polymer glycolic acid cracking; benzoic acid stannous is the catalyst used for preparing poly-glycollide with glycolide polymerizing. The benzoic acid stannous is the catalyst used for polymerizing glycolide, lactide and epsilon-caprolactone. Using the benzoic acid stannous is low content, high productivity, high product purity, low temperature and good repeatability.

Owner:ZHEJIANG HISUN BIOMATERIALS +1

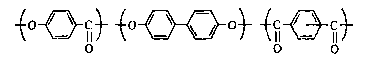

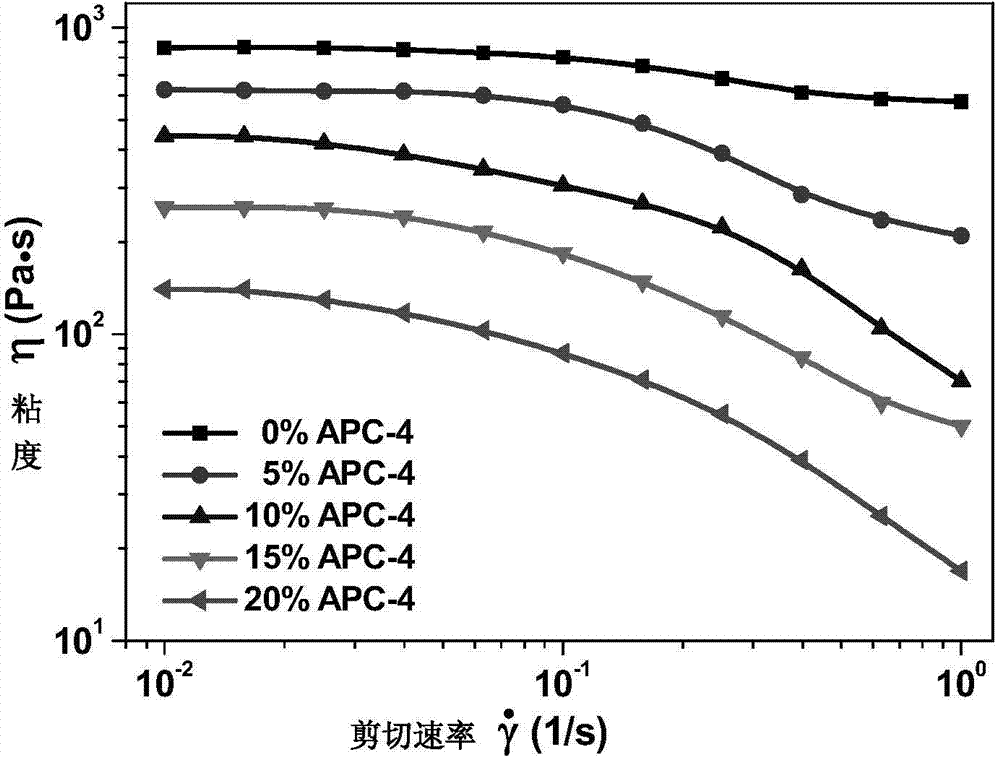

Use of liquid crystal polymer as polymer high-temperature lubricant

The invention provides a use of a liquid crystal polymer as a polymer high-temperature lubricant. The liquid crystal polymer is a thermotropic liquid crystal polymer, namely, having the fluidity of liquid and the anisotropy of the crystal at a certain temperature. The liquid crystal polymer is added to crystalline high-melting-point polymers or amorphous high-glass-transition-temperature polymers to obviously enhance the melt index or processing fluidity of the polymer and further increase the toughening function. Compared with the addition of some conventional lubricants (e.g. silicone, dimethyl silicone oil and the like), the overall performance is improved significantly.

Owner:HEFEI GENIUS NEW MATERIALS

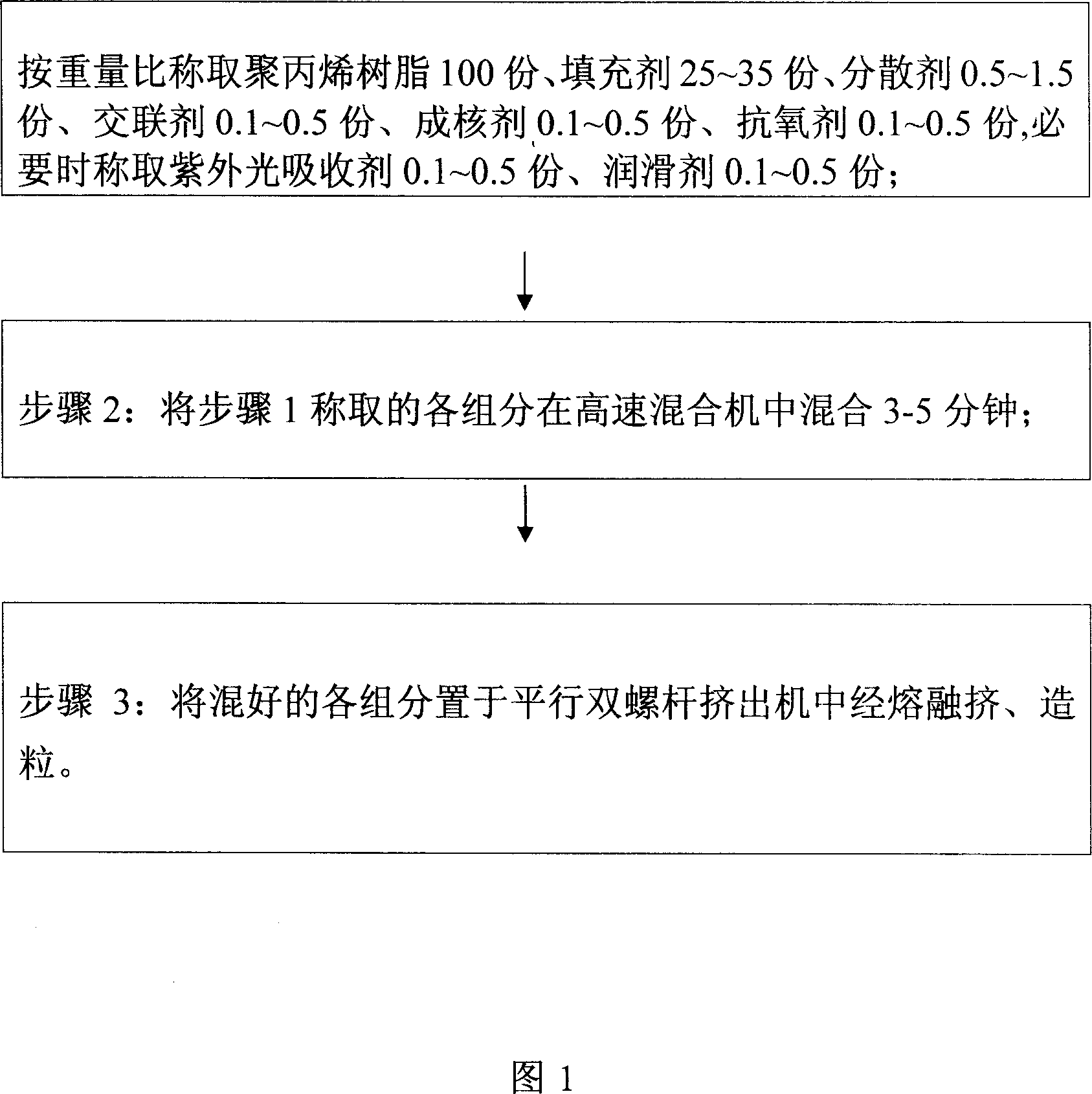

High glaze polypropylene material and preparation method thereof

A high-lustre polypropylene material and its production are disclosed. The material consists of polypropylene resin 100 proportion, filler nanometer calcium carbonate 25-35 proportion, dispersant 0.5-1.5 proportion, cross-linking agent diisopropylzene 0.1-0.5 proportion, beta-crystal nucleation agent 0.1-0.5 proportion, and antioxidant 0.1-0.5 proportion. It costs low, has better toughness and surface brightness on surface.

Owner:SHENZHEN KEJU NEW MATERIAL

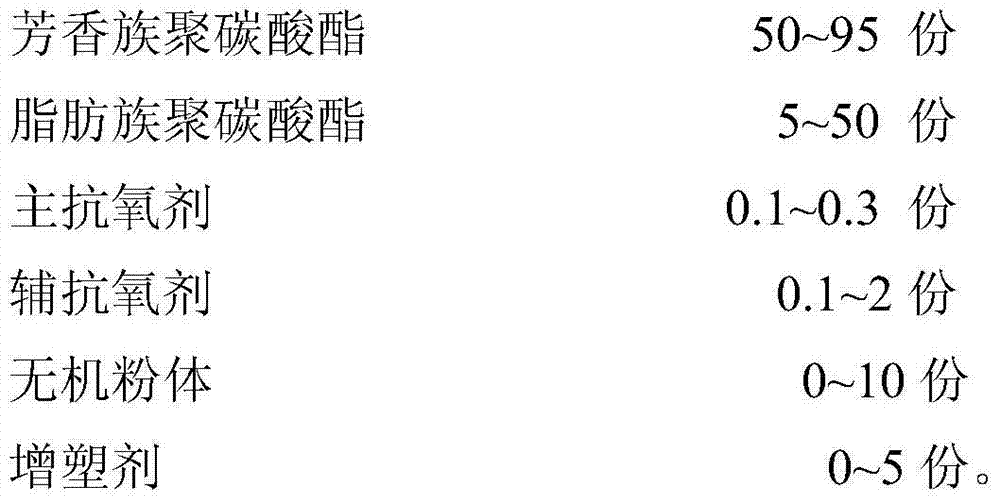

Polycarbonate composite material and preparation method thereof

The invention discloses a polycarbonate composite material and a preparation method thereof. The polycarbonate composite material is composed of the following components in parts by weight: 50-95 parts of aromatic polycarbonate, 5-50 parts of fatty group polycarbonate, 0.1-0.3 part of main antioxidant, 0.1-2 parts of auxiliary antioxidant, 0-10 parts of inorganic powder and 0-5 parts of plasticizer. The preparation method comprises the following steps: 1) respectively drying the aromatic polycarbonate and fatty group polycarbonate at 50-120 DEG C for 4-30 hours; 2) mixing the components; and 3) carrying out melt extrusion on the mixture in the step (2) through a double screw extruder, and granulating. Under the condition of not adding any compatilizer or elastomer, the polycarbonate composite material has the advantages of high notch impact strength and favorable processing flowability, and is partially biodegradable. The fatty group polycarbonate has flexible and adjustable chemical structure and molecular weight, and can be prepared into a series of polycarbonate composite materials according to practical application demands.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Production method of polypropylene cooling masterbatch

InactiveCN101798422AFast degradationReduce volatilityMonocomponent polyolefin artificial filamentMasterbatchPolymer science

The invention discloses a production method of polypropylene cooling masterbatch, including the following steps: (1) mixing: the following components by parts by weight are mixed for 10-20 minutes: 50-90 parts of polypropylene resin, 0.5-9.5 parts of dispersing agent, 0.1-0.6 part of surface modifier, 0.1-2.7 parts of lubricant and 0.2-0.8 part of liquidity regulator, and then the following components by parts by weight are sequentially added: 0.1-0.9 part of light stabilizer, 0.1-1.6 parts of antioxidant and 0.2-7 parts of molecular weight regulator, and mixing is carried out for 5-15 minutes; (2) pelletizing: the mixed material is subject to melt extrusion at 130-230 DEG C and then grain-sized dicing is carried out. The invention adopts compound peroxide as molecular weight regulator and adopts compound antioxidant, compound dispersing agent, compound light stabilizer and compound lubricant, and the produced polypropylene cooling masterbatch has the advantages of high initiator content, good dispersity and obvious cooling effect and modification effect.

