High-hardness and high-flowability PC/PMMA/AS (polycarbonate/polymethyl methacrylate/acrylonitrile-styrene copolymer) alloy and preparation method thereof

A technology of alloys and high-speed mixers, which is applied in the field of polymer materials, can solve the problems of failure to reasonably solve the scratch resistance of PC alloys, poor fluidity and gloss of alloys, and insufficient surface hardness, so as to avoid post-processing The effect of process, high melt index and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

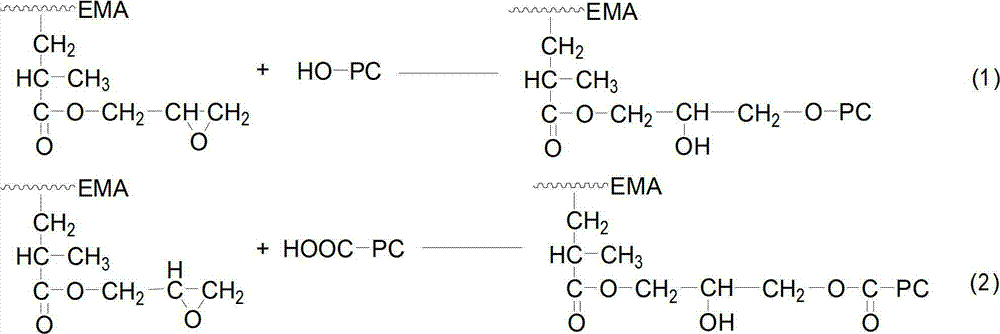

Method used

Image

Examples

Embodiment 1

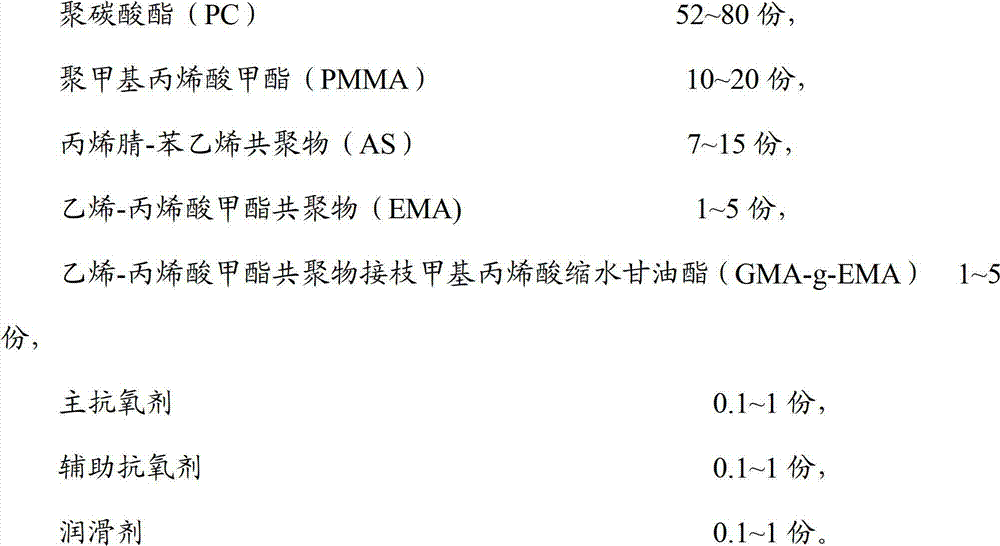

[0038] A PC / PMMA / AS alloy with high hardness and high fluidity, its raw material composition and parts by weight are:

[0039]

