Olefin polymerization catalyst composition and preparing method thereof

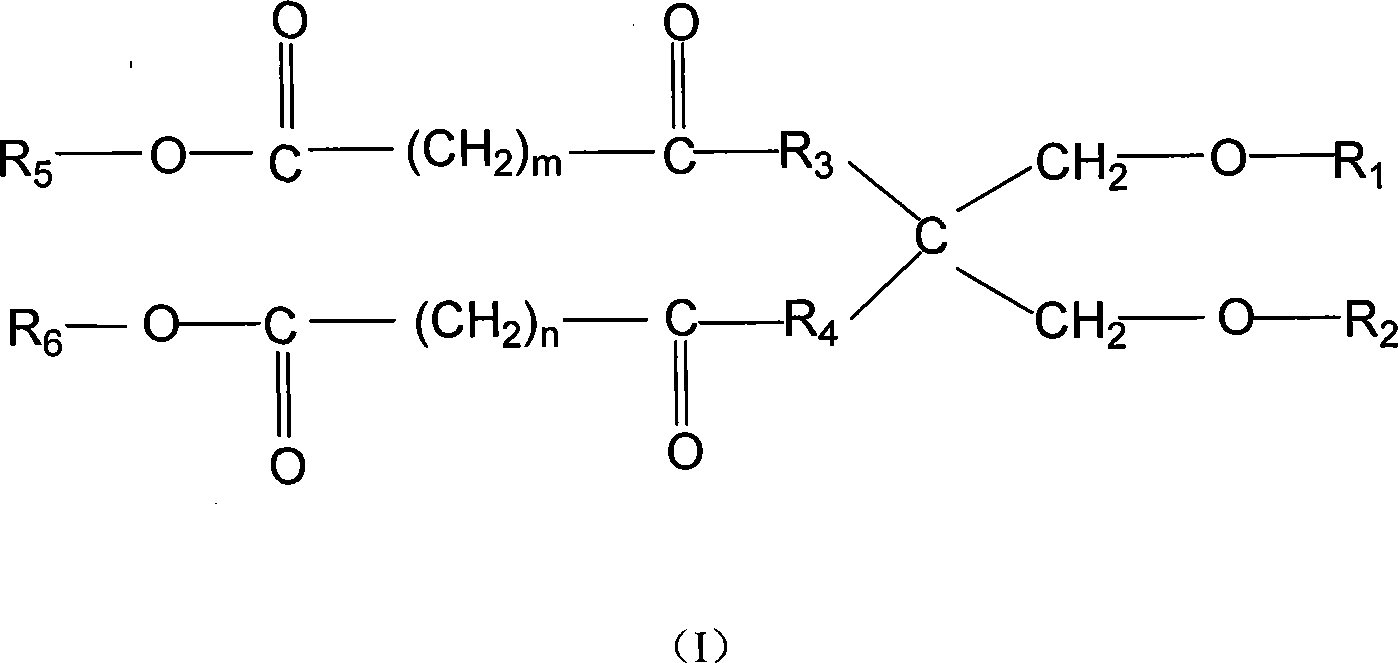

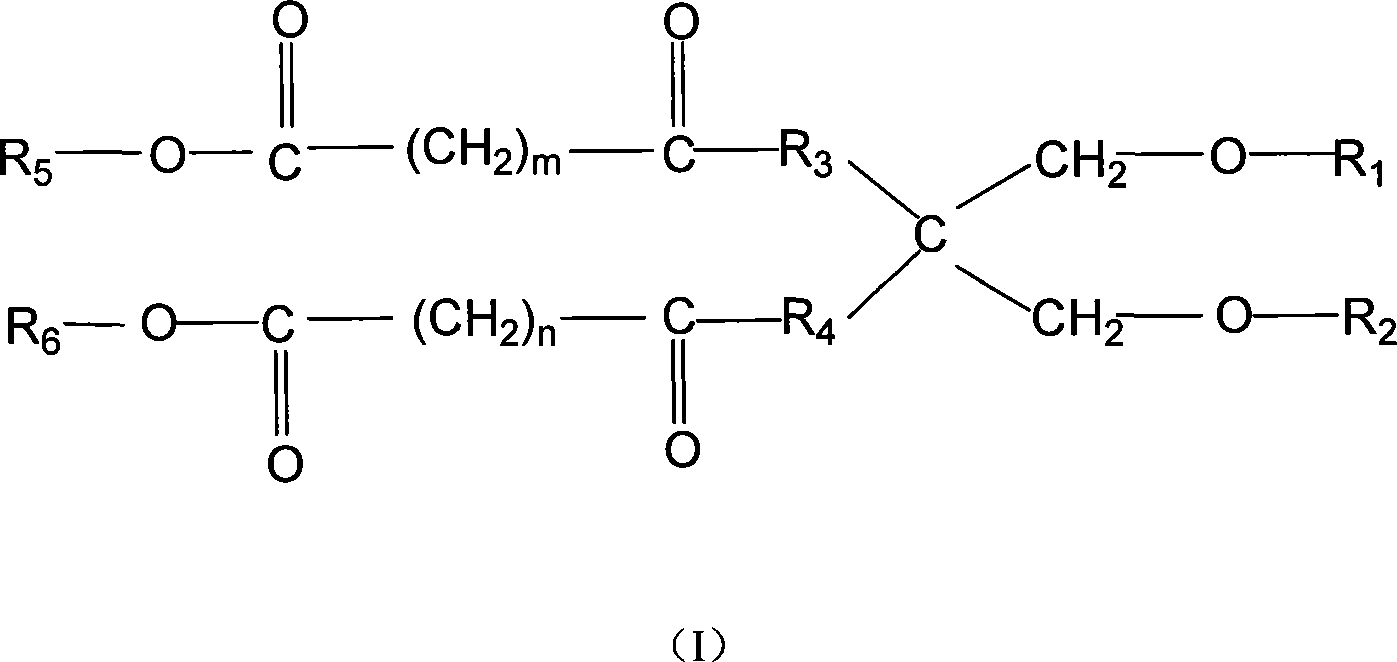

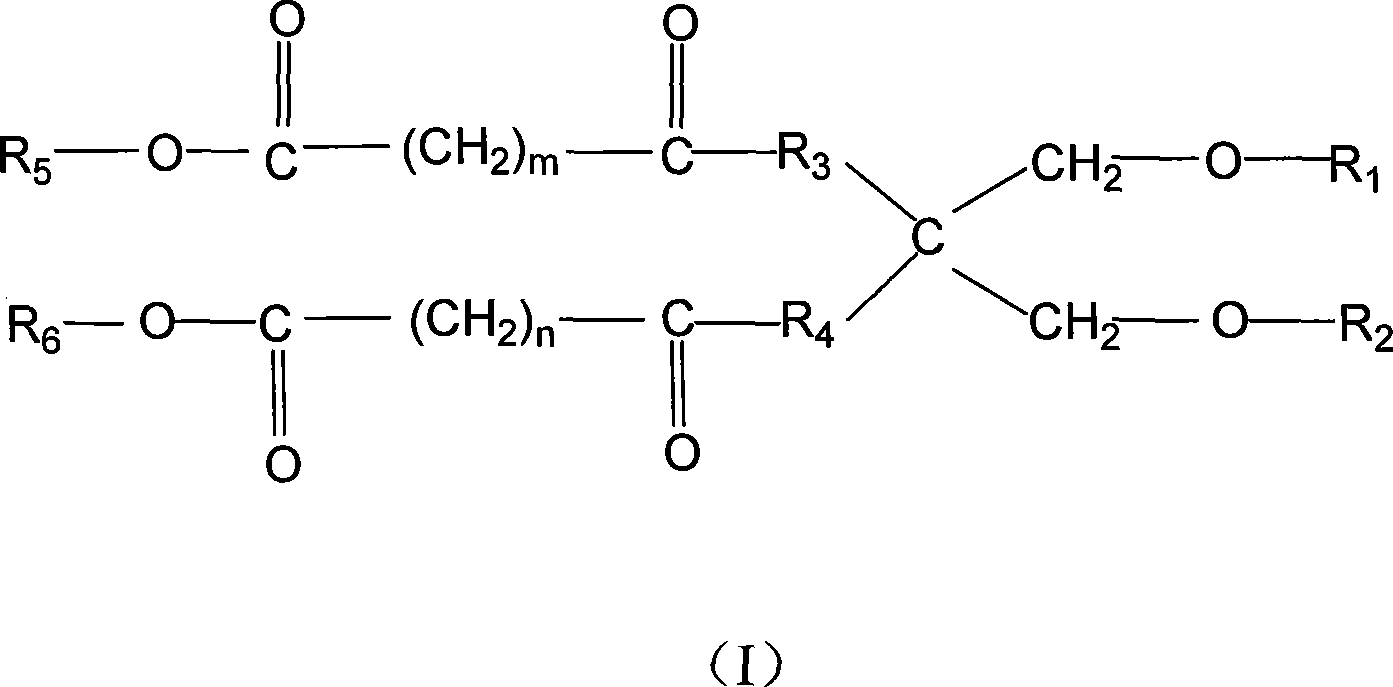

A technology for olefin polymerization and catalyst, which is applied in the field of catalyst active components and catalyst compositions containing the catalyst active components, and can solve the problem of unsatisfactory catalyst catalytic efficiency and orientation ability, increase of dealcoholization process and consumption of raw materials and energy. , the complex preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Preparation of spherical alcoholate carrier

[0057] Under the protection of nitrogen, 0.29 moles of anhydrous magnesium chloride, 0.78 moles of absolute ethanol, 7 moles of methyl silicone oil and 7 moles of liquid paraffin were sequentially added into a special reaction kettle, and the temperature of the reaction system was raised to 120°C, and the reaction system was maintained at this temperature for 3 Hour, the rotating speed of stirrer is controlled at 500 rev / min. Add 0.16 moles of 2,2-dibutanedioic acid ethyl acyl-9,9-bis(methoxymethyl)fluorene, and stir and disperse at a speed of 2000rpm