Owner:郭学阳

Chemical degradation method of polypropylene

A chemical degradation method of polypropylene comprises the degradation by adding 0.01 weight percent to 0.2 weight percent of organic peroxide and 0.1 weight percent to 1.0 weight percent of nucleating agent into the polypropylene. The method can effectively improve the efficiency of degradation, increase the melt index of degraded polypropylene, improve the molecular weight distribution of polypropylene, and maintain the good mechanical performances at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

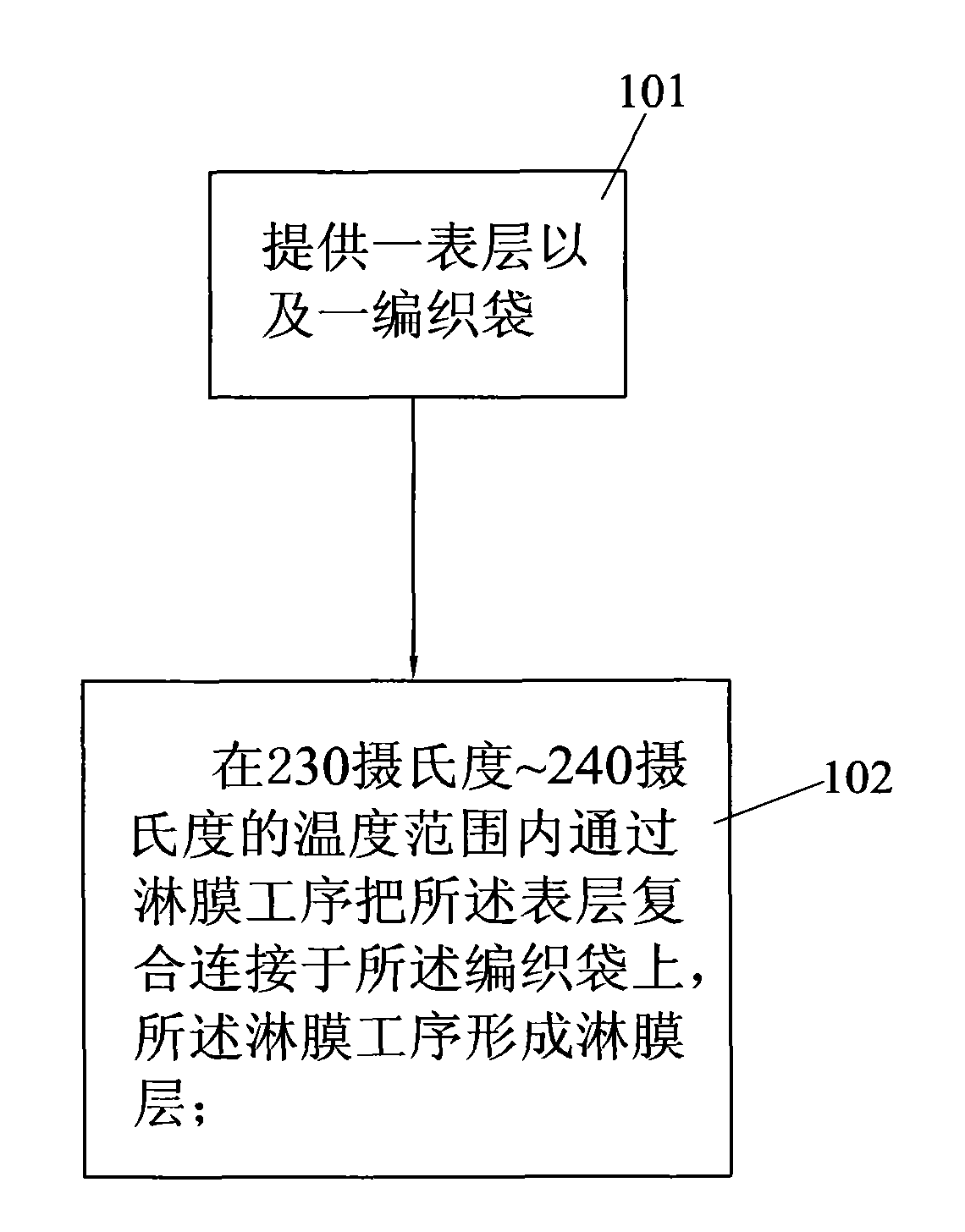

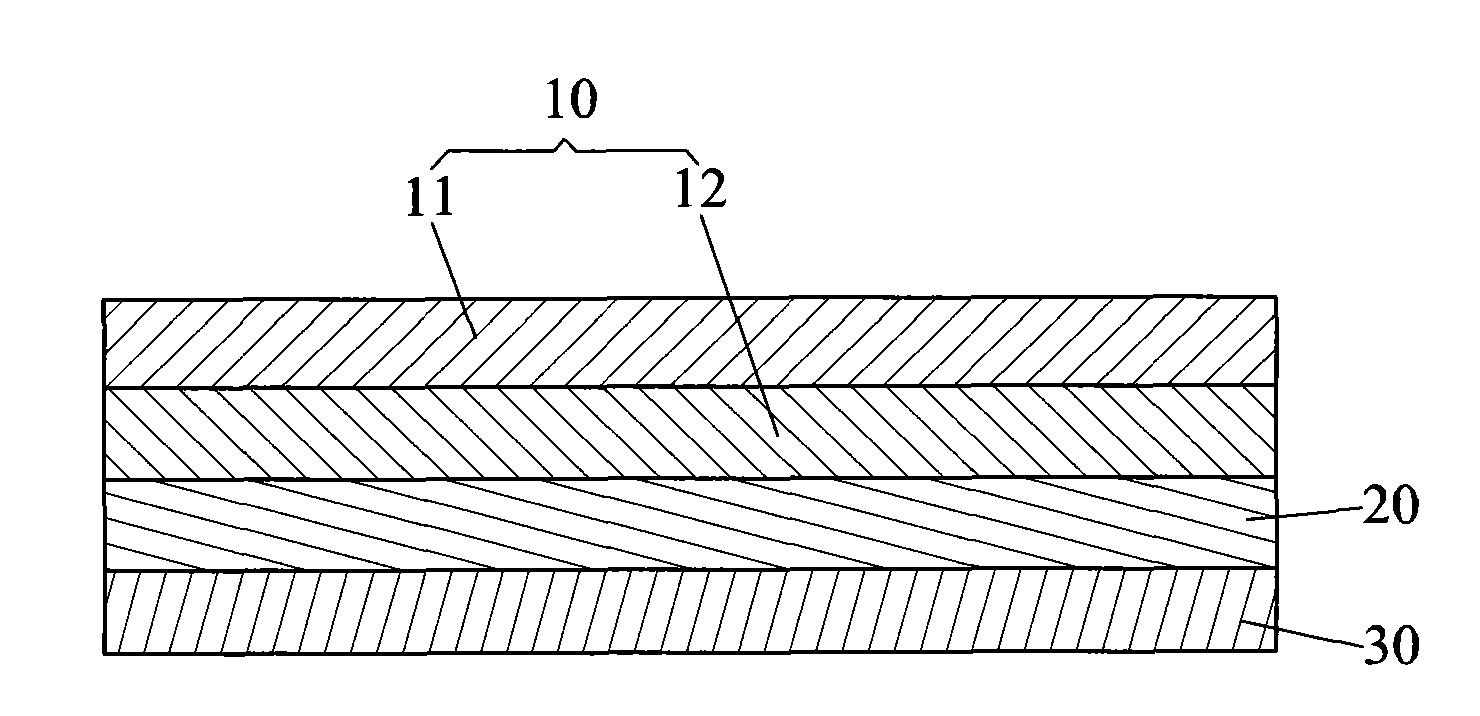

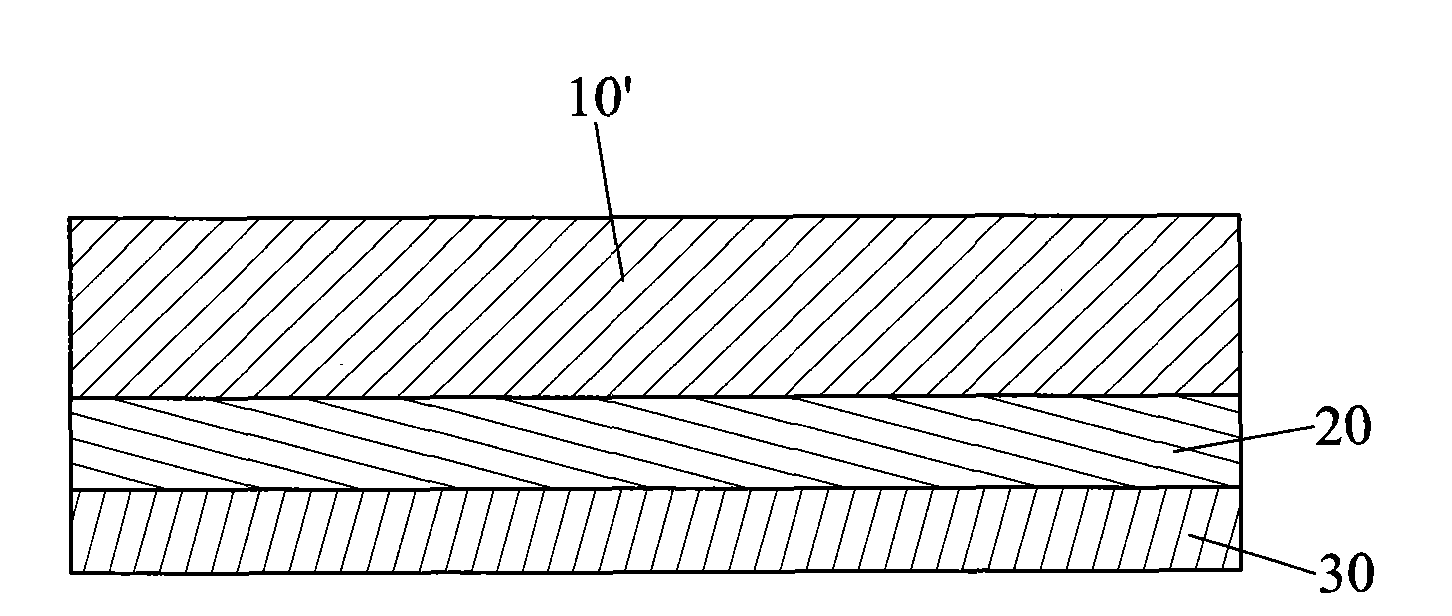

Manufacturing method of composite package

InactiveCN101954756AImproves breakage resistanceImprove melt indexContainer making machinerySurface layerPolymer science

The invention discloses a manufacturing method of composite packages, which comprises the following steps of providing a surface layer and a woven bag; compounding and connecting the surface layer to the woven bag through a filming procedure in the range of 230 DEG C to 240 DEG C, wherein filming materials used in the filming procedure comprises modified polypropylene and special polyethylene for filming, and the polypropylene contains a molecular weight regulator and other assistants; thus, the melt index of the filming materials is improved so as to improve the fluidity, promote to film at lower temperature, flatten the surfaces of the packages and improve the anti-break capability of the packages.