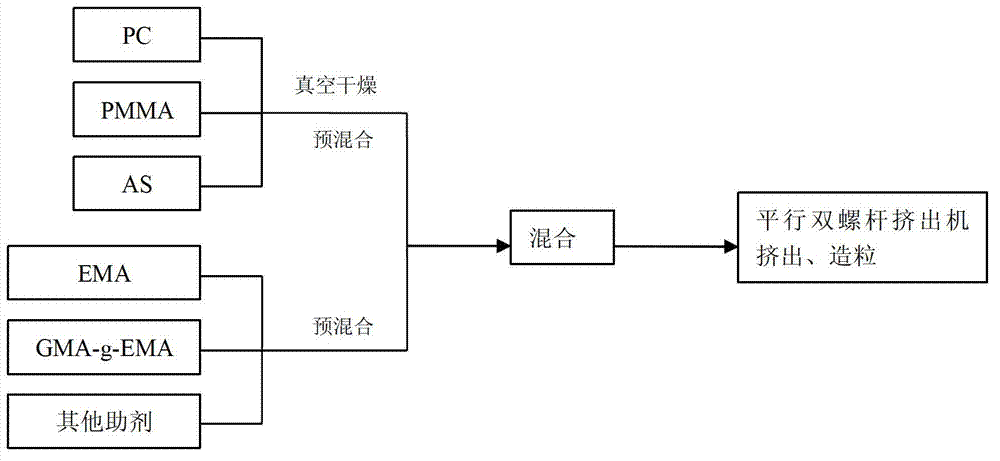

[0040] The preparation method of above-mentioned PC / PMMA / AS alloy comprises the steps:

[0041] (1) Dry polycarbonate (PC) at 110°C for 6 hours, polymethyl methacrylate (PMMA) and acrylonitrile-styrene copolymer (AS) at 80°C for 6 hours; after cooling, put Add polycarbonate, polymethyl methacrylate, and acrylonitrile-styrene copolymer to a high-speed mixer for pre-mixing;

[0042] (2) After adding toughening agent EMA, compatibilizer GMA-g-EMA, antioxidant 1076, antioxidant 168 and PETS to another high-speed mixer for mixing, add the mixture to step (1) Mix in a high-speed mixer;

[0043] (3) Place the mixed pre-mixture in a parallel twin-screw extruder for melt extrusion and granulation. The process parameters are as follows: the temperature of the first zone is 220°C, the temperature of the second zone is 225°C, the temperature of the third zo...

Embodiment 2

[0045] A PC / PMMA / AS alloy with high hardness and high fluidity, its raw material composition and parts by weight are:

[0046]

[0047] The preparation method of above-mentioned PC / PMMAAS alloy comprises the steps:

[0048] (1) Dry polycarbonate (PC) at 110°C for 6 hours, polymethyl methacrylate (PMMA) and acrylonitrile-styrene copolymer (AS) at 80°C for 6 hours; after cooling, put Add polycarbonate, polymethyl methacrylate, and acrylonitrile-styrene copolymer to a high-speed mixer for pre-mixing;

[0049] (2) After adding toughening agent EMA, compatibilizer GMA-g-EMA, antioxidant 1076, antioxidant 168 and PETS to another high-speed mixer for mixing, add the mixture to step (1) Mix in a high-speed mixer;

[0050](3) Put the mixed pre-mixture in a parallel twin-screw extruder to melt and extrude, and granulate. The process parameters are as follows: the temperature of the first zone is 200°C, the temperature of the second zone: 205°C, the temperature of the third zone is ...

Embodiment 3

[0052] A PC / PMMA / AS alloy with high hardness and high fluidity, its raw material composition and parts by weight are:

[0053]

[0054] The preparation method of above-mentioned PC / PMMA / AS alloy comprises the steps:

[0055] (1) Dry polycarbonate (PC) at 110°C for 6 hours, and dry polymethyl methacrylate (PMMA) and acrylonitrile-styrene copolymer (AS) at 80°C for 6 hours. After cooling, polycarbonate, polymethyl methacrylate, and acrylonitrile-styrene copolymer are added to a high-speed mixer for pre-mixing;

[0056] (2) After adding toughening agent EMA, compatibilizer GMA-g-EMA, antioxidant 1076, antioxidant 168 and PETS to another high-speed mixer for mixing, add the mixture to step (1) Mix in a high-speed mixer;

[0057] (3) Place the mixed pre-mixture in a parallel twin-screw extruder to melt and extrude and granulate. The process parameters are as follows: the temperature of the first zone is 215°C, the temperature of the second zone is 220°C, the temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com