for 15 minutes, then pressurize the reaction vessel, and inject the mixed hydraulic pressure into A certain amount of hexane has been added and the temperature is lowered to -30°C in a cooling kettle, and stirred at a low speed for 15 minutes. Use normal hexane to wash the solid particles 3 to 6 times, the amount of hexane is 1000 to 1500 ml / time, filter and then vacuum dr...

Embodiment 2

[0064] In addition to the low-carbon alcohol is anhydrous butanol, the addition is 1.1 moles, and the internal electron donor is 1,1-dibutanedioic acid ethyl acyl-9,9-bis(methoxymethyl)fluorene, the addition is 2.8 mol, the temperature of the spherical alcoholate carrier system is raised to 80°C, the amount of liquid paraffin added is 6 mol, and 3 mol of AlEt is used in the bulk polymerization of propylene 3 , all the other preparation conditions and the consumption of substance are identical with embodiment 1, the alcohol / Mg (mol / mol)=2.14 in the obtained carrier, the titanium content in the catalyst active component is 2.10%, record spherical catalyst activity with BET method The specific surface area of the component is 290m 2 / g, the porosity is 0.31ml / g, and the pore size distribution is at least 65% of which the pore radius is less than 100 Ȧ. The activity of catalyst is 38.3Kg polypropylene / g catalyst, and the isotacticity of polypropylene is 97.3% (boiling n-heptane...

Embodiment 3

[0066] In addition to the low-carbon alcohol is anhydrous isopropanol, the addition is 0.29 moles, the inert solvent is methyl silicone oil, the addition is 14 moles, and the electron donor 4,4-dibutanedioic acid ethyl acyl-9,9 - 0.05 moles of bis(methoxymethyl)fluorene, the spherical alcoholate carrier system is heated up to 130°C, the addition of titanium tetrabromide is 5.8 moles, and the alkyl aluminum used in the bulk polymerization of propylene is 6 moles of alkyl aluminum chloride Except, all the other preparation conditions and the consumption of substance are identical with embodiment 1, and the alcohol / Mg (mol / mol)=2.53 in the obtained carrier, the titanium content in the catalyst active component is 2.06%, records spherical catalyst by BET method The active component has a specific surface area of 290m2 / g, a porosity of 0.31ml / g, and a pore size distribution of at least 65% of which have a pore radius smaller than 100 Å. No external electron donor is added during ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com