Owner:东莞市长盈塑料编织包装有限公司

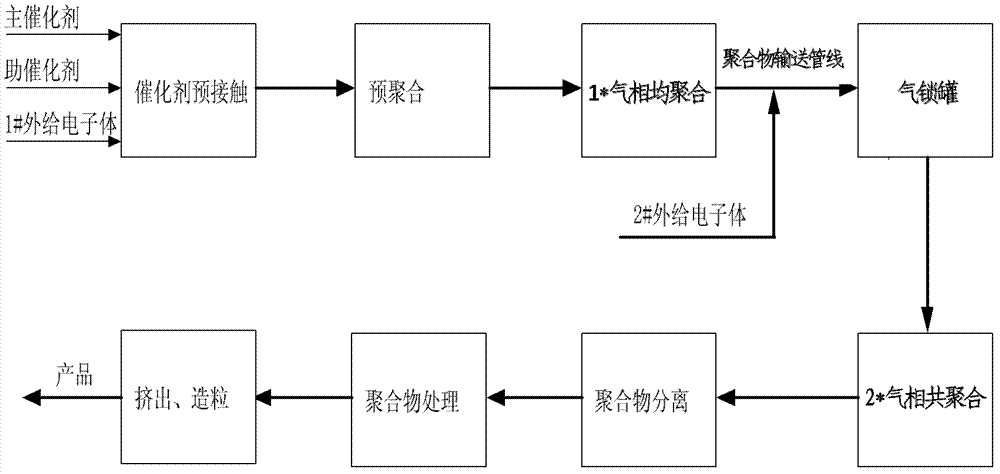

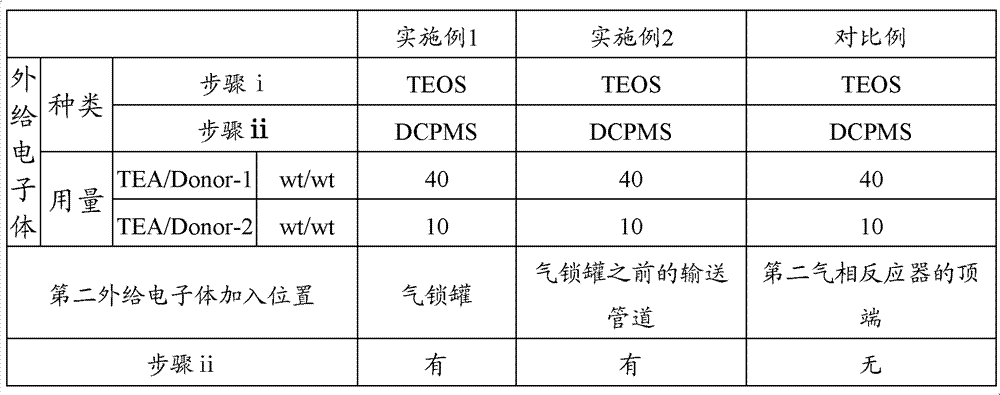

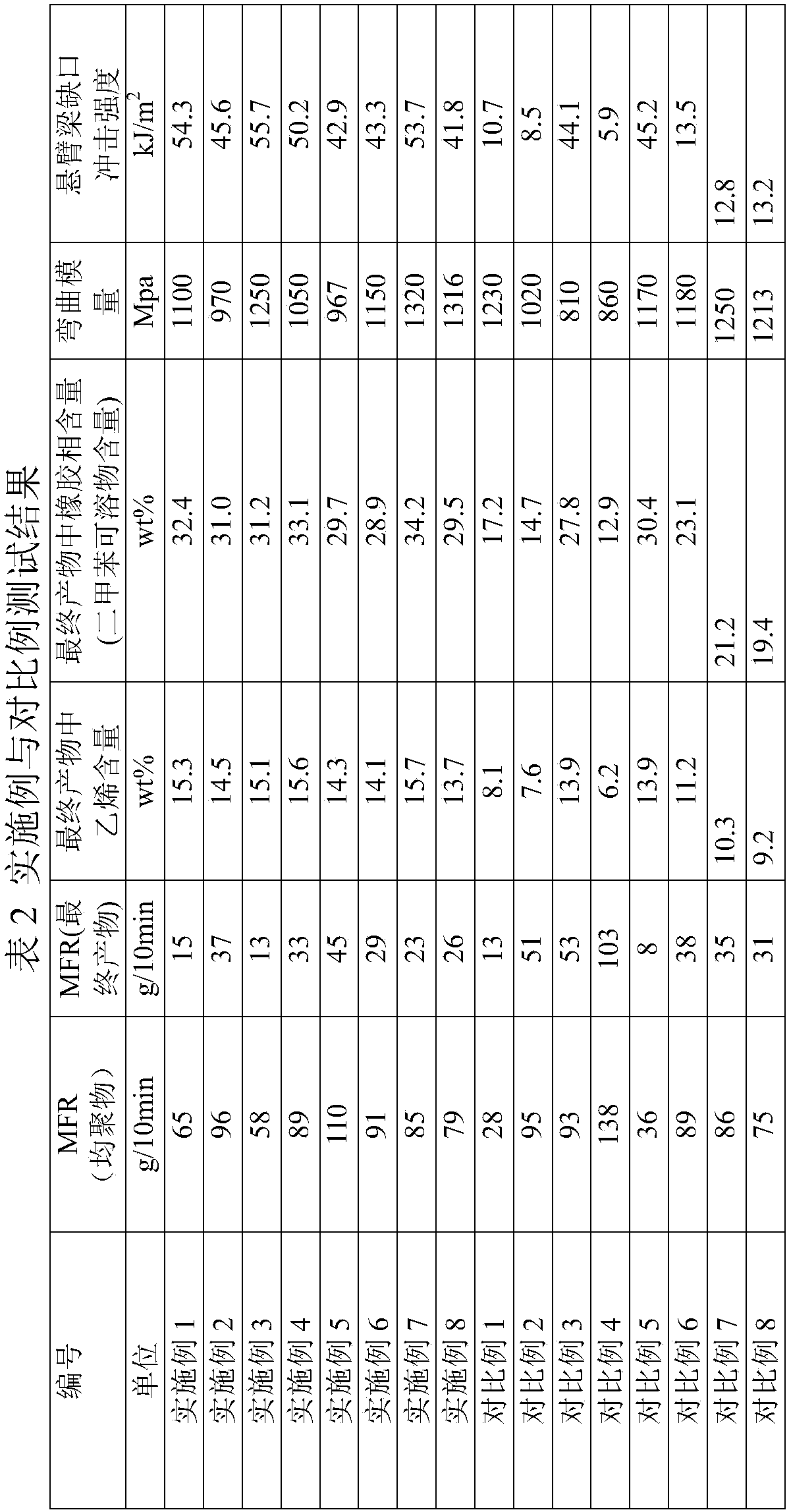

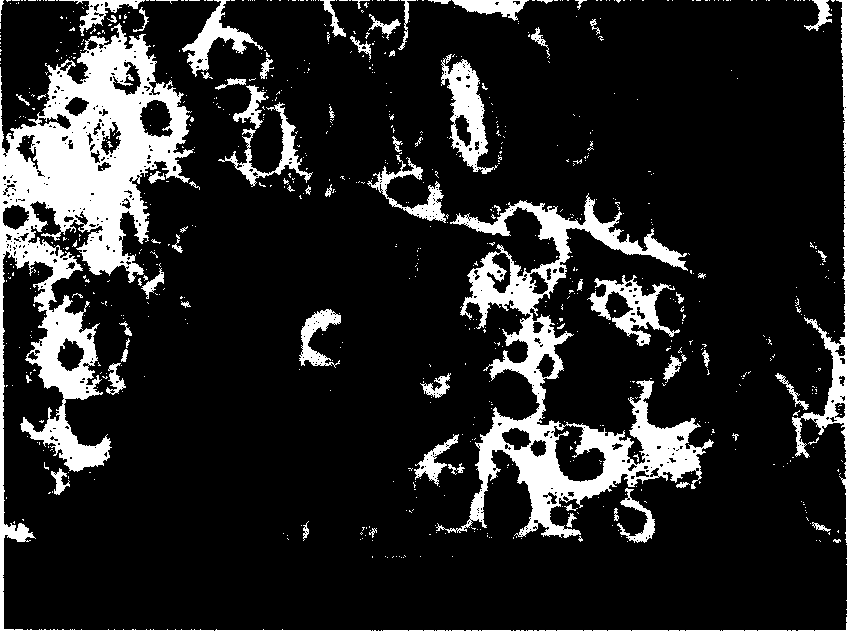

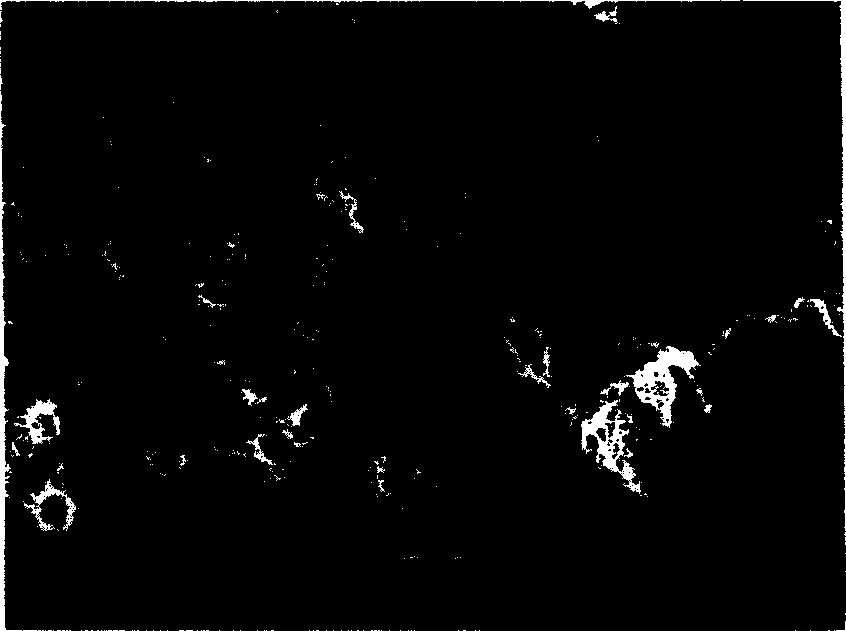

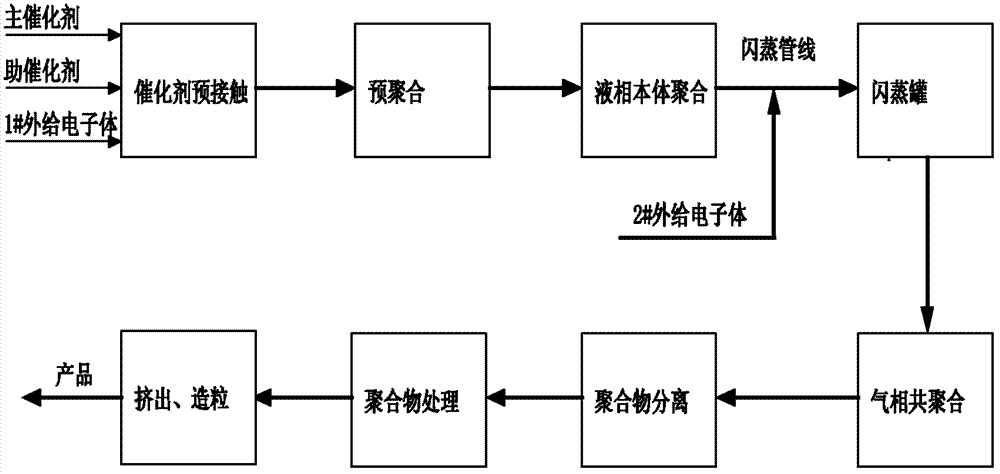

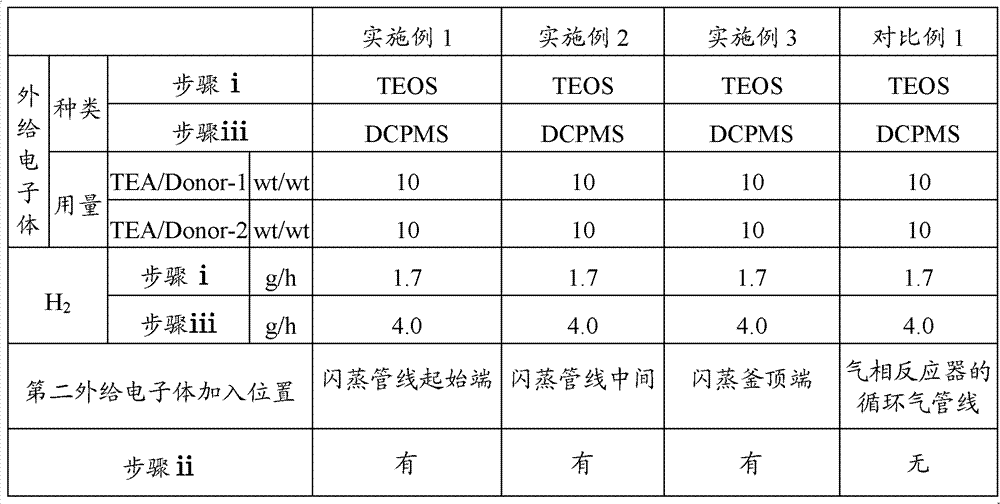

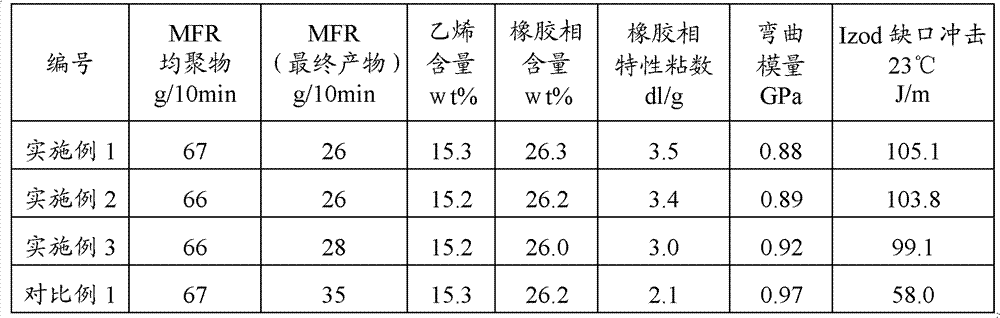

Preparation method and equipment of high-performance impact polypropylene

The invention discloses a method and equipment for preparing impact polypropylene. The method comprises the following steps of carrying out polymerization reaction in the presence of a Ziegler-Natta catalyst, and carrying out gas-phase polymerization on propylene or propylene and alpha-olefin in the presence of a catalyst containing first external electron donors to obtain a polymer A; adding a second external electron donor to be premixed with the polymer A; and carrying out gas-phase polymerization on propylene or propylene and alpha-olefin in the presence of a material after premixing to obtain a polymer B. By adopting the method provided by the invention, a polypropylene product comprising a continuous phase and a rubber phase is finally obtained by adopting the two kinds of external electron donors with different hydrogen modulation sensitivity and controlling the addition mode of the second external electron donor with weak hydrogen modulation sensitivity; and the product has higher melt index and higher impact strength and has better impact resistance while keeping higher melt fluidity.

Owner:CHINA PETROLEUM & CHEM CORP +1

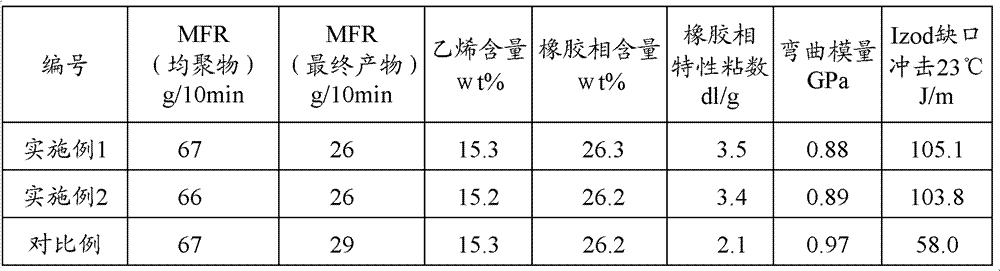

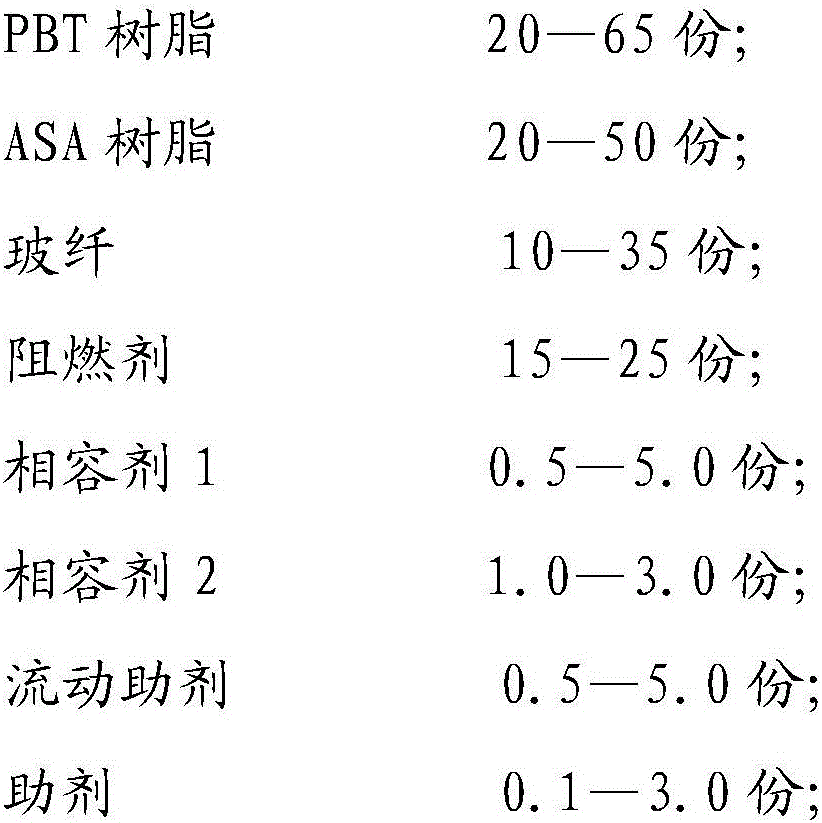

PBT/ASA alloy material and preparing method thereof

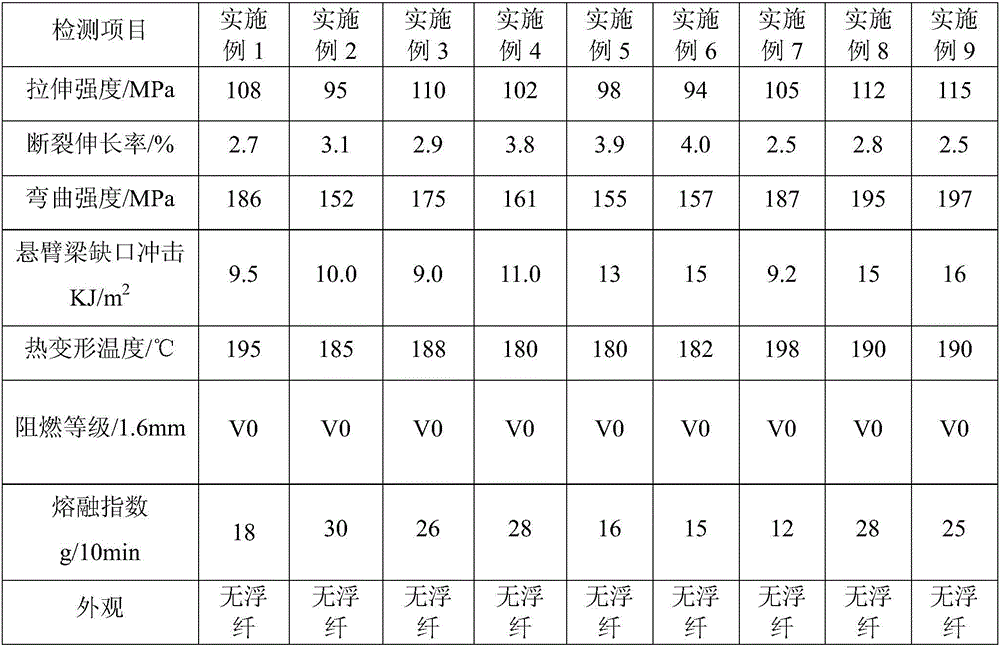

ActiveCN106589844AImprove flame retardant performanceImprove impact resistanceGlass fiberPolystyrene

The invention discloses a PBT / ASA alloy material and a preparing method thereof. The alloy material is prepared from, by weight, 20-65 parts of PBT resin, 20-50 parts of ASA resin, 10-35 parts of glass fiber, 15-25 parts of fire retardant, 0.5-5.0 parts of first compatilizer, 1.0-3.0 parts of second compatilizer, 0.5-5.0 parts of a flow promoting agent and 0.1-3.0 parts of auxiliary, wherein the fire retardant is compounded by main fire retardant brominated polystyrene and fire retardant synergist sodium antimonite according to a mass ratio of (10-20):(4-5), the first compatilizer is a styrene copolymer, and the second compatilizer is bisphenol A type epoxy resin with an epoxy value of 0.5-1.5. The prepared PBT / ASA alloy material has the functions of both flame retardancy and resistance to shocks at the same time, and the material is not prone to warpage and good in comprehensive mechanical performance.

Owner:GUANGZHOU KEYUAN INNOVATIVE MATERIALS

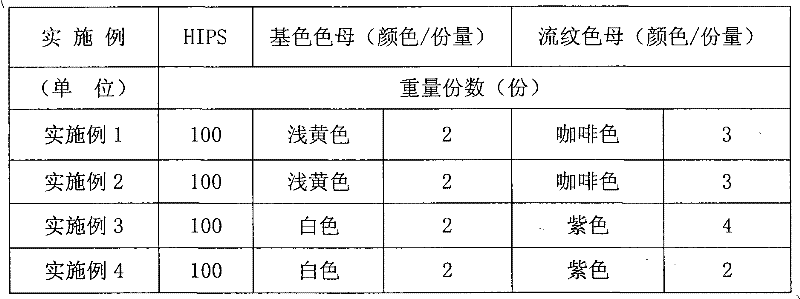

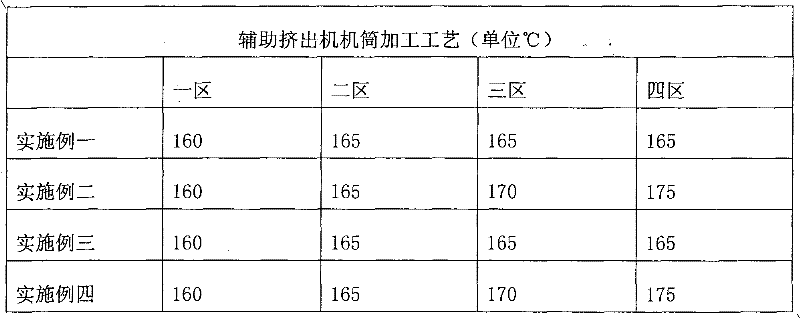

A polystyrene imitation wood profile and its preparation method

The invention relates to a preparation method of polystyrene micro-foaming co-extrusion imitation wood material. It is characterized in that: prepare the surface layer material and the core layer material, put the surface layer material and the core layer material into the auxiliary extruder and the main extruder respectively, the two extruders are co-extruded into a mold, and are fused in the mold One body, in which the surface layer material is coated on the surface of the core layer material. The base material of the surface material is high-impact polystyrene and it contains rhyolite masterbatch that is compatible with high-impact polystyrene but has different fluidity and dispersion. The core material is polystyrene micro-foaming material. The weight ratio of the core layer material to the surface layer material is 85-95%: 5-15%. The present invention can produce a variety of products with different effects according to the difference in color and weight of the primary color masterbatch and flowline masterbatch added to the surface material, the difference in the type of flowline masterbatch, and the difference in processing technology. Such as various imitation wood grain products, products of various designs and colors, etc.

Owner:SHANGHAI INTCO INDUSTRIES CO LTD +1

Preparation method of high impact resistance polypropylene

The invention provides a polymerization process of high impact resistance polypropylene. The polymerization process specifically comprises the steps that (1) a first external electron donor with excellent hydrogen sensitivity is added into a first-stage loop propylene homopolymerization reactor, so that a propylene homopolymer with a high melt flow rate is obtained at lower hydrogen concentration;(2) a second external electron donor which contributes to the improvement of the isotacticity of polypropylene is added into a second-stage loop reactor, so that high-crystallized polypropylene is prepared in the stage to enable a material to obtain excellent rigidity; and (3) a third external electron donor is sprayed on the surface of the polymer generated in the second stage, so that the thirdexternal electron donor enters a gas phase reactor of the third stage along with the polymer, so that an impact resistant propylene polymer with uniform sequence distribution and high content is obtained in the stage.

Owner:PETROCHINA CO LTD +1

Catalyst active component, its preparation and catalyst containing it

Owner:BEIJING JINDINGKE CHEM TECH

Formula system for low-shrinkage-rate stainless steel powder injection molding feedstock and formula system for molding agent thereof

InactiveCN106424704ASmall expansion coefficientReduce lubricationTransportation and packagingMetal-working apparatusShrinkage rateStearic acid

The invention discloses a formula system for low-shrinkage-rate stainless steel powder injection molding feedstock and a formula system for a molding agent thereof. The formula system for the molding agent of the low-shrinkage-rate stainless steel powder injection molding feedstock comprises stearic acid, an antioxidant, paraffin, high-density polyethylene, polyethylene-acetate, high molecular polymer wax and polyformaldehyde, wherein mass percentage of polyformaldehyde is not greater than 90%. The invention further discloses a formula system for low-shrinkage-rate stainless steel powder injection molding feedstock comprises stainless steel powder and the formula system of the molding agent. The formula system for low-shrinkage-rate stainless steel powder injection molding feedstock and the formula system for the molding agent thereof disclosed by the invention realize relatively high powder loading amount and relatively high shrinkage rate, have relatively high melt index as well as excellent blank strength and molding property, and are especially suitable for manufacturing and molding large-specification thin-wall products.

Owner:DONGGUAN HUAJING POWDER METALLURGY +1

High-strength and high-tenacity polypropylene composite materials and preparation method thereof

The invention discloses high-strength and high-tenacity polypropylene composite materials. The high-strength and high-tenacity polypropylene composite materials solve the problems that existing polypropylene is poor in tenacity and poor in strength. The high-strength and high-tenacity polypropylene composite materials are formed by the following components, by weight, 35-75% of polypropylene, 10-40% of calcium carbonate, 8-25% of calcium sulfate whisker masterbatch, 0.1-2% of coupling agents, 2-8% of compatilizer, 0.3-4% of lubricating agents and 0.2-0.8% of antioxygen. The invention further provides a preparation method of the high-strength and high-tenacity polypropylene composite materials. According to the preparation method of the high-strength and high-tenacity polypropylene composite materials, through the mode that calcium sulfate whiskers are made into masterbatch, the calcium sulfate whisker masterbatch is added to plastics to carry out co-extrusion mixing with the plastics and the like, thus, compared with powdery whiskers, material preparation can be evener and controllable, the problem that material preparation of the calcium sulfate whiskers is difficult is solved, meanwhile, the calcium sulfate whiskers are made to have better dispersity in plastic substrate, and the surfaces of products are smoother.

Owner:四川万润非金属矿物材料有限公司

Acrylic acid grafted polypropylene modified aluminium hydroxide/polypropylene flameretardant material and preparing process thereof

A modified flame-retarding aluminium hydroxide / polypropylene material is prepared from polypropylene as basic material, aluminium hydroxide as flame-retarding agent, acrylic acid grafted polypropylene as modifier and universal stabilizer for PP materials through high-speed mixing and extrudnig out in dual-screw extruder. Its advantages are high fusion index, flame retarding performance and bend strength, and improved flowability.

Owner:SUN YAT SEN UNIV

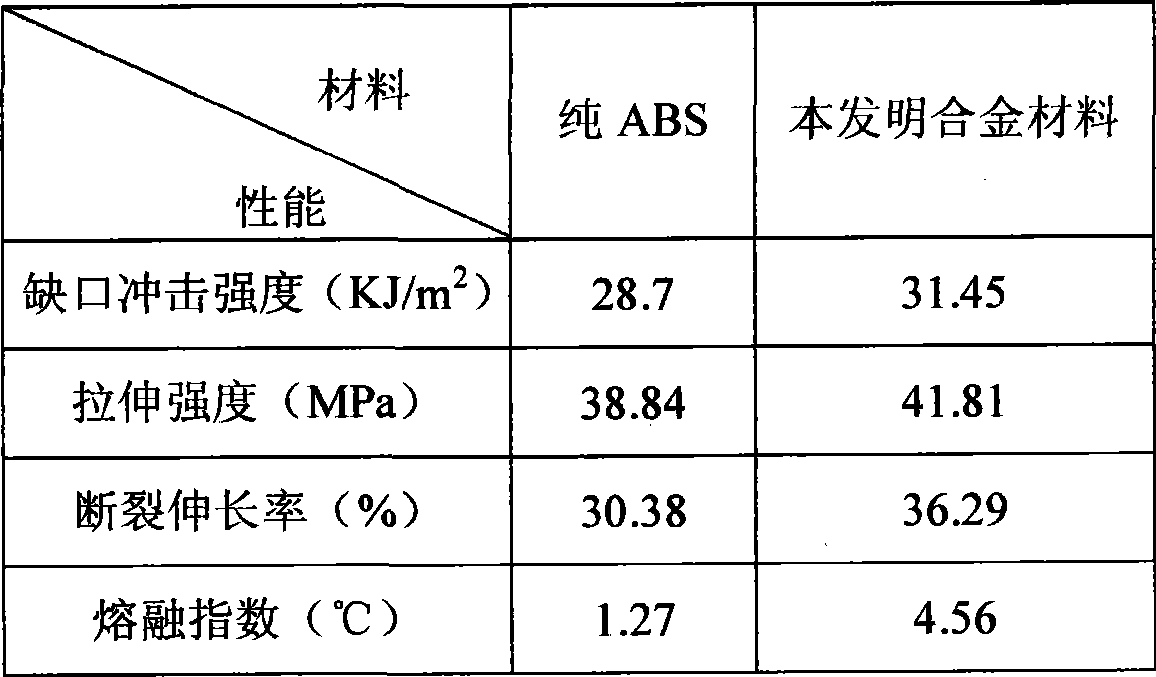

High-performance low-cost ABS/PET alloy material

The invention provides an ABS / PET alloy material with high performance and low cost. 30-95 percent of ABS and 5-70 percent of recovery PET multipolymer by weight are premixed with complex antioxidizer which is 0.1-1 percent of the total weight of the material, and the mixture is put into a double-screw extruding machine for pelleting under a normal machining condition to obtain the ABS / PET alloy material. The PET used in the invention is an unformed PET multipolymer prepared from common PET and dihydric alcohol through the modification by copolymerization, and the unformed PET multipolymer is evenly dispersed in an ABS base material to form a dispersing phase area with small size and good compatibility, therefore, the obtained alloy material not only obviously improves the tensile-strength, the rupture tensile stretch and the gap impact strength of the ABS, but also remarkably increases the melt index; in addition, the invention does not use compatilizer and impact modifying agent with high price, but uses the recovery PET multipolymer with low price, thereby greatly reducing the cost, being widely applied to industries of automobiles, electronic and electric appliances, household electric appliances, precise machinery, building materials, and the like, and having obvious economic and social benefits.

Owner:SICHUAN KINGFA TECH DEV

Uses of benzoic acid stannous as catalyst

ActiveCN101492441ALess catalystHigh yieldOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemistryOligomer

The invention mainly relates to the usage of benzoic acid stannous, in particular to the usage of the benzoic acid stannous as a catalyst for the oligomer pyrolysis. The oligomer is one of lact-acid oligomer or oligomeric hydroxyacetic acid. The lact-acid oligomer cracks to generate lactide, and the oligomeric hydroxyacetic acid cracks to generate glycolide.

Owner:ZHEJIANG HISUN BIOMATERIALS +1

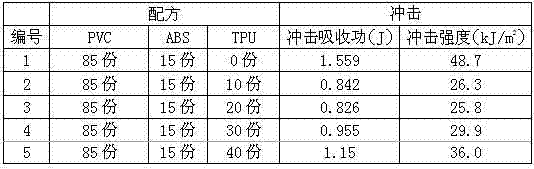

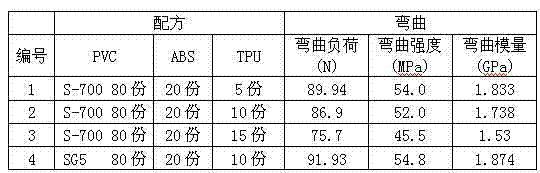

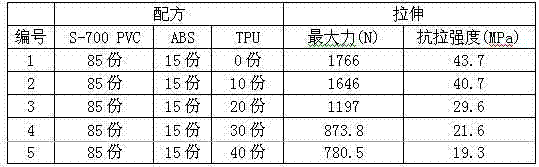

Formula and preparation method of high fluidity polyvinyl chloride alloy

The invention discloses a formula of high-liquidity polyvinyl chloride alloy and a preparation method. The formula comprises the following components in part by weight: 80-100 parts of polyvinyl chloride base, 5-20 parts of toughening agent, 1-20 parts of inorganic filler and 5-40 parts of TPU (thermoplastic polyurethane). In the invention, the liquidity of the polyvinyl chloride alloy is improved by adding the TPU so as to obtain the polyvinyl chloride alloy with proper injection molding, the mechanical property of the polyvinyl chloride alloy is excellent, the service requirement can be met, and the application range of the polyvinyl chloride alloy is expanded. The invention is simple and is easy to implement, the production efficiency is high, the cost is low and the application effectis ideal.

Owner:国家复合改性聚合物材料工程技术研究中心

Aluminum foil openable cover and preparation method thereof

ActiveCN103264840AExcellent peelabilityImprove sealingLamination ancillary operationsSynthetic resin layered productsAluminum foilProtection layer

The invention provides an aluminum foil openable cover and a preparation method thereof, and belongs to the technical field of can-type package. The aluminum foil openable cover comprises a metal cover body and an aluminum foil packaging film, wherein an article taking-out hole is formed in the metal cover body; the aluminum foil packaging film is used for blocking the article taking-out hole, and is sequentially provided with a protection layer, a blocking layer and a heat-seal layer from top to bottom; a gloss oil layer is used as the protection layer; an aluminum foil layer is used as the blocking layer; and the heat-seal layer consists of 10 to 20 weight percent of polybutylene, 40 to 60 weight percent of high-density polyethylene (HDPE) and 20 to 40 weight percent of metallocene polyethylene. The prepared aluminum foil openable cover is high in sealing performance and high in openability.

Owner:浙江博升新材料技术有限公司

Preparation method and equipment of high-performance impact polypropylene

The invention discloses a method and equipment for preparing impact polypropylene. The method comprises the following steps of carrying out polymerization reaction in the presence of a Ziegler-Natta catalyst, and carrying out liquid-phase bulk polymerization on propylene or propylene and alpha-olefin in the presence of a catalyst containing first external electron donors to obtain a polymer A; adding a second external electron donor to be premixed with the polymer A; and carrying out gas-phase polymerization on propylene or propylene and alpha-olefin in the presence of a material after premixing in the previous step to obtain a polymer B. By adopting the method and equipment provided by the invention, a polypropylene product comprising a continuous phase and a rubber phase is finally obtained by adopting two external electron donors with different hydrogen modulation sensitivity and controlling the addition mode of the second external electron donor; and the product has higher melt index and higher impact strength and has better impact resistance while keeping higher melt fluidity.

Owner:CHINA PETROLEUM & CHEM CORP +1

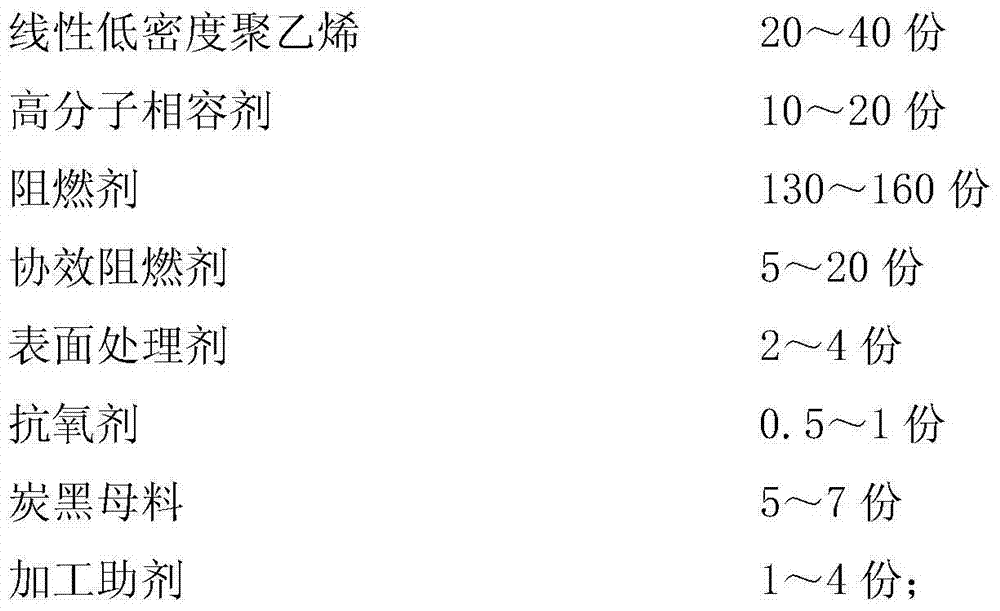

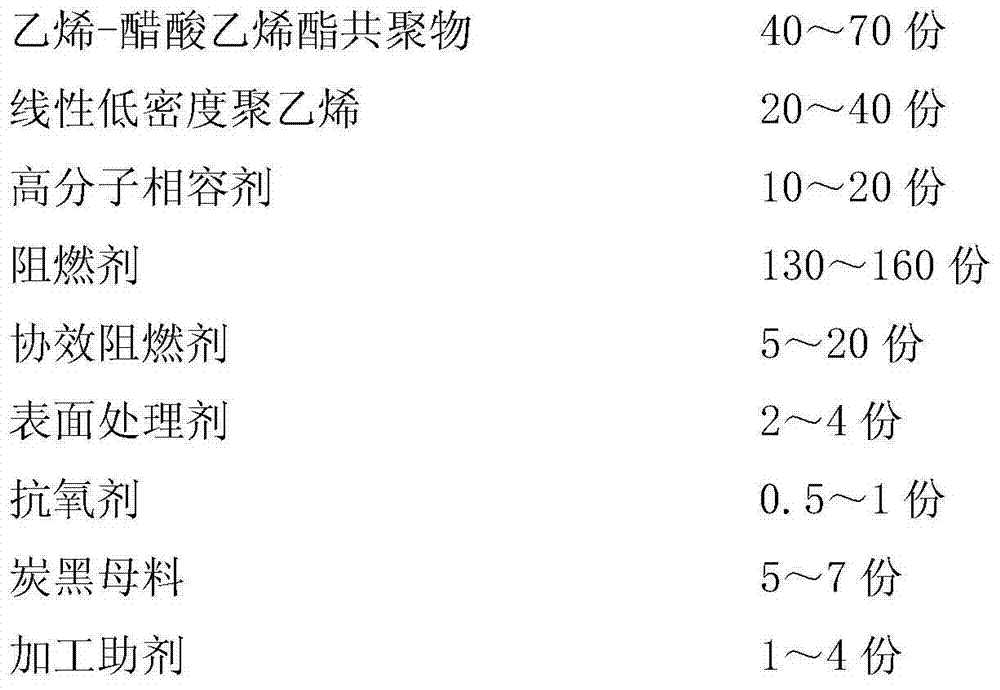

Argil-modified low-smoke zero-halogen power cable sheath material and preparation method thereof

InactiveCN103756119AImprove mechanical propertiesImprove flame retardant performanceInsulated cablesInsulatorsLinear low-density polyethyleneProcedure Agents

The invention provides an argil-modified low-smoke zero-halogen power cable sheath material which comprises the following components in parts by mass: 40-70 parts of ethylene-vinyl acetate copolymer, 20-40 parts of linear low-density polyethylene, 10-20 parts of high-molecular compatilizer, 130-160 parts of flame retardant, 5-20 parts of synergistic flame retardant, 2-4 parts of surface treating agent, 0.5-1 part of antioxidant, 5-7 parts of carbon black masterbatch and 1-4 parts of processing aid, wherein the flame retardant contains barium sulfate, and the synergistic flame retardant contains argil. The invention also provides a preparation method of the power cable sheath material.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

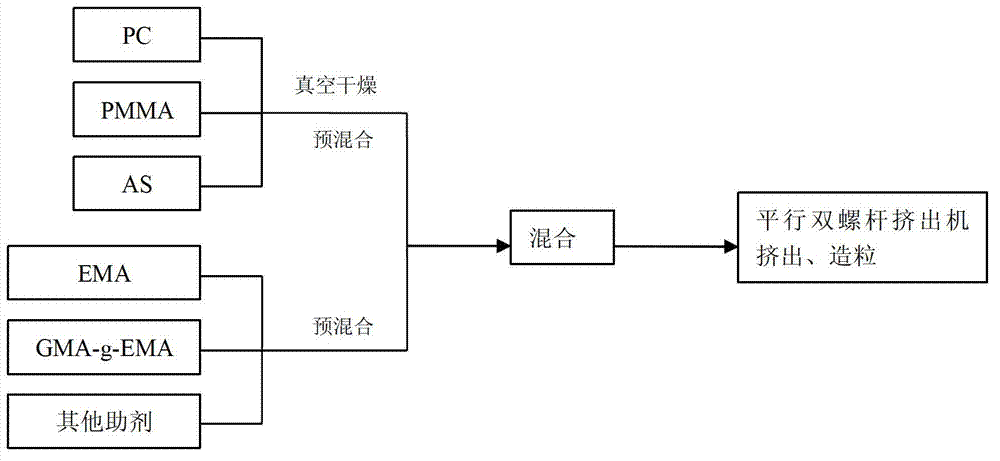

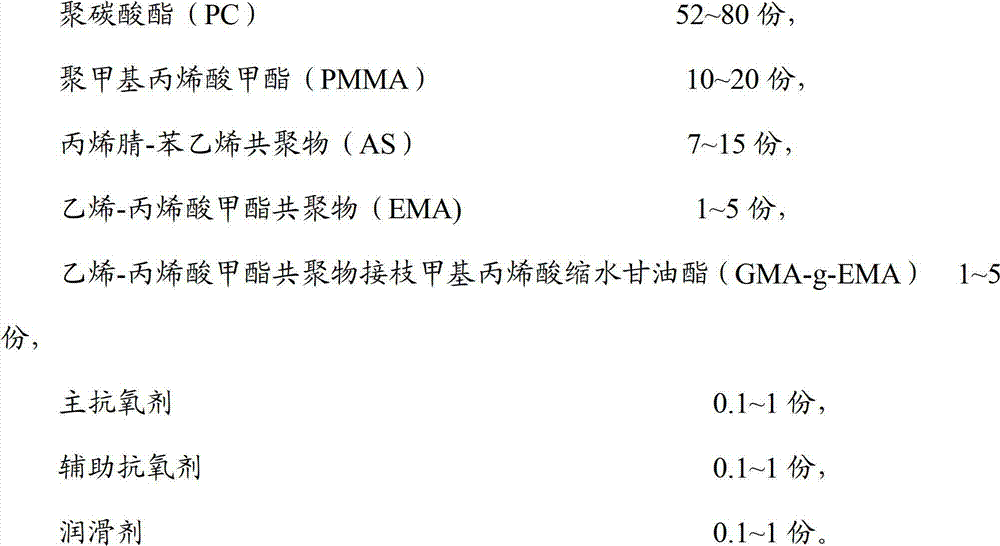

High-hardness and high-flowability PC/PMMA/AS (polycarbonate/polymethyl methacrylate/acrylonitrile-styrene copolymer) alloy and preparation method thereof

The invention discloses a PC / PMMA / AS (polycarbonate / polymethyl methacrylate / acrylonitrile-styrene copolymer) alloy and a method thereof. The PC / PMMA / AS alloy with excellent mechanical properties, high hardness and high flowability is prepared. The PC / PMMA / AS alloy comprises the following raw materials in part by weight: 52-80 parts of polycarbonate, 10-20 parts of polymethyl methacrylate, 7-15 parts of acrylonitrile-styrene copolymer, 1-5 parts of ethylene-methyl acrylate copolymer, 1-5 parts of ethylene-methyl acrylate copolymer grafted glycidyl acrylate, 0.1-1 part of main antioxidant, 0.1-1 part of auxiliary antioxidant and 0.1-1 part of lubricating agent. The prepared PC / PMMA / AS alloy can be used for preparing communication equipment housings and electronic appliance product housings with higher requirements on surface hardness and surface luster.

Owner:深圳市中塑新材料有限公司

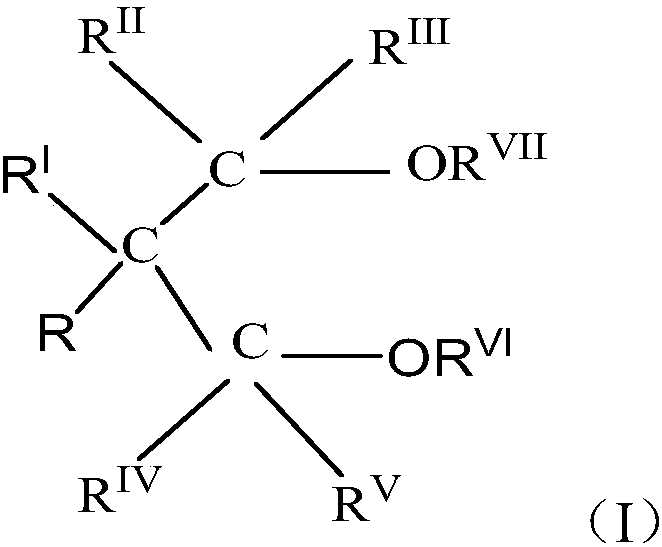

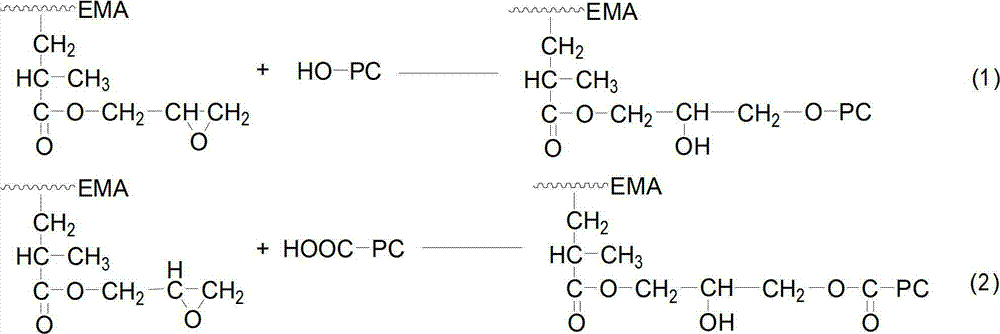

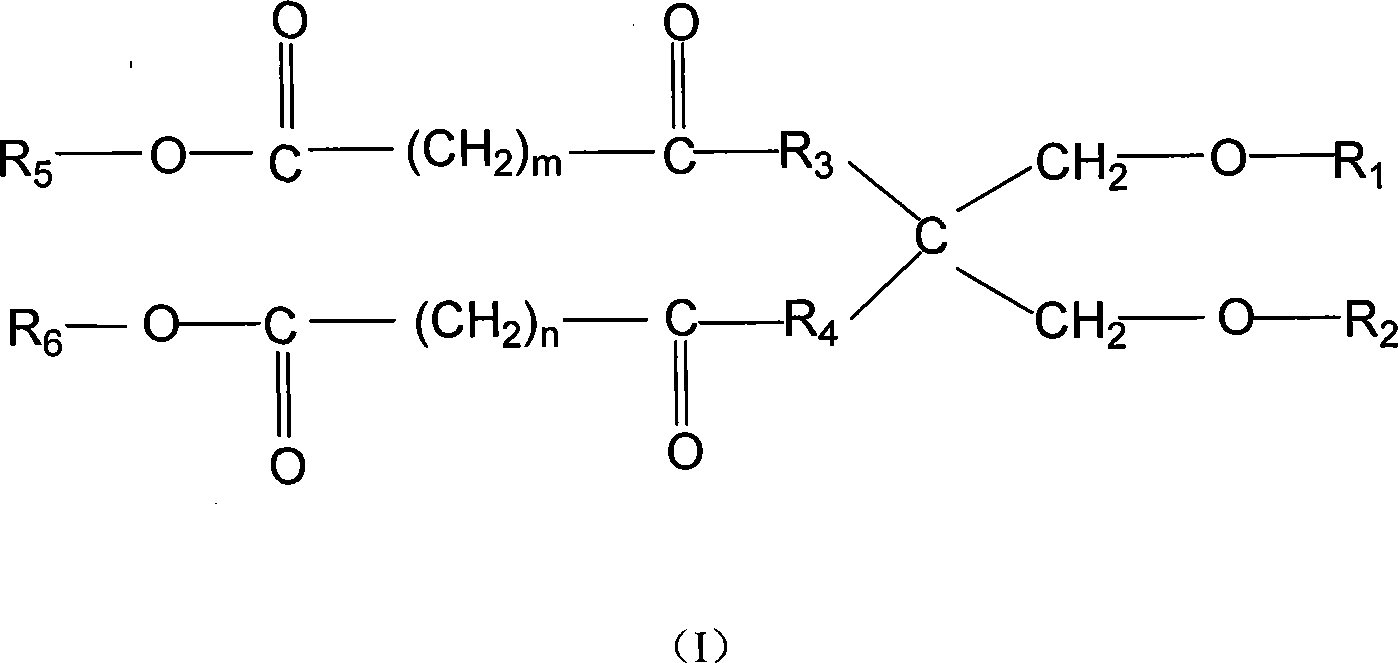

Olefin polymerization catalyst composition and preparing method thereof

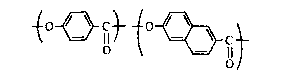

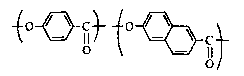

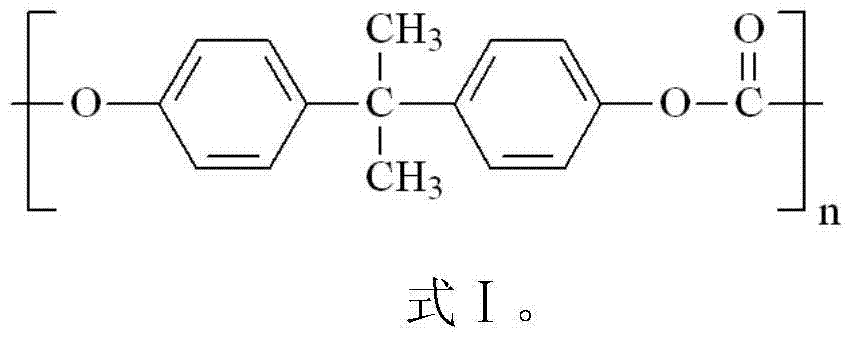

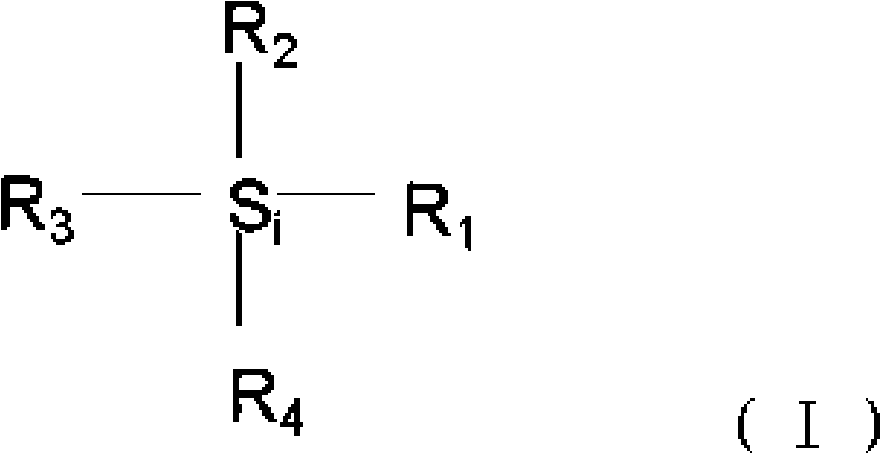

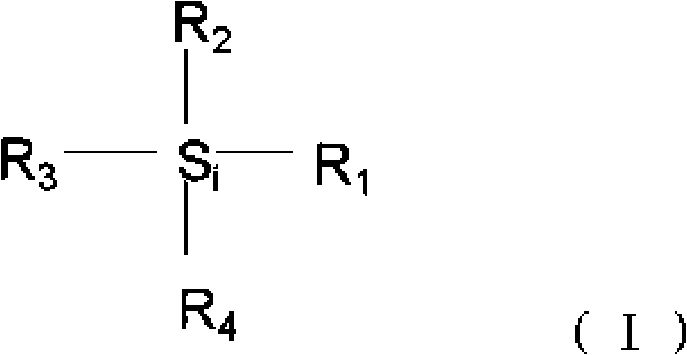

The invention relates to an olefin polymerization catalyst for the polymerization of alkene, in particular to the polymerization of propylene, or copolymerization, and a process for preparation, the invention relates to a catalytic activity component which is prepared by novel ester ether compound, and catalyst composition which contains the catalytic activity component, and a process for preparation. The catalytic activity component takes magnesium chloride to be carrier, a noevl binary ether ester compound which is showed as the general formula I is added in the process for preparation, the catalyst composition which contains catalytic activity component not only has higher catalytic activity and hydrogen sensitivity, meanwhile can guarantee polyacrylic resin to have higher stereoregularity when the composition is used for propylene polymerization. And the integrity of the polymerisate is better.

Owner:中国石油天然气股份有限公司大庆化工研究中心 +1

Polycarbonate resin compound and preparation method thereof

The invention discloses a polycarbonate resin compound and a preparation method thereof. The polycarbonate resin compound comprises the following components: 80 to 99.5 portions by weight of polycarbonate resin or polycarbonate resin alloy, and 0.5 to 20 portions by weight of organic silicon rubber. The preparation method comprises the following steps: (1) premixing, namely, adding the polycarbonate resin or the polycarbonate resin alloy and the organic silicon rubber into a mixer, and premixing the materials for 1 to 6 minutes with the rotating speed of 100 to 800 revolutions per minute at the mixing temperature of between 20 and 50 DEG C; and (2) squeezing granulation, namely adding the premixed materials into a double-screw extruder to carry out squeezing granulation, wherein the temperature of each section of the double-screw extruder is between 180 and 300 DEG C during extrusion, the rotating speed of screws is 100 to 500 revolutions per minute, and the rotating speed of a feeder is 10 to 60 revolutions per minute. The polycarbonate resin compound prepared by the method has good liquidity, thermal stability and impact resistance, and belongs to the field of polymer material modification.

Owner:CHINA NAT BLUESTAR GRP CO LTD +1

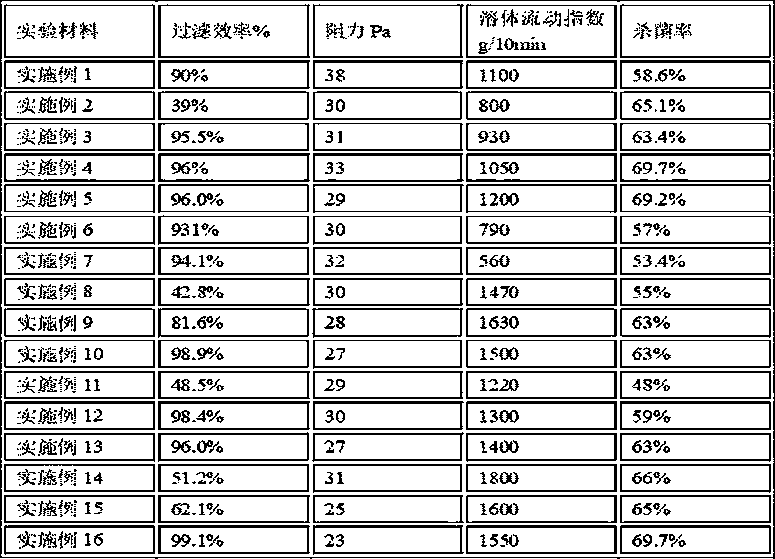

Melting-expanded electret antibacterial master batch and processing technology and application thereof

InactiveCN111423660AImprove melt indexImprove liquidityMonocomponent polyolefin artificial filamentArtifical filament manufacturePolymer sciencePlasticizer

The invention belongs to the technical field of high polymer materials, and particularly relates to a melting-expanded electret antibacterial master batch and a processing technology and application thereof. The master batch comprises the following components in parts by weight: 70-190 parts of polypropylene, 1-2 parts of a peroxide, 1-2 parts of an antioxidant, 1-2 parts of a plasticizer, 1-2 parts of a lubricant, 1-2 parts of an electret material and 1-2 parts of an antibacterial agent. The master batch has multiple functions, molecular weight breakage is caused by adding peroxide, the meltindex of the PP material is increased, the flowing property of the material is improved, and the material is easier to form. The electret material is added, so that the material can generate static electricity to adsorb viruses and particulate matters in air, and due to the antibacterial and bactericidal material in the material, the viruses and the particulate matters can be adsorbed to kill germs. Only a small amount (about 4%) of the material is added into a medium-melt-index fiber-grade PP raw material (only non-woven fabric can be used in the past), and the material can be applied to a melt-blown material, so that the problem of shortage of the melt-blown material is solved.

Owner:青岛中孚科力橡塑有限公司

Low-cost and stress cracking resistance flame-retardant ABS (Acrylonitrile Butadiene Styrene) resin composite material and preparation method of ABS resin composite material

The invention provides a low-cost and stress cracking resistance flame-retardant ABS (Acrylonitrile Butadiene Styrene) resin composite material and a preparation method of the ABS resin composite material. The ABS resin composite material consists of 250-500 parts of ABS resin A, 250-500 parts of ABS resin B, 200-250 parts of a fire retardant, 3-6 parts of an antioxidant and 5-8 parts of a lubricating agent. The melt index of the ABS resin composite material prepared by the preparation method of the ABS resin composite material disclosed by the invention is greater than 15g / 10min, so that processing and forming are facilitated; and the ABS resin composite material has the advantages of good impact and tensile properties, excellent toughness and good flame retardant property, so that the ABS resin composite material is beneficial to guarantee that no harmful effects such as easy breakage, fracture and the like on electrical components occur in subsequent processes of assembling, tapping and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Low-melting-point biological nylon material and preparation method thereof

The invention relates to a biological nylon material and a preparation method thereof, belonging to the field of synthesis of the high polymer material--nylon. The biological nylon material is prepared from the following components by mol: 7.4 to 9.0 mol of aromatic diacid, 11.0 to 12.6 mol of sebacic acid, 19.0 to 19.7 mol of aliphatic diamine, 0.035 to 0.05 mol of a nucleating agent, 0.015 to 0.03 mol of a catalyst and 220 to 300 mol of a solvent. Compared with the prior art, the invention has the following advantages: reaction steps are simple; the synthesized biological nylon has a high melt index and good fluidity, discharging of the biological nylon is convenient, direct traction and granulation can be realized after cooling, and the biological nylon is convenient to package, transport and store and has ideal mechanical properties; moreover, the prepared nylon has a melting point far lower than the melting point of common nylon and can realize blending with more low-melting-point polymers, so the application scope of the nylon is broadened.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

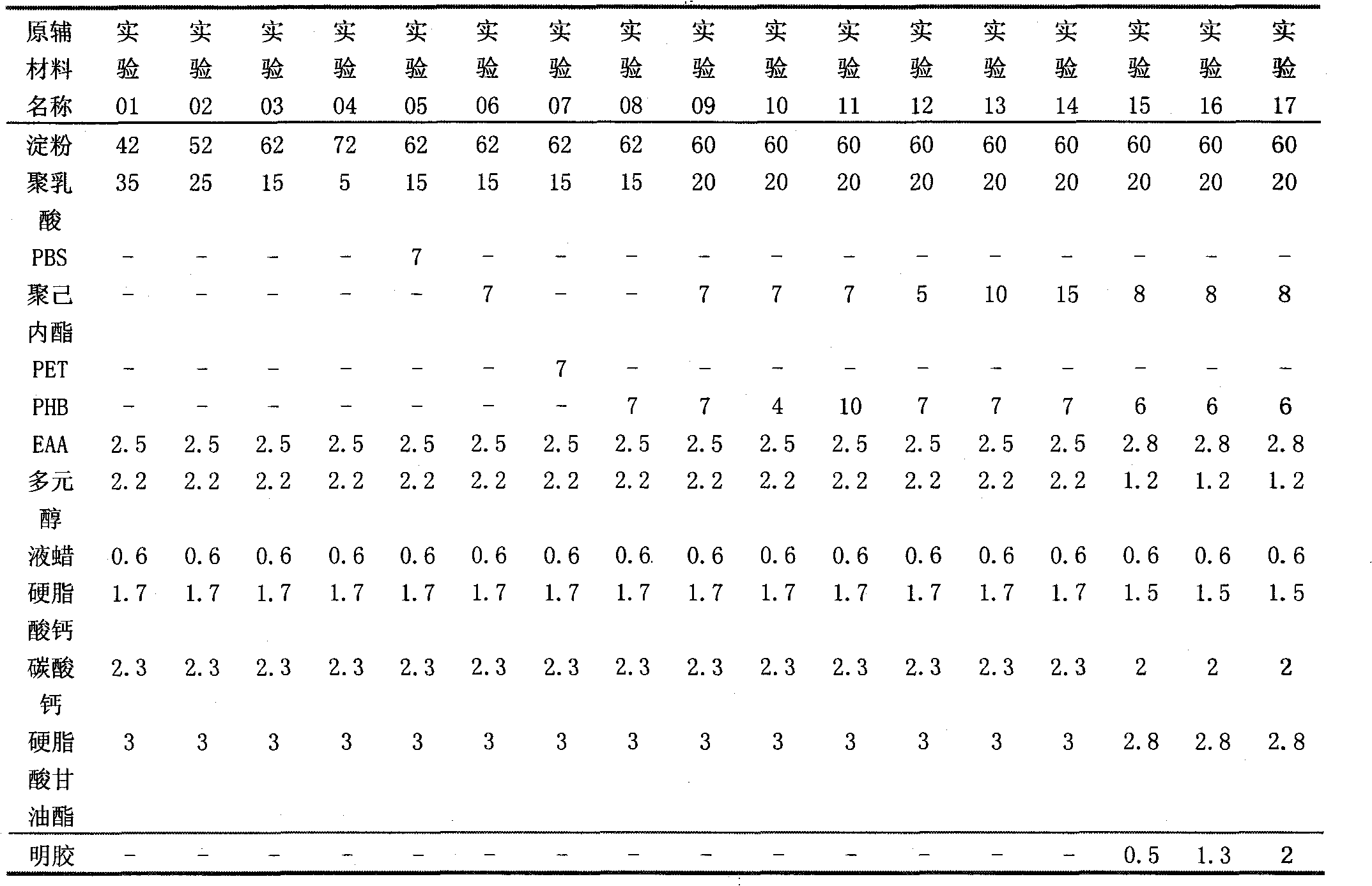

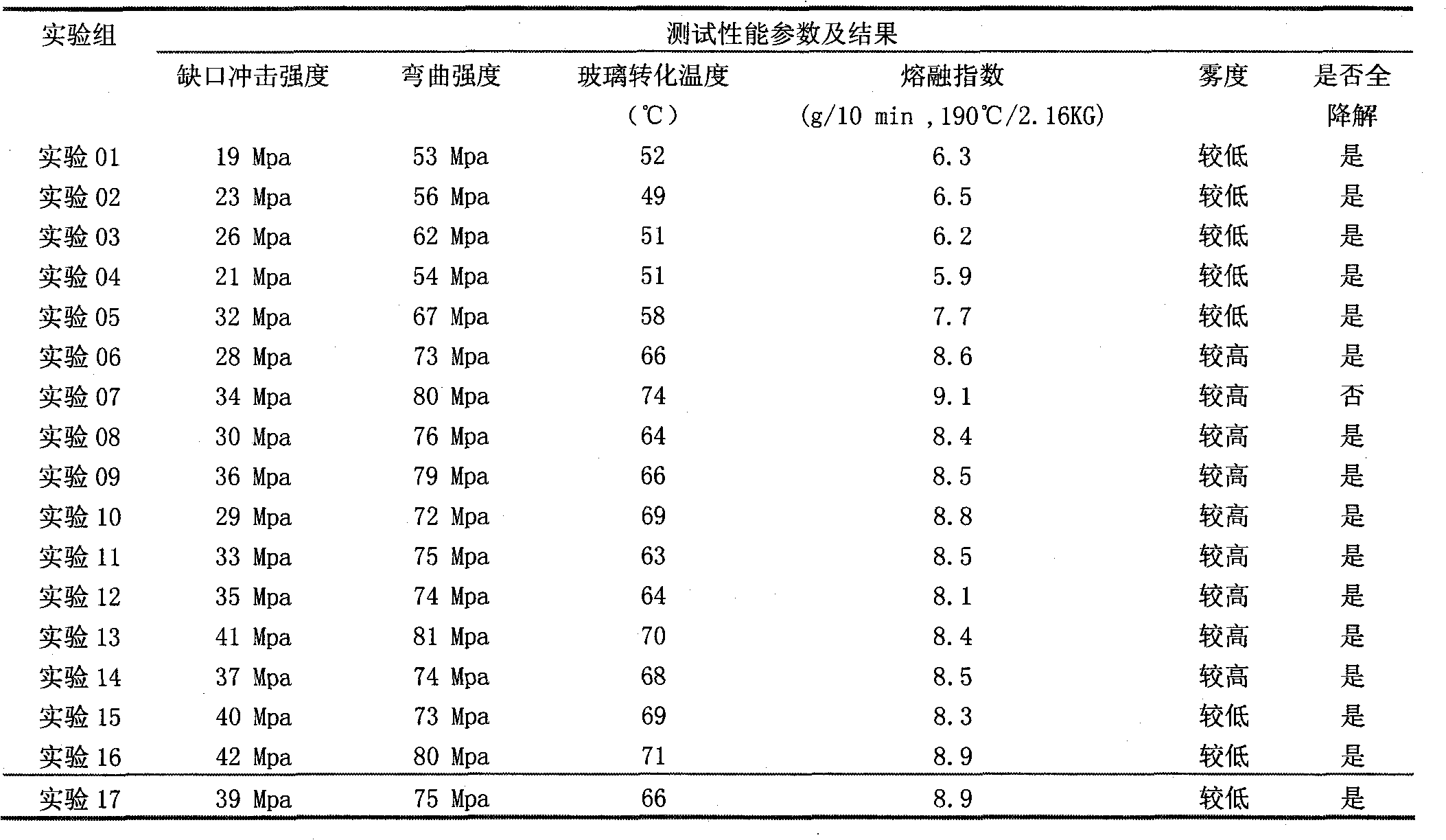

Full-degradable injection molding composite material and preparation method thereof

The invention discloses a full-degradable injection molding composite material, which is mainly prepared by blending starch, polylactic acid and polyester. In the full-degradable injection molding composite material, factors such as degradability, processability, usability, cost performance and the like are considered fully, the problems of chromatic aberration and texture are solved, and the composite material is suitable to be processed into various injection molding devices.

Owner:任伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com